SJ MSLG200 Operating and maintenance instructions

Temperature sensor/ transmitter shall be installed by professional

engineers, technicians and other qualified personnel, please read

carefully the content and important information provided by this

installation guide and label before installation.

Temperature sensor / transmitter is powered by an external

power supply, the power supply should be in accordance with

relevant standards stipulated by energy limitation circuit, and pay

attention to the high-voltage that may exist in the circuit.

Using temperature sensor/transmitter in dangerous situations,

product installation, using and maintenance should comply with

installation guide and relevant provisions of national standards.

Attention please! Disassemble the instruments under the

condition of normal atmospheric pressure only.

Safety Precautions

Product Usage

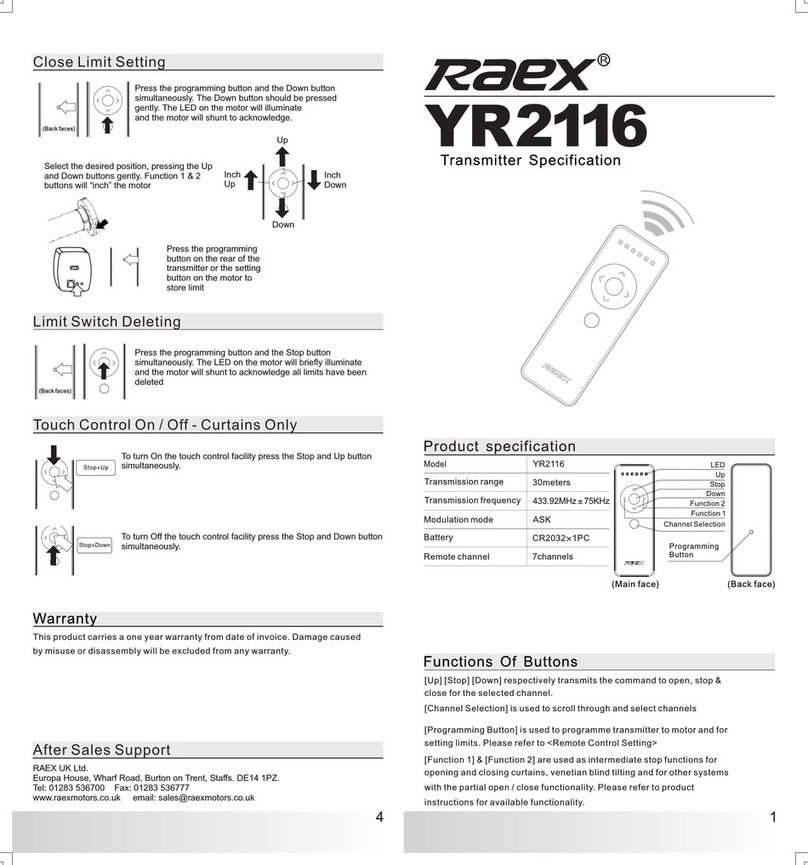

Horizontal pipe installation

Bending pipe installation

Install at top of container

To ensure measurement accuracy, the influence of medium flow

direction, wall thickness and outer shape of protection tube, insertion

depth, as well as pipe material, heat insulation material of container

insulation layer should be considered when install temperature

sensor/ transmitter.

!

!

!

Direct installation

Process connection

Welding

Holing on the pipeline according to

the protection tube outer diameter.

Insert appropriate length when welding.

Straight thread

L1

L2

L1

L2

Adopting gaskets roots sealing,

the thread length should be less than

the base length(L1<L2); adopting

gaskets end face sealing, the thread

length should be more than the base

length(L1<L2)

Movable thread

Matched movable thread can

realize insertion length adjustment and

low-intensity seal.

Tri-clamp

Usually choosing gaskets with

material of PTFE, silicon rubber and

FKM which conform to hygienic

standards

Flange

Choosing gaskets according to

medium features and temperature range

and lock evenly.

Taper thread

Sealing with teflon tape or sealant

glue. When thread lock hard, there is a

small part of space

!Hygienic process connection Tri-clamp is approved by 3-A

hygienic certificate.

The gaskets of tri-clamp and all the wetted parts comform

with FDA standards.

@

!

ExdIICT6 GYB16.1606x

When using a spanner to screw

hexagon bolt, the maximum torque force

can not exceed 50Nm.

