Entron MTR50 User manual

User Manual

MTR50

1.03

February 23

Document no. 230224-1

Firmware Version

2 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

DISCLAIMER

Information contained in this document is believed to be accurate and reliable. The manufacturer does not provide any

representations or warranties, expressed or implied, as to the accuracy or completeness of such information and shall

have no liability for the consequences of use of such information. The manufacturer reserves the right to make changes

to information published in this document, including without limitation specifications and product descriptions, at any

time and without notice.

BF ENTRON accepts no liability for any injury, loss or damage caused by improper installation, use or application of its

products. The user shall only use the product for purposes that are proper and in accordance with all applicable laws,

rules, and regulations.

Copyright © 2022 by [BF ENTRON, Ltd.]

All rights reserved. No part of this publication may be reproduced, distributed, or transmitted in any form or by any

means, including photocopying, recording, or other electronic or mechanical methods, without the prior written

permission of the publisher.

TRADEMARKS

BR ENTRON and/or its affiliates’ trademarks may not be used in connection with any product or service that is not BF

ENTRON’s, in any manner this is likely to cause confusion among customers or in any manner that disparages or

discredits BF ENTRON. All other trademarks not owned by BF ENTRON are the property of their respective owners, who

may or may not be affiliated with, connected to, or sponsored by BF ENTRON.

3 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

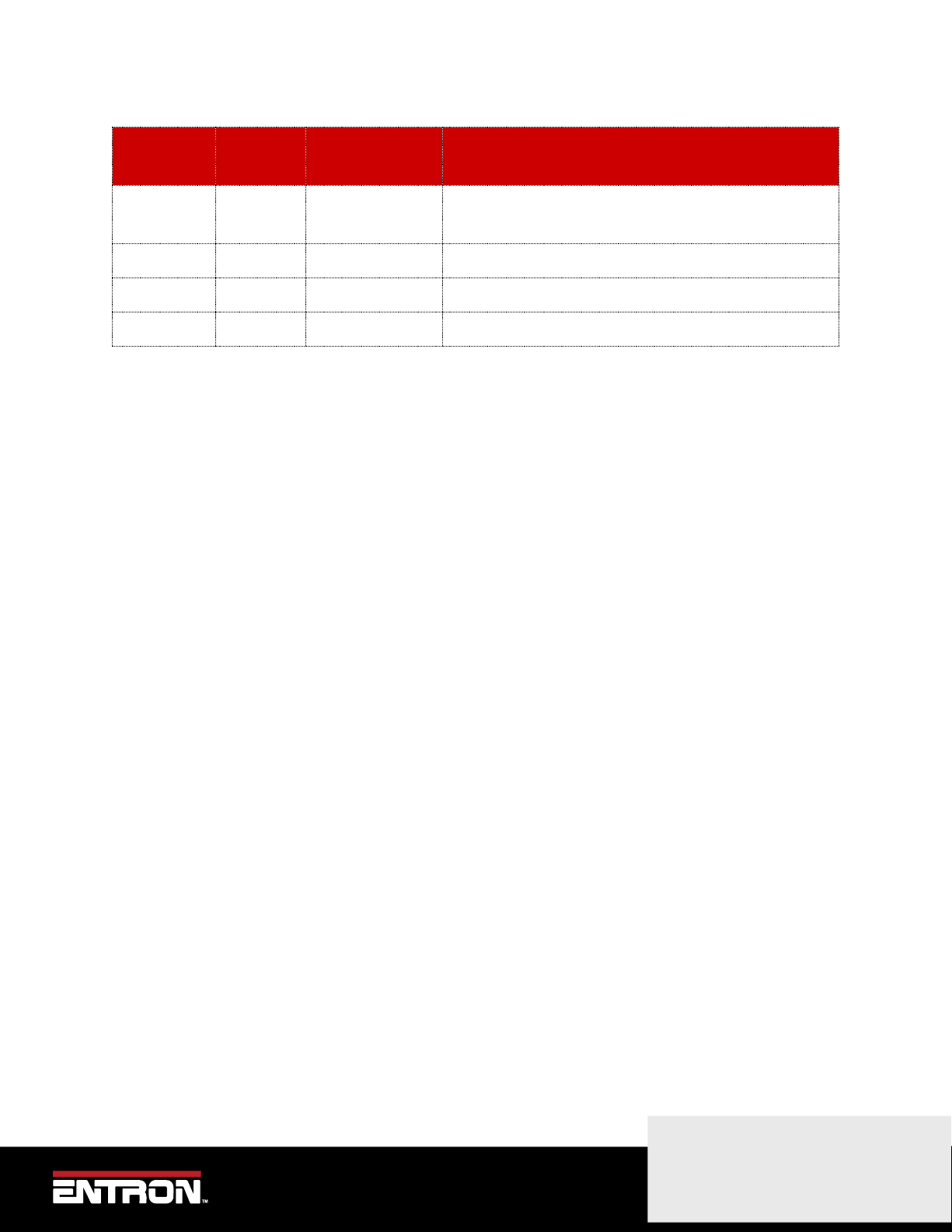

Document Revisions

Languages

This document is only published in the English language.

