16

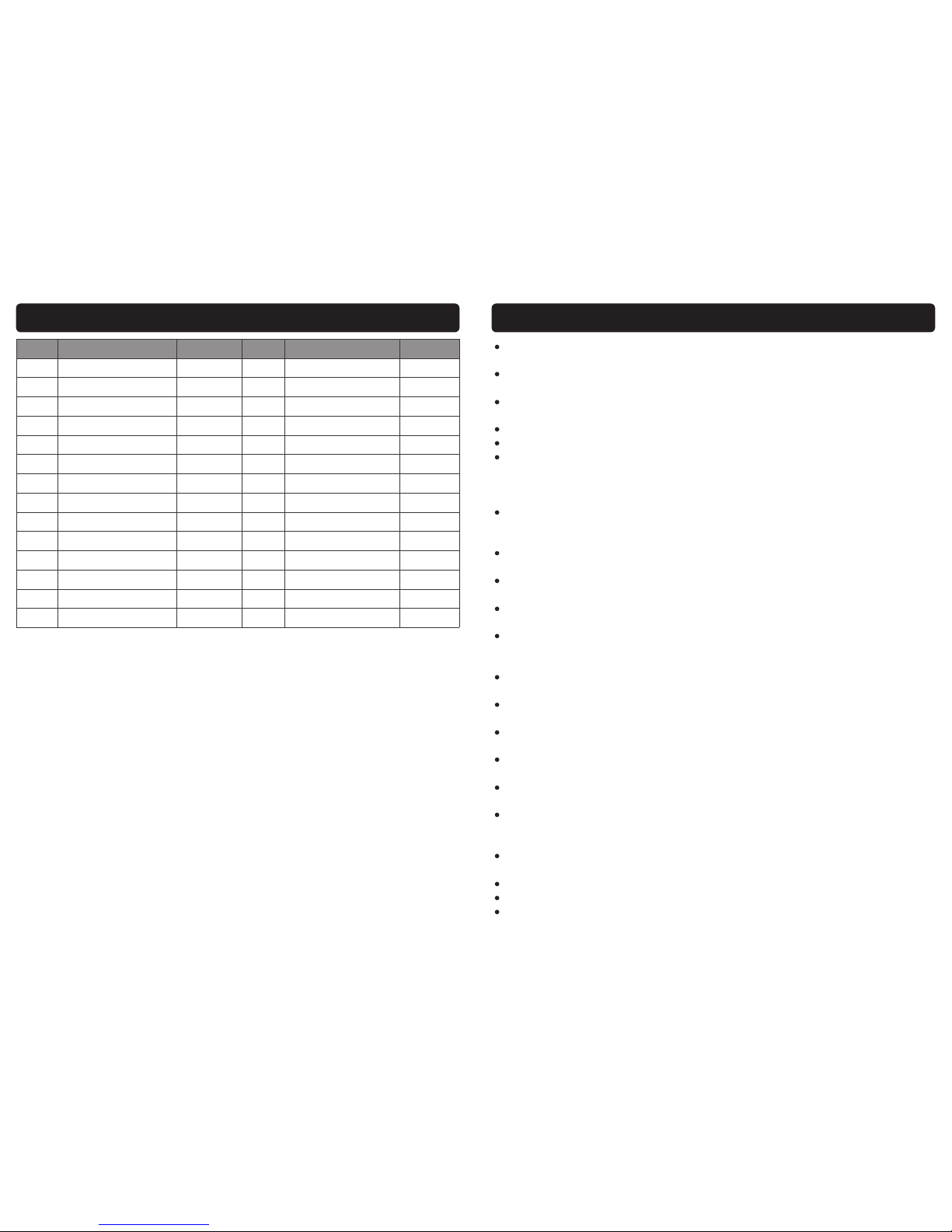

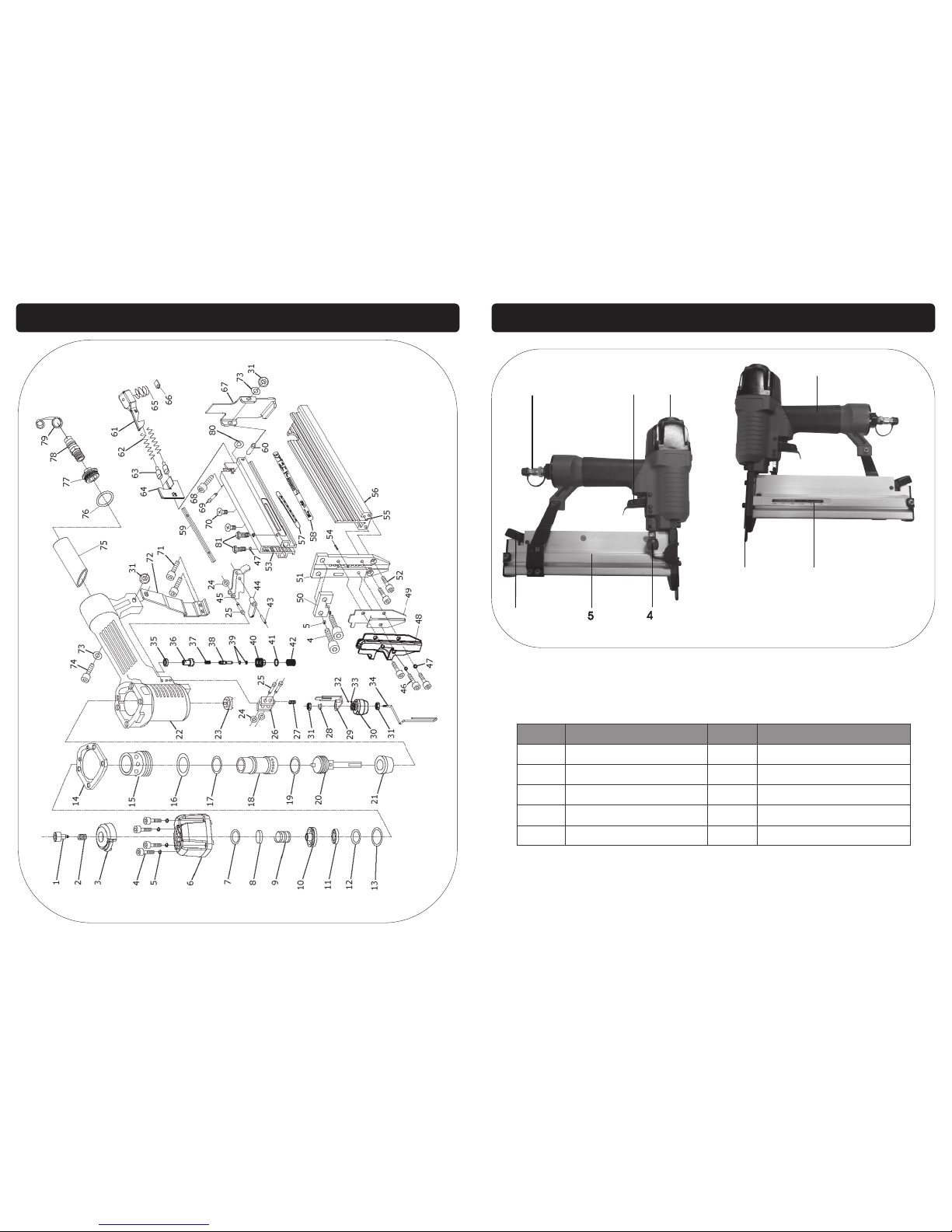

PARTS LIST….cont

Ref No. Description SIP Code Ref No. Description SIP Code

55. Inlay slice AI05-00592 69. Pin AI05-00606

56. Fixed magazine AI05-00593 70. Bolt M4x6 AI05-00295

57. Indicator label AI05-00594 71. Bolt M4x6 AI05-00295

58. Sticker plate AI05-00595 72. Support seat AI05-00607

59. Guide rail AI05-00596 73. Washer AI05-00608

60. Pipe AI05-00597 74. Bolt M4x20 AI05-00609

61. Fixed lever AI05-00598 75. Rubber handle case AI05-00610

62. Compressed spring AI05-00599 76. O-ring 36.3x3.55 AI05-00611

63. Pusher pipe AI05-00600 77. End cap AI05-00612

64. Pusher AI05-00601 78. Air inlet AI05-00613

65. Compressed spring AI05-00602 79. Protection cap AI05-00614

66. Washer AI05-00603 80. O-ring 2.4x1.6 AI05-00615

67. Fixed seat AI05-00604 81. Bolt M4x14 AI05-00616

68. Bolt M4x38 AI05-00605

5

If a problem with the nailer stapler is experienced or suspected stop using the nailer

stapler immediately and contact your distributor for repair.

Regularly inspect and lubricate the nailer stapler, ensuring that it is in good working

order and condition.

Always ensure that the work area is clean and tidy, free from unrelated materials and

has adequate lighting.

Clean and stow the nailer stapler correctly.