!

Label

MN:MSLG200-WRT-R1-T1R3-FC-Q2-G6M01-D2L0500

SN:1605-086-018-2-C1236

IN:20~- 100

OUT:4~20mA

ACC:0.5%

SUPPL

SIN JIA ENTERPRISE CO., LTD.

Y:24VDC

Φ=8mm

L-500mm

temperature transmitter 2016/05/ 2 6

1/:+

2/:-

3

4

1

2

3

4

5

1

2

5

Measuring range

Power supply

Signal outline type

Explosion proof mark

Certificate

i Important information

74-06

The axis of protection tube and vertical

pipeline should be consistent. Contact

media reversely and the insertion length

should be half of the pipe diameter at

least.

!Angle of inclination: 45- 90°

The protection tube should be inserted

with enough length to avoid error

caused by temperature stratification.

Install at side of container

The protection tube should be inserted

with enough length to avoid error

caused by contacting the wall of

container.

Protection tube should contact media

obliquely and reversely, the insertion

depth should be half of the pipe

diameter at least.

Light-weight pressure transmitter

can be mounted directly on the

pressure leading tube. Bracket is not

needed.

Temperature transmitter / Quick installation manual

2022.12

74-06

SIN JIA ENTERPRISE COMPANY LIMITED Tel: +886-2-2550-4512 Email: [email protected] Website: www.sj-gauge.com