Date

Document

Number

Approved By

Document Changes

24/02/2023

230224-1

Thomas

Warrington

Layout Update, Electrical Drawings added, new

pictures of product

4 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

Table of Contents

1Introduction ..................................................................................................................................................... 5

2Specifications ................................................................................................................................................... 6

3Connections...................................................................................................................................................... 7

3.1 Power Connection Location ....................................................................................................................... 8

3.2 Water Connection Location ....................................................................................................................... 9

4Configuring the timer..................................................................................................................................... 10

4.1 Configuration Parameters ....................................................................................................................... 10

4.1.1 Config Type .........................................................................................................................................................10

4.1.2 Input Allocations.................................................................................................................................................11

4.1.3 Output Allocations..............................................................................................................................................11

4.2 Retract ..................................................................................................................................................... 12

4.2.1 Frequency ...........................................................................................................................................................12

4.2.2 Heat Range .........................................................................................................................................................12

4.2.3 Interlock..............................................................................................................................................................12

5Welding with the MTR50 ............................................................................................................................... 14

5.1 Selecting a Weld Program ....................................................................................................................... 14

5.1.1 Using timer keypad.............................................................................................................................................14

5.2 Starting a Weld........................................................................................................................................ 15

5.3 2nd stage input........................................................................................................................................ 15

6Programming the weld programmes............................................................................................................. 16

6.1 Program parameters ............................................................................................................................... 17

7End of Sequence Output ................................................................................................................................ 18

8Counter........................................................................................................................................................... 19

8.1 Counter Parameters................................................................................................................................. 19

9Electrical Drawings......................................................................................................................................... 20

9.1 3U3742..................................................................................................................................................... 20

9.2 3U3744..................................................................................................................................................... 21

10 Technical Support........................................................................................................................................... 22

10.1.1 Internet...............................................................................................................................................................22

10.1.2 Documentation Request.....................................................................................................................................22

10.1.3 Service and Technical Support............................................................................................................................22

Introduction

5 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

1Introduction

The MTR50 welding control offers the reliability that ensues from simplicity. The MTR50 is a compact, robust unit

providing basic control for resistance welding. The membrane front panel provides a neat, water-resistant finish and

incorporates four push buttons and a display for programming purposes. Programming is quick and simple, as is

operation of the control.

The principle features of the MTR50 are:

•50 Hz or 60 Hz operation

•2 inputs and 2 outputs plus weld on/off

•8 programmes

•Single or Repeat spot operation

•Two weld intervals and pulsation

•External program select option

•2-stage initiation option

•Retract/High lift option

•Counter option

Specifications

6 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

2Specifications

Mains voltage: 240V (Part Number 10-60-10-18-00)

380V,415V,440V,480V,500V*(Range determined at manufacture) (Part Number 10-60-10-18-01)

Mains frequency: 50 or 60 Hz

Duty: 20% Max.

Load: 50kVA Max.

