SKC DCS User manual

Operating Instructions

SKC Deployable Cartridge

Sampler (DCS) System

SKC Inc.

863 Valley View Road

Eighty Four, PA 15330

Form 38048 Rev 1812

Pre3

DCS System Quick Guide

Sampling Head and Cartridge Installation

1. Disassemble sampling head: Unscrew inlet from cartridge holder section. Unscrew

cartridge holder section from exhaust section. Clean parts and allow to dry.

2. Thread cartridge holder section onto exhaust section.

3. Insert media cartridge into cartridge holder (arrow pointing toward exhaust).

4. Reinstall inlet section onto cartridge holder section.

Setup and Calibration

1. Set up sample pump. (See Leland Legacy®Quick Guide. For advanced programming,

see Leland Legacy Operating Instructions.)

2. Ensure media cartridge is installed in sampling head.

3. Thread calibration adapter into sampling head inlet.

4. Use tubing with quick-connect fitting to connect pump inlet to outlet of sampling head.

5. Use short tubing to connect inlet of calibration adapter to outlet of calibrator.

6. Calibrate pump flow rate to 10 L/min and record the pre-sample flow rate.

7. Disconnect calibrator and remove calibration adapter from sampling head.

8. Mount bracket at desired location.

9. Install sampling head on mounting bracket.

10. Install rain cover on sampling head.

Sampling

1. Turn on pump and record pertinent data. (Leland Legacy pump may be started

manually or automatically, see Leland Legacy Quick Guide.)

2. After desired sampling period, record sample stop time. Remove rain cover. Reinstate

calibration train to verify pump flow rate. Record post-sample flow rate.

3. Turn off pump. Record pertinent information.

4. Remove sampling head: Use quick-connect release to detach tubing from pump inlet.

Remove tubing from sampling head. Remove sampling head from bracket. Move

sampling head to a clean area.

Sample Removal

1. Disassemble sampling head: Unscrew inlet from cartridge holder section.

2. Lift media cartridge from cartridge holder section, wrap in aluminum foil, and place in

supplied aluminum can. Transport to lab.

SKC Inc., 863 Valley View Road, Eighty Four, PA 15330 • www.skcinc.com

Pre5

Table of Contents

Introduction............................................................................................1

Performance Profile...............................................................................2

Principle of Operation............................................................................3

Sampling Head Preparation ..................................................................4

Cleaning the Sampling Head.....................................................................................4

O-ring Care for the Sampling Head...........................................................................4

Inserting a Media Cartridge into the Sampling Head.................................................5

Sample Pump Operation .......................................................................6

Charging the Battery .................................................................................................6

Reading the Charging Status LED ............................................................................7

Battery Setup.............................................................................................................7

Battery Replacement.................................................................................................7

Leland Legacy Quick Guide ......................................................................................8

Calibration and Sampling ......................................................................9

Calibration .................................................................................................................9

Sampling .................................................................................................................10

Sample Removal and Shipping ...........................................................11

Removing the Media Cartridge from the Sampling Head........................................11

Storing and Transporting Samples..........................................................................11

Ordering Information............................................................................12

Li-Ion Battery Shipment.......................................................................13

Warranty..............................................................................................13

