SiteLab SL1188P User manual

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 1of 81

Ultrasonic Flowmeter Instruction Manual

Model: SL1188P

Revision 2.0.0

Date September.2012

Revision

Update

Record Date

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 1of 81

WARNINGSIN THISMANUAL

Caution and warning statementsareused throughout thisbooktodrawyourattention toimportant information.

WARNING

Warning”statementappearswithinformationthatisimportanttoprotectpeopleand

equipmentfromdamage. Payverycloseattentiontoall warningsthatapplytoyourapplication.

Failuretocomplywiththeseinstructionsmaydamagethemeter.

ATTENTION

Failuretocomplywiththeseinstructionsmayresult infaultyoperation.

NOTE

Note”indicatesthatignoringtherelevantrequirementsorprecautionsmayresultinflowmeter

damageormalfunction.

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 2of 81

ProductComponents

Aninspectionshouldbemadeofthedesiredareabeforeinstallingtheflowmeter.Checktoseeifthespareparts

arepresentinaccordance withthepackinglist.Makesurethatthereisnoshippingdamage.Ifyouhaveany

questions,pleasecontactyourrepresentativeassoonaspossible.

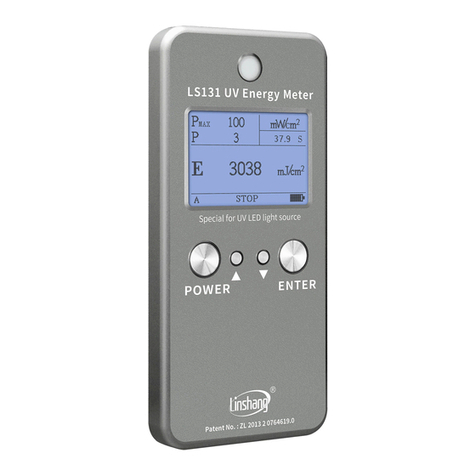

Transmitter Transducers

Accessories Documents

PipeStraps

ScrewDriver

Coupling

compound

Toolbox

Cables Software

4-20mA

SignalCable Satchel

Tape Charge

1. InstructionManual

2. PackingList

3. Certified3-PointFactoryCalibration

4. ApplicationWorksheet

TPC

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 3of 81

Content

1. TransmitterInstallationandConnection ....................................................6

1.1. Inspection Prior to Transmitter Installation..........................................................................................6

1.2. Power Supply Connections..................................................................................................................6

1.2.1. Direct Mount Method......................................................................................................................6

1.2.2. Connecting The Wiring..................................................................................................................6

1.3. Powering on........................................................................................................................................7

1.4. KeyTPC Functions...............................................................................................................................7

1.5. KeyTPC Operation...............................................................................................................................8

1.6. Flowmeter Menu Descriptions..............................................................................................................9

2. PipeParameterEntryShortcuts ..............................................................10

3. MeasurementSiteSelection....................................................................12

4. TransducerInstallation............................................................................13

4.1. Installing the Transducers..................................................................................................................13

4.1.1. Transducer Spacing.....................................................................................................................13

4.1.2. Transducer Mounting Methods.....................................................................................................13

4.1.3. V Method.....................................................................................................................................13

4.1.4. Z Method......................................................................................................................................14

4.1.5. N Method (not commonly used)...................................................................................................14

4.2. Transducer Mounting Inspection........................................................................................................14

4.2.1. Signal Strength............................................................................................................................14

4.2.2. Signal Quality (Q value)...............................................................................................................15

4.2.3. Total Time and Delta Time............................................................................................................15

4.2.4. Transit Time Ratio........................................................................................................................15

Warnings...................................................................................................................................................15

5. OperatingInstructions............................................................................16

5.1. Connecting the panel personal computer...........................................................................................16

5.2 Establishing Bluetoothcommunications.................................................................................................16

5.3.Connecting the Transmitter................................................................................................................17

5.4. System Normal Identification.............................................................................................................20

5.5. Zero Set Calibration...........................................................................................................................20

5.6. Scale Factor.......................................................................................................................................20

5.7. System Lock (Unlock)........................................................................................................................20

5.8. 4~20mACurrent Loop Verification.....................................................................................................21

5.9. Totalizer Pulse Output........................................................................................................................21

5.10. Recover the Factory Default...............................................................................................................21

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 4of 81

5.11. Analog Output Calibration.................................................................................................................21

5.12. Flowmeter PORTABLE Software Usage..............................................................................................22

5.12.1. Data Acquisition andAnalysis...........................................................................................................22

5.12.1.1. TPC Data Acquisition and Analysis Program................................................................................22

5.12.1.2. Main Interface..............................................................................................................................22

5.12.1.3. Data Acquisition..........................................................................................................................23

5.12.1.4. Data Analysis and Graph..............................................................................................................24

5.12.1.5. Data Acquisition Control For The Internal SD Card.......................................................................25

5.12.1.6. Data Reading For The SD Card.....................................................................................................26

5.12.2. UFM Data Analysis and Printing Program...........................................................................................27

5.12.2.1. Data Browsing and Printing.........................................................................................................27

5.12.2.2. Graph Display and Printing..........................................................................................................28

5.12.2.3. Data Analysis and Printing...........................................................................................................29

5.12.2.4. Configuration Information Display...............................................................................................30