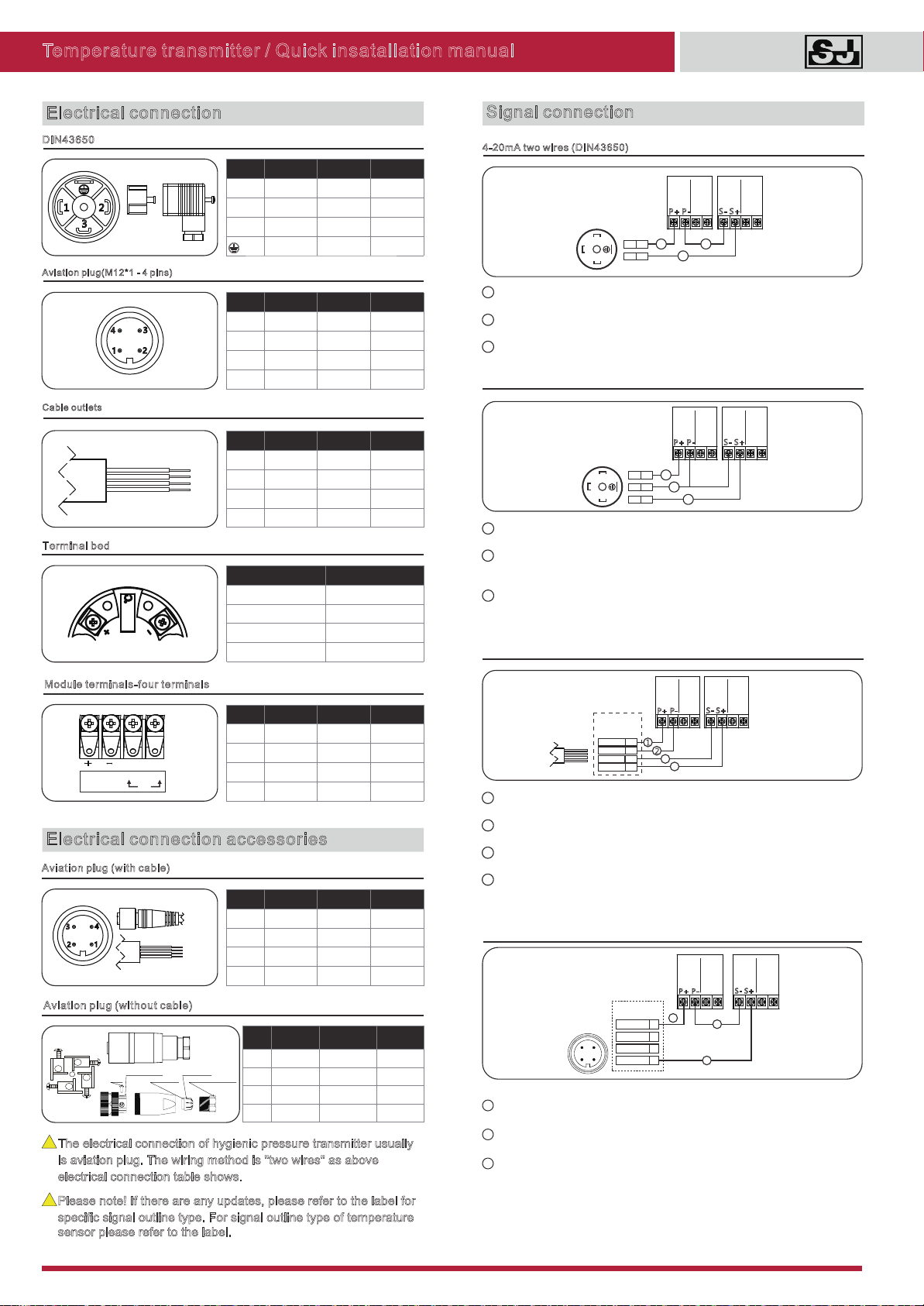

Electrical connection

DIN43650

Aviation plug(M12*1 - 4 pins)

Terminal bed

Module terminals-four terminals

1 2

Cable outlets

Red

Black

Blue

Yellow

4

1

3

2

AB

+ -

AB+ -

A

Lable Two wires

1Power+

2Power-

Aviation plug (with cable)

Brown

Black

Blue

White

3

2

4

1

Electrical connection accessories

!

The electrical connection of hygienic pressure transmitter usually

is aviation plug. The wiring method is "two wires" as above

electrical connection table shows.

Aviation plug (without cable)

Label

Two

wires

Three wires

F

our wires

1Power+ Power+

P

ower+

2

Signal-

3

Signal+

Signal+

4Power- Power-

P

ower-

!

Please note! If there are any updates, please refer to the label for

specific signal outline type. For signal outline type of temperature

sensor please refer to the label.

Signal connection

4-20mA two wires (DIN43650)

1 Connect the positive power supply (P+) to the positive power supply (P+) of

temperature transmitter (terminals 1);

2 Connect the negative power supply (P-) of temperature transmitter (terminals 2) to

the positive signal module (S+);

3 Connect the negative signal module (S-) to the negative power supply (P-)

+

-

P+ P- S- S+

1

2

1

2

31

2

3

L

abel Two wires Three wires

F

our wires

1

Power

+

Power

+

Power+

2

Power- Power-

Power-

3

Signal

+

Signal+

S

ignal-

Label

Two wires

Three wires

Four wires

1

Power+Power+

P

ower+

2

S

ignal-

3

Signal

+

Signal+

4

Power-

Power-

P

ower-

Label

Two

wires

Three

wires

Four

wires

R

ed Power+Power+

P

ower+

Black

Power-

Power-

Power-

B

lue Signal+

Signal+

Yellow

Signal-

Label

Two wires

Three wires

Four wires

+

Power+Power+

P

ower+

-

Power-

Power-

Power-

A

Signal+

Signal+

B

S

ignal-

Label

Two wires

Three wires

Four wires

1

/Brown Power+Power+

P

ower+

2/White

Signal-

3

/Blue Signal+

Signal+

4/Black

Power-

Power-

Power-

1

2

3

compression bolt

clamp ring

rubber ring

screw

block terminal

4

Block terminal

rewoP

langiS

Three wires current/voltage signal (DIN43650)

+

-

P+ P- S- S+

S+

1

2

3

1

2

3

1

2

3

1 Connect the positive power supply (P+) to the positive power supply (P+) of

temperature transmitter (terminals 1);

2 Connect the negative power supply (P-) of temperature transmitter (terminals 2) to

the negative power supply (P-), and connect the negative signal module (S-) to

negative power supply (P-);

3 Connect the positive signal module (S+) of temperature transmitter (terminals 3)

to the positive signal module (S+);

Four wires, current/voltage signal (cable)

+

-

P+ P- S- S+

S+

S-

Red

Black

Yellow

Blue

34

1 Connect the positive power supply (P+) to the positive power supply (P+) of

temperature transmitter (red wire);

2 Connect the negative power supply (P-) of temperature transmitter (black wire) to

the negative power supply (P-)

3 Connect the negative signal module (S-) of temperature transmitter (Yellow wire)

to the negative signal module (S-);

4 Connect the positive signal module(S+) of temperature transmitter (blue wire) to

the positive signal module (S+).