Indicates a reminder or note

Indicates a warning or caution

1

INTRODUCTION

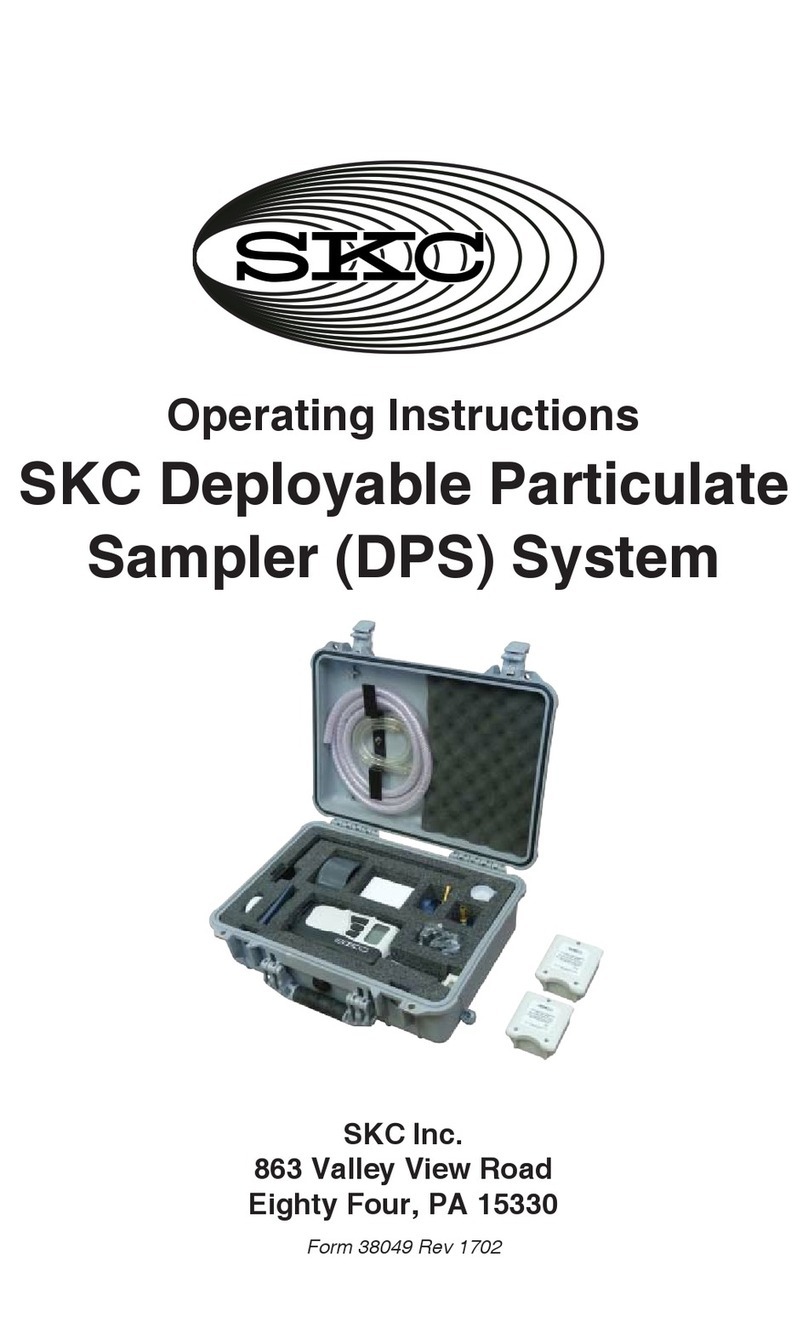

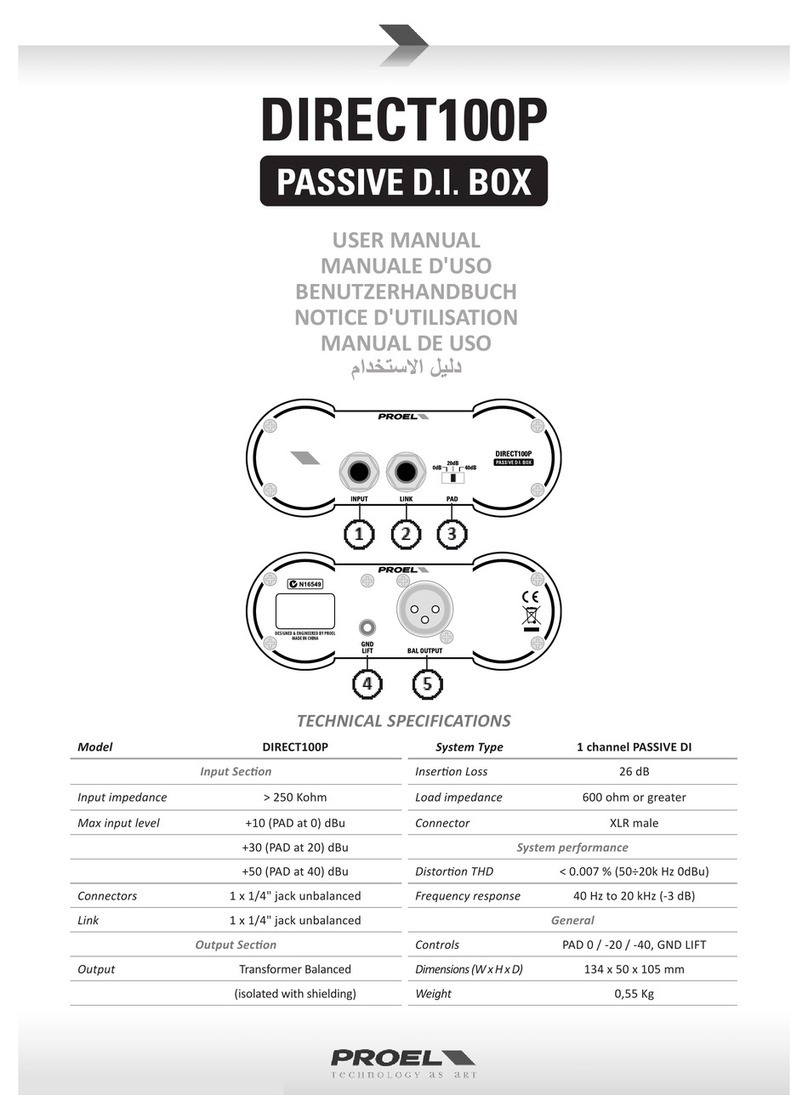

The SKC Deployable Cartridge Sampler (DCS) System (Figure 1) is a compact,

portable, and baery-operated sampling system that ensures the ability to sample

gaseous polycyclic aromatic hydrocarbons (PAHs), polychlorinated biphenyls

(PCBs), pesticides, and associated particulates. The system features the fully

programmable constant flow Leland Legacy Sample Pump and an easy-to-use

sampling head that houses a stainless steel media cartridge. See Figure 2. The

media cartridges are provided preloaded with either PUF and 47-mm quarfilter

or 47-mm quarfilter/PUF/XAD-2 sorbent/PUF. The easily deployed system is

packaged in a portable heavy-duty Pelican®case from which the system operates.

The SKC DCS System includes a Leland Legacy Sample Pump with connection case and cable,

two external baery assemblies with adapters (packaged separately), charger (100-240 V), sampling

head, calibration adapter, rain cover for sampling head, sample tubing with quick-connect fiing,

calibration tubing, and mounting bracket in a heavy-duty lockable carry case. Media cartridges

are available separately.

Calibration tubing

Mounting

bracket

Rain cover

Leland Legacy

pump with

connection

cable

Tubing with

quick-connect fitting

Quick-connect

release

Quick-connect fitting

(not shown)

External battery

assemblies

with battery

adapters (2)

Charging unit and

power supply

Calibration adapter

Sampling head

Worldwide plugs

for charger

Figure 1. DCS System

2

PERFORMANCE PROFILE

Flow Rate: 10 L/min

Run Time: 24 hrs on one battery charge

Power: Rechargeable lithium-ion (Li-Ion) battery, 7.4 V,

12-Ah capacity†, 88.8 Wh

Battery Recharge Time: 15 hrs

Pre-filter: 47-mm quartz, QM-A, 450-μm thickness

(Not supplied with system)

Sorbent: PUF (polyether type), 40-mm diameter, cleaned or

(Not supplied with system) PUF/XAD-2 sorbent/PUF

Analysis: Gas chromatography/mass spectrometry (GC/MS) or

high resolution gas chromatography/high resolution mass

spectrometry (HRGC/HRMS) dependent on method used

Tubing: 3/8-in ID reinforced flexible PVC (supplied)

