SINGFLO 2440 Series User manual

User Manual

SUBMERGED PUMP

ENGLISH

2

TABLE OF CONTENTS

PAGE(S)

INTRODUCTION 2

COMPONENTS NEEDED FOR INSTALLATION 2

PUMP CONNECTIONS & INSTALLATION INSTRUCTIONS 3-5

PARTS LIST and REPLACEMENT PART KITS 6

SUBMERSIBLE PUMP ASSEMBLY DRAWING 7

BEFORE REQUESTING SERVICE "Helpful Hints" 8

PUMP REMOVAL and DISASSEMBLY 9-10

PUMP RE-ASSEMBLY 11-13

APPLICATION WORKSHEET and FLOW CHARTS 14-15

TECHNICAL SPECIFICATIONS 16

TOOLS REQUIRED FOR INSTALLATION & MAINTENANCE 17

WARRANTY 18

INTRODUCTION

This manual has been provided as an aid to the operator with information about

installing, operating, and servicing of the SINGFLO 2440 Series Submersible Pump. The

engineers and technicians who designed and manufactured these pumps have developed

these instructions from their experiences.

These instructions should be read completely before installing your new pump. Keep this

manual readily available at all times for use when installing, operating, or servicing your pump.

For proper placement in the well refer to the application worksheet on pages 14-15.

This pump is not to be used with flammable liquids.

COMPONENTS NEEDED FOR INSTALLATION PAGE(S)

CABLE TYPE 3

COUPLERAND DISCHARGE FOR OUTLET 4

SAFETY LINE 5

POWER SUPPLY 15-16

FUSE: RECOMMENDED SIZE AND TYPE 16

TOOLS REQUIRED 17

CONTROLLER: Use of an LCB (Linear Current Booster) Unit is required for optimum performance.

COMPLETEAPPLICATION WORKSHEET 14-15

3

I. PUMP CONNECTIONS & INSTALLATION INSTRUCTIONS

WARNING: IMPROPER INSTALLATION WILL VOID WARRANTY.

1) Select proper jacketed cable size (Fig.1).

Note: DO NOT select cables with

irregular shapes, rough or

grooved surfaces.

Use a #10 AWG jacketed Submersible

cable that fits into the general size

requirements shown (Fig 1).

2) Assemble Cable Boot (Fig. 2, 3, 4).

a) Strip the outer cable jacket (Part A - not included) 2.0 in. (5 cm) (Fig. 2).

b) Cut one of the lead wires 1.0 in. (2.5 cm) (Fig. 3).

c) Wrap electrical tape around the cable. Start 2 in. (5 cm) below outer cable jacket

and continue to taper a point past the end of lead wires (Fig. 4).

Generously lubricate the cable 4 to 6 in. (10 to 15 cm) with supplied O-Ring grease.

d) Slide the cable boot components over the cable (Part A) in the following order (Fig. 4).

1) Nut (Part D). Make sure threads are toward pump end of cable.

2) Outer Cable Boot (Part C). Small end first.

NOTE: Re-lubricate cable as necessary.

3) Inner Cable Boot (Part B). Small end first.

e) Remove tape and cut the lead wires back leaving about .50 in. (1.3 cm) exposed.

Strip the inner conductor jacket .50 in. (1.3 cm) (Fig. 5).

(8 .0 m m )

.3 2 IN

(1 4 .5 m m )

.5 8 IN

(1 0 .5 m m )

.4 2 IN

(5 .5 m m )

.2 2 IN

(1 1 .5 m m )

.4 5 IN

(9 .0 m m )

.3 5 IN

FIG U R E 1

FLAT

ROUND

PARALLEL

RECOMMENDED

CABLE TYPE

MINIMUM

DIMENSION OF CABLE MAXIMUM

DIMENSION OF CABLE

(5 C M )

2 .0

FIG U R E 2

A

FIG U R E 3

1 .0

(2 .5 C M )

4

f) Insert the wire leads into Plug (Cable Adapter) connectors.

Using a 5/64" Allen Wrench tighten the set screws (Fig. 6).

g) Slide the Inner Cable Boot (Part B) over the plug until it is flush with

the first step on the collar (Fig. 6).

Wipe the grease from the surface of Inner Cable Boot and cable.

Tape end of Inner Cable Boot tightly to the cable.

Be sure to tape 4 in. (10 cm) below the Inner Cable Boot on the cable.

Note: This taped area allows the Outer Cable Boot (Part C) to slide freely over the Inner Cable Boot.

DO NOT REMOVETHETAPE.

h) Lubricate the outer surface of the Inner Cable Boot and tape with supplied O-Ring grease.

Slide the Outer Cable Boot (Part C) over the Inner Cable Boot until it is flush with

the second step on the collar (Fig. 6).

i) Push the Plug (Cable Adapter) into the Receptacle (Cable Adapter) until the collar is seated flush.

NOTE: The orientation of the Plug(Cable Adapter) will not effect the pumps performance.

j) Push the Nut (Part D) over the Plug (Cable Adapter) and then finger tighten the nut.

NOTE: Before continuing, operate the pump to check all electrical connections,

using the correct power supply. Refer to Technical Specifications (Pg. 14).

If pump does not operate Refer to "Helpful Hints" (Page 8) before continuing .

3) Install the 6 in. hose and fitting (1/2" NPT X 1/2" BARB) (Fig. 7, page 5).

a) Press the fitting into the 6 in. hose, slide the clamp on the hose and over the fitting and tighten the clamp securely.

b) Slide another clamp on the 6 in. hose, slide the assembly over the barbed fitting on the pump,

and tighten the clamp securely.

Note: Select the proper adapter hose and accessories for the pump.

USE OF DISCHARGE PIPE LARGER THAN 3/4" IS NOT RECOMMENDED..

Use 150 P.S.I. Min. (10 bars) working pressure rated 1/2 in. I.D. (12.7 mm I.D.) smooth bore hose (Part not included.).

Use All-Stainless Steel hose clamp (Part not included.

1 /2 " N P

T

5

4) Hook-up Safety Line (Sling) (Fig. 7).

CAUTION: Safety line (Sling) should be

Corrosion resistant.

a) Insert safety line (Part not included) through

lift plate holes.

b) Fasten line with appropriate connection

approximately 1-2 ft (30 - 60 cm) above the pump.