5.12.2.5. Menu Functions...........................................................................................................................31

5.13. Analog Voltage Output.......................................................................................................................31

5.14. Date and Time Settings......................................................................................................................31

5.15. Check Flow of Every Day/Month/Year.................................................................................................32

5.16. Automatic Flow Correction................................................................................................................32

5.17. Working Timer...................................................................................................................................32

5.18. Manual Totalizer.................................................................................................................................32

5.19. Analog Output Calibration.................................................................................................................32

5.20. ESN...................................................................................................................................................32

6. WindowsDisplayExplanations................................................................33

6.1. Windows Display Codes....................................................................................................................33

6.2. Display Explanation...........................................................................................................................34

7. ErrorDiagnoses......................................................................................48

7.1. Table 1. Self-diagnoses and ErrorSolutions (upon power on)............................................................48

7.2. Table 2. Error Codes and Solutions (during operation).......................................................................49

7.3. Frequently Asked Questions andAnswers.........................................................................................50

8. ProductOverview ...................................................................................51

8.1. Introduction.......................................................................................................................................51

8.2. Features of Flowmeter.......................................................................................................................51

8.3. Theory of Operation...........................................................................................................................51

8.4. Applications......................................................................................................................................52

8.5. Specifications....................................................................................................................................52

9. Appendix1 -FlowApplication Data..........................................................53

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 5of 81

9.1. Sound Velocity and Viscosity for Fluids Commonly Used..................................................................53

9.2. Sound Velocity for VariousMaterials Commonly Used.......................................................................53

9.3. Sound Velocity In Water (1 atm)At Different Temperatures.................................................................54

9.4. Sound Velocity and Viscosity of Common Liquid...............................................................................55

9.5. Sound Velocity of Common Materials.................................................................................................55

9.6. Sound Velocity In Water (1 atm)At Different Temperatures.................................................................56

9.7. Common Pipe Dimensions (English)..................................................................................................57

9.8. Common Pipe Dimensions (DIN)........................................................................................................63

9.9. Cement Lined Pipes Liner Thicknesses.............................................................................................66

9.10. Cast Iron Pipe Data............................................................................................................................66

9.11. Ductile Iron Pipe Data........................................................................................................................67

9.12. Sound Speeds In Various Fluids........................................................................................................68

9.13. Sound Speed in Various Pipe Materials..............................................................................................77

10. Appendix................................................................................................78

10.1. Install Flowmeter Software on TPC....................................................................................................78

10.2. UFM Data Installation.........................................................................................................................80

10.2.1. Hardware requirements................................................................................................................80

10.2.2. OS Requirements.........................................................................................................................80

10.2.3. Installing Method.........................................................................................................................80

UpdateInformation:

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 6of 81

1.TransmitterInstallation and Connection

1.1. InspectionPriortoTransmitterInstallation

Checkthepacking listand contentstoensurethatall necessaryand orderedpartsareon hand. Shouldanypartsbe

missingordamaged,pleasecontactSitelab Instrumentsassoonaspossible.

1.2. PowerSupplyConnections

1.2.1. DirectMountMethod

TheFlowmeterispoweredby11.1Vbatteries.Batteriescanberechargedandastandbypowersupplycanbe

connectedthroughthebatteryrechargeportonthepanel.

1.2.2. Connecting TheWiring

Openthehingedfrontcoveroftheelectronics.ShownfromlefttorightonthepanelofthePORTABLEarethe

batteryrechargeport(chargethetransmitterorconnecttothestandbypowersupply),powerswitch,powerlight

(red),run indicator(green),upstreamtransducerconnector,downstreamtransducerconnector,output

connector(4~20mAoutputandRelayoutput).

Charge On/Off

Power Run Transducer

Upstream Downstream

4-20mA

(Relay)

Red

Bushing Blue

Bushing

UPSTREAM

DOWNSTREAM

WARNING

Useonlythesuppliedchargertochargethebatteries.

Makesuretheelectronics, thesparebatteryandTPCarefullychargedbeforeusing.

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 7of 81

1.3. Powering on

AssoonastheFlowmeterisswitchedon,theself-diagnosisprogramwillstarttorun.Ifanyerrorisdetected,an

errorcodewill displayedonthescreen(seeErrorDiagnosticsonpage58).Afterthat,thesystemwill run

automaticallyusingtheprogrammed parameters.

Normaloperationisindicatedbycode *R”ontheupperleftcornerofthescreen.