Temperature: Charging: 32 to 113 F (0 to 45 C)

Operating: 32 to 104 F (0 to 40 C)

Storing: -4 to 95 F (-20 to 35 C)

Altitude: Do not use pump beyond 7500 ft.

RFI/EMI Shielding: CE marked

Case Dimensions: 18.5 x 14.1 x 6.9 in (47 x 36 x 18 cm)

Complete System Weight: 12.20 lbs (5.5 kg)

Sampling Head

Dimensions: 2.6 dia. x 3.6 H x 3.8 L in (7 x 9 x 10 cm)

Sampling Head Weight: 0.60 lb (0.27 kg)

(without cartridge)

Cartridge Weight: 0.75 lb (0.34 kg)

† DCS Systems contain Li-Ion baeries and is subject to special shipping regulations.

3

PRINCIPLE OF OPERATION

A sample pump draws air at a flow rate of 10 L/min through nozzles on top of the

sampling head and into the media cartridge inside the cartridge holder section.

The media cartridge contains a cleaned 47-mm quarfilter that collects particles

and a cleaned PUF or PUF/XAD-2/PUF sorbent that adsorbs gases and vapors.

See Figure 2. The aluminum foil-wrapped cartridge is supplied in an aluminum

can with lid so that the sample is protected from light and contamination during

transport. The filter and sorbent media are combined for extraction followed by

GC/MS or HRGC/HRMS depending on the method used.

Inlet section

PTFE O-ring

BUNA-N O-ring

Exhaust section

The two main components of the DCS System:

DCS Sampling Head and

Leland Legacy Sample Pump

Cartridge holder

section

Exploded view of the

DCS Sampling Head

Figure 2. DCS Sampling Head and Leland Legacy Pump

4

SAMPLING HEAD PREPARATION

Cleaning the Sampling Head

All cleaning, loading, and unloading should be conducted in a controlled

environment to minimize any chance of potential contamination. When new

or when using the sampler at a different location, all sample contact areas need

to be cleaned. Rinse with appropriate organic solvent. Allow the solvent to

evaporate before loading a cartridge.

For deployed applications where method-specified solvents are

unavailable, use isopropyl (rubbing) alcohol or a clean tissue wipe.

Do not place any mechanical object in the inlet nozzles.

O-ring Care for the Sampling Head

Visually inspect the condition of the BUNA-N exhaust O-ring. See Figure 2.

Ensure the O-ring surface is smooth (i.e., without cracks, cuts, or other damage).