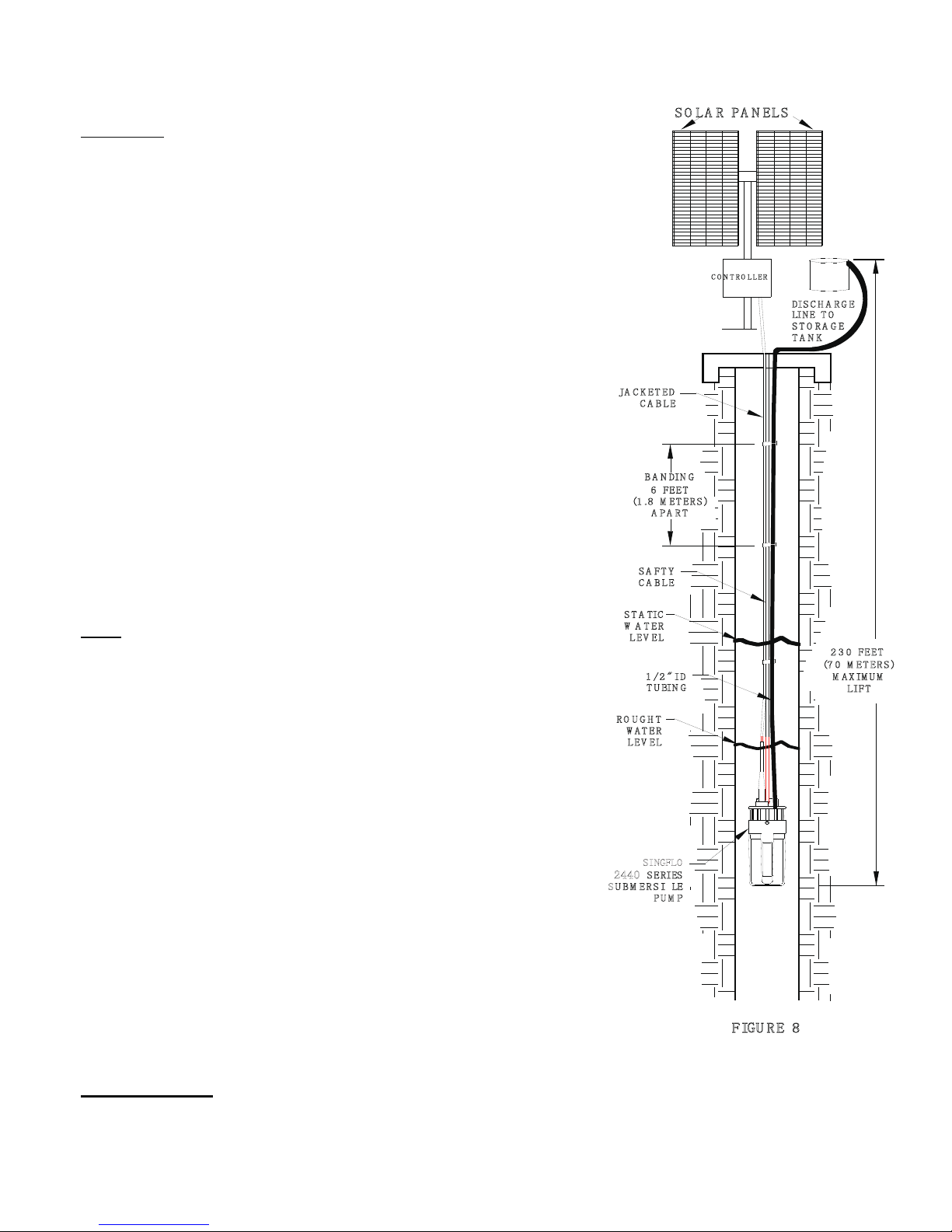

5) Band the Hose, Safety Line, and Electrical

Cable (Fig. 8).

Tie the drop lines together using tie wraps

every 6ft. (1.8 m).

This banding will prevent unnecessary damage to the

lines during Installation and Removal of pump.

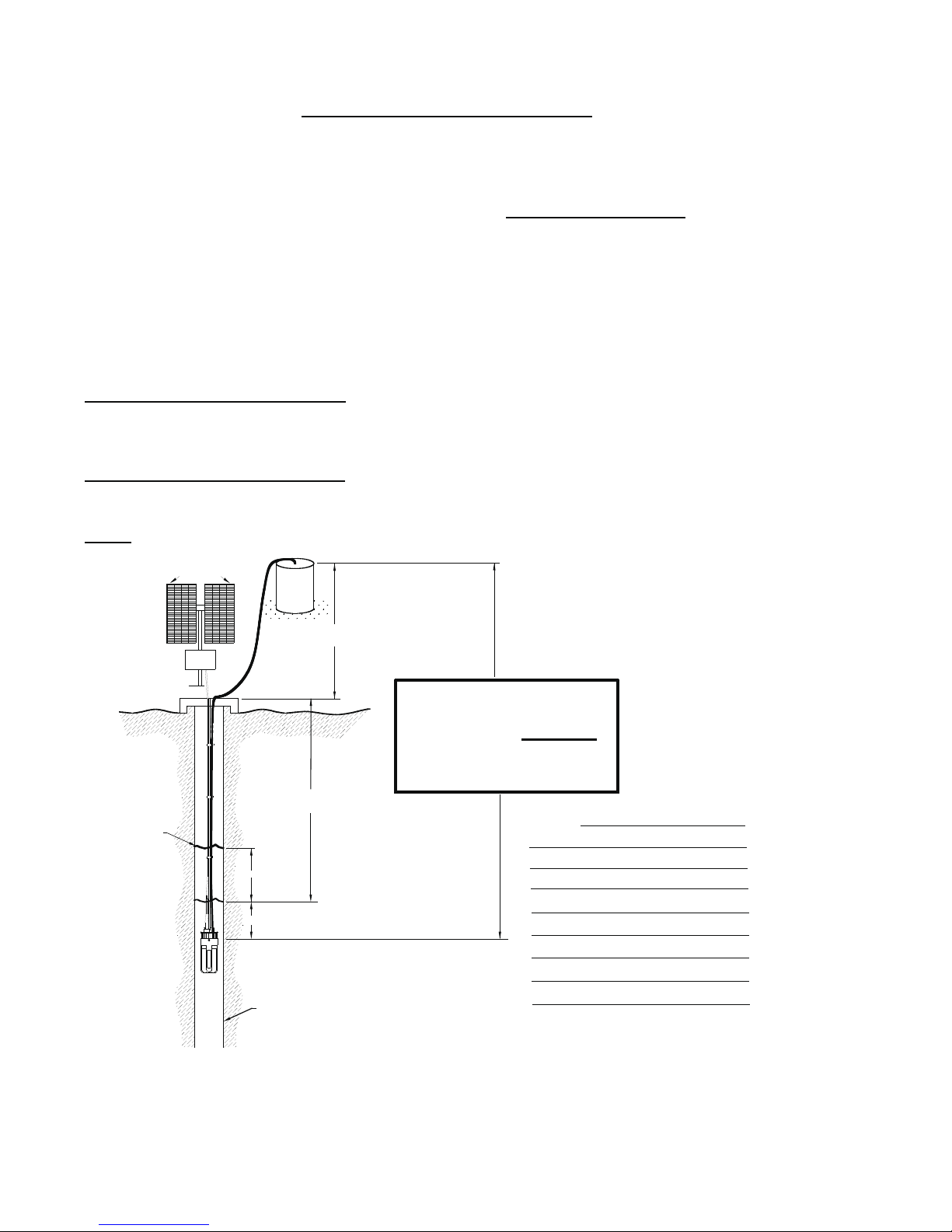

6) Install Pump (Fig. 8).

Note: Prior to installing the pump, fill in the application worksheet

on pages 14-15.

The application worksheet is a guide to make sure that the pump is

installed properly in the well.

Following the guidelines laid out in the application worksheet will

allow the pump to perform efficiently and extend the life of the unit.

Refer to "Helpful Hints" if you experience any difficulties.