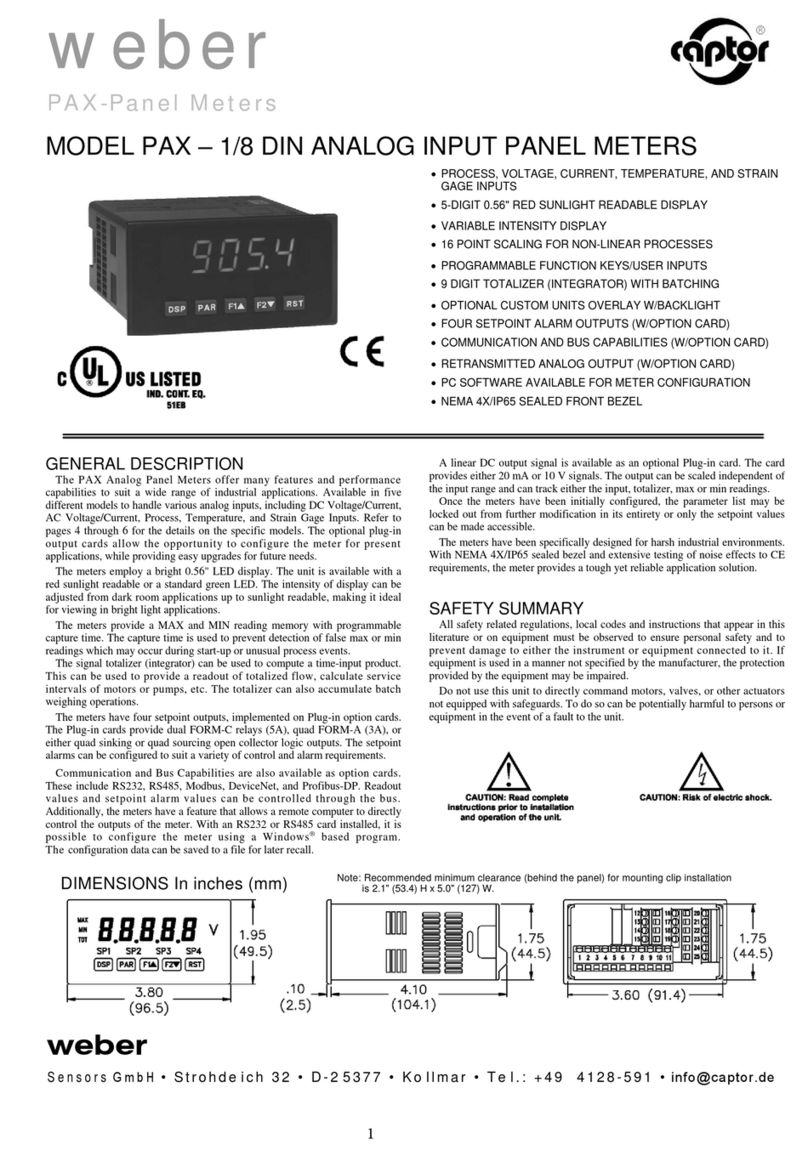

1.4. KeyTPC Functions

Theflowmetermaininterfacesshowasabovepicture –identificationarea,informationdisplayarea,entering

displayarea,mainkeyTPCareaand theshortcutkeyTPCarea.

a)Identificationarea

Softwarelogo:SiteLab SL1188P

b)Informationdisplayarea

WARNING

Whenthebatterypowerisless than15%(usetimeisless than40 seconds),thepower

indicatorlightwillchangetoorange.

Note

Turnoff thecell phonefunctionduringthemetermeasurementandsetting.

Runtheflowmeterprocedureinthepanelpersonalcomputer.Pleaseturntotheinstruction

manualfordetailson howtousethepanelpersonalcomputer.

SL1188P

Flow ConfigKeyPad

/-

32

5

89

6

1

4

7

0

Signal Aout Error Comm

ENT

Menu

/+

Flow0.0000

g/m*I

NET +1370026 x1gal

Information displayarea

SL1188P Identification area

Flow0.0000g/m*I

NET+1370026x1gal

M00 Enteringdisplayarea

Signal

Aout

Error

Comm

Mainkeypad area

Shortcut keypadarea

2

5

8

1

4

7

3

9

6

0ENT

Menu

/+

/-

/-

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 8of 81

Whenoperatingthekeyboard,it will displaythemeterreturninformation;whenoperating theshortcut

keyboard, it will displaytheinformationtipsandthemeterreturninformation.

c)Enteringdisplayarea

Displaythekeyboardoperatinginformation

d)MainkeyTPCarea

Thebutton oftheflowmeter, andpress thisbuttonequalstopress thekeyTPC.

e)ShortcutkeyTPCarea

Thefastresponseoperationkeyforthemainflowmeterinformation.

FollowtheseguidelineswhenusingtheFlowmeterkeyTPC(RefertoKeyTPCFigure):

0

~

9

and Inputnumbers.

Backspace ordeletecharacterstotheleft.

/ + and / - Returntothelastmenuoropenthenextmenu.Actsas +”

and -”functionswhenenteringnumbers.

Menu Selectamenu.Press thiskeyfirst,inputatwo-digit menunumber

and theselectedmenudatawillbedisplayed.Forexample,toinputapipe

outsidediameter,press Menu

1

1

,where 11”isthewindowIDto

displaythepipeoutsidediameter.

, Aout , Error and Comm areshortcutkeys(explainedlater).

1.5. KeyTPC Operation

Theinstrumentsetupand measurementdisplaysaresubdividedintomorethan100 independentmenus.The

operatorcaninputparameters,modifysettingsordisplaymeasurementresultsby visiting”aspecificmenu.

Thesemenusarearrangedby2-digit serialnumbersfrom00~99, thenusing+0, +1, etc.EachmenuIDcodehasa

definedmeaning.Forexample,menu11isthepipeoutsidediameter,whilemenu25 isthemountingspacing

betweenthetransducers. Eachmenuisdiscussedlaterinthismanual.

Tovisit aspecificmenu,press the Menu key, theninputthe2-digit menuIDcodeandthatmenuwillbedisplayed.