Ensure the O-ring is fied properly in its channel. Replace the exhaust O-ring

if there is apparent damage, stretching, or thinning. It is recommended that the

PTFE inlet O-ring be replaced by the manufacturer only.

5

Inserting a Media Cartridge into the Sampling Head

Wear disposable, clean, lint-free nylon or powder-free surgical gloves

to handle the media cartridge.

1. Disassemble sampling head. See Figure 2

for placement of parts.

a. Unscrew inlet section from cartridge

holder section.

b. Unscrew cartridge holder section

from exhaust section.

Clean and allow to dry. See Cleaning the

Sampling Head.

2. Thread cartridge holder section onto

exhaust section.

3. Remove media cartridge from

aluminum foil and insert into cartridge

holder section. Ensure airflow arrow on

media cartridge points to exhaust section.

The filter should be on the inlet side of the

media cartridge.

4. Thread inlet section onto cartridge

holder section until just tight. Further

hand-tighten by 1/4 turn only.

Thread cartridge holder section

onto exhaust section.

Insert media cartridge into cartridge

holder section.

Thread inlet section onto cartridge

holder section.

4

Disassemble sampling head.

1

Inlet

section

Cartridge

holder

section

Exhaust

section

6

SAMPLE PUMP OPERATION

The user may choose to:

• Operate the pump manually in the field (on/off)

• Program a schedule into the pump manually

• Program the pump for multiple schedules from a PC

with optional DataTrac®for Leland Legacy Software (see

Ordering Information, Accessories).

See the Leland Legacy Quick Guide to operate the SKC

Leland Legacy Sample Pump. For advanced programming, see

the complete Leland Legacy Pump Operating Instructions.

Charging the Battery

Completely charge a new baery pack using the SKC-approved charger (Cat. No.

223-241) before operating the pump. It may be necessary to charge the baery a

few times before maximum baery capacity is achieved.

Cautions:

• Do not charge or operate pump with or without charger in hazardous

locations.

• Use only the SKC-approved charger for this pump. Use of an

unapproved charger may damage the baery and pump and VOIDS

ANY WARRANTY.

• Do not open, disassemble, short circuit, crush, incinerate, or expose the

baery to fire or temperatures in excess of 212 F (100 C).

• Tampering with the baery pack VOIDS ANY WARRANTY.

• Ensure proper orientation of charging cable before plugging it into the

charging jack. Improper orientation/contact will short-circuit the baery

and VOIDS ANY WARRANTY.

• Short-circuiting the baery pack will render it immediately inoperative.

• Failure to follow warnings and cautions VOIDS ANY WARRANTY.

The baery pack may be kept on the SKC-approved charger for an

indefinite time.