PARTS LIST

LIFT

M A X IM U M

(7 0 M ET E R S )

2 3 0 FEET

(1 .8 M E T E R S )

A P A R T

6 FEET

B A N DIN G

C A B L E

JA C K E T ED

S U B M E R S IBLE

S E RIES

LEV EL

W A T E R

D R O U G H T

T U BIN G

LEV EL

W A T E R

S T A TIC

C A B L E

S A FT Y

T A N K

S T O R A G E

LIN E T O

SO L A R PA N ELS

2440

1 /2 " ID

FIGU RE 8

DIS C H A R G E

PU M P

C O N T RO L L ER

SINGFLO

6

ITEM DESCRIPTION QUANTITY

A CABLE [NOT INCLUDED] 1

B INNER CABLE BOOT 1

C OUTER CABLE BOOT 1

- PLUG (CABLEADAPTER) [NOT SHOWN]1

- SCREW (PLUG) [NOT SHOWN]2

D NUT 1

E SCREW (LIFT PLATE) 6

F LIFT PLATE 1

G OUTLET FITTING 1

H O-RING (OUTLET FITTING) 1

I O-RING (LIFT PLATE) 3

J RECEPTACLE (CABLEADAPTER) 1

K SET SCREW (RECEPTACLE) 2

L SCREW (MOTOR) 3

M FILTER SCREEN 1

N UPPER HOUSING 1

O O-RING (UPPER HOUSING) 2

P SPRING (BYPASS) 3

Q POPPET (BYPASS) 3

R VALVE HOUSING ASSEMBLY 1

S LOWERHOUSING ASSEMBLY 1

T MOTOR 1

U CANISTER 1

V SCREW (CANISTER) 3

W LOCK WASHER (MOTOR SCREW) 3

REPLACEMENT PART KITS

24-135-00 LIFT PLATE *[E,F,I]

24-136-00 CABLEPLUG KIT *[B,C,D,J,K,PLUG(CABLE ADAPTER) W/ SET SCREWS]

24-137-00 VALVE ASSEMBLY KIT *[O,P,Q,R]

24-138-00 LOWERHOUSING ASSEMBLY KIT *[O,S]

24-139-00 MOTOR KIT *[O,T]

24-140-00 CANISTER KIT *[O,U,V]

24-141-00 FILTER SCREEN KIT *[M]

24-142-00 O-RING KIT *[H,I,O,O-RING(VALVEHOUSING ASSEMBLY)]

24-143-00 TOOL KIT *[5/64", 5/32" and 3/16" ALLEN WRENCHES, #1 and #2 PHILLIPS SCREWDRIVERS]

*[ ] DENOTES PARTS INCLUDED IN KITS.

7

V

WEIV B I

U

T

S

R

Q

P

O

N

M

L

K

J

I

G

F

E

D

C

B

A

W

F

H

R

Q

VIEW A

P

1

2

34

5

6

7

8

1 2 3 4 5 6 7 8

Lift Plate Cable Plug Valve Lower

Housing Motor Canister Filter

Screen O-Ring

24-135-00 24-136-00 24-137-00 24-138-00 24-139-00 24-140-00 24-141-00 24-142-00

8

BEFORE REQUESTING SERVICE

"Helpful Hints"

SYMPTOM PROBABLE CAUSE CORRECTION

PUMP OPERATES but: 1) LOW VOLTAGE 1) CHECK POWER SUPPLY FOR PROPER VOLTAGE.

NO FLOW or REFER TO TECHNICAL SPECIFICATIONS (Pg. 16).

REDUCED FLOW

2) NO WATER AT PUMP 2) MAKE SURE THE PUMP IS INSTALLED

BELOW THE LOWEST ANTICIPATED

WATER LEVEL.

REFER TO INSTALLATION SECTION (Pg. 5).

3) PUMP LOCATED 3) REFER TO INSTALLATION SECTION (Pg. 5)

TOO DEEP FOR PUMP OPERATING RANGE.

4) CLOGGED FILTER 4) REMOVE FILTER SCREEN AND RINSE.

SCREEN REFER TO REMOVAL AND

DISASSEMBLY SECTION (Pg. 9).

5) FLUID PATH IN 5) CHECK FOR PINCHED HOSE, CLOGGED

PLUMBING RESTRICTED LINES.

6) LOOSECONNECTIONS 6) CHECK HOSE CLAMPS or REPLACE HOSE (Pg. 4).

or PUNCTURED HOSE.

PUMP WILL 1) INCORRECT POWER SUPPLY 1) CHECK POWER SUPPLY.

NOT OPERATE: REFER TO PUMP TECHNICAL SPECIFICATIONS

(Pg. 16).

2) WIRE CONNECTIONS 2a) CHECK ELECTRICAL CONNECTIONS ON

SYSTEM.

2b) CHECK THE PLUG(CABLE ADAPTER)

ELECTRICAL CONNECTION MADE

DURING THE INSTALLATION IS NOT

CORRODED OR LOOSE.

REFER TO CABLE BOOT INSTALLATION

INSTRUCTIONS FOR DISASSEMBLY

AND REASSEMBLY(Pg. 3-4).

2c) CHECK FOR BLOWN FUSES IN-LINE.

CONTACTAN AUTHORIZED DISTRIBUTOR FOR FURTHER ASSISTANCE.

