Siro Lasertec SL10 User manual

Tool / Machine / System

Model Designation:

Welding Laser System

Type:

SL 10

Year of Manufacture:

Serial Number:

2022

__________________

Customer Registration:

Company Name:

Order No.:

Location:

Maunfacturer’s Contact Details:

Company Name:

Siro Lasertec

Laserservice und Vertrieb GmbH

Street:

Rastatter Straße 6

Town:

D-75179 Pforzheim

Telephone:

+49 (0) 7231 154130

Telefax:

+49 (0) 7231 1541329

E-Mail:

info@siro-lasertec.de

Homepage:

www.siro-lasertec.de

Technical Customer Service

support@siro-lasertec.de

Instruction Manual:

Version:

END

Creation Date:

28.03.2023

Instruction manual

Laser Welder

Index

IM Machine Name Rev.: END I

Index

1 Foreword ........................................................................ 4

1.1 Introduction .......................................................................................... 4

1.2 Copyright and Property Rights ........................................................... 4

1.3 Information for the Operating Company ............................................ 4

2 Safety .............................................................................. 5

2.1 Information about Signs and Symbols ............................................... 5

2.2 Intended Purpose ................................................................................. 6

2.3 Reasonably Foreseeable Misuse ........................................................ 6

2.4 Residual Risks ...................................................................................... 7

2.5 Description of the Safety Devices ...................................................... 8

Position of the Emergency Stop Devices .......................................................... 8

Protection of the Eyes against Laser Radiation ................................................ 9

Protection of the Skin against Laser Radiation ................................................. 9

Welding Fumes ............................................................................................... 10

2.6 Labels and Signs on the Welding Laser System ............................. 11

2.7 Operating Personnel / User Groups ................................................. 11

2.8 Safety Instructions for the Operating Personnel ............................ 12

2.9 Safety Instructions for the Maintenance Personnel ........................ 13

Preparation for the Maintenance Work ........................................................... 13

Carrying Out the Maintenance Work ............................................................... 13

2.10 Information about Special Types of Hazard .................................... 13

Electrical .......................................................................................................... 13

Raw Material, Solvents, Oils, Greases and other Chemical Substances ........ 16

Noise ............................................................................................................... 17

3 Product Description .................................................... 18

3.1 Function .............................................................................................. 18

3.2 Construction of the Welding laser system ....................................... 19

3.3 The Work Chamber ............................................................................ 20

3.4 Electrical ............................................................................................. 20

3.5 Shielding Gas ..................................................................................... 21

Index

IM Machine Name Rev.: END II

3.6 Cooling Water ..................................................................................... 21

3.7 Technical Data .................................................................................... 21

4 Transport and Installation .......................................... 22

4.1 Transport ............................................................................................. 22

4.2 Installation .......................................................................................... 23

Safety Devices ................................................................................................ 23

5 Operation ...................................................................... 24

5.1 Safe Operation .................................................................................... 24

Instructions for the Operating Company ......................................................... 25

Electro-technical Instructions .......................................................................... 25

5.2 Operating Controls ............................................................................. 26

User Interface .................................................................................................. 26

Operating Side ................................................................................................ 27

Emergency Stop Button and Key Switch ........................................................ 28

Foot Switch ..................................................................................................... 29

Cross-hair Rotary Control ............................................................................... 29

5.3 Commissioning, Switching On and Off ............................................ 30

Commissioning ................................................................................................ 30

Shielding Gas Connection ............................................................................... 32

Switching On ................................................................................................... 32

Switching Off ................................................................................................... 33

5.4 Operation ............................................................................................ 33

Cross-hair Adjustment ..................................................................................... 34

5.5 Faults ................................................................................................... 35

6 Maintenance ................................................................. 36

6.1 Care / Cleaning ................................................................................... 37

6.2 Maintenance ........................................................................................ 38

General Maintenance Instructions .................................................................. 38

Preparation of the Repair and Maintenance Work .......................................... 38