Label

4-20mA two wires (aviation plug with cable)

1 Connect the positive power supply (P+) to the positive power supply (P+) of

temperature transmitter (terminals 1/brown wire);

2 Connect the negative power supply (P-) of temperature transmitter

(terminals 4/black wire) to the positive signal module (S+);

3 Connect the negative signal module (S-) to the negative power supply (P-)

+

-

P+ P- S- S+

13

4

3

212

Label

Blue/3

Brown/1

White/2

Black/4

Temperature transmitter / Quick insatallation manual

2022.12 SIN JIA ENTERPRISE COMPANY LIMITED Tel: +886-2-2550-4512 Email: [email protected] Website: www.sj-gauge.com

rewoP

langiS

rewoP

langiS

rewoP

langiS

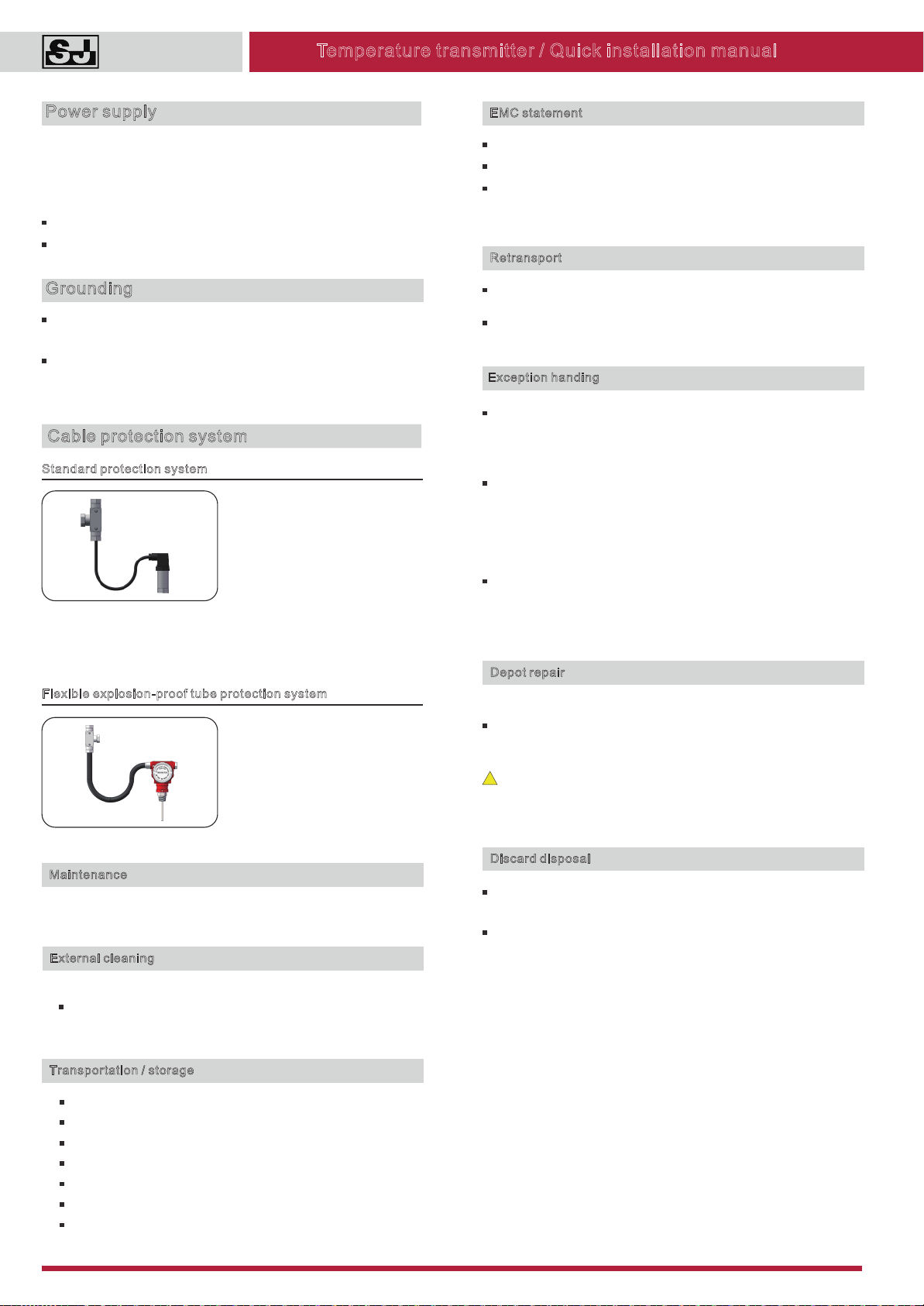

Standard protection system

Flexible explosion-proof tube protection system

Cable protection system

In order to avoid the liquid flowing

along with the cable to flow into the

terminal box or result in waterproof

joint effusion, an U-shaped ring

needs to be configured between

pull box and temperature

transmitter as the picture shows,

and please ensure the U-shaped

bottom is under the temperature

transmitter. Considering the

maintenance and replacement,

enough cable length needs to be

Using flame proof temperature

transmitter in dangerous situations,

please use metal flexible explosion-

proof tube to connect the signal

cable into pull box and lead to the

safety zone.

Maintenance

Requires no maintenance

External cleaning

Please notice the following when cleaning:

Use washing agent which will not damage to the instruments

surface and seal ring.

Transportation / storage

Do not store at outside

Keep dry and dust-free

Do not expose to the corrosive medium

Avoid solar radiation

Avoid mechanical shock and vibration

Storage temperature: -40~100°C

Maximum relative humidity: 95%

EMC statement

EMC equipment instructions 2014/30/EU.

CE mark suggests the instruments are in line with EU standards

Users need to ensure the whole equipment conform to all the

applicable standards.

Depot repair

Please finish the following steps before the depot repair:

Removal of all the residues which would be harmful to human

health, such as inflammable, poisonous, cancerigenic and

radioactive substances.

Warning! Do not return the instruments if can not ensure the

dangerous residues are removed, eg: the dangerous residues

permeate into cracks or spread to the plastic.

!

Discard disposal

The instrument is not restrained of WEEE instruction 2002/96/EG

and laws of relevant countries.

Please pass the instrument to specialized recycling companies