9

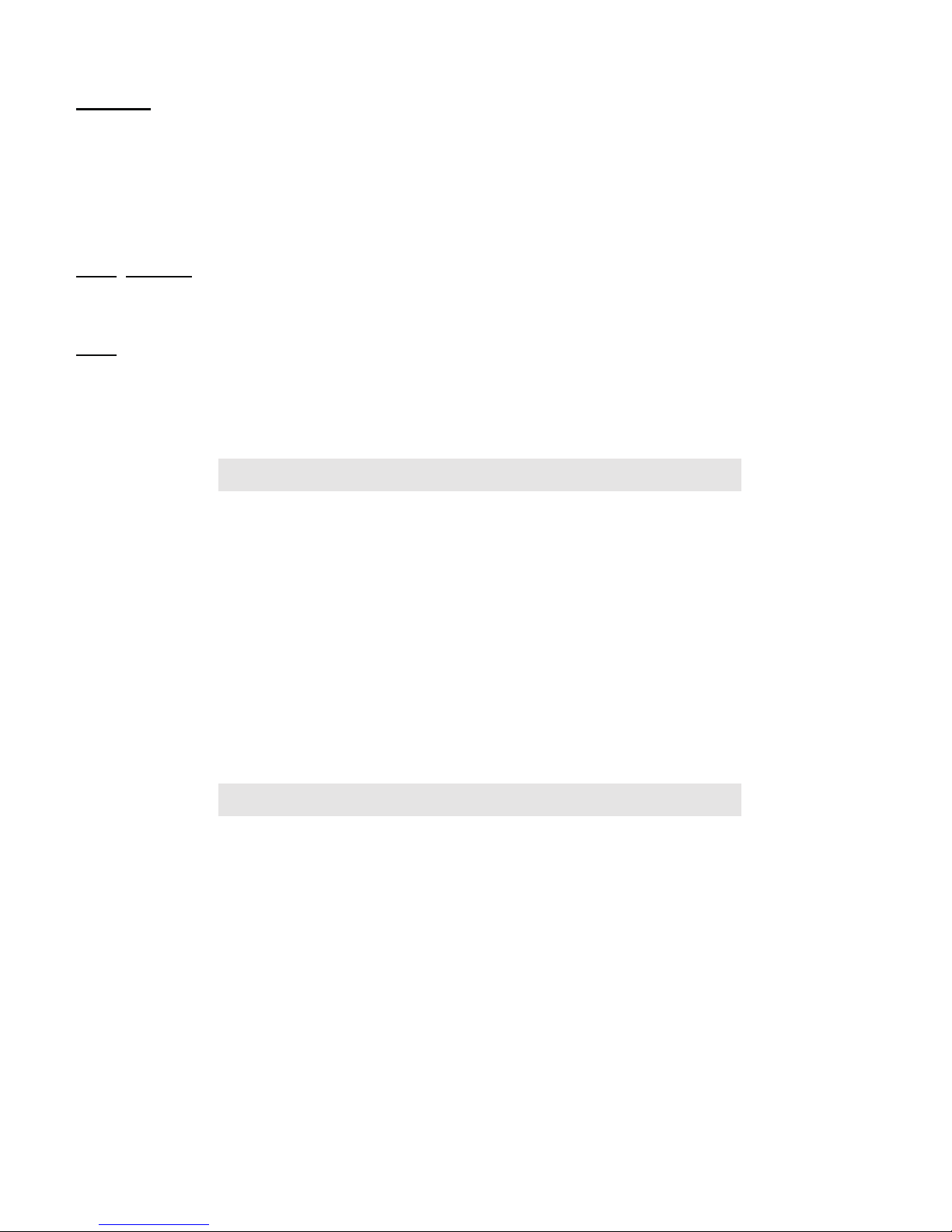

II. PUMP REMOVAL AND DISASSEMBLY

For servicing using Replacement Part Kits.

Warning: Make sure all electrical power is off and the Hose (Pipe) is

not under pressure.

Warning: Canister maybe pressurized, disassemble the pump in proper order.

Follow the manual directions carefully.

Note: Keep all of the parts clean after disassembly.

Upper Housing Assembly contains small parts.

Be careful not to lose parts after removing Upper Housing (Part N) step 9.

1) Remove the Pump from the well.

To prevent damaging the Electrical Connection during removal from well

DO NOT PUT STRESS ON THE ELECTRICAL CORD.

2) Disconnect the Hose.

Remove the Hose clamp, pull and twist the hose to remove it

from the fitting.

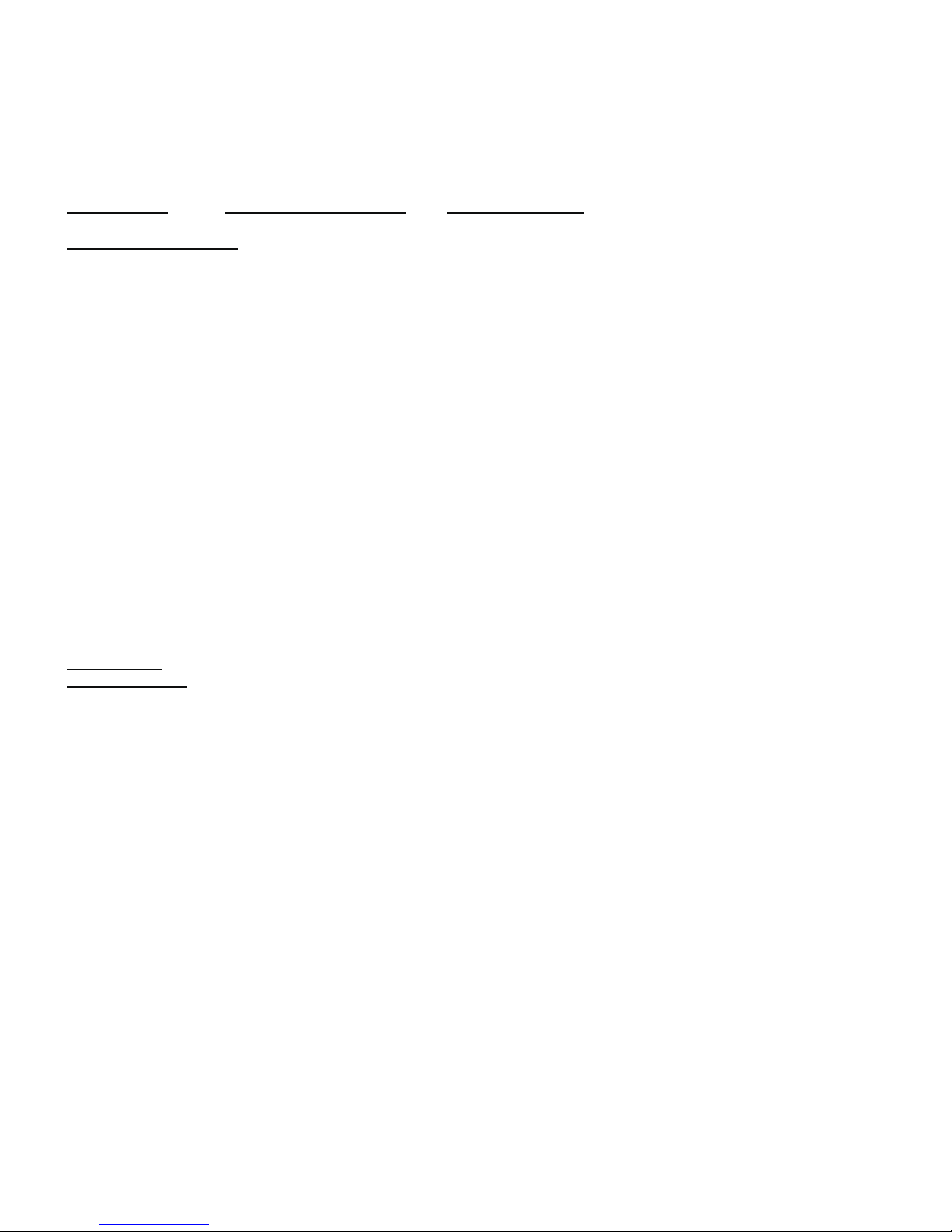

3) Unplug the Cable Adapter Assembly (Fig 9).

Remove the Nut (Part D) unscrewing it counterclockwise and

pull the plug up.

4) Remove the Lift Plate (Part F) (Fig. 9).

Using a #2 Phillips Screwdriver remove the screws (Part E) from 6 places

and pull up the Lift Plate.

Note: Be sure to put the O-Rings (Part I) back on

the Lift Plate Posts (Fig. 9, View B) before continuing to step 5.

If necessary, the filter screen may be removed for

cleaning at this stage of the disassembly.

5) Remove the Outlet Fitting (Part G) (Fig. 9).

Remove the fitting from the Upper Housing (Part N) by

pulling it straight out.

6) Remove the Receptacle (Cable Adapter) (Part J) (Fig. 9).

Note: DO NOT PULL ON THE ELECTRICAL PRONGS.

a) Using pliers carefully pull up on the shoulder of the

Receptacle (Cable Adapter) and pull it completely out

of the Upper Housing (Part N).

b) Using a 5/64" Allen Wrench, loosen the screws

holding the motor leads (Part k) from 2 places and

disconnect the Receptacle (Cable Adapter).

