Sitron SC404 User manual

USER’S GUIDE

SC404

Capacitive

Level Sensor

Installation, Operation, Maintenance Instructions

Contents

3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Models & Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mounting Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Terms & Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4

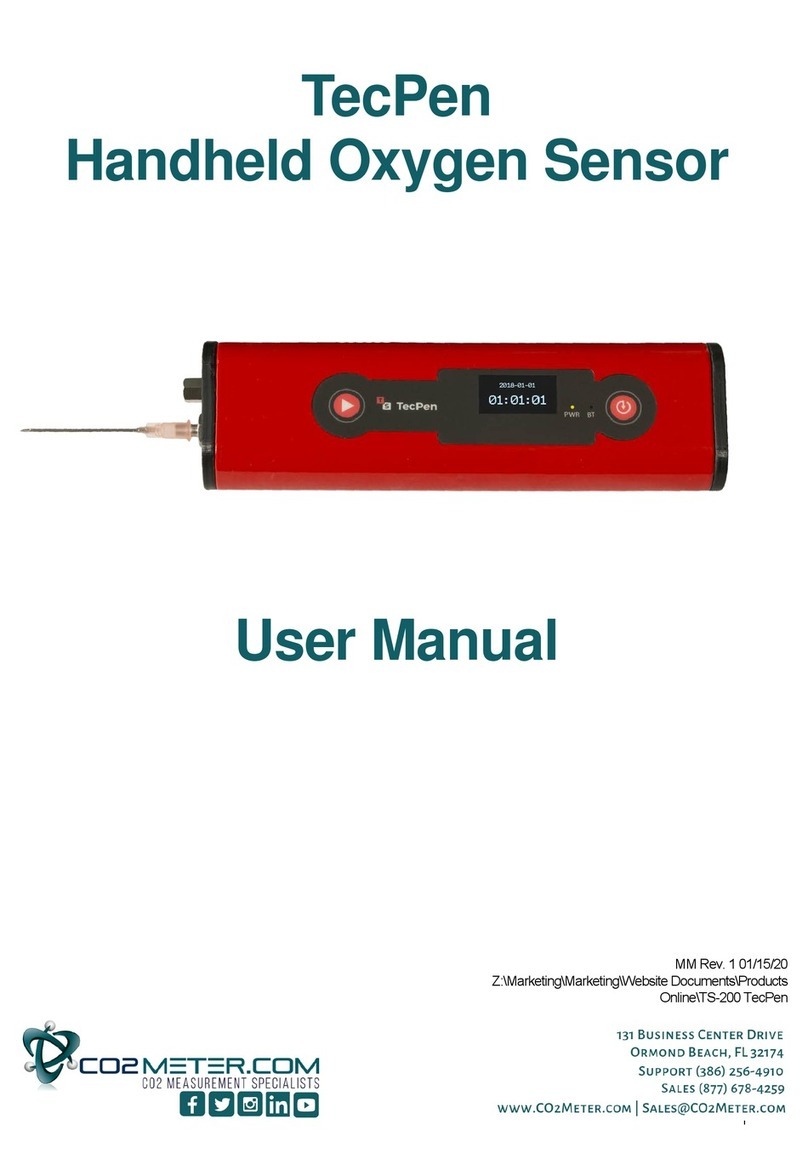

SC404 - Capacitive

Level Sensor

The SC404 is a capacitance continuous level transmitter with an

integrated electronics module mounted within the housing. This 2 wire

loop powered unit provides a 4-20mA output (galvanically isolated).

Set up and calibration is achieved with a zero and span adjustment

which works best when starting with an empty tank to set the zero and

then filling it to set the span. This flexible level measurement device

works well in many industrial processes and process media including

a variety of liquids, powders and pastes. The SC404 is made with

316SS rigid rods or 316SS cables (coatings are required for

conductive mediums) and can also be made with a secondary

reference rod or reference sheath built into the process connection.

The wide range of applications for RF analog level measurement

probes (such as liquids, pastes, solids and granules), requires

attention in selecting the correct configuration and installing it in the

proper location. To cater to all applications, Sitron's probes are offered

with different designs and features.

Wide range of applications/industries:

i.e. water, oils, corrosives, solids, powders, grains, etc.

Accurate and reliable measurement

No moving parts - Rugged construction

Can operate at high temperatures and pressure

Functions on conductive as well as non-conductive medias

Galvanic Isolation

Features

Introduction

Sitron-USA - Phone (516) 935-8001 / Fax (800) 516-1656

5

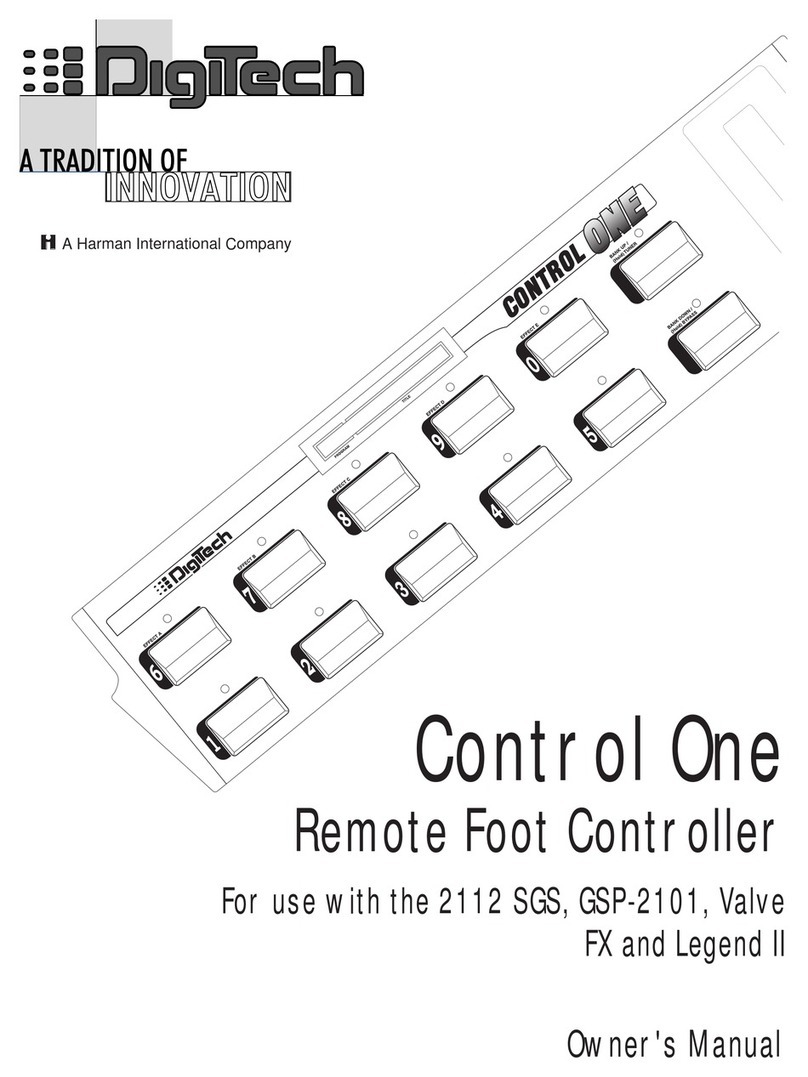

Models and Dimensions

Threaded

SC404 W/

Reference Sheath

SC404 W/

Reference Rod

SC404 w/ Cable

(also w/ reference cable)