Checking of the Safety Devices ...................................................................... 38

Safe Maintenance of the Electrical Devices .................................................... 39

6.3 Maintenance Plan ............................................................................... 40

Maintenance of Outsourced Components ....................................................... 41

Water Changes ............................................................................................... 41

Index

IM Machine Name Rev.: END III

Filter Fleece Changes ..................................................................................... 41

6.4 Repairs ................................................................................................ 42

Changing the Safety Glass of the Focusing Lens ........................................... 43

Clean the protective glass of the focusing lens ............................................... 43

Laser Lamp Changes ...................................................................................... 44

7 Disposal ....................................................................... 51

7.1 Environmental Protection .................................................................. 51

7.2 Oil and Oil-containing Waste, Lubricating Greases ........................ 51

7.3 Plastics ................................................................................................ 51

7.4 Metals .................................................................................................. 51

7.5 Electrical and Electronic Scrap ......................................................... 52

7.6 Scrap ................................................................................................... 52

8 Annexes ....................................................................... 53

8.1 Declaration of Conformity ................................................................. 54

8.2 General Assembly Drawing ............................................................... 55

8.3 Parts List with Spare Part Recommendations / Identification ....... 56

8.4 Protocols and Measurement Results ............................................... 57

8.5 Circuit Diagram + Parts List .............................................................. 58

8.6 Software .............................................................................................. 59

8.7 Component Supplier Documentation ............................................... 60

Foreword

IM Machine Name Rev.: END 4

1 Foreword

1.1 Introduction

This instruction manual contains important information for the safe, proper and

economic operation of the welding laser system. Its observance prevents hazards,

reduces repair costs and downtime and increases the reliability and service life of the

welding laser system.

The instruction manual must always be available and be read and applied by every

person who carries out work on or with the welding laser system.

To this belong, amongst other things

– the operating and elimination of faults during operation,

– the maintenance (care, servicing and repair),

– the transportation.

1.2 Copyright and Property Rights

● Make this instruction manual accessible only to authorized personnel.

This instruction manual is protected by copyright law.

The disclosure or duplication of documents, also in the form of extracts, as well as the

exploitation and communication of its contents are not permitted insofar as not

expressly permitted by us in writing.

Infringements shall be punishable and shall commit the offender to pay damages. All

rights for the exercising of industrial property rights are reserved by Siro Lasertec.

1.3 Information for the Operating Company

This instruction manual is an essential component of the welding laser system.

● Ensure that all people who work with or on the welding laser system observe this

instruction manual.

● Spare parts must comply with the technical requirements specified by Siro

Lasertec. This is always guaranteed with the use of original spare parts.

Safety

IM Machine Name Rev.: END 5

2 Safety

The welding laser system has been designed and built in accordance with the state-of-

the-art of technology and the recognized safety-related regulations.

When operating the welding laser systemFehler! Verweisquelle konnte nicht g

efunden werden., hazards for the personnel who work on or with the welding laser

system and / or impairment of the welding laser system as well as other material

assets can occur when they:

– are operated by untrained or uninstructed personnel,

– are not used in accordance with the intended purpose and / or

– are improperly maintained.

2.1 Information about Signs and Symbols

In this instruction manual, the following designations and / or signs and symbols are

used for giving particularly important information:

● Work and / or operating steps are identified with bullet points. Carry out the steps

in the given sequence.

– Lists are identified with indents.

DANGER

This is a warning of an imminent threat of a dangerous situation

with the inevitable consequence of most serious injuries or death if

the specific instruction is not followed exactly.

WARNING

This warns of a dangerous situation that could lead to serious

injuries to people or to death if the specific instruction is not

followed exactly.

CAUTION

This is a warning of a potentially dangerous situation possibly

resulting in moderate or minor injuries if the specific instruction is

not followed exactly.

`

Safety

IM Machine Name Rev.: END 6

INFORMATION

This is a warning of a potentially dangerous situation possibly

resulting in material damage if the specific instruction is not

followed exactly.

