1/4

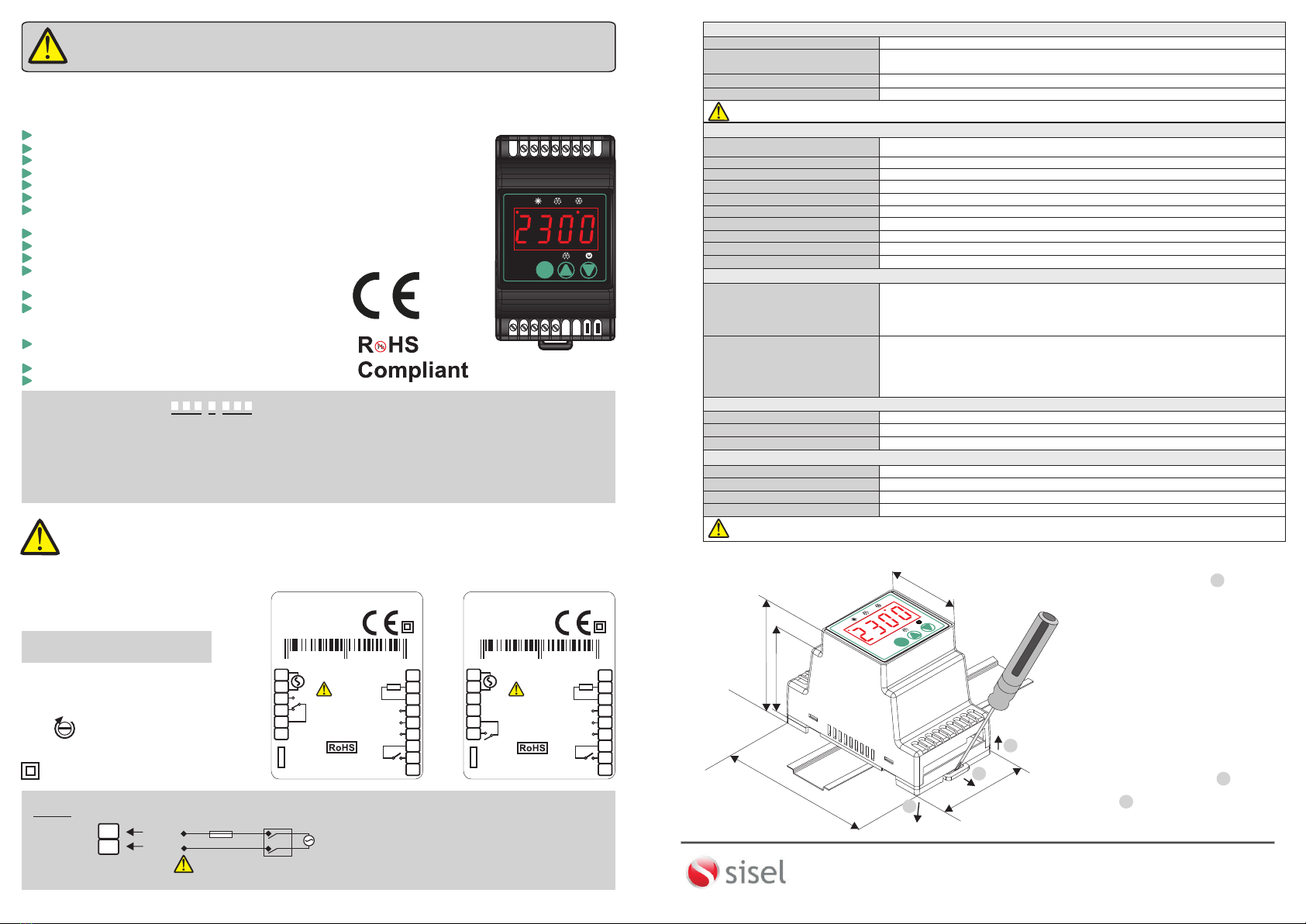

Thank you for choosing ENDA EDT5411A temperature controller.

ENDA EDT5411A DIGITAL THERMOSTAT

54x94mm.

On-Off control.

Relay output for cooling or heating control.

Single NTC probe input.

Offset value can be entered for NTC input.

Compressor protection parameters can be entered.

In case of probe failure, output status can be set to

ON, OFF or periodic.

Upper and Lower setpoint value limits can be adjusted.

Defrosting duration and intervals can be adjusted.

6 Different warning tone selections.

Lower and upper alarm limit can be adjusted to depending

on set value.

Temperature unit can be selected °C or °F.

Digital input ;

- External alarm

- Initiate defrost

Transfer device parameter settings with ENDAKEY

- No power-up required.