SC404 Standard

Note: Minimal insertion for the SC404 is ½ meter

Extended necks for medium temperature (up to 120°C)

3/4”

1 ½”

1 ½”

1 ½”

2 ½”

2 ½”

1”

2”

2”

2”

3”

N1- Nylon G1-Aluminum G2 - Aluminum

1”

1,75

Tri-Clamp Flange

Housing Types

Mounting Options for SC404

Process Connections

TC Connection

ANSI 150#

ANSI 300#

Rubber Seal

Process Connection

NPT BSP FF

RF

L

20

½”

1,6

1”NPT

1”NPT

½”

½”

L

25

66

1/4”

1 1/2”NPT

L

20

50mm

126mm

130mm

130mm 118mm

89mm

76mm

89mm 80mm

SC404 with N1 Housing

0

2

0

2

Span

Zero

Gain

SC404

Sub

+_

123

1

+_

23

0

2Gain

SC404-G

On

S

Z

SC404 with G1 Housing

1- Power Supply (+)

2- Power Supply ( )

3- Ground

24Vdc / 4...20mA

C

A

D

B

A- Adjust Sensibility (Gain)

B- Adjust Sensibility (Sub gain)

C- Adjust Zero (begin scale)

D- Adjust Span (end of scale)

A

B

C

D

1- Power Supply (+)

2- Power Supply ( )

3- Ground

24Vdc / 4...20mA

A- Adjust Sensibility (Gain)

B- Adjust Sensibility (Sub gain)

C- Adjust Zero (begin scale)

D- Adjust Span (end of scale)

Sitron-USA - Phone (516) 935-8001 / Fax (800) 516-1656

0

2

Sub

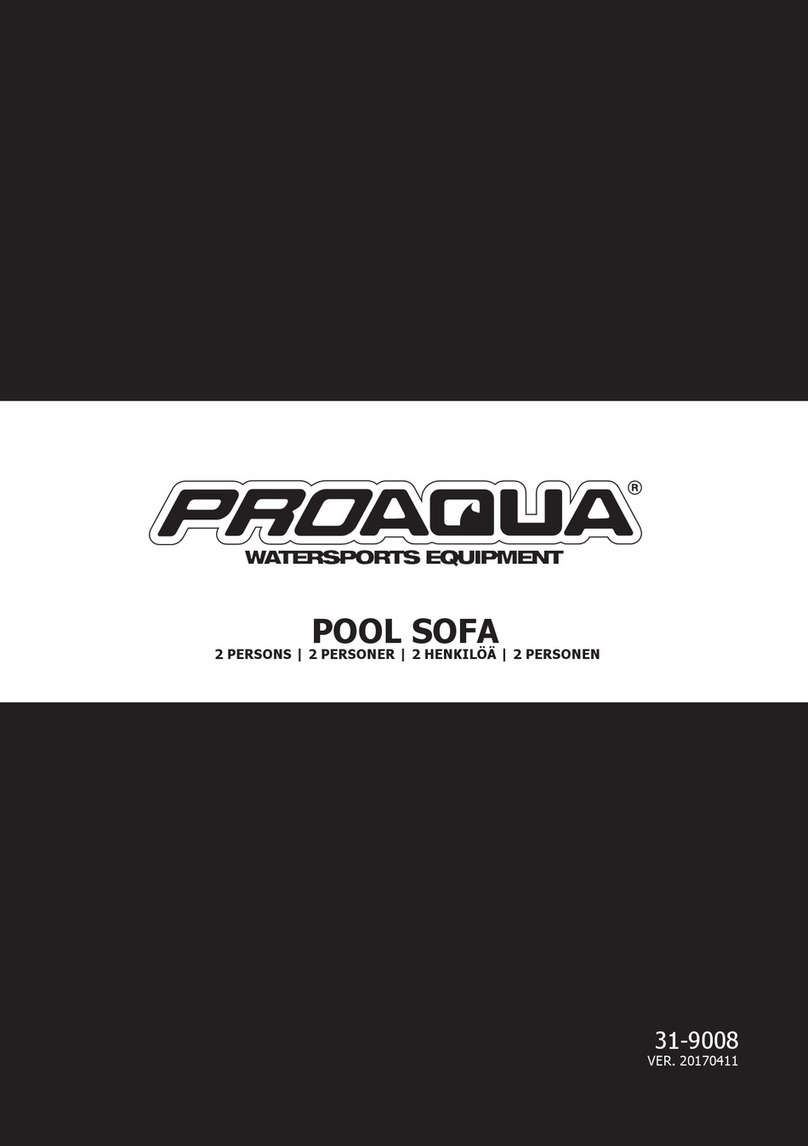

Wiring Diagram

6

SC404 with G2

A

B

C

Wiring Diagram

1

24Vdc

(+-10%)

+

4...20mA

2

-

3

D

On

Gain

0

2

Zero

Sub

0

2

Span

SC 404

7

1- Power Supply (+)

2- Power Supply ( )

3- Ground

24Vdc / 4...20mA

A- Adjust Sensibility (Gain)

B- Adjust Sensibility (Sub gain)

C- Adjust Zero (begin scale)

D- Adjust Span (end of scale)

8

Wiring Diagram

Sitron-USA - Phone (516) 935-8001 / Fax (800) 516-1656

Galvanic Isolator - ISO420

1- Probe (+)

2- Probe( )

11- Power Supply (+)

12- Power Suppy ( ) 6mm

69.8mm

DIN 35mm

111mm

83.5mm

35mm

44mm

in 24 VDC

4...20mA

4...20mA

Zone 0

out

ISO 420

11+ -12

1+ -2

L1

in _

11+

1 + 2

_

12

4...20mA

4...20mA

Zone 0

out

ISO 420

+

-

+

-N

Security Barrier ISO 420 PLC

4...20mA

Transmitter

4...20mA

9

Wiring Diagram

Electrical connection using the Galvanic Isolator for a PLC with an active input card.