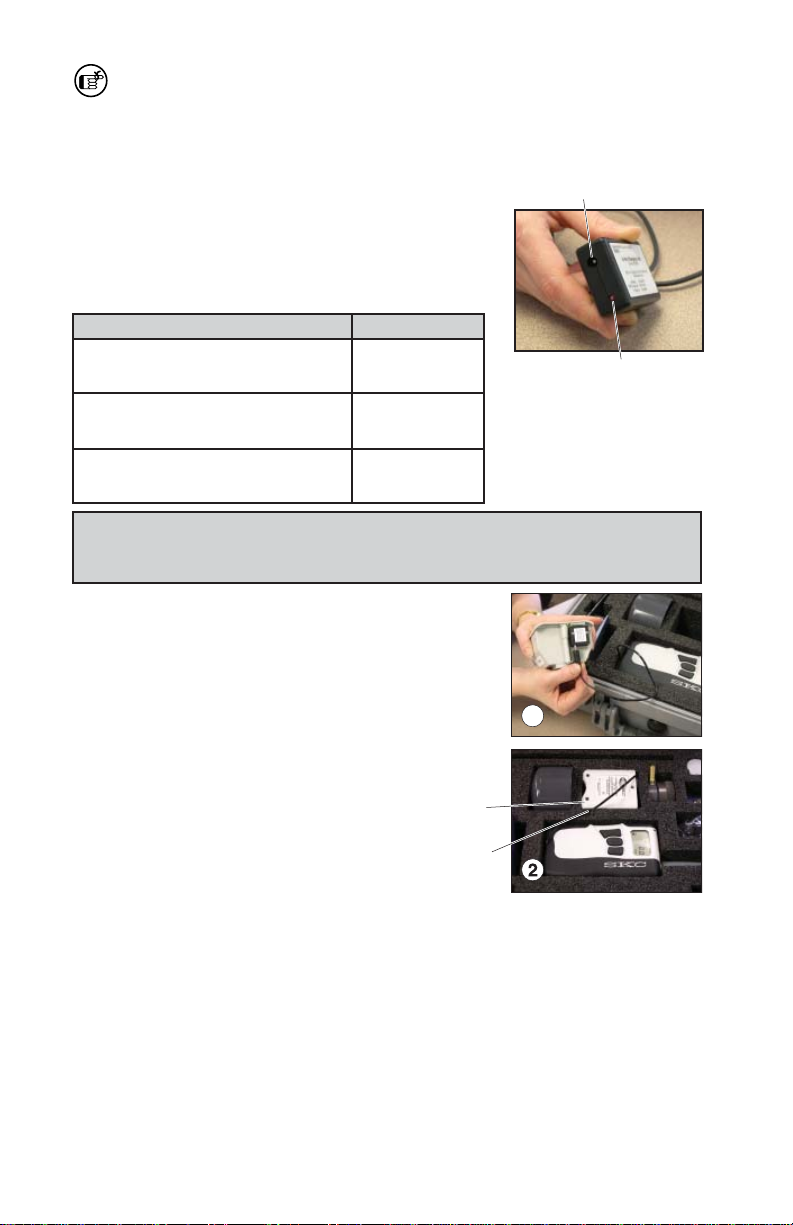

1. Insert the plug from the charging unit into the

charging port on the baery adapter (on top of the

external baery assembly).

2. Insert plug from power supply into the jack on the

charging unit.

3. Install the appropriate wall plug on the power

supply and plug power supply into a wall outlet.

The baery will recharge in approximately 15

hours. For a complete charge, do not run the pump

connected to the external baery assembly during

charging. After charging is complete, disconnect

baery from charger and connect pump to baery.

See Baery Setup.

1

External

battery

assembly

Battery

adapter

Charging

unit plug

Power

supply

Charging

unit

External

battery

assembly

7

After charging the baery pack, it is good practice to run the pump for

approximately 5 minutes before calibrating. This ensures the baery is

in more steady-state conditions and improves the agreement in pre and

post-sampling calibrations.

Reading the Charging Status LED

The Li-Ion Charging Unit indicates baery charge

status via an LED on the unit that blinks in specific

paerns. Observe the LED steadily for > 5 seconds

to read charge status.

LED Action Charge Status

ON

steady

Charge in progress

ON

2 sec

OFF

{

.25 sec

ON

2 sec

(Repeats) Approximately

80% charged

OFF

{

2 sec

ON

.25 sec

OFF

{

2 sec

(Repeats) Charge completed

Battery Setup

1. Insert the plug on connecting cable from pump

into the jack on the baery adapter (on top of

the external baery assembly).

2. Insert external baery assembly into a foam

compartment in the case. Ensure there is no

tension on the connecting cable.

Battery Replacement

1. Record all necessary data before unplugging pump from baery.

2. Remove plug on connecting cable from jack on baery adapter (on top of

the external baery assembly).

3. Insert plug on connecting cable into baery adapter jack on new, fully

charged external baery assembly.

4. Insert external baery assembly into foam compartment in case. Ensure

there is no tension on the connecting cable.

Power supply jack

Charge status LED

For more information on SKC Lithium-ion pump batteries, go to

http://www.skcinc.com/instructions/1918.pdf.

1

Connecting cable

External battery

assembly

8

Leland Legacy Quick Guide

Terms »

Star button

• Scrolls through run time data and Setup options

Up and down arrow buttons

• Toggle between display choices and increase or decrease sampling parameters in Setup

Button sequence

= press buttons individually

[] = press simultaneously

= security code, always press in sequence

Security code

• Prevents unauthorized changes to the pump’s sampling program

Programming Sequences »

• To activate pump (e.g., to change pump from Sleep to Hold):

Press any button.

• To change pump from Hold to Run or Run to Hold:

Press [].

• To reset accumulated data:

Press [], then . Press until CLr displays then press []; press until End displays then

press [].

• To set pump flow rate:

Press [], then . Flow rate and SET flash. Press or to change flow rate. Press until End

appears then press [] to save setting and place pump in Hold.

• To calibrate flow rate with standard calibrator:

Press [], then . Flow rate and SET flash. Press or to change flow rate. Press once. ADJ

displays. Press or until desired flow rate is indicated on calibrator. When finished, press until End displays

then press [] to save new setting and place pump in Hold. For CalChek Calibration, see operating instructions.

• To change temperature scale from F to C or C to F:

Press [], then . Press until temperature displays. Press or to switch units; press until

End displays then press [] to save new setting.

• To change atmospheric pressure scale (mm, mb, In):

Press [], then . Press until pressure displays then press or to switch units; press until

End displays then press [] to save new setting.

• To change time scale (12 Hr/24 Hr/Dela):

Press [], then . Press until 12 Hr, 24 Hr, or Dela displays then press or to switch units;

press until End displays then press [] to save new setting. To set delayed start (Dela), see operating

instructions.