This is an indication of useful information about safe and proper

handling.

● Observe the warning signs, operating labels or component markings attached to

the welding laser system. They must not be removed.

● Always maintain these signs and symbols in a fully legible condition.

2.2 Intended Purpose

The welding laser system is working equipment for the welding of metal joints by

means of pulsed laser beams

● Observe the specifications in Chapter 3, Section Technical Data.

Always comply unequivocally with these specifications.

Also belonging to use for the intended purpose is the compliance with the instructions

– for safety,

– for operation and control,

– for maintenance and service,

specified in this instruction manual.

Other uses or use over and above this shall be considered as use not for the

intended purpose. The operating company shall bear the sole liability for any

damages resulting from this. This shall also likewise apply to any unauthorized

modifications made to the welding laser system .

2.3 Reasonably Foreseeable Misuse

The following stated example processing procedures shall be considered as use not

for the intended purpose:

– The use and / or processing of explosive substances.

– The processing of materials other than those stated for the intended purpose.

– The operation of the welding laser system in potentially explosive atmospheres.

– The operation of the welding laser system without fully fitted safety devices.

– Use by private users or users without professional instruction and training.

– The storage of explosive or highly flammable materials in the vicinity of the welding

laser system.

Safety

IM Machine Name Rev.: END 7

– The installation of the welding laser system in unprotected, weather-exposed

rooms or halls.

2.4 Residual Risks

Even with the compliance with all safety regulations, the residual risks described

below remain during the operation of the welding laser system.

● As the employer / operating company, ensure that all personnel that work on or

with the welding laser system are aware of the residual risks.

● Follow the instructions that prevent the residual risks from leading to accidents or

injury or damage.

During setup and preparation work, it may be necessary to disassemble in-house

fitted safety devices. Various residual risks and potential dangers which every

operator must make him- or herself aware of arise through this:

DANGER

Danger to life due to electric shock

Electric shock can result in fatal injuries.

● Before all repair, setup and maintenance work, disconnect the

welding laser system from the power supply.

● Secure the welding laser system against unintentional

switching back on.

● In addition, activate an Emergency Stop button.

Safety

IM Machine Name Rev.: END 8

WARNING

Danger from optical radiation

Class 4 laser light is very dangerous for the eyes and dangerous

for the skin. Even diffusely scattered radiation can be dangerous.

The laser beam can cause fire and explosion hazards. The closed

slats in front of the work chamber downgrade the laser radiation to

Class 1.

● Avoid exposing the eyes or skin to direct or scattered radiation.

● Before starting up the welding laser system, check that all

safety devices are installed and function correctly.

● Never operate the laser with open or damaged slats in front of

the work chamber.

2.5 Description of the Safety Devices

Position of the Emergency Stop Devices

Illustration 1 Emergency Stop

An Emergency Stop button (arrow) is present on the left-hand side next to the

microscope.

● Trigger the Emergency Stop devices once per year.

● Check the function – all drives must come to a safe stop

● Record this process.

Safety

IM Machine Name Rev.: END 9

Protection of the Eyes against Laser Radiation

Devices on the equipment that guarantee complete eye protection of the operator and

other people in the vicinity of the welding laser system:

Safety Beam Shutter

The safety beam shutter prevents the generation of laser pulses or the unwanted

emission of laser radiation from the laser beam source and is closed

– When there is no control voltage applied to it,

– When it delivers no or an incorrect status message to the control system.

Release of the Laser Pulse

The release of the laser pulse takes place only when

– the setting of the laser nominal values has been completed

– the recharging of the energy reservoir has been completed

– the foot switch has been pressed down.

Other Devices for Eye Protection:

– a large observation window in laser protection polymer for the safe direct

observation of the welding operation.

– automatic UV and glare protection in the beam path of the stereo microscope is

activated during the welding.

– the entire laser beam path is optically sealed towards the outside.

The device fulfils all the conditions for complete eye protection.