Number of digital inputs: 2

Input requirement: 24 V DC, < 10mA

Number of digital outputs: 2

Digital output rating: 24 V DC, < 500mA

Connections

7 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

3Connections

Connections

8 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

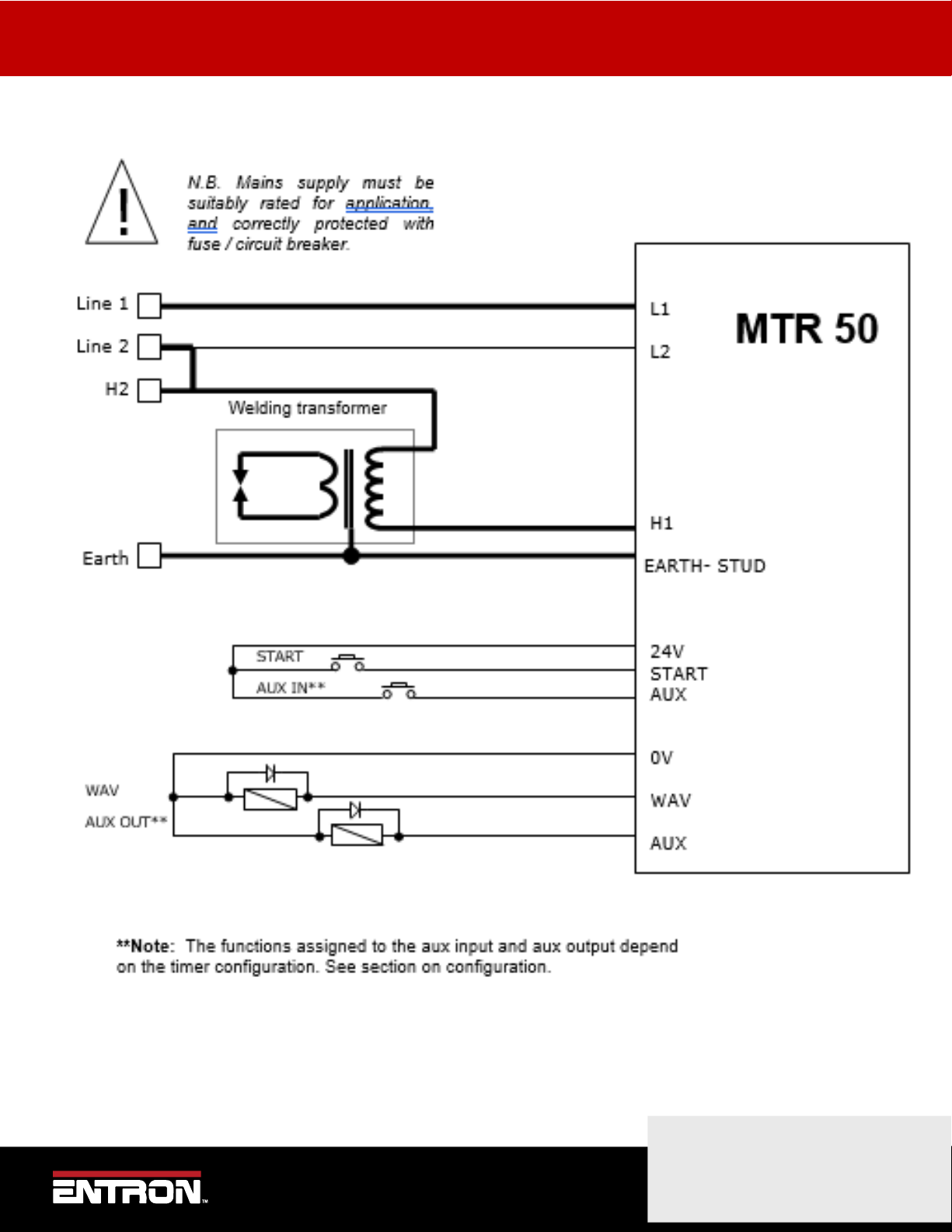

3.1 Power Connection Location

The connections for the wiring of the timer are shown graphically below.

Particular care should be taken to ensure that the wiring sizes are correct for your application and that all local

electrical regulations are adhered to.

NB. The Earth connection connects directly to the main earthing stud.

Earth

L1

L2

H2

H1

User

Connections

Connections

9 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

3.2 Water Connection Location

CAUTION! The MTR50 must be connected to a suitable water supply before use.

Ensure a minimum flow rate of 4.5 litres per minute, at a maximum of 40 degrees C at the inlet.

Use 3/8 inch ID pipe, secured to the hose barbs with suitable jubilee clips. Test for water leakage before

applying electrical power to the unit.

Gland for Control Cable

Gland plate for main electrical connection.

Remove this plate and fit suitable cable glands.