V

E

DG

F

M

U

N

10

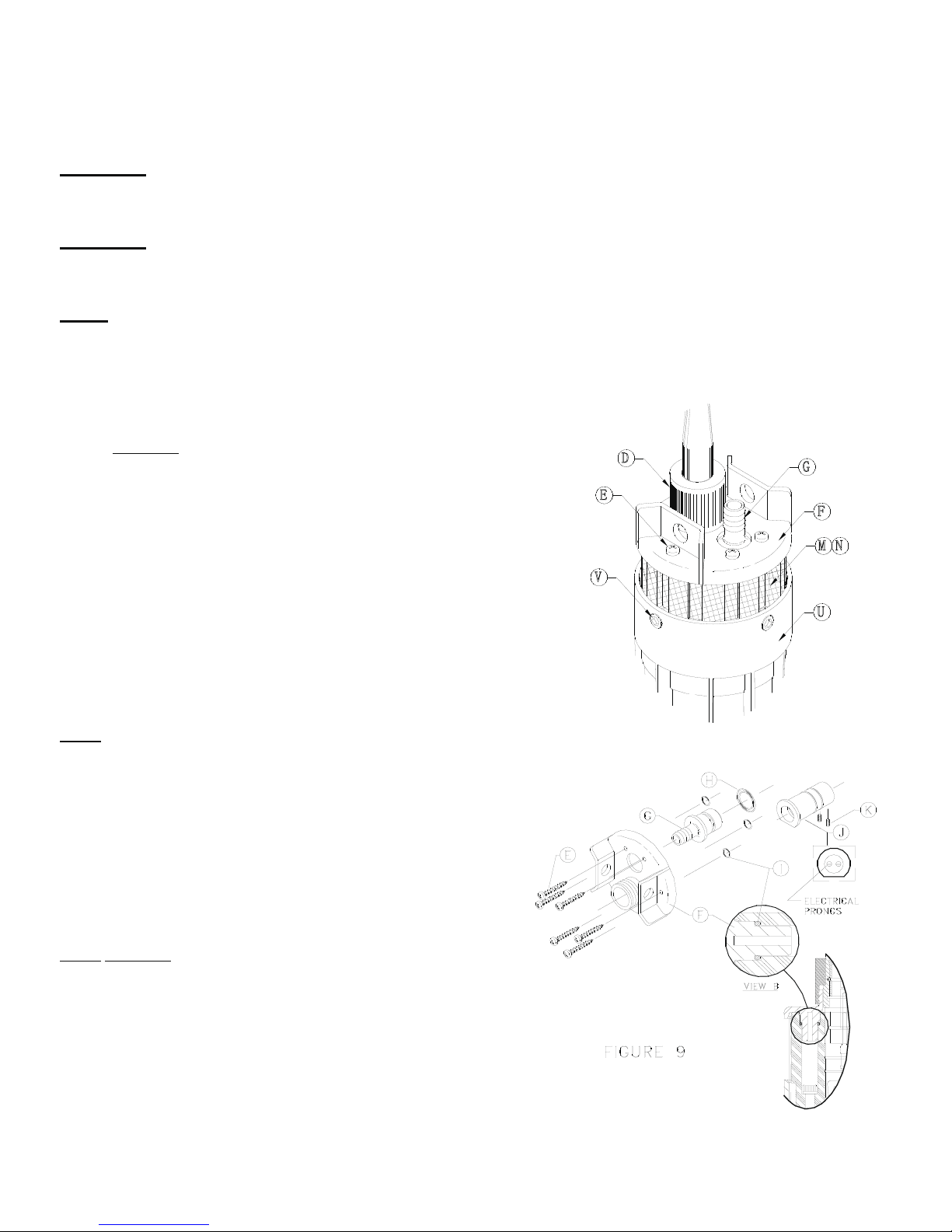

7) Slide off the Filter Screen (Part M) (Fig. 10).

8) Remove the Canister (Part U) (Fig. 10).

a) Using a 3/16" Allen Wrench remove the screws (Part V) from 3 places.

b) Place one hand on the Upper Housing and the other on the Canister. Twist and pull the Assembly apart.

9) Remove Upper Housing (Part N) and Motor (Part T) (Fig. 10).

Note: Keep all parts clean after disassembly.

The Upper Housing Assembly contains small parts.

Be careful not to lose parts after removing Upper Housing.

a) Using a 5/32" Allen Wrench remove the screws (Part L) from 3 places.

b) Before separating the Upper Housing from the Motor, place the assembly on the Upper Housing(Down)

and the Motor facing up.

c) Separate the Upper Housing, Valve Housing and Lower Housing Assembly (Parts R, S), Poppets (Part Q),

and Springs (Part P).

10) Contact an authorized distributor for assistance with diagnosis and

replacement Parts (Refer to page 6 for replacement part kit list).

FIG U R E 1 0

L

N

O

P

Q

R

S

T

U

V

W

M

11

III. PUMP RE-ASSEMBLY

Warning: The order of Assembly is important to ensure proper sealing.

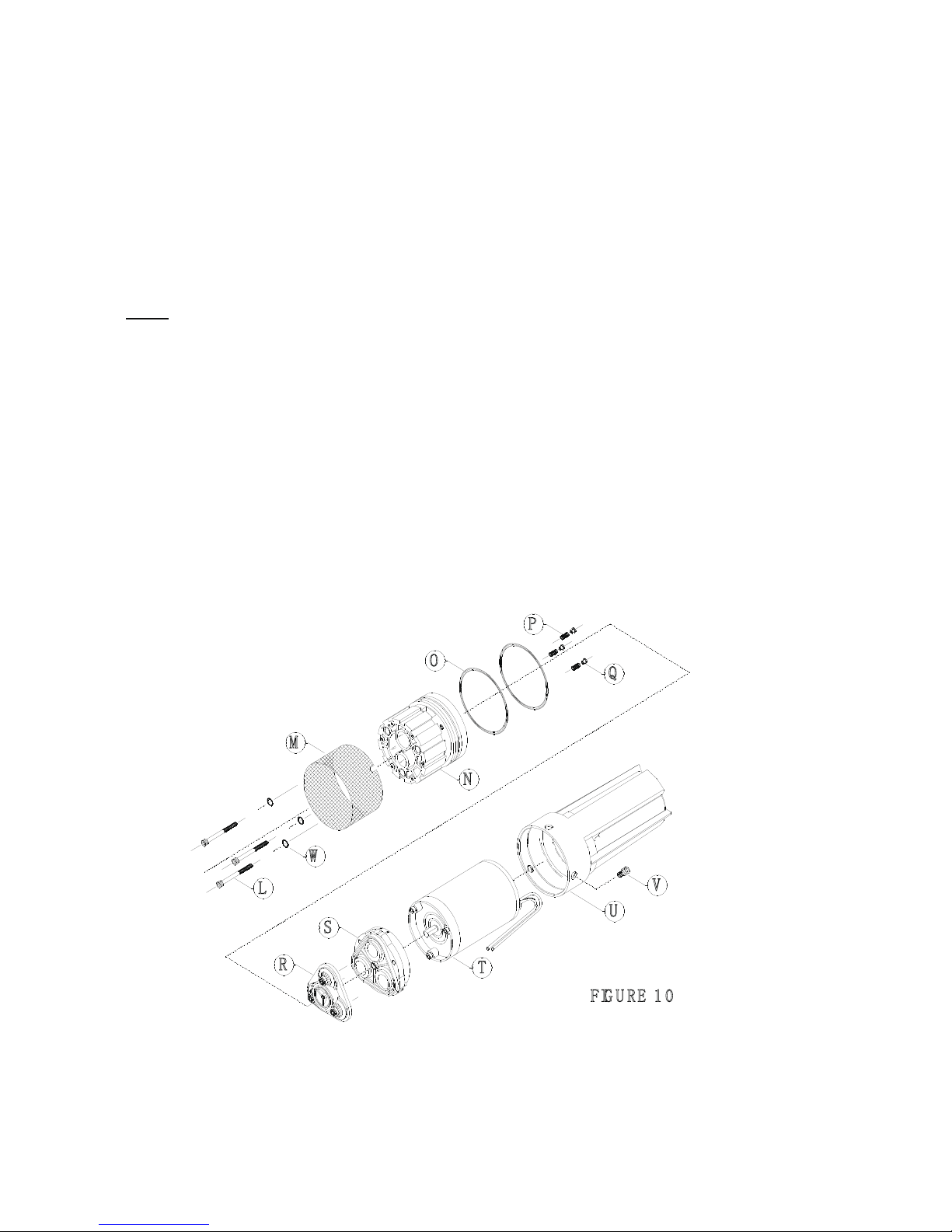

1) Install the Upper Housing Large O-Rings (Part O) (Fig. 11).

a) Remove the existing Large O-Rings and thoroughly clean the

O-Ring grooves with a dry cloth and a cotton tipped applicator.