Thereby, the single condition for laser Class I is satisfied.

Protection of the Skin against Laser Radiation

The protection of the skin against laser radiation cannot be process-relatedly

completely ensured as hands need to be put in the danger area.

The device is intended for use in dental laboratories, in goldsmiths‘ workshops and

many other workshops and laboratories.

The operating procedure cannot be automated as every workpiece is an individual

item. Manual work is necessary as a large number of the most diverse materials with

different dimensions, outward forms, surface qualities, fit tolerances, electrical,

mechanical and thermal properties must be joined with each other in various

combinations or must be surface-treated.

Laser radiation protective gloves are generally speaking very cumbersome and only

suitable for rough welding work. The same applies to the use of holders, tweezers,

etc. Therefore, this device must be classed as work equipment for manual work from

which the risk of minor injuries can occur.

Due to the equipment design, the danger area is restricted to the hands of the

operator only. Through exposure to laser radiation, localized burn injuries to the skin

tissue can occur in the event of incorrect operation.

Safety

IM Machine Name Rev.: END 10

Direct laser radiation striking your hands can be avoided through:

● never holding your hands in the direct laser beam.

● looking through the stereo microscope and positioning the workpiece so that the

welding point is in sharp focus and lies in the cross-hairs

● as far as possible, ensuring that your hands cannot be seen in the viewing area of

the stereo microscope.

● keeping your hands still whilst triggering the laser pulse using the foot switch.

● repeatedly looking through the stereo microscope and checking your hands and

the position of the workpiece.

Not only the direct laser radiation is dangerous for the skin but also radiation reflected

and scattered by the workpiece or a tool.

Scattered laser radiation striking your hands can be avoided through:

Especially objects with reflective, bright surfaces can scatter or divert the laser

radiation so that even at a great distance from the welding point there is still the risk

of a certain local burn injury.

● Where possible, not wearing jewellery on the arms or fingers when working with

laser radiation.

● Wearing thin cotton or leather gloves. Thus, you not only protect your skin against

laser radiation but also against burn injuries from hot workpieces. This is

especially necessary with materials such as silver or copper with good thermal

conductivity.

Welding Fumes

Fumes harmful to health can occur during welding work. Welding fumes are a

hazardous substance.

The exact composition and the extent of the danger are dependent on the materials

involved in the welding. For the maintenance of the purity of the respiratory air, the

employers' liability insurance association, therefore, requires that appropriate welding

fume extraction is used during welding work with the laser.

The integrated extraction system of the welding laser system is only approved for the

extraction of laser welding fumes.

It must not be used for other purposes such as, for example, the extraction of

– highly flammable or explosive gases

– liquids of any kind

– organic substances.

The exhaust openings must always be kept clear. The welding fume extraction

system must only be operated with a non-flammable filter fleece.

Safety

IM Machine Name Rev.: END 11

2.6 Labels and Signs on the Welding Laser System

Sign

Meaning

Attachment Point

Rating plate with the information:

– Name and full address of the manufacturer

– Model:

– Type / Designation:

– Machine No.:

– Year of Manufacture:

– Technical Data (for example, electrics,

weight)

– CE Mark

Clearly legible on the welding laser

system

Warning of dangerous electrical

voltage

Signs on all terminal boxes, switch

cabinets and control cabinets for

low voltage.

Protective earth connection

Next to the earthing screws

Warning of Class 1 laser radiation

On the outside of the welding laser

system

Warning of Class 4 laser radiation

On the laser unit.

2.7 Operating Personnel / User Groups

Personnel that handle the welding laser system must satisfy the following

requirements:

Personnel

Activities

Necessary Qualifications

Hauliers

Transport from site

to site

Qualification as a transport

specialist for machines

Transporters

Transport within the

works

Trained for the transportation with

lifting equipment (crane, forklift,

AGV, etc.)