Configuring the timer

10 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

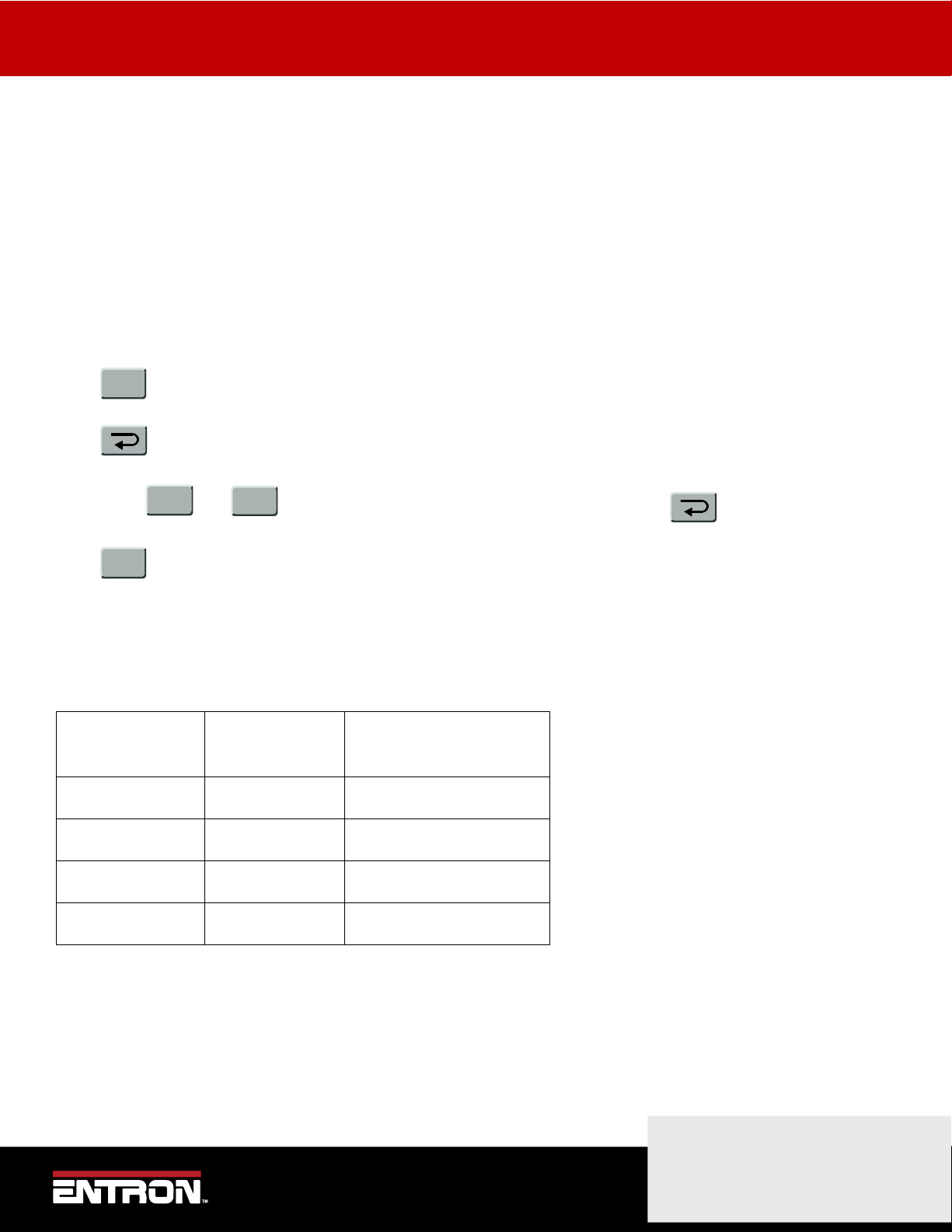

4Configuring the timer

The MTR50 has various configurations to tailor it for specific applications.

•Press until it the display reads MTR50 Vx.xx

•Hold down and then press . The display will read CONFIGURE.

•Press The display will read, for example, CONFIG TYPE 00 This is the first item in the list of

configuration parameters.

a) If you wish to change the parameter setting (in this case 00), use the or keys. Press to enter

the new value. If you do not wish to change this parameter move directly to b). Note that the new value is not

stored until the key is pressed.

b) Press to move to the next item in the configuration file.

•Repeat steps a) and b) until the configuration is complete, then press .

4.1 Configuration Parameters

The items in the list of configuration parameters is shown below.

Parameter

Options

Config type

0, 1, 2, 3

Retract

None/Simple

High Lift +

High Lift -

Frequency

50 Hz or 60 Hz

Interlock

Full / Delay / Off

Heat range

Low or High

4.1.1 Config Type

The MTR50 has 4 modes of operation, numbered as “Types” 0, 1, 2 and 3. Each Type offers different features

and may use the aux input and aux output connections in different ways. The following table gives a brief

description of what each type does.

F

F

+

-

F

Configuring the timer

11 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

The table should be used in conjunction with the tables of input and output allocations which show how the

inputs and outputs are used for each configuration type.

Config Type

MTR50 Operation

0

Spot welding with an input for controlling the program

number.

1

4.1.1.1 Spot welding with an external 2nd stage start input.

2

Spot welding with an input and output for controlling the

“open” and “working” positions of the welding gun (retract).

3

Spot welding with an input and output for controlling a weld

counter.