Anothermethodtovisit aparticularmenuistopress the / + / - keystoscroll throughthemenus. Forexample,

ifthecurrentmenuIDcodeis03, press / + keytoentermenu02, press the / + buttonagaintoentermenu01;

thenpress the / - keytogobacktomenu02, thenpress the / - keyagaintoentermenu03.

Example1:Toenterapipeouterdiameterof219.234,

theprocedureisasfollows:

Press Menu

1

1

keystoentermenu 11(the

numericalvaluedisplayedcurrentlyistheprevious

pipeouterdiameter).Nowpress ENT key.The

symbol >”and aflashingcursoraredisplayedatthe

leftendofthesecondlineonthescreen.Thenew

valuecannowbeentered.

2

1

9

2

3

4

ENT

PipeOuterDiameter

>_

Signal

32

5

89

6

1

4

7

0

Signal Aout Error Comm

ENT

Menu

/+

/-

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 9of 81

Example2:Ifthepipematerialis Stainless Steel”,

press Menu

1

4

toenterMenu14, thenpress ENT

tomodifytheoptions. Then,select 1.Stainless Steel”

fromthedrop-downmenu(youmaycyclethroughthe

choicesby pressingthe / + and / - keys)and then

press ENT toconfirmtheselection.Itisalsopossible

topress the

1

keytochangetheselectionandwait

until 1. Stainless Steel”isdisplayedonthesecond

lineofthescreen. Thenpress the ENT keytoconfirm.

PipeMaterial [14

>1. Stainless Steel

PipeMateria [14

>5. PVC

ATTENTION

The ENT keyisusedtoenterormodifydata.If youcannotdo soafterpressingthe ENT key,it

meansthatsomeonehasenabledpasswordprotection.To unlock”it,select unlock”inmenu47

and enterthepassword(thispasswordhastobesetbytheuser).

1.6. FlowmeterMenuDescriptions

Menusareassignedasfollows:

00~09 Displaymenus:Usedtodisplayflowrate,positivetotal, negativetotal,nettotal,velocity,date

&timeetc.

10~29 Setupmenus:Usedtoenterpipeouterdiameter,pipewall thickness,fluidtype,transducer

type, transducermountingand spacingetc.

30~38 Flowunitsselectionandtotalizeroperatingmenus:Usedtoselectunitsofmeasurement.Othermenus

set/resetthevarioustotalizermodes.

40~49 Systemmenus:Flowcorrectionoperatingmenusandsystemlockmenusetc.

55~83 Inputandoutputsetupmenus:currentloopmodeselect,4mAor0mAoutputvalue,etc.

90~94 Diagnostics:signalstrengthquality(menu90),TOM/TOS*100 (menu91),soundvelocity

(menu92),totaltimeanddeltatimeofthemeasuredsignal(menu93),Reynoldsnumberand K

factor(menu94).

+0~+9 Appendix:Poweron/offtime,totalworkinghours,on/off timesetc.

-0~-9 4~20mAcorrectionmenus.

ATTENTION

missing”menusareforhardwareadjustment(setbythemanufacturer).

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 10 of81

2.PipeParameterEntryShortcuts

Example:LetssaywehaveaDN200 (8”)pipe,measuringwater, Materialiscarbonsteel withno liner.These

parametersshouldbeenteredasfollows:

Step1. Pipeoutsidediameter

Press Menu

1

1

keystoentermenu11,

enterthepipeoutsidediameter,thenpress the

ENT key.

PipeOuterDiameter

200mm

Step2. Pipewall thickness

Press the Menu

1

2

keytoentermenu12,

enterthepipewall thickness (wall thickness

forvariouspipeschedulescanbefoundinthe

appendix), thenpress the ENT key.

PipeWallThickness

6mm

Step3. Pipematerial

Press the Menu

1

4

keytoentermenu14,

press the ENT key,usethe / + or / - key

toselectthepipematerialfromthedrop-down

menu, thenpress the ENT key.

PipeMaterial [14

0. Carbon Steel

Step4. Linermaterialparameters

(includingthickness andsoundvelocity,if

needed)

Press the Menu

1

6

keytoentermenu16,

press the ENT key,usethe / + or / - key

toselectlinermaterialfromthedrop-down

menu, thenpress the ENT key.

LinerMaterial[16

0. None, NoLiner

Step5. Fluidtype

Press the Menu

2

0

keytoentermenu20,

press the ENT key,usethe / + or / - key

toselectfluidtypefromthedrop-downmenu,

thenpress the ENT key.

FluidType[20

0. Water

Step6. Transducertype

(Thetransmitterisavailableforvarious

transducertypes)

Press the Menu

2

3

keytoentermenu23,

press the ENT key,usethe / + or / - key

toselecttransducertypefromthedrop-down

menu, thenpress the ENT key.

Transducer Type[23

0. Standard

ATTENTION

Unless otherwisedirected,youwill use0. standardhere.High Tsensorsarebeing developed

and eventuallymaybeselectedhere. (along withotherspecialtysensors)

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 11 of 81

Step7. Transducermountingmethods

Press the Menu

2

4

keytoentermenu24,

press the ENT key,usethe / + or / - key

toselecttransducer-mounting fromthe

drop-downmenu, thenpress the ENT key.