RS485 ModBus protocol communication feature (optional).

CE marked according to European Norms.

Please read this document carefully before using this product. The guarantee will be invalidated if the device is

damaged by not following instructions detailed in the manual. The company shall not be responsible for any damage

or

losses however

caused,

which may

be experienced

as a

result of

the installation or

use

of

this

product.

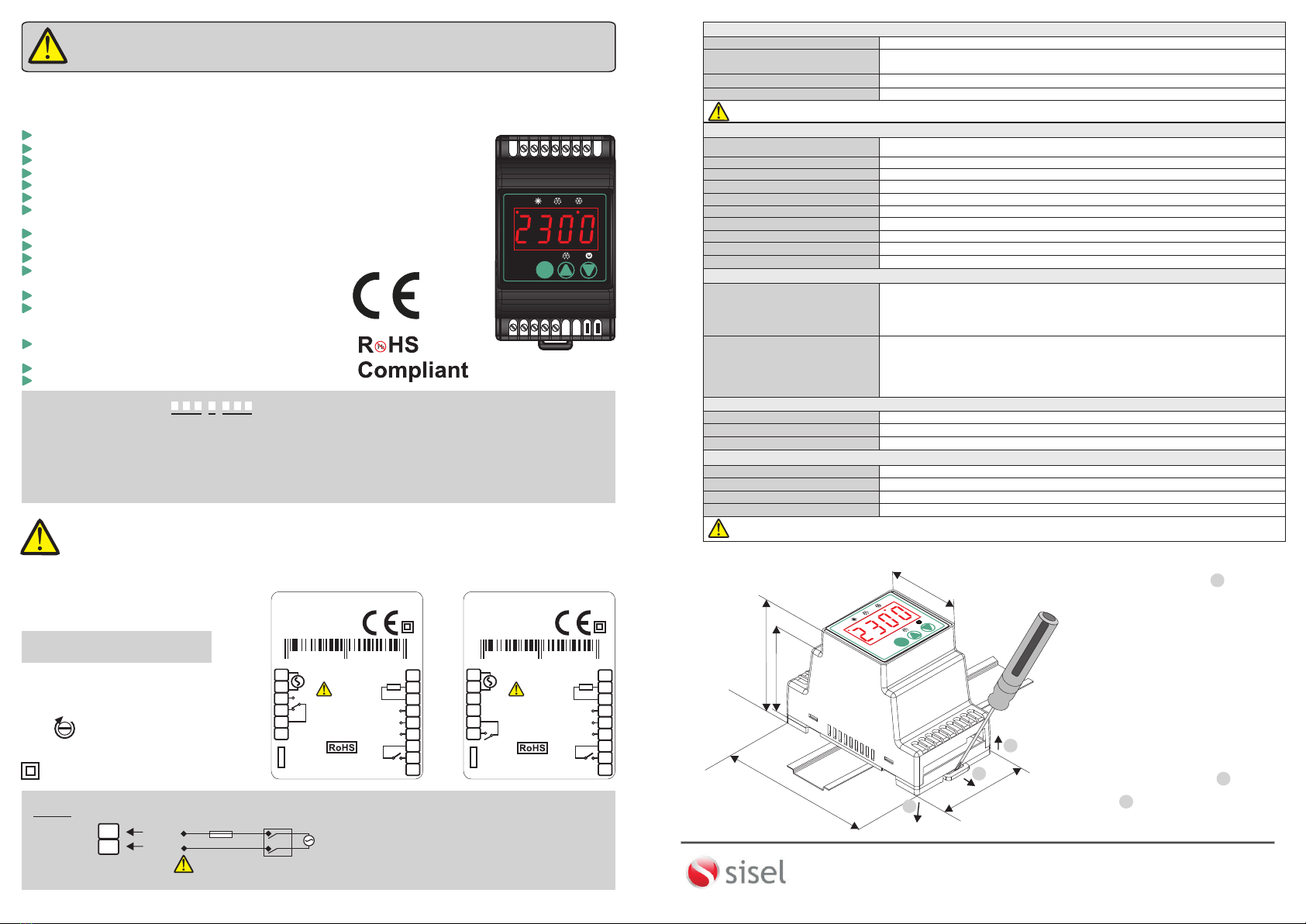

CONNECTION DIAGRAM

ENDA EDT5411A is intended for installation in control panels. Make sure that the device is used

only for intended purpose. The electrical connections must be carried out by a qualified staff

and must be according to the relevant locally applicable regulations. During an installation, all of the cables that are

connected to the device must be free of electrical power. The device must be protected against inadmissible humidity,

vibrations, severe soiling and make sure that the operation temperature is not exceeded. The cables should not be

close to the power cables or components.