• To change clock:

Press [], then . Press until clock displays then press or to change flashing hour; press to

move to minutes and or to change setting. Press until End displays then press [] to save new setting.

• To change the sampling time function:

Press [], then . Press until ST L/min displays then press to change flashing digit; press until

End displays then press [] to save new setting. To delete, follow above steps and press until 0 appears.

Exit Setup.

Note: When in Setup, choosing Esc instead of End will exit Setup without saving new settings.

SKC Inc., 863 Valley View Road, Eighty Four, PA 15330 • www.skcinc.com

9

CALIBRATION AND SAMPLING

Calibration

Calibrate pump flow rate with the sampling head loaded with a media

cartridge in line. See pump and calibrator operating instructions.

Allow the pump to equilibrate after moving it from one temperature extreme

to another.

Wear disposable, clean, lint-free nylon or powder-free surgical gloves to

handle the media cartridge.

Ensure pump has run for 5 minutes

before calibrating. Ensure rain

cover is removed from inlet and

that sampling head is completely

assembled with a media cartridge

(see Inserting a Media Cartridge

into the Sampling Head).

Thread calibration adapter into sampling head inlet.

Set and calibrate pump flow rate to 10 L/min (see Leland

Legacy Quick Guide). Record the pre-sample flow rate. See

pump and calibrator operating instructions.

1

When calibration is completed,

disconnect calibrator and tubing

from calibration adapter. Remove

calibration adapter from sampling

head.

Use provided short length of calibration tubing to connect inlet of calibration

adapter to outlet of a calibrator to form a calibration train.

Unscrew quick-connect plug on side of case. Use tubing with quick-connect

fiing to aach case (pump) inlet to exhaust of sampling head.

Ensure O-ring is installed on the quick-connect fiing before inserting it into

the inlet. Absence of the O-ring can affect measurements. See Replacement Parts.

Inlet

Quick-

connect

plug

Inlet line

to pump

Quick-

connect

fitting on

tubing

Inlet to

pump Calibration adapter

Calibrator

outlet

Sample

head

outlet

10

Sampling

Locate system in an unobstructed area, at least 6 feet (2 meters) from

any obstacle to airflow.

Allow pump to equilibrate after moving it from

one temperature extreme to another.