Transducer Mounting

0. V

Step8. AdjustTransducerspacing

Press the Menu

2

5

keytoentermenu25,

accuratelyinstall thetransduceraccordingto

thedisplayedtransducermountingspacingand

theselectedmountingmethod(Referto

InstallingtheTransducersinthischapter).

Transducer Spacing

159.86mm

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 12 of81

3.MeasurementSiteSelection

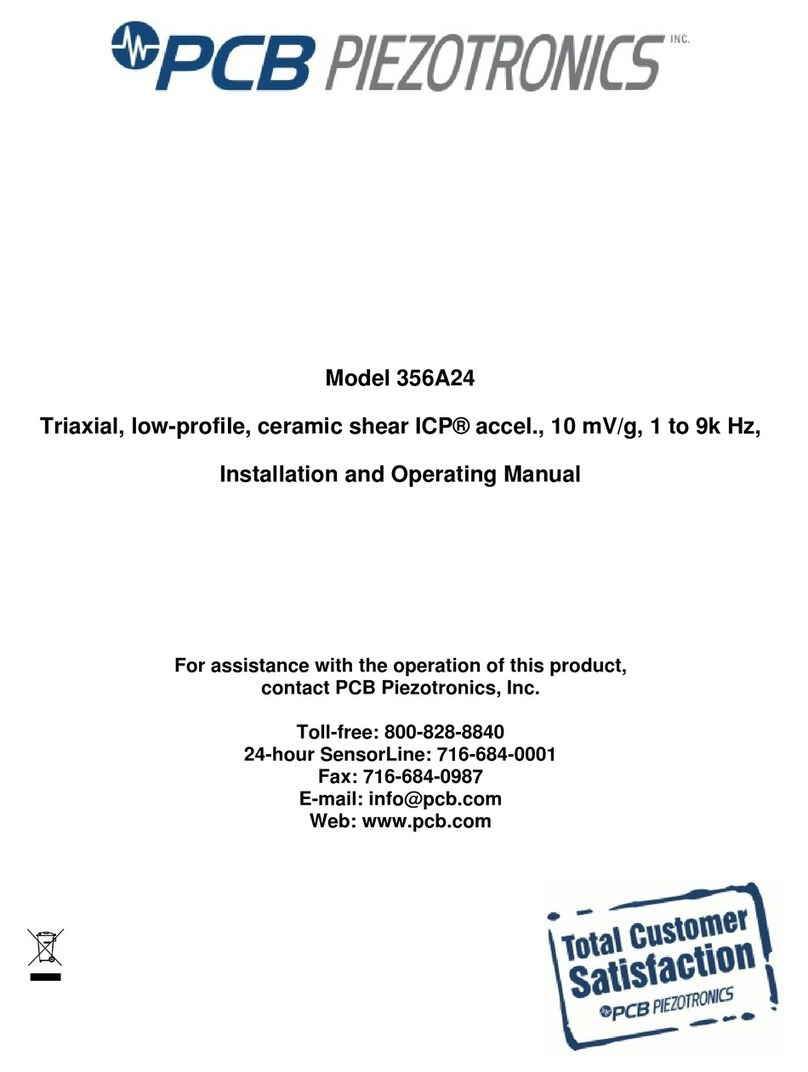

Whenselectingameasurementsite,it isimportanttoselectanareawherethefluidflowprofileisfullydeveloped

toguarantee ahighlyaccuratemeasurement. Usethefollowing guidelinestoselectaproperinstallation site:

Chooseasectionofpipethatisalwaysfull ofliquid,suchasaverticalpipewithflowintheupwarddirectionora

full horizontalpipe.

Ensureenoughstraightpipelengthatleastequaltothefigureshownbelowfortheupstreamanddownstream

transducersinstallation.

Pump

Valve

Reduce

Diffuser

Tee

90obend

Straightlengthof

downstream piping

Straightlength ofupstream

piping

Name

Detector

10Dmin

0.5Dmin

L≥5D

L ≥5D

L≥10D

Flowcontrolleddownstream

10Dmin

L ≥10D

L ≥5D

L ≥10D

10Dmin

L ≥50D

L ≥30D

D

5Dmin

L≥10D

L≥30D

Flowcontrolledupstream

L≥50D

P

Checkvalve

Stop valve

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 13 of81

Ensurethatthepipesurface temperatureatthemeasuringpointiswithinthetransducertemperaturelimits.

Considertheinsideconditionofthepipecarefully.Ifpossible,selectasectionofpipewheretheinsideisfreeof

excessivecorrosionorscaling.

4.TransducerInstallation

4.1. InstallingtheTransducers

Beforeinstallingthetransducers, cleanthepipesurface wherethetransducersaretobemounted. Removeanyrust,

scaleorloosepaintandmakeasmoothsurface.Applyawidebandofsoniccouplingcompounddownthecenter

oftheface ofeachtransduceraswell ason thepipesurface,and thenattachthetransducerstothepipewiththe

strapsprovidedandtightenthemsecurely.

Note:

Thetwotransducersshouldbemountedatthepipe’scenterlineonhorizontalpipes.

Makesurethatthetransducermountingdirection isparallelwiththeflow.