Note: Lubricate the O-Rings with the Supplied O-Ring Grease.

DO NOT USE PETROLEUM BASED LUBRICANT.

b) Slide the two new Large O-Rings over the Upper Housing (Part N) and

into the O-Ring grooves.

c) Place the Upper Housing down with the internal cavities exposed.

Turn the Upper Housing until the motor wire holes are directly in front.

2) Install the Bypass Assembly (Parts P and Q) (Fig. 11).

a) Place the Poppets (Part Q) into the Springs (Part P).

Note: Make sure that the Poppets are seated flush against the Springs.

b) Locate the three bypass cavities and place the Spring/Poppet Assembly

into the cavities with the Poppet up.

3) Install the Valve Housing Assembly (Parts R) (Fig. 11).

Place the Valve Housing Assembly into the Upper Housing (Part N).

Note: Make sure that the inlet valves are centered on top of the bypass

Poppets (Part Q).

4) Install the Lower Housing Assembly (Part S) (Fig. 11).

a) Place the Lower Housing Assembly onto the

Valve Housing Assembly (Part R) (Fig. 11).

Note: DO NOT FORCE THE ASSEMBLY.

IT SHOULD SNAP TOGETHER EASILY IN

ORDER TO SEAL PROPERLY.

5) Install the Motor (Part T) (Fig. 11).

a) Lubricate the motor shaft with a small amount of general purpose grease.

b) Align the "D" flat of the motor shaft with the "D" flat on the

Lower Housing Assembly (Part R).

c) Align the motor lead wires with the Upper Housing (Part N) wire holes.

Align the three tabs on the motor with the holes on the

Lower Housing Assembly (Parts R) and set the motor onto the Lower

Housing.

d) Insert the motor lead wires into the Upper Housing motor wire holes.

Push the wires until they touch the surface that the Upper Housing is resting on.

O -R IN G

G R O O V E S

O

N

"D " FL A T

M O T O R S H A FT

P

Q

T

O

R

S

M O T O R L EA D

W IR E S

FIG U R E 1 1

IN LET V A L V ES

U P P ER H O U S IN G

T

O R W IRE H O LE S

Y P A S S C A V IT IES

12

6) Install the Canister (Part U) (Fig. 12).

a) Clean the inside of the Canister with a dry cloth.

b) Align the wire channel in the canister with the motor lead wires.

c) Slide the canister over the entire assembly .

d) Twist the canister to align the screw holes and carefully press on

end to seat properly.

7) Install the Screws (Part V) (Fig. 12).

Note: DO NOT USE MORE THAN15 (±5) in lb [1.7 Nm (±.5)] torque

TO PREVENT STRIPPING.

Using a 3/16" Allen Wrench tighten the screws in 3 places into

the Upper Housing (Part N).

8) Turn the assembly over as shown in Figure 13.

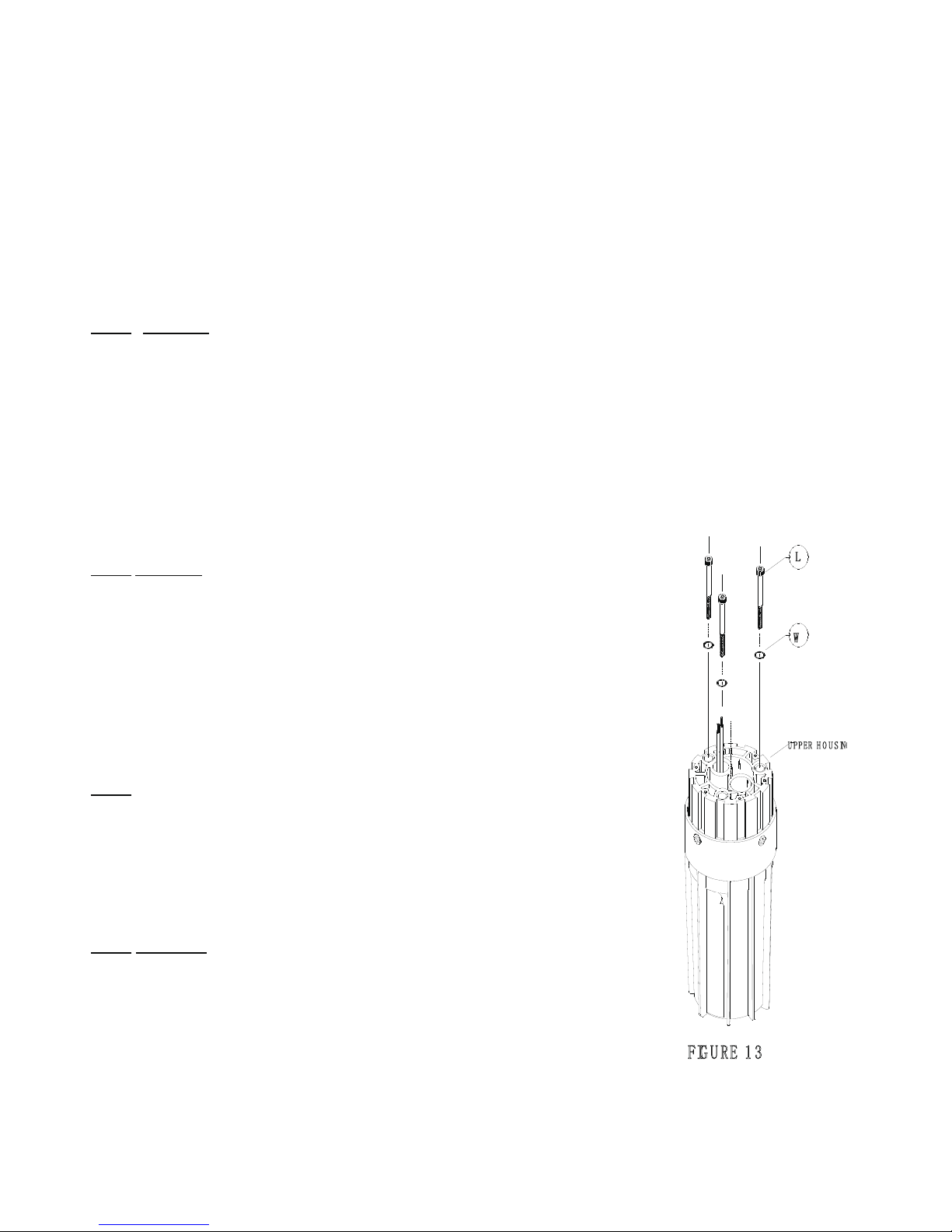

9) Install the Lock Washers (Part W) and Screws (Part L) (Fig. 13).

a) Slide the three Lock Washers onto the screws and place the screws

in 3 places into the Upper Housing (Part N).