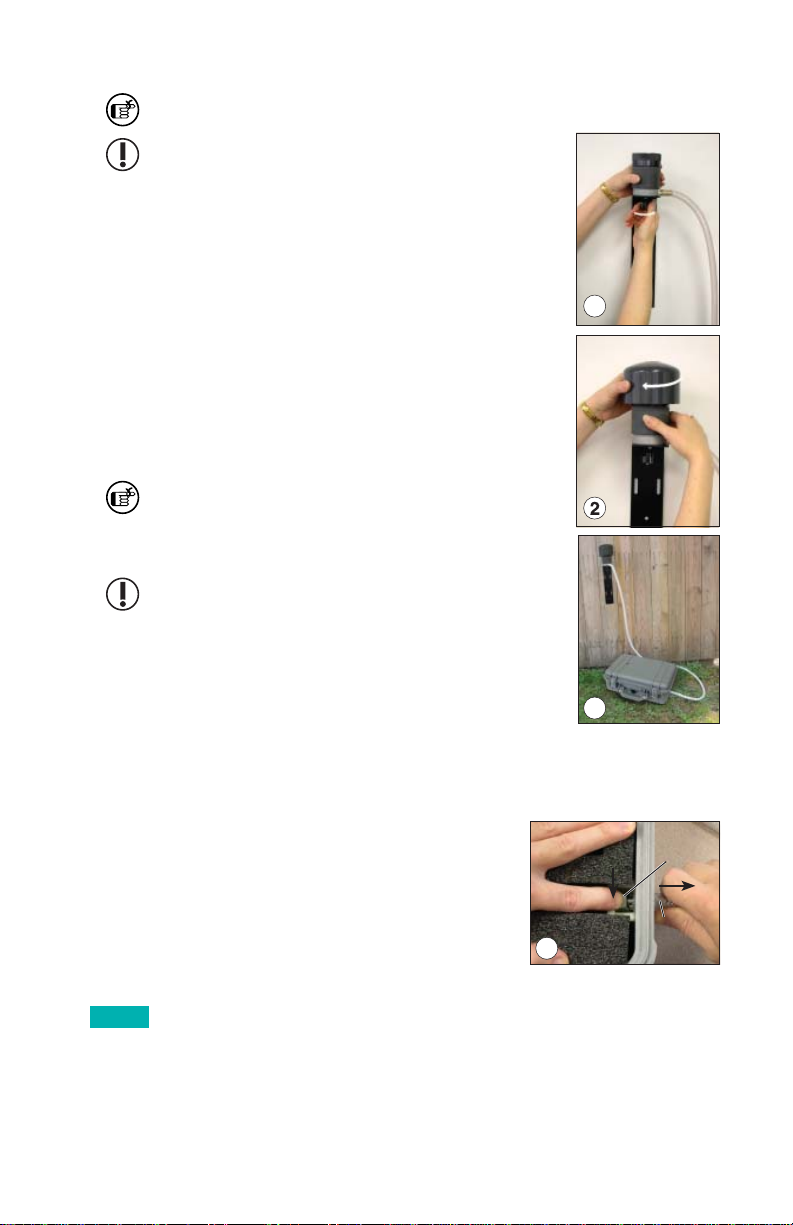

1. Aach mounting bracket at the desired location and

at breathing zone height (6 feet or 2 meters) using

wire ties or other fasteners. Mount sampling head

loaded with media cartridge on mounting bracket

by threading clamp knob into boom of sampling

head.

2. Insert screw on rain cover into top of the sampling

head inlet and rotate cover until tight.

3. Turn on pump and record sample start time, ambient

temperature, ambient pressure, and other pertinent

data.

Sample start time and duration can be pro-

grammed into the Leland Legacy Sample Pump

in advance and sampling may be started manu-

ally or automatically.

Record all necessary data before disconnecting

pump from baery and reconnecting to new

baery.

4. After desired sample time has elapsed, record sample

stop time. Remove rain cover from sampling head and

reinstate calibration adapter, tubing, and calibrator

(see Calibration). Record post-sample flow rate.

5. Turn offpump. Record total volume, ambient temperature, ambient

pressure, and other pertinent data.

6. Reach inside case and press quick-connect

release while pulling tubing from case (pump)

inlet. Remove tubing from sampling head.

Remove sampling head from bracket.

7. Remove sampling head to a clean area.

• The supplied rain cover should be used for all outdoor sampling.

• Keep Leland Legacy Sample Pump inside the Pelican case and the case

closed during sampling to protect sample pump from weather.

1

3

Press quick-connect release to

remove tubing.

6

Quick-connect

release inside

case

Tubing with

quick-connect

fitting

Tips

11

SAMPLE REMOVAL AND SHIPPING

Removing the Media Cartridge from the Sampling Head

Wear disposable, clean, lint-free nylon or powder-free surgical gloves

to handle the media cartridge.

1. Unscrew inlet section from cartridge

holder section.

Ensure media cartridge remains

vertical to avoid loss of sample from

filter.

2. Lift media cartridge from cartridge holder

section.

3. Wrap media cartridge in supplied foil or

clean aluminum foil and place in supplied

aluminum can to protect sample from light

and contamination.

Storing and Transporting Samples

1. Store samples with ice packs (< 39.2 F [4 C]) in the field.

2. Package and transport samples and blanks with ice packs (< 39.2 F [4 C])

until receipt at the analytical laboratory.

Lift media cartridge from cartridge

holder section.

1

3

Remove inlet section

from cartridge holder section.

Wrap media cartridge in foil and

insert in aluminum can.

12

ORDERING INFORMATION

Description Cat. No.

DCS System†#*includes a Leland Legacy sample pump with connection

case and cable, charger (100-240 V), 2 external battery assemblies with

adapters (packaged separately), sampling head, calibration adapter,

rain cover for sampling head, sample tubing with quick-connect fitting,

calibration tubing, and mounting bracket in a heavy-duty lockable carry

case. Cartridges, filters, and sorbent media available separately 100-3960

† DCS Systems contain Li-Ion batteries and is subject to special shipping regulations.

# Use in non-explosive environments only. Not UL Listed for intrinsic safety

* Provides data similar to Federal Reference Method samplers. The DCS System is not a U.S. EPA

reference or equivalent method for compliance sampling.

Media Cartridges, required, select based on application

Stainless steel cartridges containing media as described below, stainless steel support

screens, and gaskets. Each cartridge is wrapped in aluminum foil and shipped in an

aluminum can with lid.

Filter/PUF contains 41.3-mm length of PUF and a 47-mm quartz filter 226-206

Filter/PUF/XAD-2/PUF contains a 47-mm quartz filter and 2 grams of

XAD-2 sorbent sandwiched between two 20.6-mm lengths of PUF 226-207

Accessories

TSI 4146 Calibrator Kit, 0.01 to 20 L/min, includes calibrator, soft-sided

case, mounting lugs, tubing (1/4-in ID), battery pack, 6 AA batteries, inlet

filter, dampening module, NIST certificate, and manual 740-4146

DataTrac for Leland Legacy Software includes software on CD and

adapter cable (requires Windows 7 or higher and available USB port) 877-92

Replacement Parts Cat. No.

