Item # __________________________

C.S.I. Section 11420

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201, TEL. 1-800-814-2028

502-778-2791 QUOTE & ORDER FAX: 1-800-444-0602

A2780

ISO9001

Vulcan-Hart Co.

F-32574 (8-04)

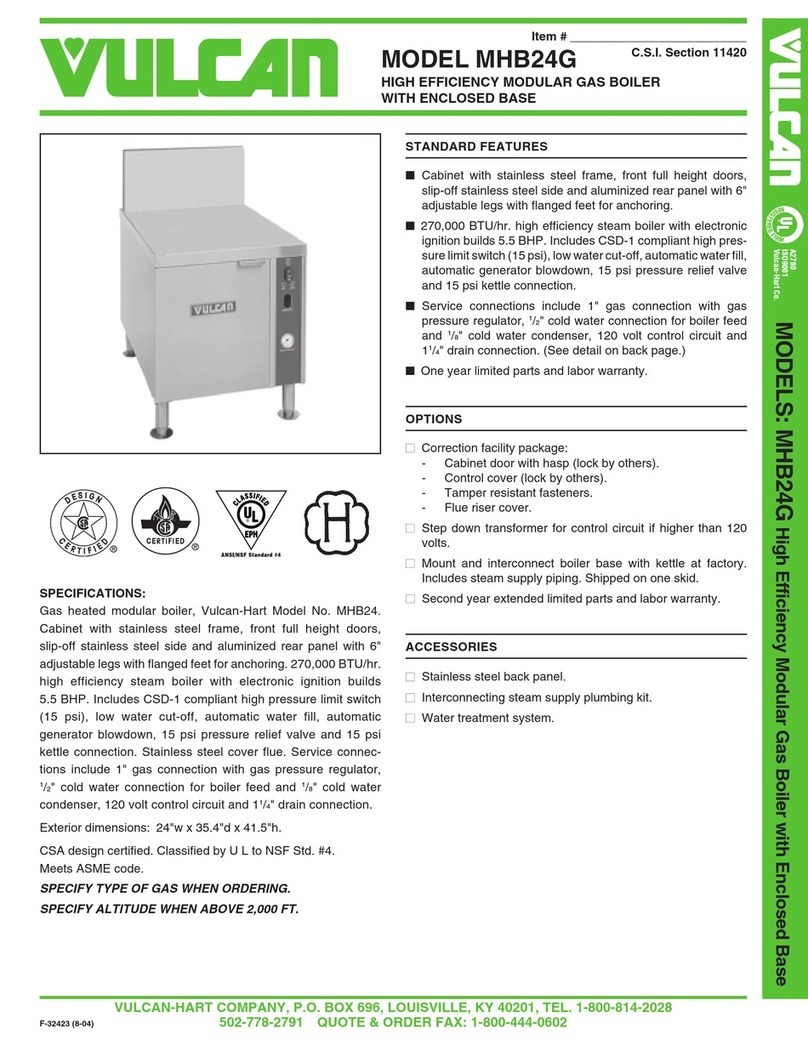

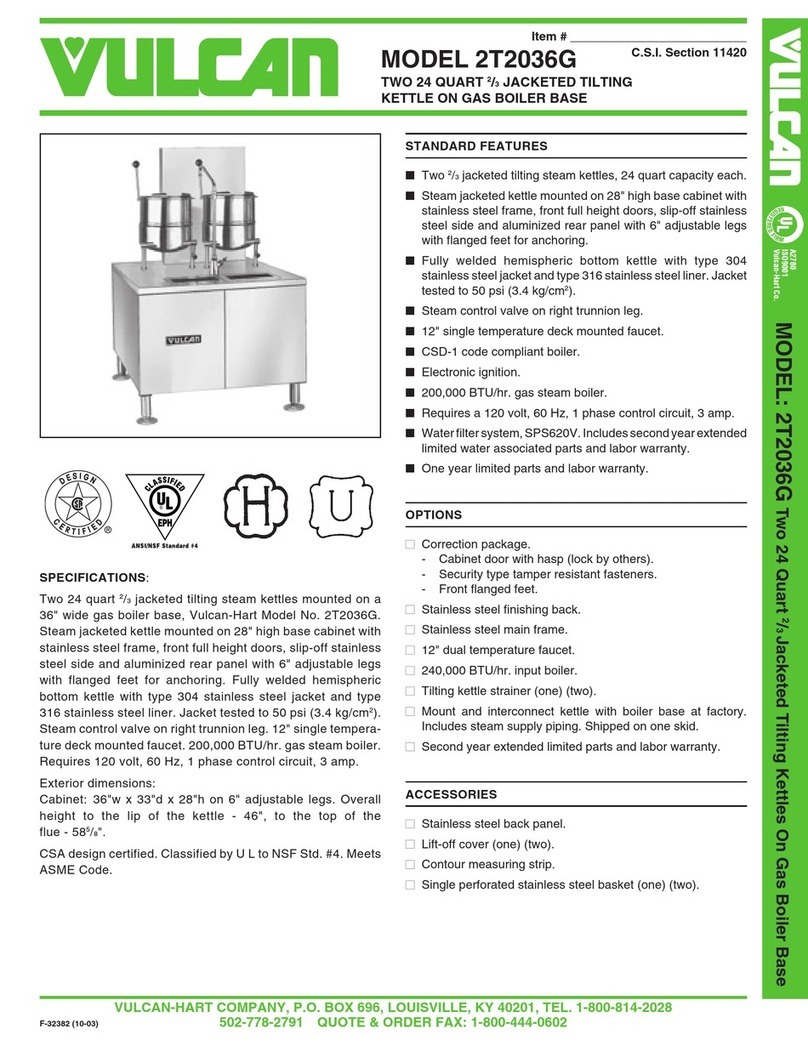

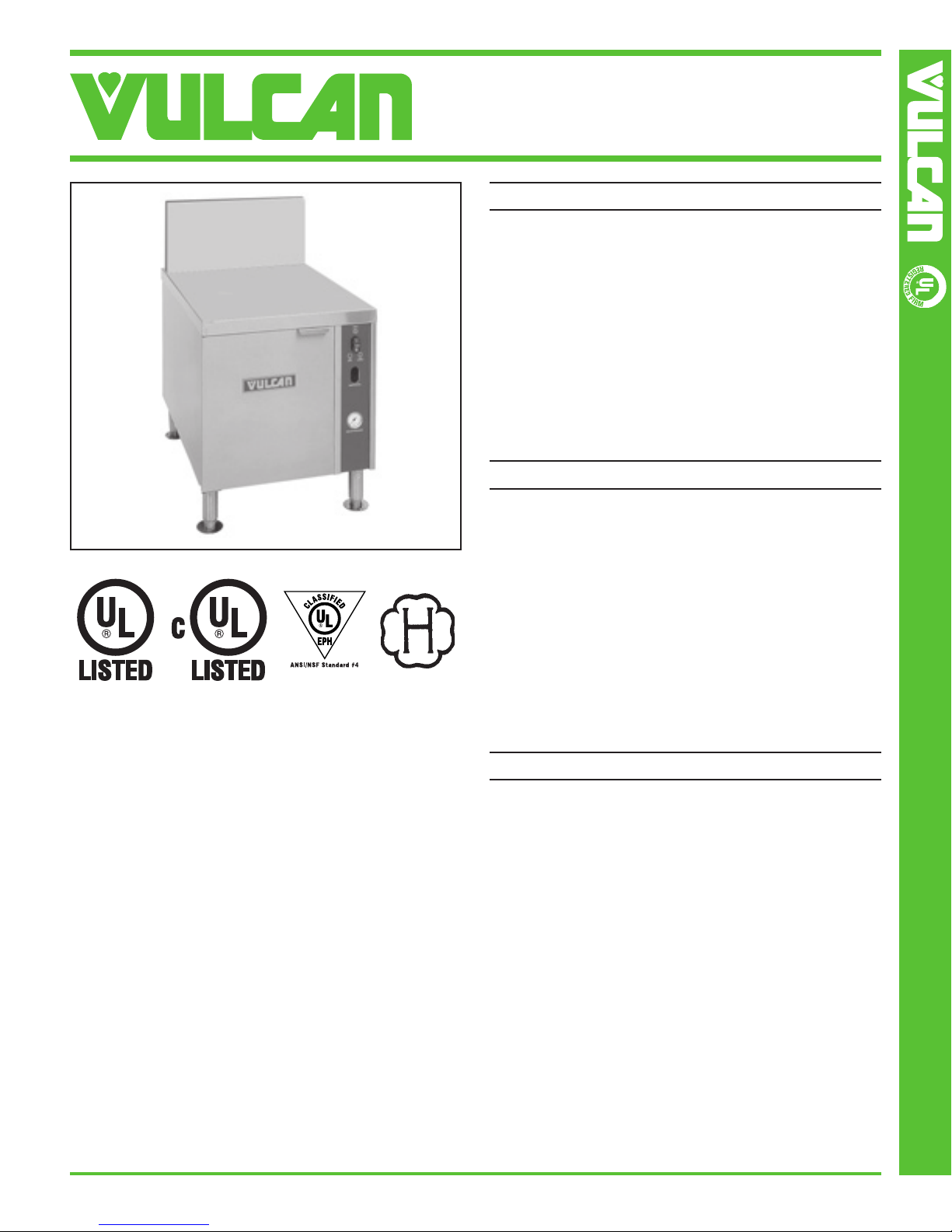

MODEL MHB24E

MODULAR ELECTRIC BOILER

WITH ENCLOSED BASE

MODELS: MHB24E Modular Electric Boiler with Enclosed Base

STANDARD FEATURES

■Cabinet with stainless steel frame, front full height doors,

slip-off stainless steel side and aluminized rear panel with

6" adjustable legs with flanged feet for anchoring.

■24 KW electric steam boiler builds 2.3 BHP. Includes CSD-1

compliant high pressure limit switch (15 psi), low water cut-off,

automatic water fill, automatic generator blowdown, 15 psi