other than local recycling points.

Retransport

Keep clean of the temperature transmitter. Stay away from any

Please adopt proper package to avoid damage in transportation.

dangerous medium!

Power supply

Independent linear direct-current power supply is suggested to be adopted for

the power supply of temperature transmitter, over large resistive load will result

in a large pressure drop, so it requires to calculate the all-in resistance of

signal cable, display meter and other record and display equipment, to ensure

the voltage provided to the temperature transmitter accord with normal

operating requirements.

Standard current signal output: 12-30VDC,

1~5VDC voltage output: 12-30VDC.

Grounding

Using cable with shielded twisted-pair signal has the best effect. To avoid

ground loop, shielded layer adopts single-end grounded.

Transient resistance built-in module is effective only in the case of good

grounding. Metal shell and internal grounding terminals are used to the nearest

Measurement signal is abnormal which should judge the process pressure is

abnormal, measuring system error or influence of installation environment or

abnormal in the pressure transmitter, then analyze the reason and take

corresponding measures.

No signal output, process pressure changes but no measurement

corresponding change, or , it may be an abnormalchange does not correspond

pressure transmitter, it needs to check the power supply voltage, wiring, power

consumption and load resistance whether they meet normal operating

requirements. Also need to check if there is leaks and pressure impulse line

blockage, shut-off valve not turned on, etc.

Signal output error is too big or it exceeds need to checkthe normal range,

the power supply voltage, power consumption and load resistance whether

they meet normal operating requirements, the measuring range setting, if

adjustment is correct. Also need to check if there is leaks and pressure impulse

line blockage, shut-off valve not turned on, rapid temperature fluctuations, etc.

Exception handing

Temperature transmitter / Quick installation manual

2022.12 SIN JIA ENTERPRISE COMPANY LIMITED Tel: +886-2-2550-4512 Email: [email protected] Website: www.sj-gauge.com

Popular Transmitter manuals by other brands

Teledyne

Teledyne 300P operating instructions

EMX Industries

EMX Industries WEL-200K operating instructions

Endress+Hauser

Endress+Hauser RMA 422 operating instructions

Sennheiser

Sennheiser TV Clear Transmitter 2 instruction manual

Novus

Novus NP600 instruction manual

American Fibertek

American Fibertek MT-1890 instruction manual