DCS Sampling Head 225-620

Quick-connect Fitting O-rings, pk/3 P31996

Rain Cover, gray 225-398

Mounting Bracket 225-399

Stainless Steel Support 225-2647A

Quick-connect Fitting, on 6.5-foot reinforced flexible PVC tubing P42741

Reinforced Flexible PVC Tubing, 6.5 feet P30004

Calibration Tubing, 1 foot, reinforced flexible PVC P300041

Silicone Tubing, 0.4 foot, pk/2 P30255A

DCS Case, Pelican, with foam and hardware 225-3901

Calibration Adapter 225-394

Quick-connect Plug with retaining chain P42742

External Battery Assembly with battery adapter 223-247

Battery Adapter 223-248

Connection Case with cable and plug 223-249

Support Screens for Media Cartridge, pk/2 P26033

Gaskets for Media Cartridge, pk/4 P52413

13

LI-ION BATTERY SHIPMENT

Rechargeable lithium-ion baeries for use with SKC sample pumps have been

tested in accordance with the UN Manual and are proven to meet the requirements

of each test in the UN Manual of Tests and Criteria, Part III, subsection 38.3. The

baeries are rated below 100 wa-hours (Wh). Consult with your carrier for

information on Lithium Baery Shipping Regulations UN 3480 and UN 3481

or visit SKC’s website for more information at www.skcinc.com/catalog/pdf/

instructions/1921.pdf.

SKC LIMITED WARRANTY AND RETURN POLICY

SKC products are subject to the SKC Limited Warranty and Return Policy, which

provides SKC’s sole liability and the buyer’s exclusive remedy. To view the

complete SKC Limited Warranty and Return Policy, go to hp://www.skcinc.

com/warranty.

Table of contents

Other SKC Recording Equipment manuals

Popular Recording Equipment manuals by other brands

Donner

Donner PODSOLER PC-02 user manual

Superscope

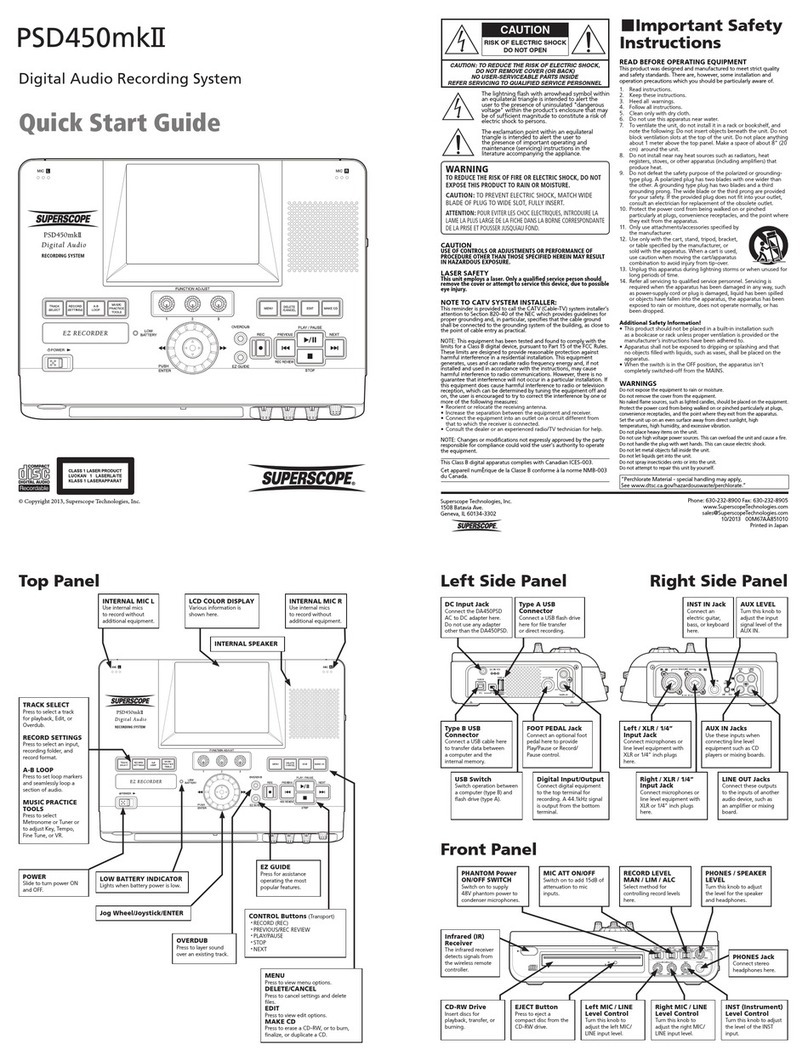

Superscope PSD450mkII quick start guide

Omnitron Systems Technology

Omnitron Systems Technology iConverter GM4 quick start guide

Denon

Denon CDR-1000 operating instructions

Nice

Nice IT4WIFI Instructions and warnings for installation and use

Axis

Axis 2191 installation guide