Electrical connection using the Galvanic Isolator for a PLC with a passive input card.

Connecting directly into the power supply

Active PLC input card

Passive PLC input card

___

+++

PLC

___

+++

Power

Supply

4 ... 20 mA

0 ... 100 %

___

___

+++

+++

Power

Supply

PLC

+

+

+

-

-

-

Ground

Ground

Ground

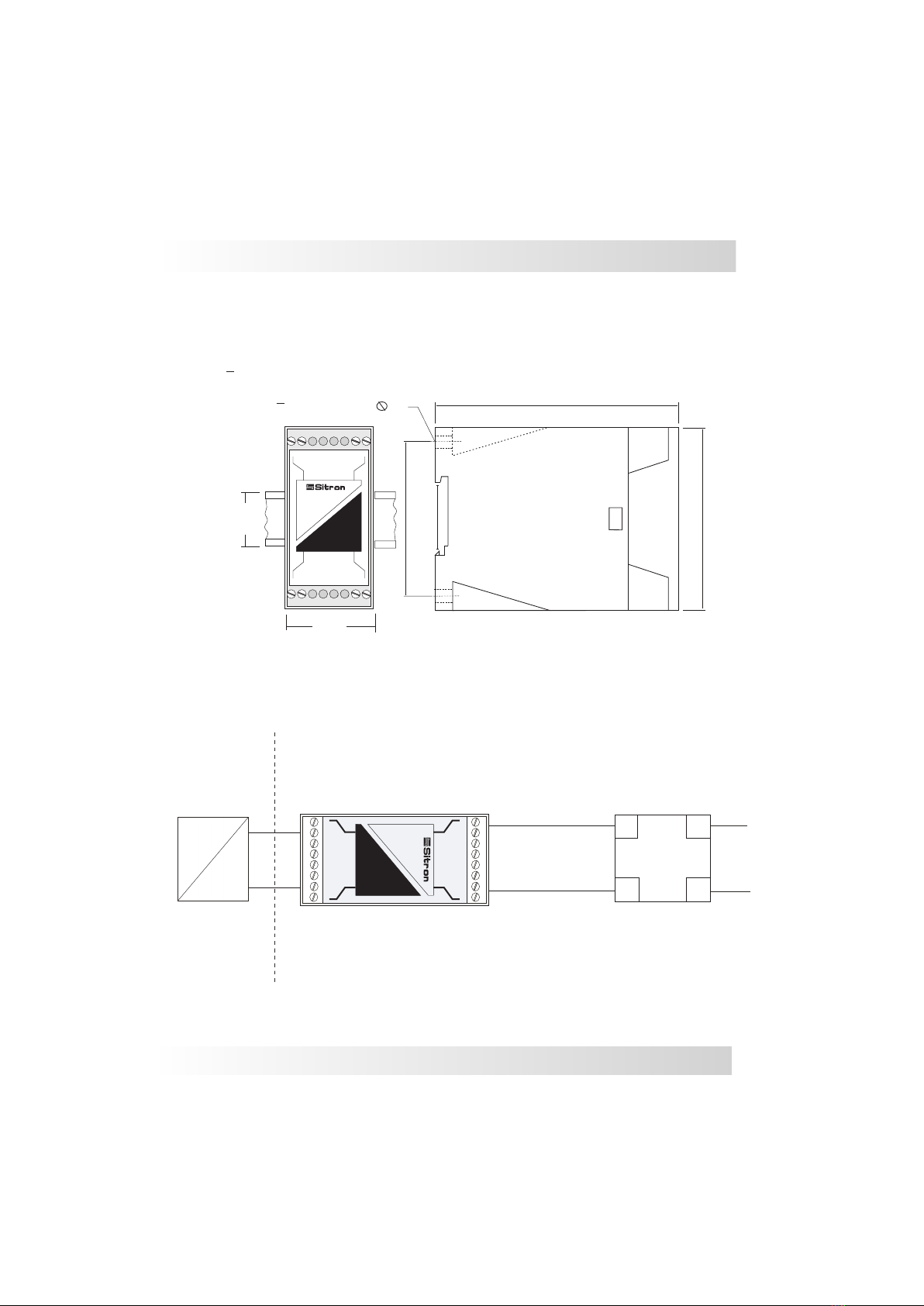

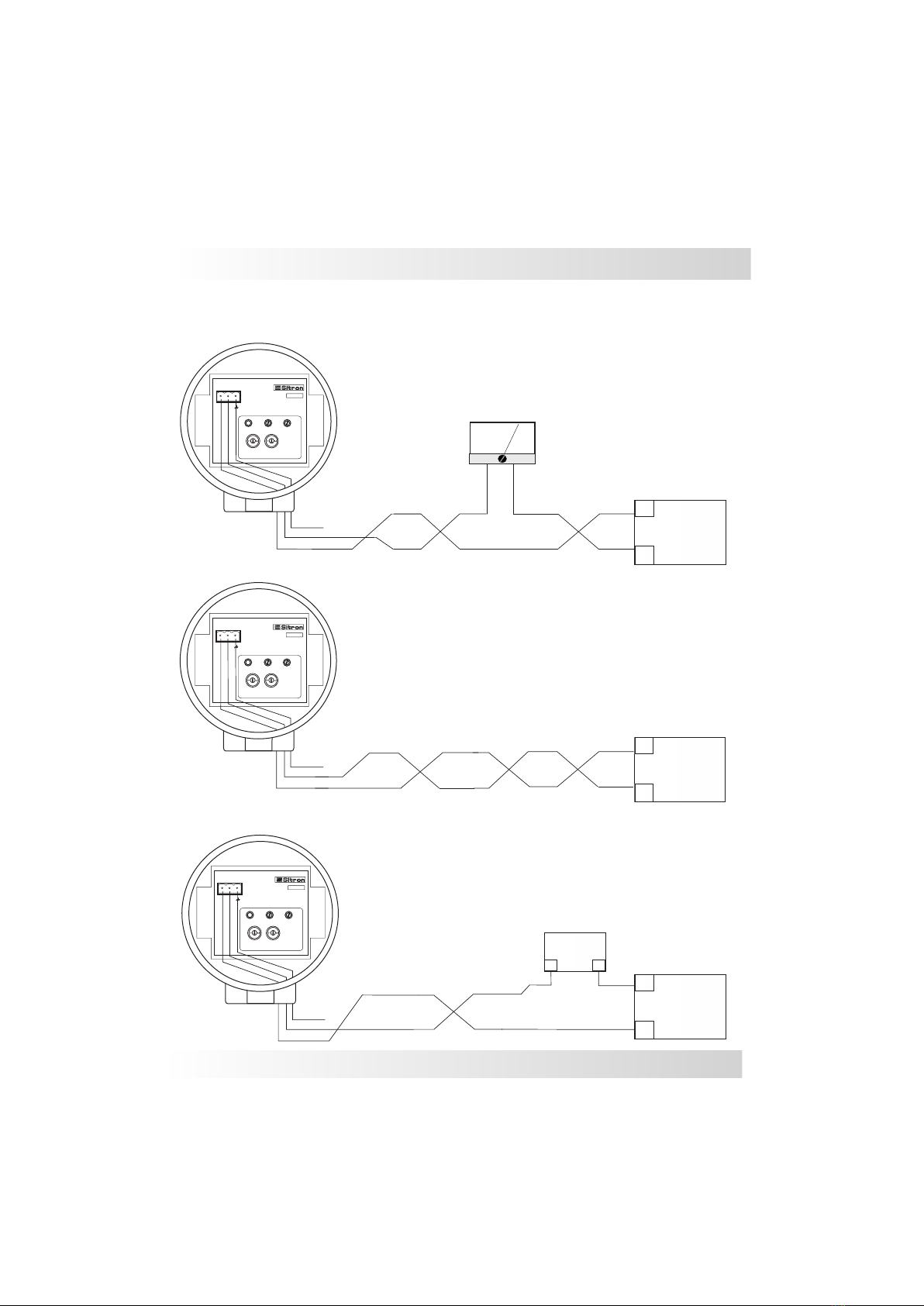

Different wiring scenarios for the N1 electronics

0

2

0

2

0

2

0

2

0

2

0

2

Span

Span

Span

Zero

Zero

Zero

Gain

Gain

Gain

SC404

SC404

SC404

Sub

Sub

Sub

10...30VDC

10...30VDC

10...30VDC

4...20mA

4...20mA

4...20mA

+

+

+

_

_

_

1

1

1

2

2

2

3

3

3

24Vdc

24Vdc (+/- 10%)