Duringtheinstallation,thereshouldbenoairbubblesorparticlesbetweenthetransducerandthepipewall.On

horizontalpipes,thetransducersshouldbemountedinthe3o’clockand9o’clockpositionsofthepipesection in

ordertoavoidanyairbubblesinsidethetopportionofthepipe.(RefertoTransducerMounting).Ifthe

transducerscannotbemountedhorizontallysymmetricallyduetolimitationofthelocalinstallationconditions,it

maybenecessarytomountthetransducersatalocationwherethereisaguaranteedfullpipecondition(thepipeis

alwaysfull ofliquid).

4.1.1. TransducerSpacing

Afterenteringtherequiredparameters,thespacingbetweentheENDSofthetwotransducersisconsideredasthe

standardtransducerspacing(RefertoTop Viewontransducermounting methods).Checkthedatadisplayedin

WindowM25 andspacethetransducersaccordingly.

4.1.2. TransducerMounting Methods

Fourtransducermountingmethodsareavailable.Theyarerespectively:Vmethod,ZmethodandNmethod.The

Vmethodisprimarilyusedonsmall diameterpipes(DN100~400mm,4”~16”).TheZmethodisusedin

applicationswheretheVmethodcannotworkduetopoorsignalorno signaldetected.Inaddition,theZmethod

generallyworksbetteronlargerdiameterpipes(overDN300mm, 12”)orcastiron pipes.

TheNmethodisanuncommonlyusedmethod. Itisusedonsmallerdiameterpipes(belowDN50mm, 2”).

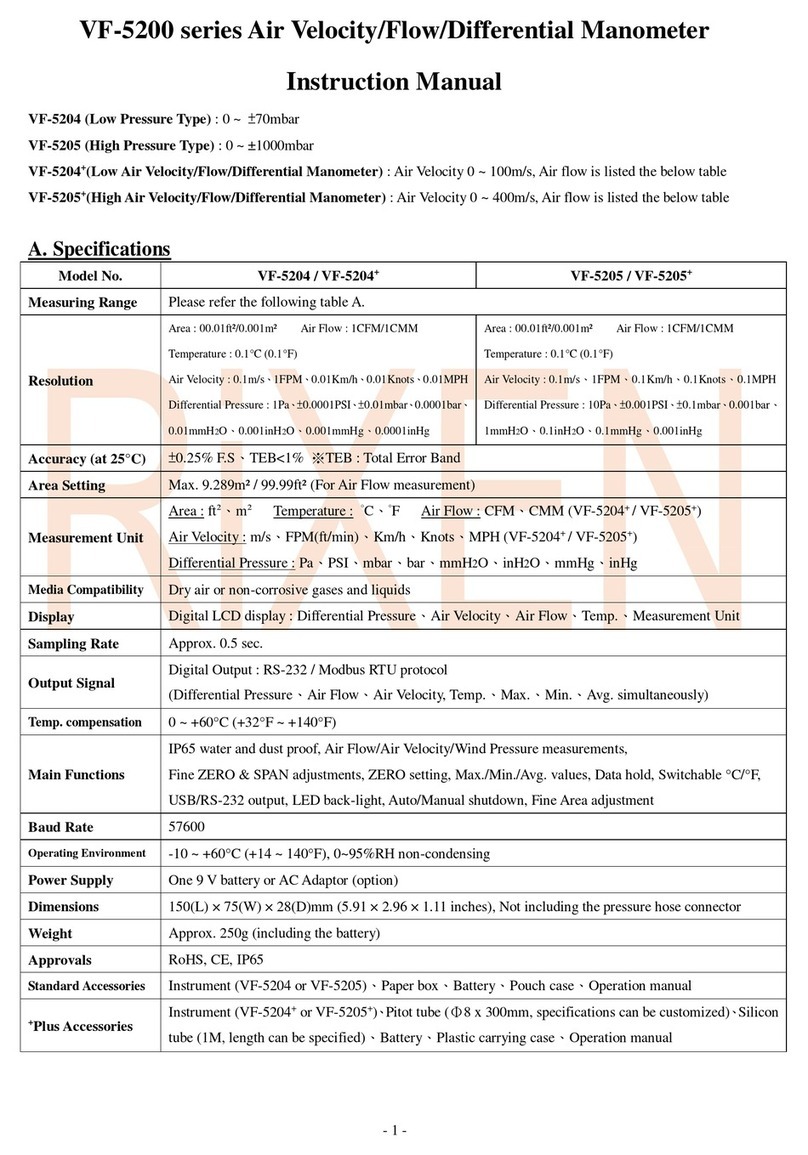

4.1.3. VMethod

TheVmethodisconsideredasthestandardmethod.Itusuallygivesamoreaccuratereadingandisusedonpipe

diametersranging from25mmto400mm (1~16”)approximately.Also,it isconvenienttouse,butstill requires

properinstallationofthetransducer,contactonthepipeatthepipe’scenterlineandequalspacingoneithersideof

thecenterline.

DownstreamTransducer

UpstreamTransducer

Flow

TransducerSpace

Flow

SideView Top ViewSection

PipeStrap

Transducer

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 14 of81

4.1.4. ZMethod

ThesignaltransmittedinaZmethodinstallationhasless attenuationthanasignaltransmittedwiththeVmethod.

ThisisbecausetheZmethodutilizesadirectlytransmitted(ratherthanreflected)signalwhichtransversesthe

liquidonlyonce.

TheZmethodisabletomeasureonpipediametersrangingfrom100mmto3000mm (4”~120”)approximately.

Therefore,werecommendtheZmethodforpipediametersover300mm (12”).