Electrical Technician

Electrical installation

Skilled electrician

Commissioning

Engineer

Initial

commissioning,

recommissioning

Qualified personnel with under-

standing of process-related systems

Safety

IM Machine Name Rev.: END 12

Personnel

Activities

Necessary Qualifications

Setter

Machine setting

Qualified personnel with under-

standing of process-related systems

Operator

Operation

Semi-skilled assistant

Electrical

Maintenance

Personnel

On electrical parts:

Fault finding

Service

Maintenance

Decommissioning

Dismantling

Skilled Electrician

Disposer

Disposal of the

machine

Waste disposal expert

2.8 Safety Instructions for the Operating Personnel

Every person assigned to work on or with the welding laser system must have fully

read and understood this instruction manual.

● Start the welding laser system only with it in a technically faultless condition as

well as only for its intended purpose, safety and risk aware and in compliance

with this instruction manual.

No liability whatsoever shall be assumed for injury, damage and / or accidents that

arise from the non-observance of this instruction manual.

● Immediately rectify all faults.

● Always keep the instruction manual readily available at the welding laser system.

● Do not wear jewellery.

● Only reliable, trained and qualified personnel who have reached the statutory

minimum permissible age in accordance with the Young Persons Employment Act

may work on or with the welding laser system.

● Personnel to be trained, taught, instructed or who are undergoing general training

may only work whilst under the constant supervision of an experienced person.

If safety-related changes occur on the welding laser system:

● Immediately shutdown the welding laser system.

● Secure the welding laser system.

● Report the event to the responsible position / person.

Safety

IM Machine Name Rev.: END 13

2.9 Safety Instructions for the Maintenance Personnel

● Observe the time limits for recurring checks / inspections prescribed or specified in

the instruction manual.

Preparation for the Maintenance Work

Appropriate workshop equipment is required for the carrying out of the maintenance

work.

● Only carry out set up, maintenance and repair work as well as fault finding with

the welding laser system disconnected.

● Insofar as is necessary, secure the maintenance area with a red and white

safety chain and a warning sign.

● Before starting the service / repair / care work, clean contamination or

maintenance products off the connections and screw fittings in particular.

Carrying Out the Maintenance Work

● Never stand under suspended loads.

● During replacement, carefully attach and secure individual components and larger

assemblies to the lifting equipment so that the hazard arising from them is

minimized. Use only suitable and technically perfect lifting equipment and lifting

tackle with adequate load bearing capacity.

● During the maintenance and repair work, always tighten loosened screw

connections in accordance with the specifications and using a torque wrench.

● Ensure the safe and environmentally friendly disposal of operating and auxiliary

materials and replacement parts as described in Chapter 0.

2.10 Information about Special Types of Hazard

Electrical

Work on the electrical equipment of the welding laser system must only be carried out

by skilled electricians or by instructed personnel under the supervision of a skilled

electrician in accordance with the electrical engineering regulations.

● Before opening the control cabinet, switch off the welding laser system at the key

switch and remove the key.

● Switch electrical components on which inspection, maintenance and / or repair

work is to be carried out to zero potential.

● Use only original fuses with the specified current rating.

● Secure the operating equipment used for the switching off against unintentional or

automatic switching back on (lock away the fuse, block the circuit breaker, etc.).

● With switched off electrical components, first check the freedom from voltage then

isolate neighbouring live components.

Safety

IM Machine Name Rev.: END 14

● During repairs, ensure that structural features are not changed to the detriment of

safety (for example, do not reduce creep and air gaps and clearances through

insulation).

When working on live components (only in exceptional situations) it is necessary to:

● Call in an additional person to activate the Emergency Stop button or the mains

isolating device in an emergency.

● Use only electrically insulated tools.

The proper earthing of the electrical system must be ensured by means of protected

conductor systems. Permanent installation is necessary with a leakage current to

earth (PE) >3.5 mA.

● Regularly check cables for damage.

● Immediately replace defective cables.

For further information, see also Chapter 6.2.4 Safe Maintenance of the Electrical

Devices.

Due to the special properties of laser radiation and the biological effects resulting

from it, special protective and precautionary measures are necessary during the use

of laser radiation.