24Vdc (+/- 10%)

10

Wiring Diagram

Connecting directly into the power supply

Active PLC input card

Passive PLC input card

___

+++

PLC

___

+++

Power

Supply

4 ... 20 mA

0 ... 100 %

___

___

+++

+++

Power

Supply

PLC

Different wiring scenarios for the G1 electronics

1

+_

23

V=10...30VDC

I=4...20mA

0

2

Gain

SC404-G

On

S

Z

+

-

Ground

1

1

+

+

_

_

2

2

3

3

V=10...30VDC

V=10...30VDC

I=4...20mA

I=4...20mA

0

0

2

2

Gain

Gain

SC404-G

SC404-G

On

On

S

S

Z

Z

+

+

-

-

Ground

Ground

0

2

Sub

0

2

Sub

0

2

Sub

12...30Vdc

24Vdc (+/- 10%)

24Vdc (+/- 10%)

11

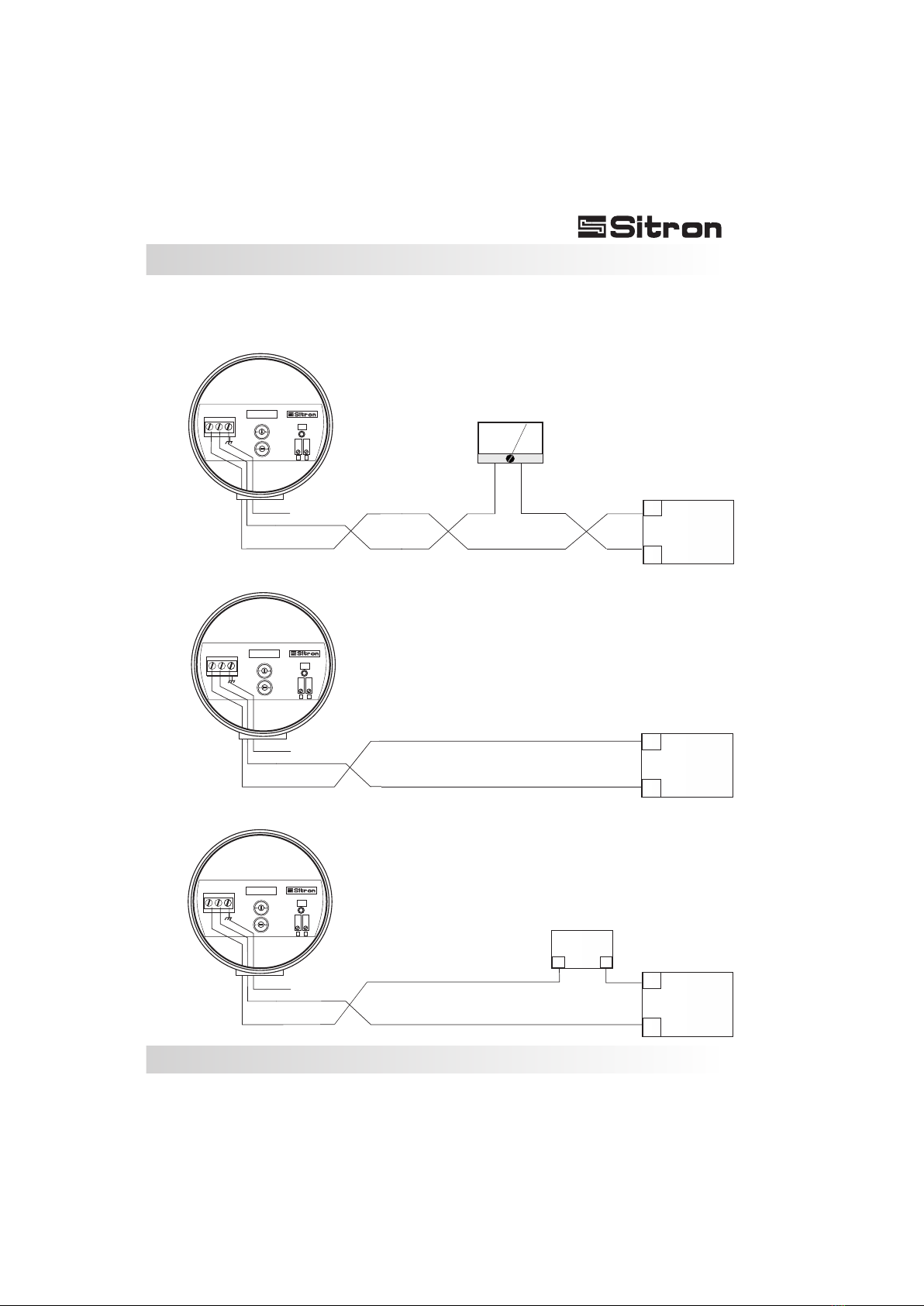

Wiring Diagram

Electrical connection for a PLC with an active input card.