4.1.2 Input Allocations

Config Type

Start input

Aux input

0

Start

Program select

1

Start

2nd stage start

2

Start

Retract

3

Start

Counter reset

4.1.3 Output Allocations

Config Type

WAV output

Aux output

0

Weld air valve

End of sequence

1

Weld air valve

End of sequence

2

Weld air valve

Retract air valve

3

Weld air valve

Counter output

Configuring the timer

12 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

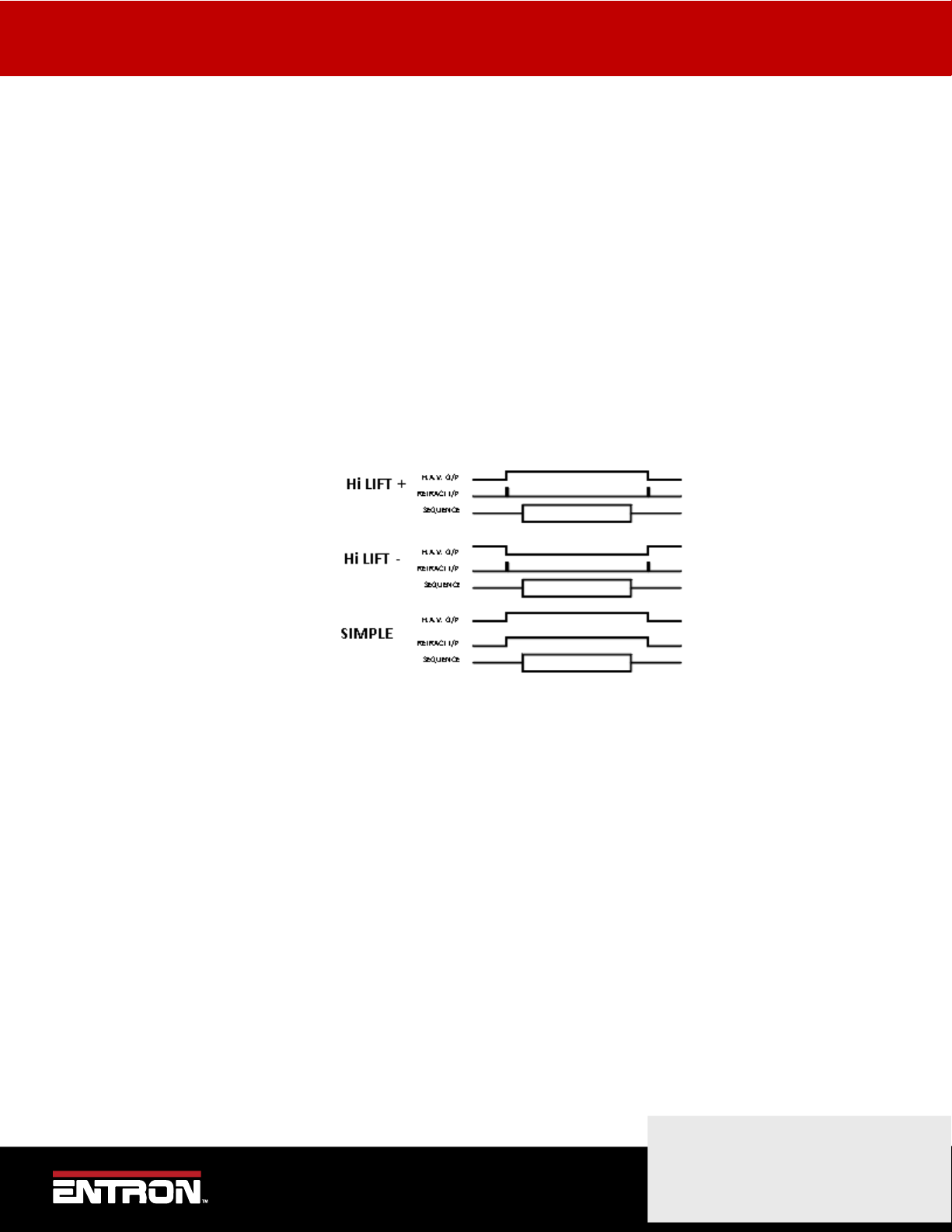

4.2 Retract

Configuration type 2 provides a retract facility. This feature is used when a welding gun has two “open” states: a

wide-open state for positioning the gun around a component, and a working state.

There are three modes of Retract operation:

Simple Retract The retract output directly mimics the retract input. The retract output must be off for

welding to proceed. If the retract output is on, the display will read “Retract not ready”.

Hi Lift + With this mode of retract, an impulse on the retract input changes the state of the retract

output. In this case the retract output must be on for welding to take place. If the retract

output is off, the display will read, “Retract not ready”.

Hi Lift - With this mode of retract, an impulse on the retract input changes the state of the retract

output. In this case the retract output must be off for welding to take place. If the retract

output is on, the display will read, “Retract not ready”.

4.2.1 Frequency

Select frequency of mains supply.

4.2.2 Heat Range

Select heat range High for hotter heat settings. The use of this setting may result in “dead angle” at higher heats.

(After a certain point, increasing the heat no longer increases the current).

Select heat range low for cooler heat settings. This should be used if low heat levels in the “High” setting,

produce too much current.

4.2.3 Interlock

Select Interlock OFF for machines with no weld air valve, such as pedal spot welders and poke welders. In this

mode, the weld sequence is terminated if the Start signal is removed before the sequence has completed.

Select Interlock DELAY for machines where the electrodes are controlled by the MTR50 weld air valve output. In

this mode, when a weld sequence has progressed beyond the Squeeze time, the sequence continues to

completion, regardless of the state of the Start signal.

Configuring the timer

13 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

Select Interlock FULL for machines operating at very high speeds or in automation systems. In this mode, when a

weld sequence has initiated, the sequence continues to completion, regardless of the state of the Start signal.

Use with caution! This mode is not available for config type 1 and will default to interlock DELAY.

WARNING! Only use the interlock FULL setting if you are absolutely sure that there is no possibility of an

operator becoming trapped by the moving parts of the welding equipment.

Welding with the MTR50

14 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

5Welding with the MTR50

To weld, the MTR50 needs to have been configured for your specific application. (See section on “Configuration”).

Having been configured, the timer must be programmed with the weld parameters for the job in hand. Eight sets of

weld parameters can be held in the MT50. Each set of parameters is called a “Program”.

5.1 Selecting a Weld Program

5.1.1 Using timer keypad

Press until the MTR50 displays READY.

Press . The display will show USE PROGRAM n.

Press either or to select the required program number (n), then press .

Press to return to normal mode.

Note that for configuration type 0, the timer has an external program select line. If this input is on, then this causes the

timer to add 1 to the selected program number.

e.g.

USE PROGRAM

AUX INPUT

Program to be run by

timer

3

Off

3

3

On

4

7

Off

7

7

On

0

F

+

-

F

Welding with the MTR50

15 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

5.2 Starting a Weld

When the timer has been configured and programmed, welding can proceed. Select the program to be used (see

previous section) and operate the Start input (input 1). A weld sequence will begin.

The Start signal must be held on until the first weld period. If the Start signal is removed before this, the weld sequence

will be aborted.

5.3 2nd stage input

Note that for configuration type 1, the timer has an external 2nd stage start input. If this input is off, then the sequence

will pause at the end of the squeeze time, and the display will show

NO 2nd STAGE

If the Start signal goes off at this point, then the sequence is aborted, and no weld is made. The sequence will not

continue until the aux input goes momentarily on.