DownstreamTransducer

UpstreamTransducer

Flow

TransducerSpacing

Flow

SideView Top ViewSection

PipeStrap

Transducer

4.1.5. NMethod (notcommonlyused)

WiththeNmethod,thesoundwavestraversethefluidtwiceandbouncethreetimesoffthepipewalls.Itis

suitableforsmall pipediametermeasurement.

Themeasurementaccuracycanbeimprovedbyextendingthetransit distancewiththeNmethod (uncommonly

used).

DownstreamTransducer

UpstreamTransducer

Flow

TransducerSpacing

Flow

SideView Top ViewSection

PipeStrap

Transducer

4.2. TransducerMountingInspection

Checktoseeifthetransducerisinstalledproperlyand ifthereisanaccurateandstrongenoughultrasonicsignal

toensureproperoperationandhighreliabilityofthetransducer.Itcanbeconfirmedbychecking thedetected

signalstrength, totaltransit time,deltatimeaswell astransit timeratio. Thesechecksareexplainedbelow.

The mounting”conditiondirectlyinfluencestheflowvalueaccuracyand systemreliability.Inmostinstances,

applyawidebeadofsoniccouplingcompoundlengthwiseonthefaceofthetransducerandstickit totheoutside

pipewall togetgoodmeasurementresults.However,thefollowinginspectionsstillneedtobecarriedoutinorder

toensureahighreliabilityofthemeasurementandlong-termoperationoftheinstrument.

4.2.1. Signal Strength

Signalstrength(displayedinmenu 90)indicatesadetectedstrengthofthesignalbothfromupstreamand

downstreamdirections.Therelevantsignalstrengthisindicatedby numbersfrom00.0~99.9. 00.0 representsno

signaldetectedwhile99.9 representmaximumsignalstrength.

Normally, thestrongerthesignalstrengthdetected, thebetterthemeasurement.

Adjustthetransducerspacingtothebestpositionandchecktoensurethatenoughsoniccouplingcompound is

appliedduring installationinordertoobtainthemaximumsignalstrength.Thisisessentiallyfinetuning the

calculatedspacingshowninmenu25 (transducerspacing).Itmaybeslightlydifferent.

Systemnormaloperationrequiressignalstrengthover60.0, whichisdetectedfrombothupstreamand

downstreamdirections.If thesignalstrengthdetectedistoo low,thetransducerinstallationpositionand the

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 15 of81

transducermountingspacingshouldbere-adjustedandthepipeshouldbere-inspected.If necessary,changethe

mountingtotheZmethod(Zhasthehighestsignalstrength).

4.2.2. Signal Quality(Qvalue)

QvalueisshortforSignalQuality(displayedinmenu 90).Itindicatesthelevelofthesignaldetected.Qvalueis

indicatedbynumbersfrom00~99. 00 representstheminimumsignaldetectedwhile99 representthemaximum.

Thetransducerpositionmaybeadjustedandenough couplingusedtogetthesignalqualitydetectedasstrongas

possible.

4.2.3. TotalTimeandDeltaTime

TotalTimeand DeltaTime”aredisplayedinmenu93. Themeasurementcalculationsintheflowmeterarebased

upon thesetwoparameters.Therefore,when DeltaTime”fluctuateswidely,theflowand velocitiesfluctuate

accordingly.Thismeansthatthesignalqualitydetectedistoopoor. Itmaybetheresultedofpoorpipe-installation

conditions, inadequatetransducerinstallationorincorrectparameterinput.

Generally, DeltaTime”fluctuationshouldbeless than±20%.Onlywhenthepipediameteristoosmall or

velocityistoolowcanthefluctuationbewider.

4.2.4. TransitTimeRatio

Transit TimeRatioindicatesifthetransducermountingspacingisaccurate.Thenormaltransit timeratioshould

be100±3 iftheinstallationisproper. Checkit menu91.

ATTENTION

If thetransit timeratioisover100±3, it isnecessarytocheck:

(1) If theparameters(pipeoutsidediameter,wall thickness,pipematerial,liner,etc.)have

beenenteredcorrectly,

(2) If thetransducermountingspacingisaccordancewiththedisplayinmenu25,

(3) If thetransducerismountedatthepipe’scenterlineonthesamediameter,

(4) If thescaleistoothickorthepipemountingisdistortedin shape, etc.

Warnings

Pipeparametersenteredmustbeaccurate;otherwisetheflowmeterwill notworkproperly.

(1) Duringtheinstallation,applyenoughcouplingcompoundtostickthetransducerontothepipewall.

WhilecheckingthesignalstrengthandQvalue,movethetransducerslowlyaroundthemountingsite

until thestrongestsignalandmaximumQvalueareobtained.Thelargerthepipediameter,themore

thetransducermayhavetobemoved.

(2) Checktobesurethemountingspacingisascalculatedinmenu25 and thetransducerismountedat

thepipe’scenterlineonthesamediameter.Notethatyou canadjustthespacingslightlyasdescribed

abovetofinetunethedevice.

