Choose carefully capacity (in liters) of the water boiler. At lowered capacity in liters, the

water can boil and at elevated water does not reach the desired temperature. Before

purchasing the boiler think over the number of consumers and volume of consumption of

hot water. When calculating the engine capacity of the boiler it is necessary to consider

that average per person daily consumption, considering taking a shower is about 30-50

liters of hot water.Aseller or a company representative will help you to choose appropriate

displacement of boiler. For more information please visit our homepage www.skamet.ee.

Dear customer.

You have purchased a quality water boiler, which will delight you for many years. This

installation and operation manual was compiled in order to provide you more information.

Initially, check that delivered to you boiler has not been damaged. At detection of

damages during the shipping, contact the shipping company who delivered water boiler,

or consult with the seller who sold you the boiler.

Functionality

The manufacturer conrms that the boilers meet the requirements of the CE marking, and

their production complies with EN 15332:2007. The boilers are intended to heat water

from the external heat source. Boilers of ferrous metal are not intended as a source of

drinking water. Have also to be considered that the water can be rusty hue in the boilers

of ferrous metal. The manufacturer is not responsible for unauthorized changes made

by user of the boiler, and is not responsible for damages resulting from such actions.

Scheduled maintenance required for normal operation, is also a part of functionality.

General information

In summer time the use of central heating system for heating the water is impractical and

inefcient, since consumption of energy and fuel, and wear of equipment unreasonably

overvalued compared to winter time, when the total volume of heated water is

incomparably larger. Manufactured by us boilers connect to any water heating systems

(stoves, cookers, sauna stoves, etc.)

Standard boilers are volumetric and water heats thro the so-called natural circulation

through water heating exchanger when during the operation of the heater the circulation

of water occurs (hot water rises up and cold presses down). Besides the standard boiler

we also produce the two-system boilers: the two-body or with register (coil).

A pipe connection for connecting a tubular electric heating element (an electric

heater) can be ordered for installation on our boilers. To use an external heat source

for permanent year-round hot water consumption is reasonably and quite economical.

Even when stoking ovens, cookers, etc. the preheated water enters into the boiler and

electric heater switches off and water heating occurs from the heat exchanger. At the

termination of the stoking the water heating comes from an external source of electricity

(an electric heater). All of the boilers are necessary to be earthed. When should I install

an external heat source? The answer is simple: when there is not enough of hot water.

GB A lot of consumers due to summer outages remain without hot water. Also in old houses,

where hot water did not exist at all. For efcient use of hot water boiler the installation of

it is necessary to make as close as possible to the place of consumption. For horizontal

boilers - this distance is not more than 120 cm from the heat source, for vertical boilers

- ranging from 180 cm. Hot water should reach the faucet maximum after four seconds.

Between consumption and boiler in pipes remains hot water, which eventually cools,

so the closer boiler is to the place of consumption of hot water, the less are the losses.

The information about standard boilers

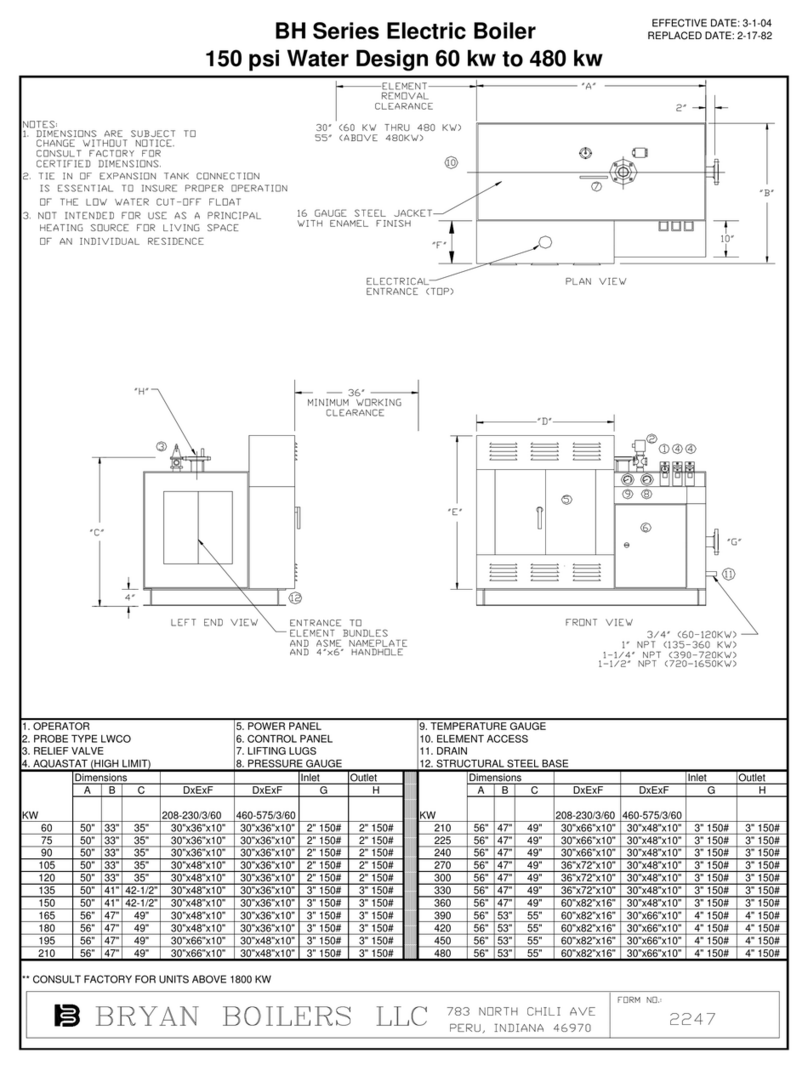

We manufacture boilers both under pressure and open pass type. Sealed boilers that

connect to the system and work under pressure - vertical or horizontal: for horizontal

boilers (Pic. 1) provided brackets (two), can be obtained furthermore, for xing the boiler

to the wall. Brackets are attached to the boiler with the supplied bolts with a strong

tightening and installation on an equable distance, taking into account the center of

gravity. On the sidewise of established boiler is located ½ inch nipple (hot water outlet),

and below ¾ inch nipple (inlet of hot water from the heater) and in the bottom of the boiler