pressure relief valve and 15 psi kettle connection.

■Service connections include 1/2" cold water connection for

boiler feed, 1/8" cold water condenser and 11/4" drain connec-

tion. (See detail on back page.)

■One year limited parts and labor warranty.

OPTIONS

■■Correction facility package:

-Cabinet door with hasp (lock by others).

-Control cover (lock by others).

-Tamper resistant fasteners.

-Flue riser cover.

■■36 KW, 208 or 240 volt, 60 Hz, 3 phase.

■■42 KW, 208, 60 Hz, 3 phase.

■■48 KW, 240 volt, 60 Hz, 3 phase.

■■Mount and interconnect boiler base with kettle at factory.

Includes steam supply piping. Shipped on one skid.

■■Second year extended limited parts and labor warranty.

ACCESSORIES

■■Stainless steel back panel.

■■Interconnecting steam supply plumbing kit.

■■Water treatment system.

SPECIFICATIONS:

Modular electric boiler, Vulcan-Hart Model No. MHB24E.

Cabinet with stainless steel frame, front full height doors, slip-off

stainless steel side and aluminized rear panel with 6" adjustable

legs with flanged feet for anchoring. 24 KW steam boiler builds

2.3 BHP. Includes CSD-1 compliant high pressure limit switch

(15 psi), low water cut-off, automatic water fill, automatic

generator blowdown, 15 psi pressure relief valve and 15 psi

kettle connection. Stainless steel cover flue. Service connec-

tions include 1/2" cold water connection for boiler feed , 1/8" cold

water condenser and 11/4" drain connection.

Exterior dimensions: 24"w x 35.4"d x 41.5"h.

U L listed. U L listed to Canadian safety standards. Classified by

U L to NSF Std. #4.

Meets ASME code.

SPECIFY TYPE OF GAS WHEN ORDERING.

SPECIFY ALTITUDE WHEN ABOVE 2,000 FT.