(3) Payspecialattentiontothosepipesthatformedbysteelrolls(pipewithseams),sincesuchpipeis

alwaysirregular.If thesignalstrengthisalwaysdisplayedas0.00, thatmeansthereisnosignal

detected.Thus,it isnecessarytocheckthattheparameters(includingall thepipeparameters)have

beenenteredaccurately. Checktobesurethetransducermountingmethodhasbeen selectedproperly,

thepipeisnotworn-out,andthelinerisnottoothick.Makesurethereisthereisindeedfluidinthe

pipeorthetransducerisnotveryclosetoavalveorelbow,and therearenottoomanyairbubblesin

thefluid,etc.Onceyouhaveruledoutall thesereasons,ifthereisstill nosignaldetected,the

measurementsitehastobechanged.

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 16 of81

5.OperatingInstructions

5.1. Connectingthepanel personal computer

Turntheelectronicsunit on. Thismustbeinsequence;theelectronicsMUSTbeturnedonFIRST,thenthepanel

personalcomputer.FailuretodosointhissequencewillresultinalackofBluetoothcommunication.Clickthe

icon[SL1188P]tooperatethesoftware.

FullScreenDisplay:TheprogramhastheabilitytodisplayMENU00~04and shortcutkeysFlow,Velo,+Total,

-Totalinfullscreenview.Operatorscancheckthedataeasily.Press any pointandbacktotheoriginaldisplay

mode.

If thepanelpersonalcomputercommunicationsfail orillegallyusethissoftware(illegalcopyortheserialnumber

doesnotmatchwiththetransmitter),and thentherewill bewarninginformationtwice andtheinstrumentcannot

worknormally.Press OK”and enterthemain interface,press [Comm]tocheckwhethertheconnectioniscorrect

ornot, OK”meansnormalconnection, Failure”meansnot.

Misoperationwill causethepanelpersonalcomputersystemhalted(noresponse),pleaselogoutthesoftware,

press backspace keytoreturntodesktop.Pleaserefertothepanelpersonalcomputeroperationinstructionfor

moredetails.

Picture5-1logoutoperationofpanelpersonalcomputer

5.2 EstablishingBluetoothcommunications

ConnecttheTPCwithtransmitterthroughBluetooth,theTPCwillautomaticallylaunchtheSiteLabFlowmeter

applicationand searchforBluetoothdevices.Itwill showalistofcompatibleBluetoothdeviceswithrange.

Selectthesuitabledevicetoconnectand intheeventthatadatawindowappearsaskingforapassword, enterthe

passwordof1234. Thiswill unlocktheunit andallowcommunicationstoproceed.

Note

Whileinstallingthesoftware, themainprogramSL1188P.apk andDctp.pdb

filehavetobeputundertheSDkagancatalogue.

ReturnKey

Menu MainScreen Search

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 17 of81

If you arestill unabletocommunicate,activatetheresetfunction.Thiswill forcearebootandrecycletheTPC

software, again,oncetheTPCsoftwareiscompletelybootedup, theflowmeterwill automaticallylaunch.

5.3.ConnectingtheTransmitter

Once thetransducersaresecurelymountedonthepipe,connectthecablestoeachtransducerand thentothe

electronicsbox. Careshouldbetakenhereasthetransducercableendsarekeyedtofit intothetransducerswiring

connectionand thenfastenedwithacircularconnector.Theoppositeendisacircularconnectorplug thatsimply

insertsintothecorrespondingUpstreamandDownstreamconnection point.Oncethese2cablesaresecurely

connected,youareready toreadtheflow.

MATING:Asdrawingshows,holdthesmoothpartin

backoftheplugand pushwhenthekeyoftheplug

areinline.Theconnectorisfullyseatedwhenaclick

isheardorfelt fromthequickdisconnectring.

UNMATING:Asdrawingshows,holdthecoupling nut

and pull tounmated.

Theupstreamtransducercablehasredterminalendsanddownstreamtransducercablehasblueterminalends.

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 18 of81

Wheninstallingtransducerstorelativelysmall pipes{sizesunder8”inmostapplications},thetransducerspacing

displayedinMENU25 maybeless than7.5”(190mm),thenwecaninstall thetransducersinsingleslideruler

rack.Theinstallationmethodisunscrewingatransducerofftherackatfirst,

theninstall thetwotransducerstoonerackface-to-face.

Theflowmeterwill nowworkasusual.Exercisecautionduringthisprocedureasthetransducersarespring

loadedintheracks.

SL1188PUltrasonictransit-timeflowmeter

Revision 2.0.0 Page 19 of81

Whenfinishedinstallingbothtransducersinasinglerack,theyshouldappearasshowninthephotobelow.The

ovaltransducercrystalsshouldbefacingeachother.Theyaredesignedtosendsignalsbackandforthtoone

another, and iftheyareinstalledbackwards, theywill notfunction.

Eachtransducerhasa flowdirectionarroworanUpstream/DownstreamIdentification.Additionally, each

rackhastheflowdirectionarrowdepictedonit. Ensurethearrowspointinthecorrectdirectiontoensure

properoperation.

Once thecablesareconnected,simplyselectMENU00 andyouwill displaytheflowrate.You canthenusethe

shortcutkeysforadditionalflowinformation asdesired.

NOTE

The2transducersmustbefixedatthefrontposition(i.e.3or9o’clockpositionofthe

pipe)topreventsignallosswhichcanbecausedbysedimentalongthebottomofthepipe

orairbubblesandairpocketsalongtheupperpartinthepipe.

Table of contents

Other SiteLab Measuring Instrument manuals