Singer XL-420 User manual

Other Singer Sewing Machine manuals

Singer

Singer 610D User manual

Singer

Singer 114-21 User manual

Singer

Singer 52-54 User manual

Singer

Singer 451k41 Troubleshooting guide

Singer

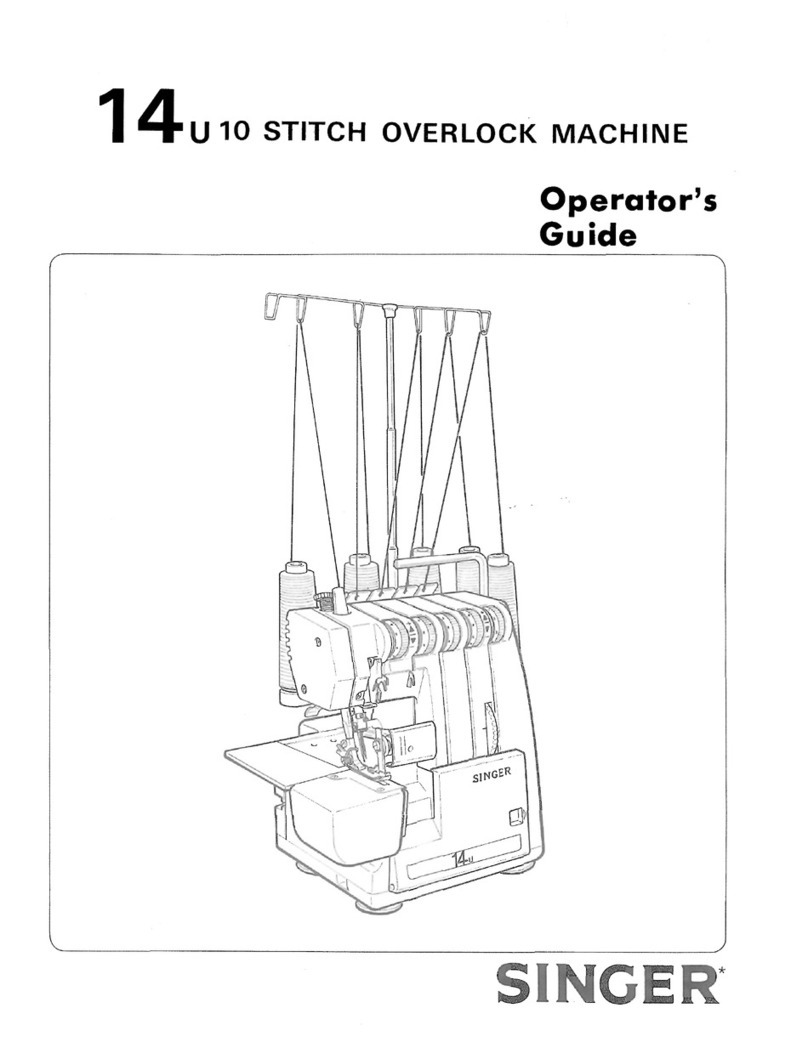

Singer 14U User manual

Singer

Singer 145W302 Setup guide

Singer

Singer 65W Installation and operation manual

Singer

Singer 147-36 User manual

Singer

Singer 7466 User manual

Singer

Singer Fashion Mate 7256 Owner's manual

Singer

Singer 1191D200A User manual

Singer

Singer 14T967DC QuantumLock Operation instructions

Singer

Singer 99-13 User manual

Singer

Singer 81K70 User manual

Singer

Singer 144 A 104 User manual

Singer

Singer Scholastic 5511 User manual

Singer

Singer 8780HSN Owner's manual

Singer

Singer FEATHERWEIGHT II 118 User manual

Singer

Singer 675 User manual

Singer

Singer Quantum XL-100 User manual