SUPPLY:

NOTE:

184-253V AC

50/60Hz 4VA

Line

Neutral

230V AC

Supply

Switch

Note:

Cable size: 1,5mm²

Fuse

F 100 mA

250V AC

Fuse should

be connected

1) Mains supply cords shall meet the requirements of

IEC 60227 or IEC 60245.

2) In accordance with the safety regulations, the power

supply switch shall bring the identification of the

relevant instrument and it should be easily

accessible by the operator.

10

11

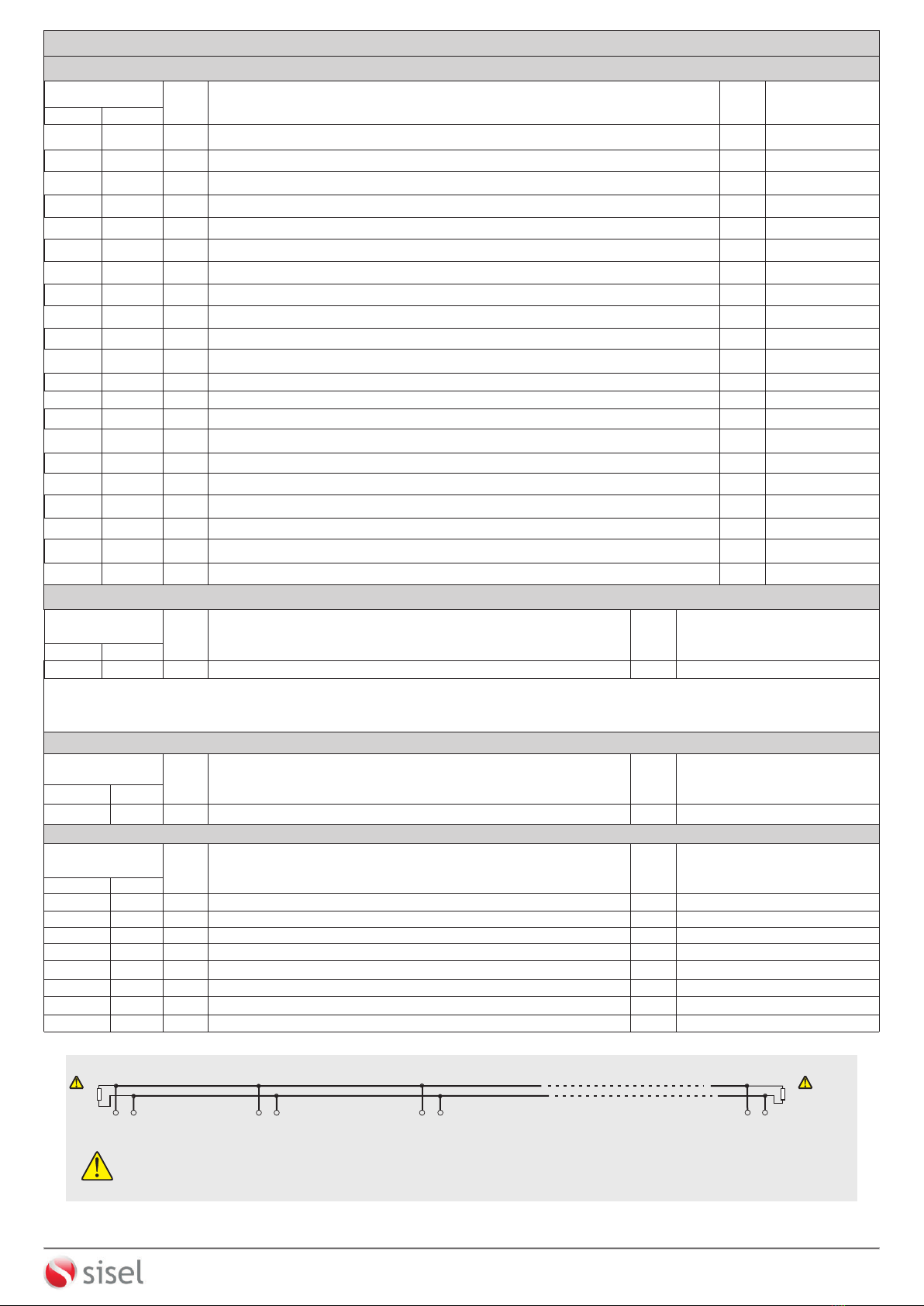

Order Code : EDT5411A - - -

1 2 3

1 - Supply Voltage

230........230V AC

110.........110V AC

24........24V AC/DC

12........12V AC/DC

SM........9-30VDC / 7-24V AC

2-Output

R......... 8A Relay output

P......... 20A Relay output

3 - Modbus

RS........ RS-485 Modbus Available

(Optional / Specify at order)

Blank.... N/A

Holding screw

0.4-0.5Nm

Equipment is protected throughout

by DOUBLE INSULATION.