Note: DO NOT COMPLETELY TIGHTEN ONE SCREW AT A TIME.

TIGHTEN THE SCREWS WITH TWO PASSES

SLOWLY COMPRESSING THE ASSEMBLY TOGETHER.

b) Using a 5/32" Allen Wrench tighten the screws on the first pass

with 25 (±5) in lb [2.8 Nm (±.5)] torque.

c) Tighten the screws on the second pass

with 65 (±5) in lb [7.3 Nm (±.5)] torque.

10) Connect the Receptacle (Cable Adapter) (Part J) (Fig. 14, page 13).

Note: The orientation of the motor lead wires will not effect the pumps

performance.

a) Pull the motor lead wires up through the Upper Housing (Part N) and insert

them into the Receptacle (Cable Adapter).

b) Using a 5/64" Allen Wrench hand tighten the screws on the

Receptacle (Cable Adapter) for both wires.

Note: DO NOT TIGHTEN WITH A POWER TOOL.

c) Lubricate the outer surface of the Receptacle (Cable Adapter) with the

Supplied O-Ring grease.

d) Match the flat side of the Receptacle (Cable Adapter) with the flat side

of the hole in the Upper Housing.

e) Push the Receptacle (Cable Adapter) into the hole in the Upper Housing

until it is seated flush.

f) Spread each Receptacle (Cable Adapter) electrical prong slightly to insure the electrical connection.

W

L

FIG U RE 1 3

U PPER H O U S IN

13

11) Install the Filter Screen (Part M) (Fig. 15).

a) Slide the Filter Screen onto the Upper Housing (Part N).

b) Align the slots in the Filter Screen with the screws (Part V) in the Upper Housing and

slide the Filter Screen over the screws.

12) Install the Outlet Fitting (Part G) (Fig. 15).

a) Lubricate the O-Ring (Part H) and slide it into the O-Ring groove

on the Outlet Fitting.

b) Push the Outlet Fitting into the hole in the Upper Housing (Part N).

13) Install the Lift Plate (Part F) with three the O-Rings (Part I)

on the posts (Fig. 15).

a) Align the three posts with the Upper Housing (Part N) screw holes and

press on the Lift Plate until it is flush against the Upper Housing.

Note: DO NOT USE MORE THAN20 (±5) in lb [2.25 Nm (±.5)] TORQUE

TO PREVENT STRIPPING .

b) Using a #2 Phillips Screwdriver install the screws (Part E) 6 places

into the Lift Plate.

14) Install the Plug (Cable Adapter) Assembly.

Note: The orientation of the Plug(Cable Adapter) will not effect

the pumps performance.

Note: IF IT BECOMES NECESSARY TO REASSEMBLE

THE PLUG (CABLE ADAPTER) ASSEMBLY, REFER

TO PUMP CONNECTIONS & INSTALLATION INSTRUCTIONS (Pg. 3-

5).

a) Align the Plug (Cable Adapter) connector holes with the electrical prongs

in the Receptacle (Cable Adapter).

b) Push the Plug (Cable Adapter) into the Receptacle (Cable Adapter)

until the collar is seated flush.

c) Push the Nut (Part D) over the Plug (Cable Adapter) and finger tighten the nut.

Note: Before placing the pump back into the well, operate

the pump to check all electrical connections using the

correct power supply.

Refer to Technical Specifications (Pg. 14).

FIG U R E 1 5

I

E

F

G

H

U P P E R H O U S IN G

M

V

14

APPLICATION WORKSHEET

Please fill in for your records.

MODEL NUMBER_____________________________ PUMP DISTRIBUTOR:

SERIAL NUMBER_____________________________ Name_______________________________________________

MFG. DATE__________________________________ Address_____________________________________________

PURCHASE DATE_____________________________ City________________________________________________

TOTAL WELL DEPTH_________________FT(M) Phone( )__________________________________________

WELL RECOVERY

RATE________________________________________________________________________________________________________

SOLAR ARRAYINFORMATION:

MAKE/MODEL_______________________________________________________________________________________________

WATTS AVAILABLE (NO. OF PANELS X WATTS PER PANEL= )______________________________________________________

CONTROLLERINFORMATION:

MAKE/MODEL_______________________________________________________________________________________________

NOTE: Use of an LCB (Linear Current Booster) Unit is required for optimum performance.

SOLAR PANELS

CONTROLLER

DISCHARGE HEAD = H1

STORAGE

TANK

WATER LEVEL = H2

DRAW DOWN

SUBMERGENCE = H3

WELL CASING DIAMETER=_________IN(cm)

LEVEL

STATIC WATER

H1= DISCHARGE HEAD =_________FT(M)

+ H2=WATER LEVEL=_________FT(M)

+ *H3=SUBMERGENCE= FT(M)

**TOTAL VERTICAL LIFT=__________FT(M)

**NOT TO EXCEED 230 FT(70m)

(WHEN PUMPING)

(ABOVE GROUND)

*NOT TO EXCEED 100 FT(30m)

Comments:

(H1 + H2 + H3)

15

TERMS:

H1=DISCHARGE HEAD = Vertical distance in feet from ground level to level of water in elevated storage tank.

H2=WATER LEVEL = Vertical distance in feet from level of water in well when pumping up to ground level.

H3=SUBMERGENCE = Vertical distance in feet from level of water in well when pumping, to pump position in well.

Note: DO NOT submerse the pump deeper than necessary unless the water level is known to

be highly variable (Pump may operate dry for short periods of time.).

Draw down =Vertical distance in feet from static water level to water level when pumping.

Note: Make sure the pump is installed below the lowest anticipated water level.

Consider the seasonal changes in the region.