Electrical connection for a PLC with a passive input card.

Connecting directly into the power supply

Active PLC input card

Passive PLC input card

___

+++

Power

Supply

4 ... 20 mA

4 ... 20 mA

4 ... 20 mA

0 ... 100 %

___

___

___

+++

+++

+++

Power

Supply

PLC

PLC

+

+

+

-

-

-

Ground

Ground

Ground

Different wiring scenarios for the G2 electronics

The G2 offers a built in galvanic isolator. In this case a separate one is not necessary.

0

0

0

2

2

2

0

0

0

2

2

2

Span

Span

Span

On

On

On

Zero

Zero

Zero

Gain

Gain

Gain

Sub

Sub

Sub

1

1

1

2

2

2

3

3

3

SC 404

SC 404

SC 404

24Vdc

24Vdc

24Vdc

(+-10%)

(+-10%)

(+-10%)

+

+

+

-

-

-

4...20mA

4...20mA

4...20mA

Sitron-USA - Phone (516) 935-8001 / Fax (800) 516-1656

24Vdc (+/- 10%)

24Vdc (+/- 10%)

24Vdc (+/- 10%)

12

Mounting Note

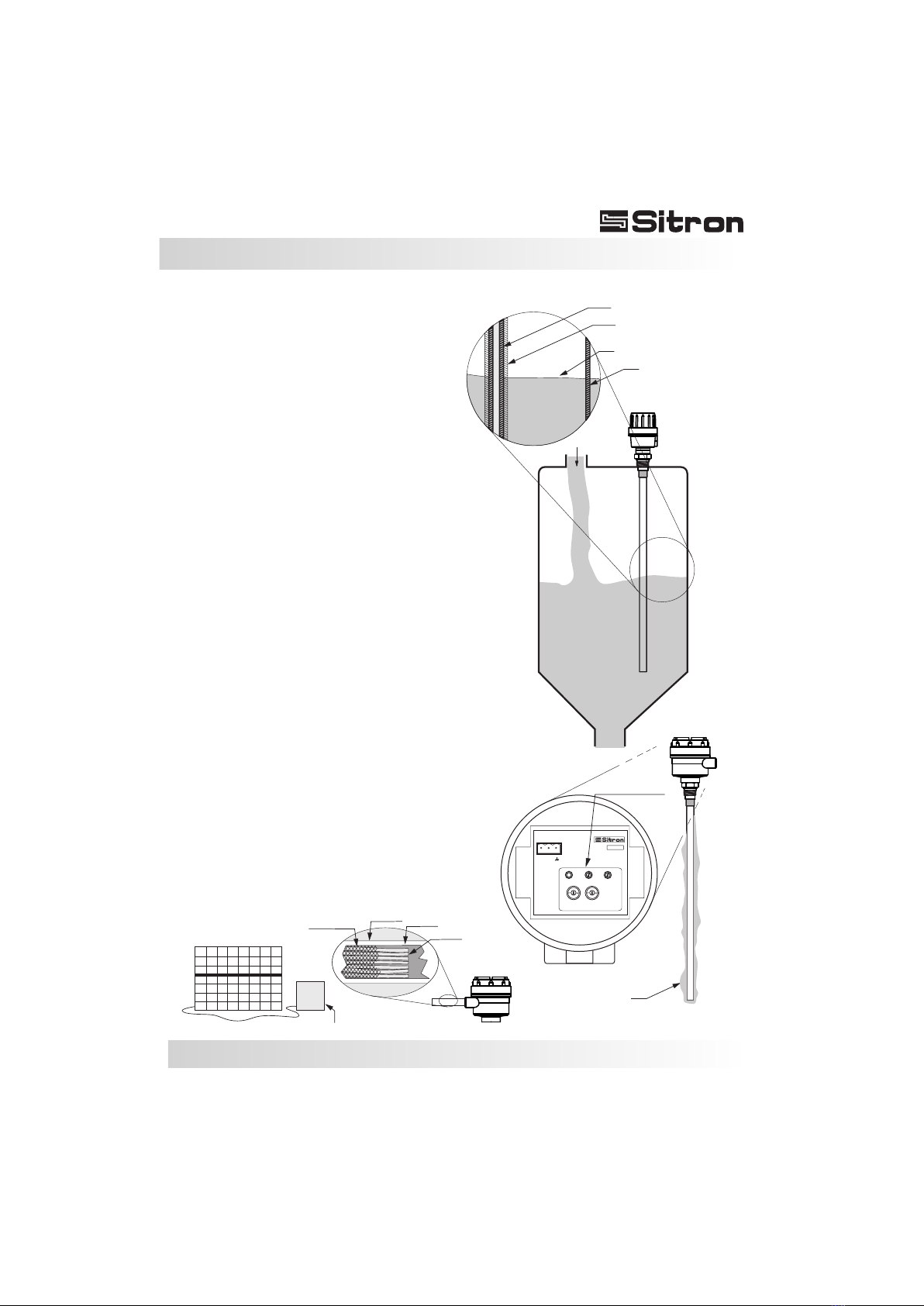

Materials that are conductive will cause a

short circuit between a bare stainless steel

probe and the tank wall. For that reason we

recommend the use of Teflon or other types

of insulating coatings on the rod's surface

(Fig. 1)

Material build-up also affects the accuracy

of RF capacitive measurements, and

therefore additional adjustment to the

probe's sensitivity is recommended in

applications where build-up is a concern

(Fig. 2)

Housings must also be compatible with the

requirements for wash-down, wet, and/or

d u s t y e n v i r o n m e n t s . H a z a r d o u s

environments may require the housing to be

certified. In addition, the active probe might

need to be intrinsically safe or have an

intrinsic safety barrier (Fig. 3).

The electronic circuitry of the probe

performs several functions such as

rectifying and filtering the incoming power,

generating the radio frequency signal,

measuring the changes in current flow,

analog signal generators and display

meters. The circuitry is provided with

potentiometer adjustments for setting

sensitivity that is located in the housing of

the probe. These adjustments give an

added level of fine-tuning which enable our

customers to control the probe's sensitivity

with greater accuracy (Fig. 3).

Variation in current input (power supply) to

the probe will affect the output. Therefore, a

stable power supply should be available

(Fig. 4).