Lasers are classified in accordance with their hazard potential. In each individual

case, the necessary protective measures arise from this.

Of special importance are protective measures for the protection of the operator in the

use of powerful lasers in engineering and medicine.

Laser Class

Definition

Class 1

The accessible laser radiation is not dangerous under reasonably

foreseeable conditions.

1. Lasers that are so encapsulated that the escape of radiation is

completely prevented.

2. Lasers with very low power (40 µW for blue light). Even with

longer exposure, these lasers cause no damage to the eyes

even when optical instruments (magnifying glasses, lenses,

telescopes, etc.) are held in the beam path.

Class 1M

The accessible laser radiation lies in the wavelength range from

302.5 nm to 4 000 nm. The accessible laser beam is not dangerous

for the eyes as long as the cross section is not reduced by optical

instruments (magnifying glasses, lenses, telescopes, etc.)!

The laser must not be harmful during the exposure of the naked

eye. Eye damage can occur if optical instruments are present during

the exposure.

Safety

IM Machine Name Rev.: END 15

Laser Class

Definition

Class 2

The accessible laser radiation lies in the visible spectral range (400

nm to 700 nm). It is also not dangerous for the eyes at a short

exposure time (up to 0.25 s). Additional radiation components

outside the wavelength range of 400 - 700 nm comply with the

conditions for Class 1.

The power of the lasers of Class 2 is limited to 1 mW. The eye is

adequately protected against damage through incidental short-term

looking into the radiation by the eyelid closure reflex that occurs

within 0.25 s due to the dazzling effect of the radiation. This also

applies if optical instruments are present in the beam path.

● Avoid intentional, sustained looking into the beam path.

If the laser also emits radiation of other wavelengths, these must be

completely harmless to the eyes.

Class 2M

The accessible laser radiation lies in the visible spectral range of

400 nm to 700 nm. It is not dangerous for the eyes at a short

exposure time (up to 0.25 s), as long as the cross section is not

reduced by optical instruments (magnifying glasses, lenses,

telescopes, etc.). Additional radiation components outside the

wavelength range of 400 - 700 nm comply with the conditions for

Class 1M.

Lasers with lower power up to 1 mW. They are not harmful to the

naked eye due to the eyelid closure reflex. Eye damage can occur if

an optical instrument is present during the exposure.

Class 3R

The accessible laser radiation lies in the wavelength range from

302.5 nm to 106 nm and is dangerorous for the eyes. The power

respectively the energy is a maximum of five times the limit value of

the permissible radiation of Class 2 in the wavelength range from

400 nm to 700 nm.

The lasers of this Class are in principle dangerous for the eyes. The

level of danger is limited in that the power in the visible range may

not exceed 5 mW and outside the visible range must not exceed

five times the power of Class 1 lasers.

Class 3B

The accessible laser radiation is dangerous for the eyes and in

specific cases also for the skin.

The radiation of Class 3B lasers (medium power) is dangerous for

the eyes, not only with direct exposure but also with exposure to

reflected radiation. In the upper power range, these lasers can also

damage the skin. The power is limited to 500 mW.

Safety

IM Machine Name Rev.: END 16

Laser Class

Definition

Class 4

The accessible laser radiation is very dangerous for the eyes and

dangerous for the skin. Even diffusely scattered radiation can be

dangerous. The laser beam can cause fire and explosion hazards.

Lasers of Class 4 are high power lasers. Their radiation is so

intense that damage is to be expected with any kind of exposure of

the eyes or the skin. In addition, there is the risk of fire or explosion

with lasers of this Class.

The operating company of the laser facility is responsible for compliance with the

protective measures.

● Provide suitable fire-extinguishing facilities.

● Ensure that the laser devices are assigned to a laser Class and are labelled

accordingly.

● Report the operation of Class 3R, 3B and 4 laser facilities to the responsible

market surveillance authorities.

● When operating such lasers, define and mark out the laser area.