¾ inch nipple (tap of cold water to the heater) and ½ inch nipple (supply of cold water

from the track) . The horizontal boilers can be attached to the wall (connecting pipe in

the right or left position) to the ceiling or with the installation on the oor (as Pic.1).

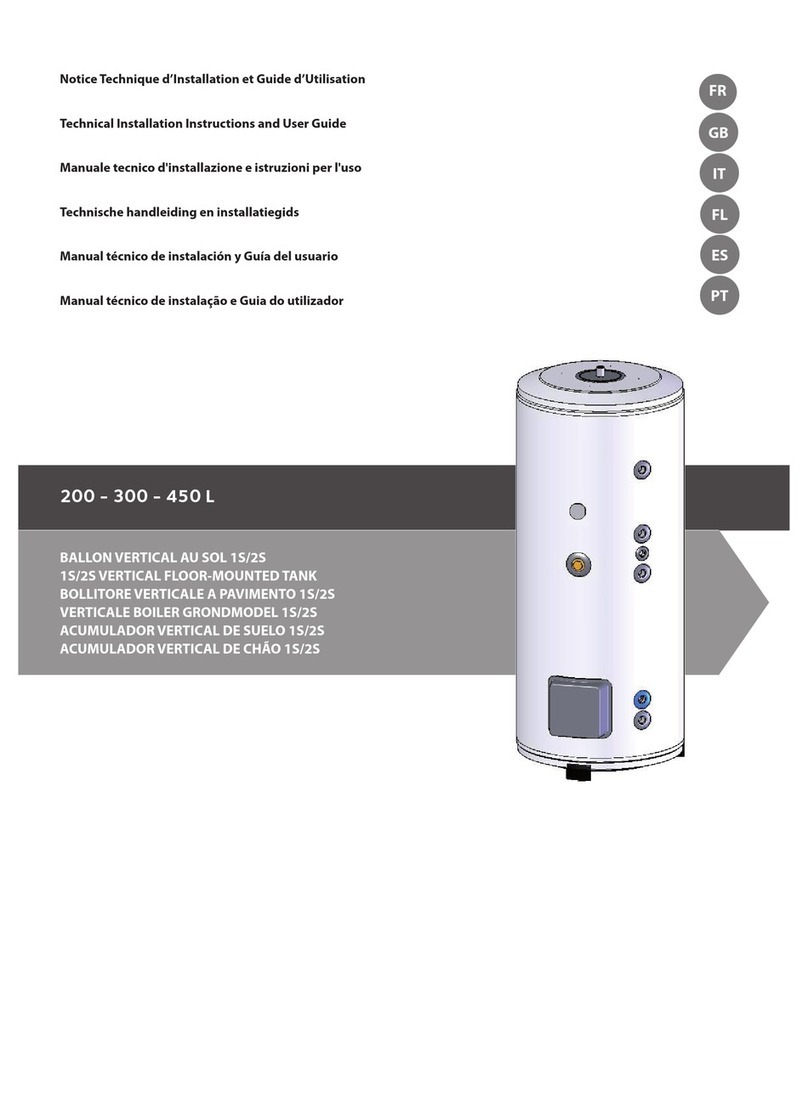

On the vertical boilers (Fig. 2) mountings are welded to the body. ½ inch nipples at the

bottom (for supply cold water from the track) and on the top (for hot water drainage)

and two ¾ inch nipples on the left or right for connection it to the heater (you can get

information from the seller).

Open pass boiler on legs (Fig. 3). Two ¾ inch sidewise nipples (on the left or on the right)

of the boiler destined for connecting to the heater and one ½ inch nipple located on the

bottom of the boiler destined for water outlet from the boiler. It is possible to order extra

nipples (with male thread) or coupling (female screw).

In boilers of ferrous metal during rst months of operation is possible outlet of brown

water that is caused by poor quality of water or muddy system, which eventually stops. If

the process continues is necessary to install a clearing lter on the cold water. Not worth

to use chemical cleaners for cleaning the boiler.

The constitution of water boiler

The boiler made of high quality sheet metal air pressure 4 bars tested, which corresponds

to 6,5 bar of water. The boiler is targeted at prolonged use under not more than 3,5

bar water pressure in the trunk. At elevated pressure, have to be installed a pressure

regulator. Thickness of metal of ferrous boilers is - 3 mm and stainless steel - 2 mm. The

boiler equipped with two connecting pipes ½“: one for connecting cold water and the

other for hot water outlet and two connecting pipes ¾” for connection to inlet and outlet

of the heat source (see Pic 1, 2 and 3).

At hourly heating the temperature increases by 30-50 ˚C, depending on volume of the

boiler and capacity of the heating element.

It is necessary to know that the vertical boiler of the same size and capacity of the heater

is on 15% efcient.