Programming the weld programmes

16 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

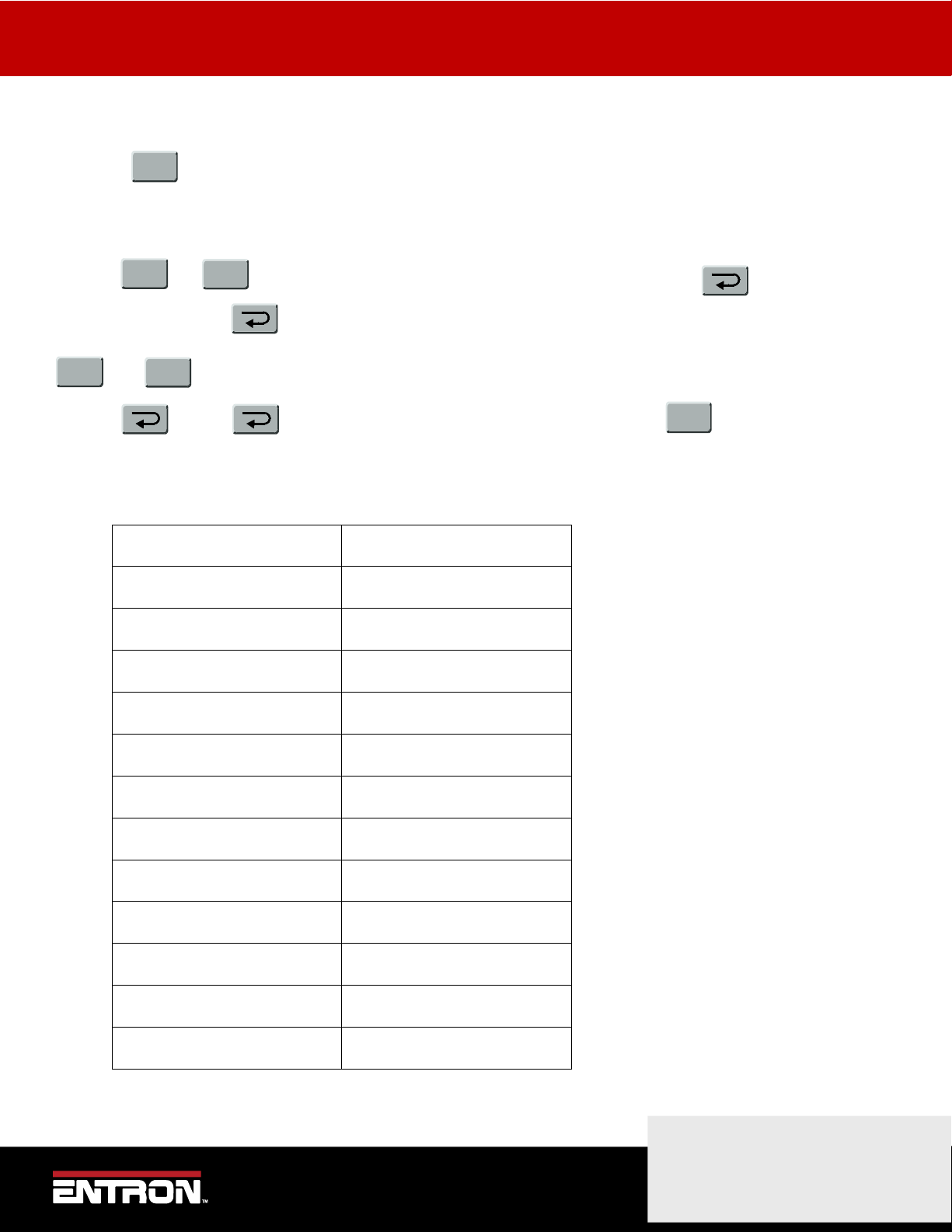

6Programming the weld programmes

Press the key until the display reads

EDIT PROGRAM 0

Use the or key to select the program required. The display will flash. Press to enter the

program number. Press again to move the programmer to the first parameter. With each parameter use the

and keys to change the value. This will cause the display to flash. When the value is correct, enter it by

pressing . Press again to move onto the next parameter. At any point can be pressed to exit

programming weld parameters.

The table below shows the welding parameters and the order in which they appear.

Parameter

Range of values

Mode

Single or Repeat

Heat 1

0 –99

Heat 2

0 –99

Presqueeze **

0 –99

Squeeze

0 –99

Weld 1

0 –99

Cool 1

0 –99

Weld 2

0 –99

Cool 2

0 –99

Pulses

1 –9

Hold

0 –99

Off **

0 –99

**NOTE: these parameters will only appear if the MODE parameter has been set to REPEAT.

F

+

-

+

-

F

Programming the weld programmes

17 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

6.1 Program parameters

Mode Selects either Single Sequence or Repeat Sequence operation. Single Sequence

operation performs one weld sequence when the timer is initiated. Repeat Sequence

performs successive weld sequences for the duration of the Start signal.

Heat 1 Controls the heat of the first weld interval.

Heat 2 Controls the heat of the second weld interval.

Presqueeze The time (in cycles) allowed for the electrodes to initially meet (only used for the first

spot in repeat mode).