● As the operating company of Class 3R 3B and 4 laser facilities, appoint a qualified

person as Laser Protection Officer.

● Instruct the personnel that operate Class 1M, 2, 2M, 3R, 3B or 4 laser facilities, or

those that can be present in the laser area of Class 1M, 2, 2M, 3R, 3B or 4 lasers,

in the effects of the laser radiation and the necessary protective measures.

● Provide suitable PSR laser glasses, protective clothing or protective gloves for the

operation of Class 3R, 3B and 4 laser facilities.

The operating company is also responsible for the compliance with the special safety

requirements for the operation of the different laser types.

Raw Material, Solvents, Oils, Greases and other Chemical Substances

● When handling raw material, solvents, oils, greases and other chemical

substances, observe the applicable regulations and safety data sheets of the

manufacturers of these substances with respect to storage, handling, use and

disposal and comply with them.

● All work with corrosive cleaning agents and substances can cause serious

chemical burns and serious eye injuries!

● Therefore, always wear personal protective equipment during all work with

chemical substances:

– Safety glasses,

– Safety gloves,

– Protective clothing resistant to the substances,

– Safety shoes.

Safety

IM Machine Name Rev.: END 17

● In the event of eye or skin contact, immediately flush the affected areas with plenty

of water. Suitable facilities (eye wash bottles, wash basin, shower) must be

available in the workplace vicinity!

● After washing, apply skin care to the cleaning agent and disinfectant-affected skin.

Skin damage can be avoided through the preventive application of skin protection

products and suitable skin care.

● Choose the care products to be applied according to the exposure to the harmful

substances and the individual condition of the skin. A fat-containing care product

should mainly be used.

● Do not eat, drink or smoke and never store foodstuffs in rooms in which there are

chemicals!

Noise

In the normal operation of the welding laser system the equivalent continuous A-

weighted sound pressure level at the operator workstation is below 80 dB(A).

● As the operating company, provide the operating personnel with the appropriate

protective equipment when, due to the local conditions, there is a higher sound

pressure level at the operating site of the welding laser system.