Coating (PTFE or Halar)

Bare Rod

Fig. 1

Fig. 2

Fig. 4

Fig. 3

Steel Tank

Conductive Medium

Adjust Sensitivity

Build up

Power Supply Conduit

Conduit Cable

Wires

Wire Shield

0

2

0

2

Span

On Zero

Gain Sub

123

SC 404

24Vdc

(+-10%)

+

-

4...20mA

13

Sitron - Equip. Eletrônicos Ltda. - Fone/Fax (5511) 3825-2111 / 3825-2171

500mm

100mm

Fig. 2

Fig. 1

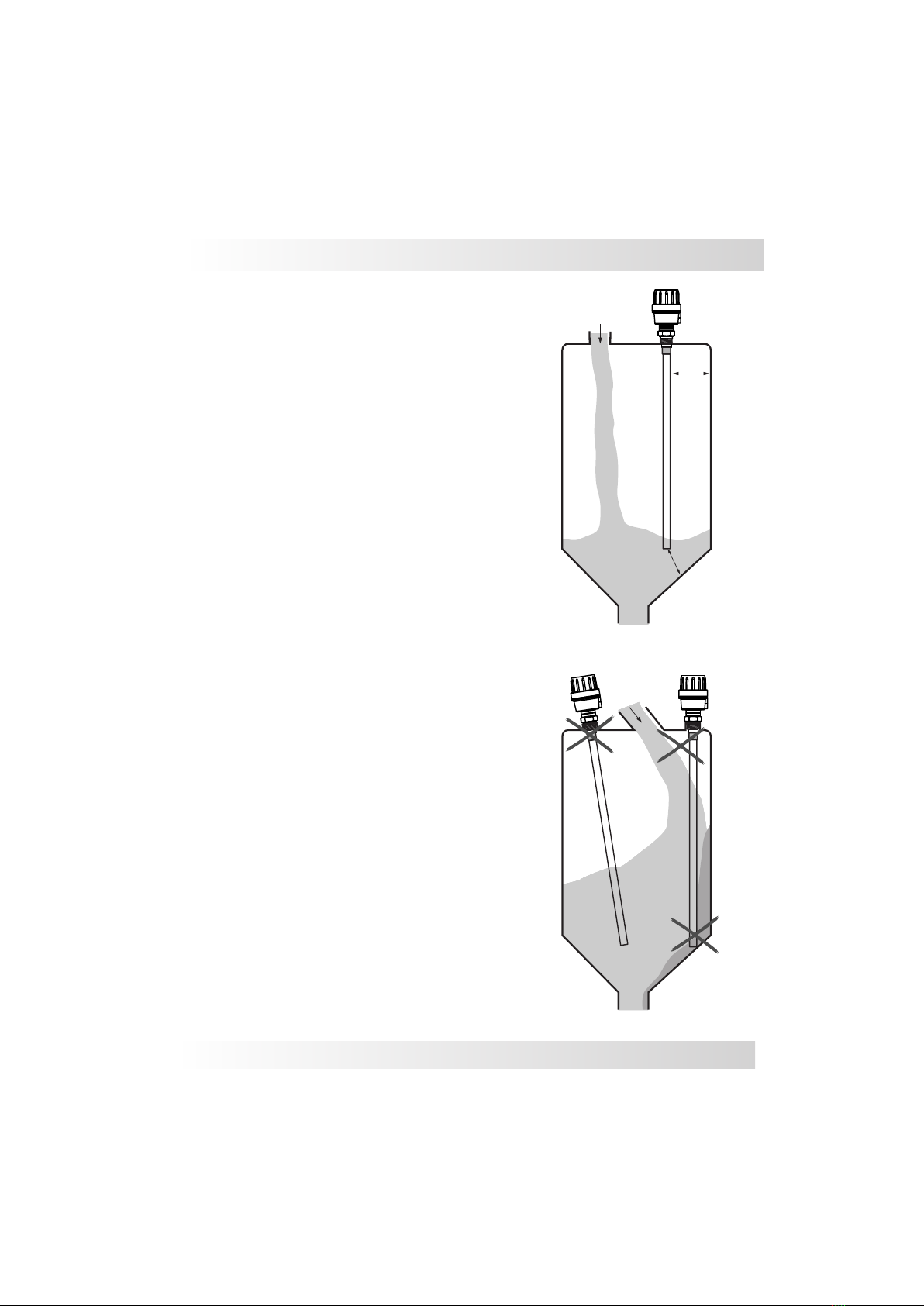

When installing the probe either directly to the

tank, or utilizing a connection, the capacitance

probe should be mounted on the top of the tank,

never on the side or angle, so that the rod stays

parallel to the tank wall (Fig. 1 correct Fig. 2

Incorrect).

The mounting location of the probe should stay

clear away from the point where the medium

enters, this will avoid false reading from the sensor

while being filled (Fig. 1 correct Fig. 2 Incorrect).

The recommended distance of installation of the

probe from the internal wall is a minimum of

500mm, and from the tip of the rod to the bottom of

the tank is 100mm, this will prevent a false signal

and possible build up between the wall and probe

(Fig. 1 correct Fig. 2 Incorrect).

Installation

14

The tank must be free from turbulence or

vortices throughout use. If this is not

possible we highly recommend a stilling

well or sheath (Fig. 1 correct, Fig. 2

incorrect).

Ensure that mounting position does not

interfere with any obstructions wthin the

vessel or tank (Fig. 1 correct, Fig. 2

incorrect).

Fig. 1

Fig. 2

Level

Rod

Sheath

Installation

Sitron-USA - Phone (516) 935-8001 / Fax (800) 516-1656

Installation

When installing the SC404 with cable and

reference be sure that they are well connected

to the bottom of the tank and that it has no slack.

(Fig. 1 correct Fig. 2 Incorrect).

The mounting location of the probe should stay

clear away from the point where the medium

enters, this will avoid false reading from the

sensor while being filled (Fig. 1 correct Fig. 2

Incorrect).

The recommended distance of installation of

the probe from the internal wall is a minimum of

500mm, and from the tip of the pendulum to the

bottom of the tank is 100mm, this will prevent a

false signal and possible build up between the

wall and probe (Fig. 1 correct Fig. 2 Incorrect).

If the cable is secure to the bottom of the vessel

it must be isolated and the vessel is steel it must

be isolated so that it does not create a short

circuit.