Squeeze The time (in cycles) allowed for the electrodes to build up full welding pressure on the

component.

Weld 1 The duration (in cycles) of the first weld interval.

Cool 1 The time (in cycles) between the first and second weld intervals.

Weld 2 The duration (in cycles) of the second weld interval.

Cool 2 (Only applicable when using pulsations) The time (in cycles) between pulses of Weld 2.

Pulses The number of pulses of Weld 2.

Hold The time (in cycles) for which welding pressure is maintained on the weld after welding

current has ceased.

Off (Only applicable in Repeat mode). The time (in cycles) between successive weld

sequences.

End of Sequence Output

18 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

7End of Sequence Output

For configuration types 0 and 1, at the end of the weld sequence the End of Sequence output switches on. If the Start

signal is still present, the End of Sequence signal remains on until the Start signal is removed.

In Single Spot operation, at the end of the weld sequence the End of Sequence output switches on. If the Start signal is

absent, the End of Sequence signal switches on only momentarily.

In Repeat Spot operation the End of Sequence output switches on for the Off time between sequences, and

momentarily after the final sequence.

Start Signal

End of Seq. Signal

Weld Sequence

Start Signal

End of Seq. Signal

Weld Sequence

Start Signal

End of Seq.

Weld Sequence

Counter

19 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

8Counter

Configuration type 3 provides a counter facility. In this, an “End Count” value is programmed into the MTR50. A counter

within the MTR50 increments each time a weld sequence is completed. When the number of welds completed equals

the number of welds programmed as “End Count”, the Count Output switches on.

If “Stop at End” has been programmed, the timer will ignore Start inputs when this stage has been reached. If “Continue

at End” has been programmed, welding can continue.

The counter and the Count Output can be cleared by applying a signal to the Reset input.

At any stage the progress of the counter can be observed, and changed if required.

•Press until it the display reads COUNTER

•Press The display will read, for example, COUNT NOW = 0005

a) If you wish to change the parameter use the or keys. Press to enter the new value. Note that

the new value is not stored until the key is pressed.

b) Press to move to the next item in the counter file.

•Repeat steps a) and b) until the counter set-up is complete, then press .

8.1 Counter Parameters

The items in the list of counter parameters is shown below.

Parameter

Options

Count now

0 .. 9999

Count up to

0 .. 9999

Stop at end

Stop or Continue

Count now: this is the value presently counted. This can be reset to zero by applying the reset counter input, or by

entering zero from the keypad.

Count up to: this is the value which defines the end of the count. When Count now is greater than or equal to Count

up to, the counter output will turn on.

Stop/Continue at end: If Stop at end is selected, then no further welding is permitted when the end of count is

reached. If Continue at end is selected, then further welding may take place, but the counter output will remain on.