TOTAL VERTICAL LIFT= H1+H2+H3

12 VDC FLOW CHART

TOTAL FLOWRATE SOLARARRAYSIZE CURRENT

VERTICALLIFT PERHOUR MINIMUMTOTALPOWERRATING AMPS

STTAWRTLLAGSRETEMTEEF

20 6.1 56 212 22 1.2

40 12.2 54 204 28 1.5

60 18.3 52 197 33 1.8

80 24.4 50 189 37 2.0

100 30.5 49 186 40 2.1

120 36.6 47 178 45 2.4

140 42.7 46 174 51 2.7

160 48.8 44 166 56 3.0

180 54.9 43 163 61 3.3

200 61.0 41 155 64 3.4

230 70.1 36 136 72 3.9

24 VDC FLOW CHART

TOTAL FLOWRATE SOLARARRAYSIZE CURRENT

VERTICALLIFT PERHOUR MINIMUMTOTALPOWERRATING AMPS

STTAWRTLLAGSRETEMTEEF

20 6.1 117 443 58 1.5

40 12.2 114 432 65 1.7

60 18.3 109 413 78 2.1

80 24.4 106 401 89 2.4

100 30.5 103 390 99 2.6

120 36.6 101 382 104 2.8

140 42.7 99 375 115 3.1

160 48.8 98 371 123 3.3

180 54.9 93 352 135 3.6

200 61.0 91 345 141 3.8

230 70.1 82 310 155 4.1

16

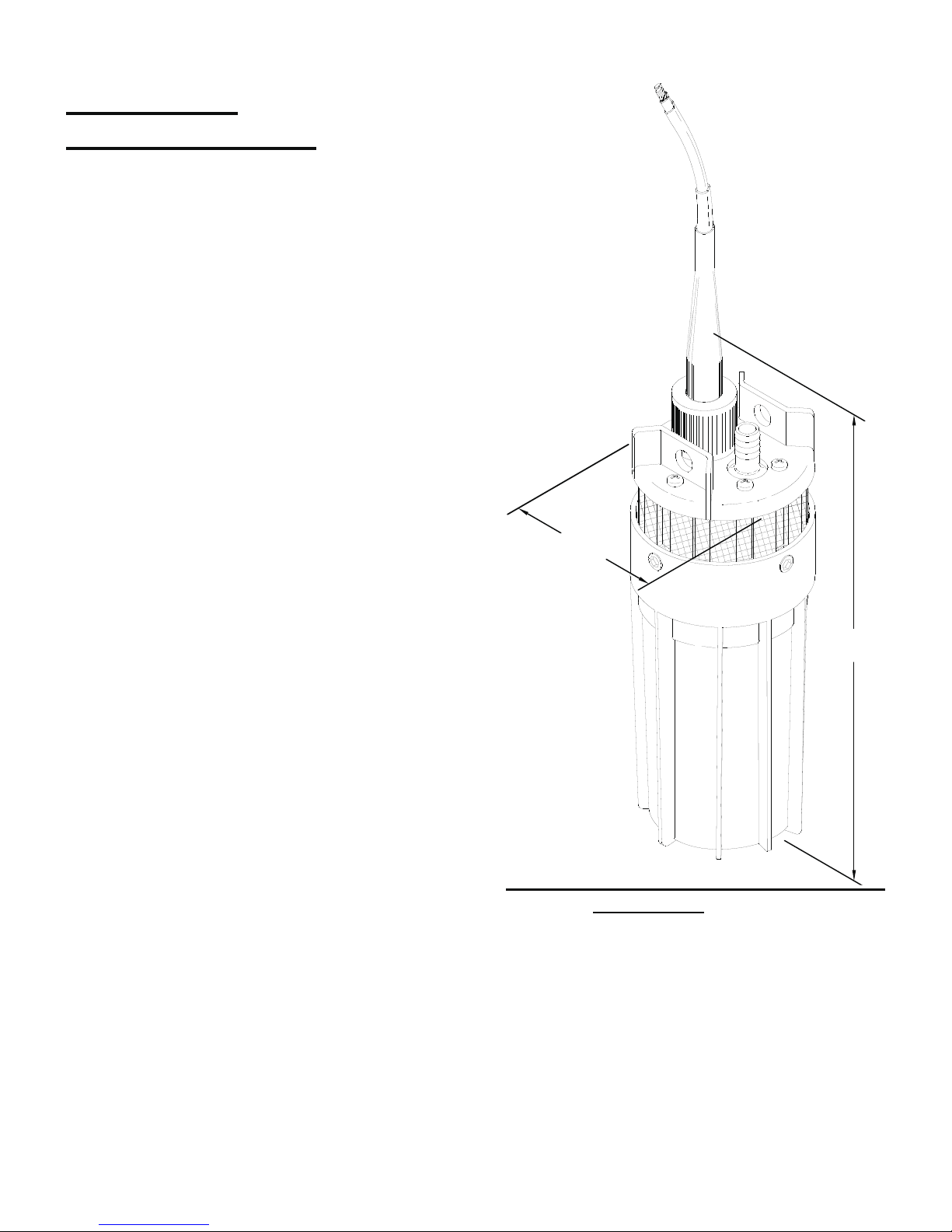

TECHNICAL

SPECIFICATIONS:

MODEL NUMBER: YM 2440-30

PUMP DESIGN: Positive Displacement

3 Chamber Diaphragm Pump

CAM: 3.0 Degree

MOTOR: Permanent Magnet, P/N 11-175-00

Thermally protected

VOLTAGE: 24 VDC Nominal

WATTS: 120W

AMPS: 4.0 MAX

FUSE: 7.5 AMP (Automotive)

INTERNAL BYPASS: 105-110 P.S.I. MAX (7.2-7.5 bars)

MAXIMUM LIFT: 230 ft (70 M)

MAXIMUM SUBMERSION: 100ft (30 M)

OUTLET PORT: 1/2" (12.7 mm I.D.) Barbed Fitting

for 1/2" I.D. (12.7 mm I.D.)Tubing.

INLET: 50 MESH STAINLESS STEEL SCREEN

MATERIALS: HIGH STRENGTH ENGINEERED PLASTICS

and STAINLESS STEEL FASTENERS

TYPICAL APPLICATIONS: Potable water well pump. DIMENSIONS: Inches(Millimeters)

Design and specifications are subject to

change W/Onotice.

NET WEIGHT: 6 lbs (2.72 kg)

(95 mm)

3.75 in.

(305 mm

)

12 in.

17

TOOLS REQUIRED FOR INSTALLATION & MAINTENANCE

*#1 and #2 Phillips Screwdriver Wire Cutters

*5/64" Allen Wrench Wire Strippers

*5/32" Allen Wrench Pliers

*3/16" Allen Wrench Dry Cloth or Cotton Tipped Applicator for cleaning O-Ring grooves

Electrical Tape

Tie wraps

*Note: A tool kit is available, components included are listed above.

NOTES:____________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

WARRANTY

LIMITED WARRANTY PROCEDURE

SINGFLO warrants its pump to be free of defects in material and workmanship to the original retail

purchaser for the period of one year beginning with the purchase date of the unit or, in the absence of

proof of purchase date, one year from the date of manufacture as shown on the pump, not to exceed

two (2) years in any event. Each pump has been operated and tested before being shipped from

SINGFLO's factory. During the warranty period if the pump is not operating correctly, you may return it

freight pre-paid to your local distributor, dealer or directly to SINGFLO.

Upon SINGFLO's inspection, any unit found faulty due to manufacturing defects will be repaired or

replaced at no charge. This warranty does not apply to any damage resulting from misuse, negligence,

accidents, improper installation or wiring. Abuses such as removal of the SINGFLO label, improper

repair, installation, application, or damaged lower housing assembly due to running dry, are also not

considered warrant able. There will be charges applied for any of the above mentioned non-warrantable

items.

If you send the pump to us for prompt repair, please package it carefully to avoid shipping damage.

Enclose your name, address, a phone number where you may be reached and your proof of purchase

date.

The above represents our warranty policy. Under no circumstances will we assume or accept

responsibility for unauthorized expenditures, losses, or any costs greater than the basic pump value.

Table of contents

Popular Water Pump manuals by other brands

Zoeller

Zoeller ProPak 507 installation instructions

Summit

Summit SP Installation, operation and maintenance manual

Wacker Neuson

Wacker Neuson PDT 2A Operator's manual

GEL

GEL DOSAMATIC PP Installation, use and maintenance manual

Atlas Copco

Atlas Copco WEDA L110 Instruction handbook

CET

CET PFP-18HPVGD-2D Instruction handbook

CET

CET PFP-11hpHND-EM Instruction handbook

Speck pumpen

Speck pumpen BADU Spyder I operating instructions

Stenner Pumps

Stenner Pumps SVP4L1 Installation and maintenance manual

Knauer

Knauer Azura V6840 user manual

EINHELL

EINHELL ROYAL HW 1300 Niro/Niro operating instructions

Parker

Parker DCP3 installation manual