Fig. 1

Fig. 2

500mm

100mm

Isolator

15

Installation

Fig. 2

Fig. 1

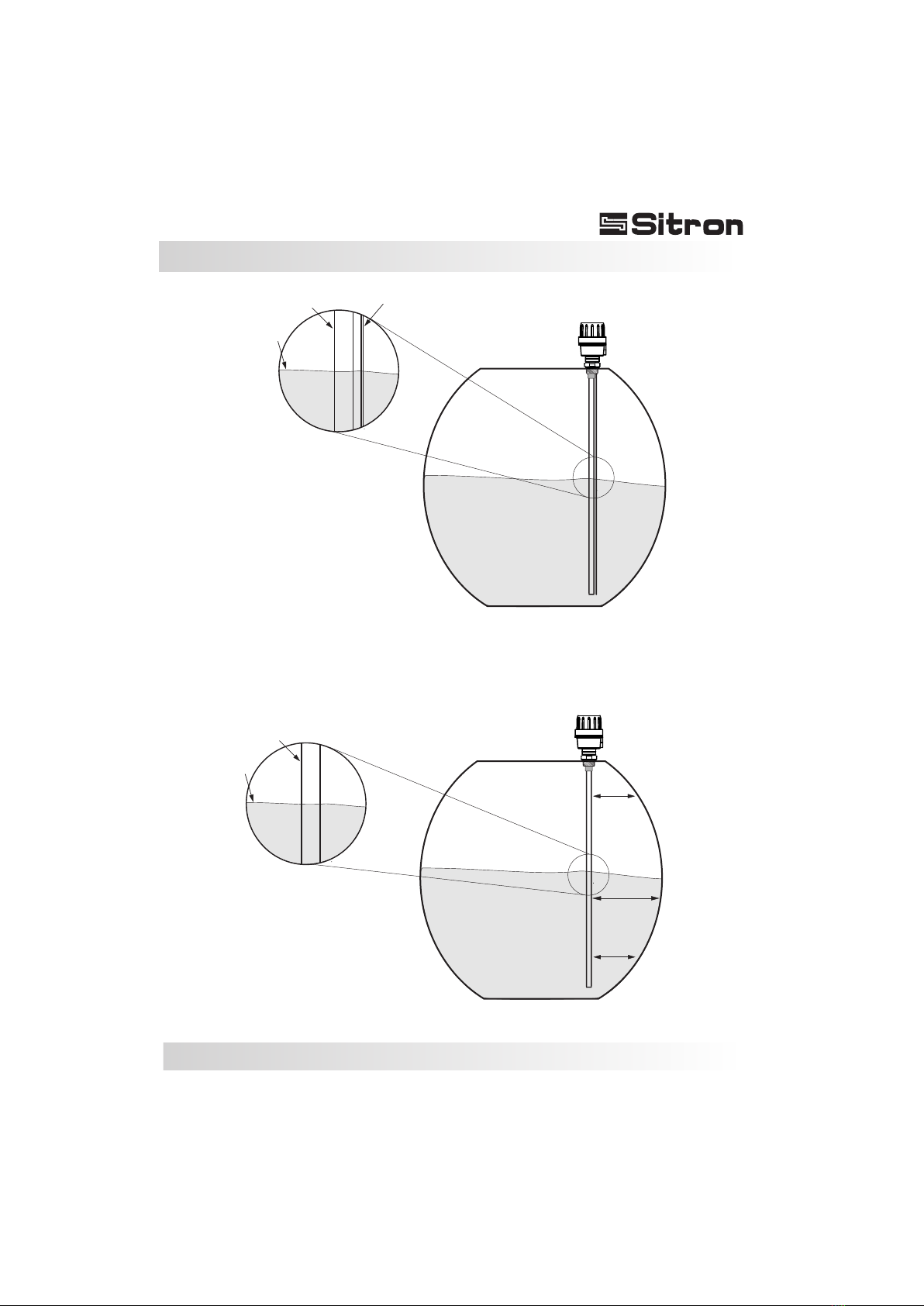

In order to achieve a linear output

signal, the main rod of the probe

must have a parallel reference

either to the tank or to a

secondary reference rod or

sheath. If the probe is mounted

without this parallel reference

within a cylindrical tank that is

mounted on its side, the output

signal will not be linear. Please

consult one of our applications

engineers if you have further

questions (Fig.1 correct Fig. 2

incorrect).

L=y

L=z

L=x

Level

Level

Rod

Single Rod

Reference Rod

16

Sitron-USA - Phone (516) 935-8001 / Fax (800) 516-1656

Calibration

8) With the 20mA signal adjusted it is best to re-

adjust the Zero. Drain the tank back down to the

starting level and re-adjust (if necessary) the

minimum level to 4mA one more time. After this

stage, set-up is complete.

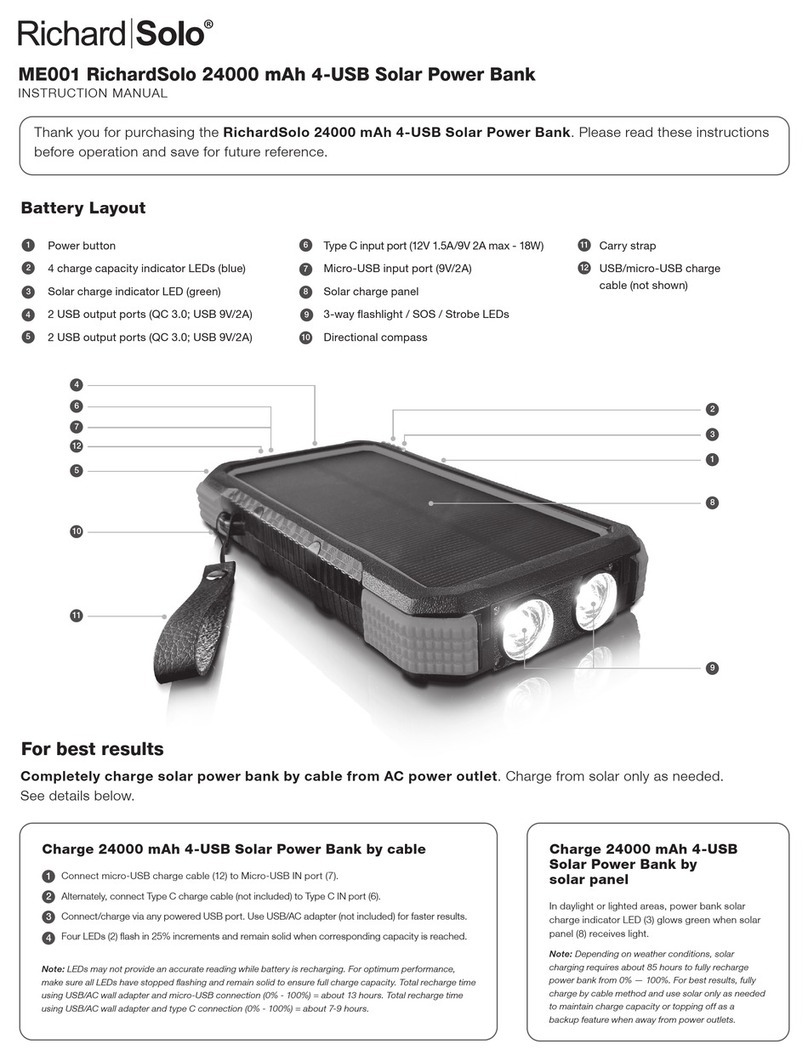

Adjustment (4-20mA):

It is recommended that an multimeter be connected

according to the figure below (fig.5) to monitor the

current value during the calibration.