F

+

-

F

Electrical Drawings

20 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: MTR50

February 23 | Doc No. 230224-1

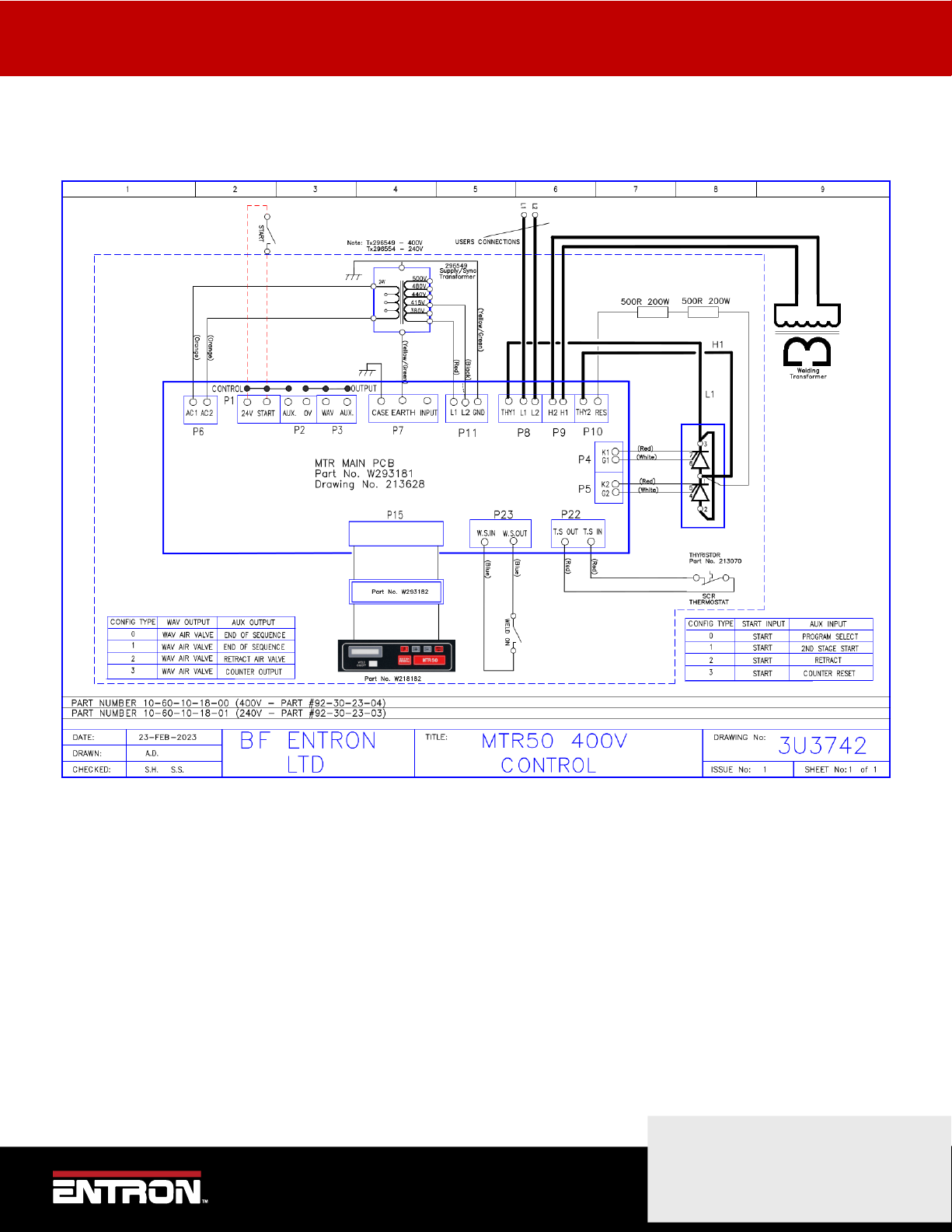

9Electrical Drawings

9.1 3U3742

Table of contents

Popular Welding System manuals by other brands

Magmaweld

Magmaweld ID 400E user manual

Amada

Amada EZ-AIR Operation manual

STAUFF

STAUFF SWG-WG operating manual

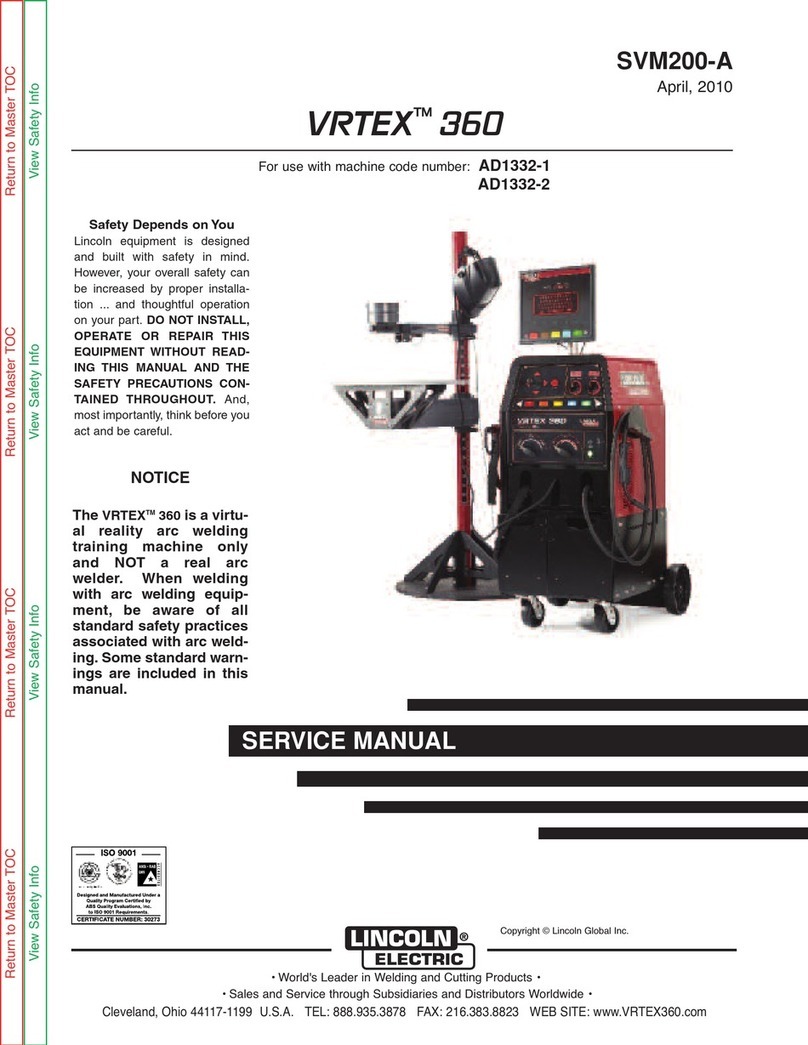

Lincoln Electric

Lincoln Electric VRTEXTM 360 SVM200-A Service manual

Miller Electric

Miller Electric SWINGER 180 Installation, operation & maintenance manual

Michigan Welding

Michigan Welding MIG135 operating instructions

Polyvance

Polyvance Nitro-Fuzer 8002 quick start guide

Lincoln Electric

Lincoln Electric MARQUETTE AutoPro 90S Operator's manual

Miller

Miller DYNASTY 700 owner's manual

WIA

WIA Weldmatic Weldarc 145i Operator's manual

Hypertherm

Hypertherm powermax1650 Operator's manual

ESAB

ESAB Migmaster 173 instruction manual