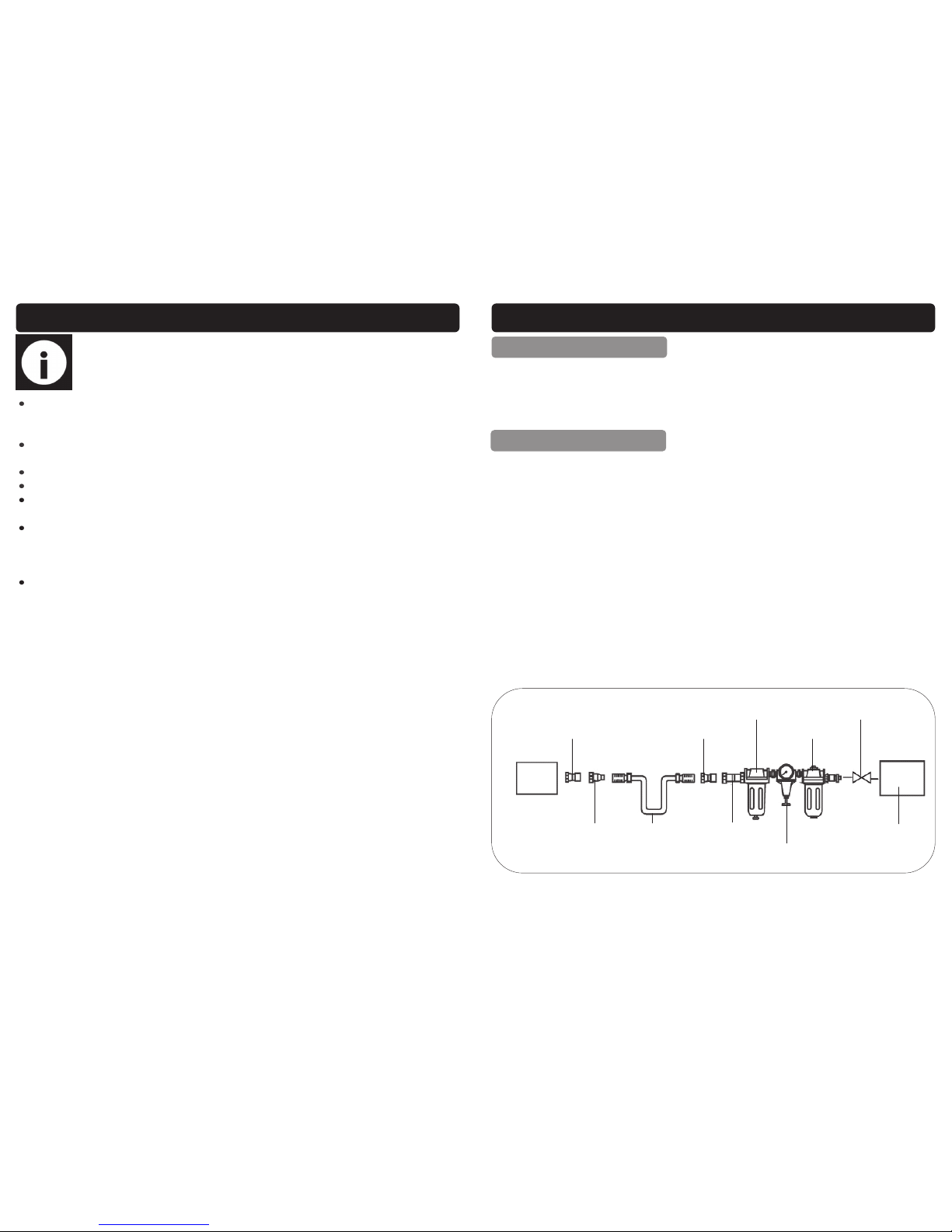

DO ensure that only compressed air is used to supply the air tool.

The compressed air supply MUST be at a suitable regulated pressure. Pipe work, reg-

ulators, hoses, isolation valves and connection devices MUST be suitable for the in-

tended application correctly installed and maintained in good condition by a com-

petent person.

Appropriate Personal protective equipment MUST be worn and MUST be designed to

protect against all hazards created. Severe permanent injury can result from using

inappropriate or insufficient protective equipment - eyes in particular are at risk.

Long hair MUST be tied back; Loose clothing MUST NOT be worn. There is a severe

risk of these being drawn in or trapped by the moving parts of the air tool.

Open or damaged compressed air lines present a significant ‘whip’ hazard; Isolate

the problem hose from the air supply and repair / replace the hose immediately.

This air tool is electrically conductive DO NOT allow it to come into contact with any

source of electrical supply.

When putting the air tool aside you MUST ensure that it placed in a stable position. To

avoid inadvertent operation DO NOT place the air tool where it can be knocked or

moved accidentally either directly or by the air connection hose.

If the air tool is not required or the air supply is interrupted, disconnect the air tool

from the air supply and place in secure storage to prevent unauthorised use.

Ensure the air valve (or trigger / throttle) is in the “off” position before connecting the

nailer stapler to the air supply.

Disconnect the nailer stapler from the air supply before making adjustments, chang-

ing nails or staples etc. and before servicing the tool.

Always keep your air tool clean and lubricated. Daily lubrication is essential to avoid

internal corrosion and possible failure.

Do not overload the tool. Allow the tool to operate at its optimum speed for maxi-

mum efficiency.

Do not increase the air pressure above the manufacturers recommended level, as

excessive pressure can cause the tool casing to split. This can also create excessive

wear on moving parts and possible failure.

Always ensure that the work-piece is firmly secured leaving both hands free to control

the nailer stapler.

Always wear safety goggles or glasses during operation.

Do not wear watches, rings, bracelets or loose clothing when using air tools.

Use as light weight a hose as possible from the tool to the wall or compressor cou-

SAFETY INSTRUCTIONS….cont