1) Drain the tank to minimum level (Zero% or 4mA).

2) Select the Gain switch 1,2,3 and Sub positions

1,2 or 3. It is recommended to begin with Gain switch

1 and Sub position 1 (Fig. 2).

3) Use the Zero potentiometer to set the current

value for the actual level to 4mA. Turn the

potentiometer clockwise to increase current. Turn

the potentiometer counter-clockwise to decrease

current (If the adjustment wasn't possible, alter the

Sub and Gain position and try in adjust the minimum

value (4mA) through the Zero Potentiometer)(Fig.3)

4) After calibrating the minimum value (4mA), fill up

the tank to maximum level (100% - level).

5) The Sub and Gain switches should be in the same

position as adjusted to 4mA.

6) Use the Span potentiometer to set the current

value for the actual level to 20mA. Turn the

potentiometer clockwise to increase current. Turn

the potentiometer counter-clockwise to decrease

current (Fig.4).

7) If the current is lower than 20mA after fully turning

the Span Potentiometer clockwise, it is necessary to

increase the sensitivity by selecting the next level of

the switch (Sub and Gain). If the current still remains

lower than 20mA, continue on to the next level until

you achieve 20mA.

0

0

0

0

2

2

2

2

0

0

0

0

2

2

2

2

Span

Span

Span

Span

On

On

On

On

Zero

Zero

Zero

Zero

Gain

Gain

Gain

Gain

Sub

Sub

Sub

Sub

Fig.2

Fig.3

Fig.4

Fig.5

17

Nylon-N1

Aluminum-G1

Aluminum-G2

0

2

0

2

Span

On Zero

Gain Sub

123

SC 404

24Vdc

(+-10%)

+

-

4...20mA

0

2

0

2

Span

Zero

Gain

SC404

Sub

10...30VDC

4...20mA

+_

123

1

+_

23

V=10...30VDC

I=4...20mA

0

2

Gain

SC404-G

On

S

Z

0

2Gain

0

2

0

2

Zero

Gain

SC404

Sub

+_

123

0

2

On Zero

Gain Sub

0

2

Calibration

The dielectric value varies according to

the product, temperature, pressure,

rod's length and shape of the tank.

Because of these variations, the

parameters of the capacitive probe need

to be adjusted according to each

application as well as each tank. While

the SC404 can be tested on a bench, the

results of calibrating it will not be the

same as calibrating the unit within the

actual tank that you plan on installing it in.

The SC 404 has 3 stages of sensitivity

and that can be adjusted by a selective

switch. Each stage has 3 subdivisions

(1, 2, 3) for the SC404 and 4 subdivisions

(1, 2, 3, 4) for the SC404-G to be

combined with the selective switch.

Check the values on the chart below

according to your application.

Capacitive Range for the SC404-G:

Gain Sub

1) 1600pF to 5500pF 1 - 3750 to 5500pF

2 - 2500 to 3750pF

3 - 1600 to 2500pF

2) 400pF to 1500pF 1 - 900 to 1500pF

2 - 600 to 900pF

3 - 400 to 600pF

3) 100pF to 330pF 1 - 225 to 330pF

2 -150 to 225pF

3 -100 to 150pF

4) 25pF to 150pF 1 - 150 to 100pF

2 -100 to 70pF

3 - 70 to 25pF

0

2

Sub

0

2

Sub

18

19

Sitron-USA - Phone (516) 935-8001 / Fax (800) 516-1656

Handling

Probes:

Care should be taken when handling and installing

probes with coated rods to avoid scratching them.

Scratching the coating could interfere with the

probe performance.

Periodic visual inspection of the probe is required

to check for corrosion or deposit build-up. If

deposits are found, clean the sensor to ensure

optimum performance.

The probe should not be dropped or suffer any

impact or fall that could damage the electronics or

the coating of the probe (Fig. 4 and 5).

Seal the thread with Teflon tape before

installation (Fig. 1).

Do not turn or handle by the housing (Fig. 2).

When tightening the sensor, use only use the

316S.S. hexagon fitting to achieve a seal, do not

twist with the body of the sensor. (Fig. 3)

When cleaning the rod use a soft brush or any

other similar object.

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 1

20

Technical Specifications

Sitron-USA - Phone (516) 935-8001 / Fax (800) 516-1656

SC404

22mA max

24Vdc (+/- 10%)

Application

Operating Voltage

Current Consumption

Electrical Connection

Ambient / Operating temp.

Cable gland - 1/2” NPT conduit entry or M12 connector

Output

Max Pressure

IP 65 (N1)

IP66 (G1/G2)

Accuracy

Enclosure Material Glass filled nylon, Aluminum

Wetted Parts 316 Stainless Steel, PTFE

Class Protection

Process Connection

Adjustment

Sensitivity Range

Frequency Oscillation

Zero & Span Potentiometer

4...20mA (2 wires)

100 to 5500pF

400 kHz

Continuous Level Measurement for Liquids and Solids

290 PSI (20 Bar)

0.5%

3/4” to 1 1/2” BSP or NPT Flange or Sanitary Connections

-10 to 60ºC / -10 to 80°C (120°C extended neck)

G2G1N1

Galvanic Isolation 3KVdc/60s

100M ohms, 500VDC

21

Trouble Shooting

No signal

Signal over

22mA

Signal under

20mA

Lack of linearity

Probable short circuit

Sensitivity to high

Sensitivity to low

Reference is incorrect

Add a Reference

Sheath the rod

Coating on the rod

is damaged Send back for repair

Lack of signal from

referance rod

Signal Fluctuating

No power supply

Verify the grounding

Verify that the rod is coated for

conductive mediums

Adjust sensibility again

Adjust sensibility again

Verify power supply

Fault Cause Solution

Verify the polarity of the power supply

Inadaquate connection

Sitron-USA - Phone (516) 935-8001 / Fax (800) 516-1656

Table of contents

Popular Accessories manuals by other brands

Equalizer

Equalizer Livewire LFT412 user guide

Silvercrest

Silvercrest SPS 5000 A1 operating instructions

Silvercrest

Silvercrest SPB 10000 A1 operating instructions

Heath Zenith

Heath Zenith Notifi Elite owner's manual

Alarmcom

Alarmcom Flex IO installation guide

Heath Zenith

Heath Zenith 6106 installation guide