Product Description

IM Machine Name Rev.: END 18

3 Product Description

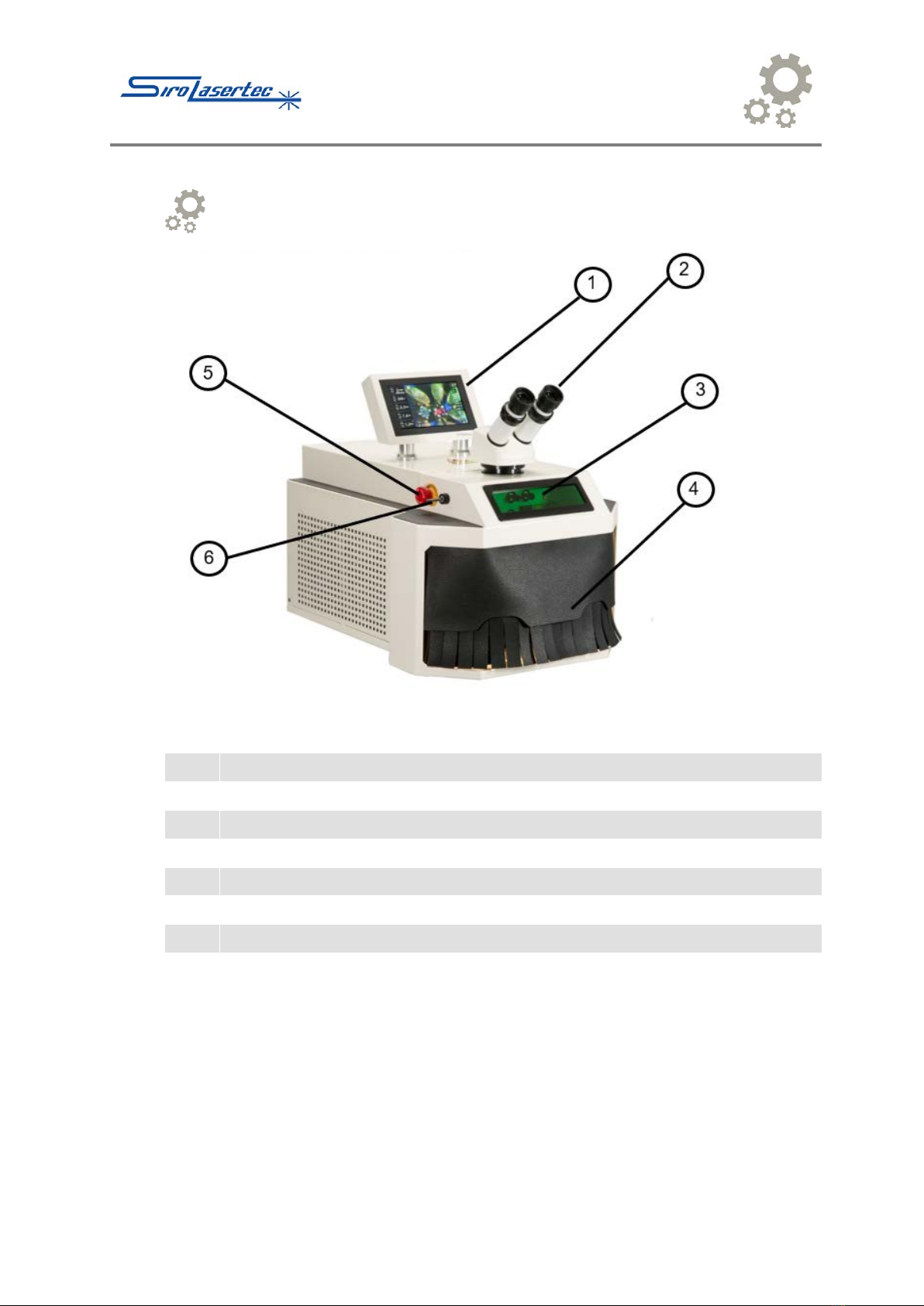

Illustration 2 Welding laser system SL 10

Item

Designation

1

Touchscreen operating panel

2

Microscope

3

Observation window

4

Work chamber with protective slats

5

Emergency Stop button

6

Key switch

3.1 Function

The SL 10 welding laser system is a very compact tabletop device for manual use. It

delivers short, high-energy invisible laser pulses for the welding of metal joints.

The workpieces are placed in the integrated laser-safe work chamber for processing.

The workpiece is positioned under the stereo microscope by hand and held for

welding. If both hands are in the work chamber, no laser radiation can escape to the

outside.

Product Description

IM Machine Name Rev.: END 19

3.2 Construction of the Welding laser system

Illustration 3 Construction Block Diagram - In the picture, left to right, top to bottom: Power supply,

Monitoring and control electronics, Protection and safety, Flashbulb, Laser, Beam guidance, Cooling

circuit with storage vessel and circulation pump, Workpiece holder and positioning, Process gas control,

Exhaust gas purification, Housing.

All functions for the operation of the SL 10 welding laser system are integrated in the

housing.

The core of the welding laser system is the solid-state laser. It receives its energy

from a flashbulb that is operated by a power supply unit with high electrical efficiency.

The laser flash is guided through the observation microscope on to the workpiece via

a carefully coordinated beam path.

In the closed cooling water circuit, the cooling water is pumped through the pump

chamber of the laser and cools down the flashbulb and the laser rod. The heat

generated is dissipated into the ambient air via a heat exchanger and a fan.

The shielding gas, for example, argon, required for the protection of the weld seam is

externally supplied via a connection fitted on the back of the device. The shielding

gas can be routed directly to the weld point via a rigid as well as a flexible supply line

in the work chamber. The gas flow is controlled via the foot switch.

The welding fumes generated during the welding are extracted out of the welding

chamber.

Table of contents