ENVIRONMENTAL CONDITIONS

Height Max. 2000m

Ambient / Storage Temperature

Relative Humidity

0 ... +50°C/-25 ... 70°C (without icing)

Protection Class According to EN60529; Front panel : IP65, Rear panel : IP20

Supply Voltage

230V AC / 110V AC +%10 -%20 50/60Hz ; 12V AC/DC ± %10 ,24V AC/DC ±%10 or 9-30V DC / 7-24V AC SMPS.

Power Consumption Max. 5VA

2.5mm² screw-terminal connections

±1%

4 Digits, 12.5mm, 7 Segment Red LED

Connection

Scale

Sensitivity

Accuracy

Time Accuracy

Display

EMC

Safety Requirements

EN 61326-1: 2013

EN 61010-1: 2010 (Pollution degree 2, overvoltage category II)

ELECTRICAL CHARACTERISTICS

-60.0 ... +150.0°C (-76.0 ... +302.0°F)

0.1°C (Can be selected as 0.1ºC or 1ºC.)

±1°C

CONTROL

Control Type Single set-point control

On-Off control

Control Algorithm

Hysteresis Adjustable between 1 ... 20.0 °C.

Life Expectancy for Relay

OUTPUTS

HOUSING

Housing Type Suitable for flush -panel mounting

Dimensions W54xH94xD68mm

Weight Approx. 190g (After packing)

Enclosure Material Self extinguishing plastics.

Relay Output

For EDT5411A-X-R ; Without load 30.000.000 mechanical;

250V AC, 8A resistive load 100.000 electrical operation.

For EDT5411A-X-P ; Without load 10.000.000 switching;

277V AC,20A (for resistive load) 100.000 electrical operation.

For EDT5411A-X-R ; Relay : NO+NC 250V AC,8A (resistive load),

1/2HP, 0.37KW 240V AC (inductive load)

For EDT5411A-X-P ; Relay : NO 277V AC,20A (resistive load),

1/2HP, 0.37KW 250V AC (inductive load)

Max. humidity 80% for temperatures up to 31°C decreasing linearly to

50% relative humidity at 40°C.

INDUSTRIAL ELECTRONICS

EDT5411A-230-R-RS

DIGITAL THERMOSTAT

SN: XXXXXXXXX

ENDA

ENDAKEY

COMPRESSOR

250V AC 8A

RESISTIVE LOAD

15 14 13 12 11 10

1234567 8 9

230V AC +10% -20%

50/60Hz 5VA

NTC

GND

COM

B

A

GND

DIG INP

Made in Turkey

INDUSTRIAL ELECTRONICS

EDT5411A-230-P-RS

DIGITAL THERMOSTAT

SN: XXXXXXXXX

ENDA

ENDAKEY

COMPRESSOR

250V AC 20A

RESISTIVE LOAD

15 14 13 12 11 10

1234567 8 9

230V AC +10% -20%

50/60Hz 5VA

NTC

GND

COM

B

A

GND

DIG INP

Made in Turkey

DIMENSIONS

To removing the device from rail ;

Push the rail lock in direction 2 with a

screwdriver and pull the device in

direction 3 .

To mounting the device to the panel ;

Push the device in direction 1 , the rails

provide the key to keeping the rail.

CAL

EDT5411A

°C

1 2 3 4 56789

1817

1615

14

13

12

11

10

ENDA

EDT5411A SET

°C

°F

EDT5411-EN-01-191216

SİSEL MÜHENDİSLİK ELEKTRONİK SAN. VE TİC. A.Ş.

Şerifali Mah. Y.Dudullu 34775

ÜMRANİYE/İSTANBUL-TURKEY

Tel : +90 216 499 46 64 Pbx. Fax : +90 216 365 74 01

url : www.enda.com.tr

Barbaros Cad. No:18 ENDA

TM

Please see page 4 for

Modbus Connection Diagram

KEEP AWAY device from exposed to corrosive, volatile and flammable gases or

liquids and DO NOT USE the device in similar hazardous locations.

Avoid any liquid contact when the device is switched on.

DO NOT clean the device with solvent (thinner, gasoline, acid etc.) and / or abrasive cleaning agents.

3

2

68mm

94mm

54mm

1

46mm

46,5mm

CAL

EDT5411AA

°C

ENDA

EDT5411A SET

°C

°F

1

2

3

1

2

3