Shakmat Harlequin's Context User manual

Shakmat

Harlequin’s Context

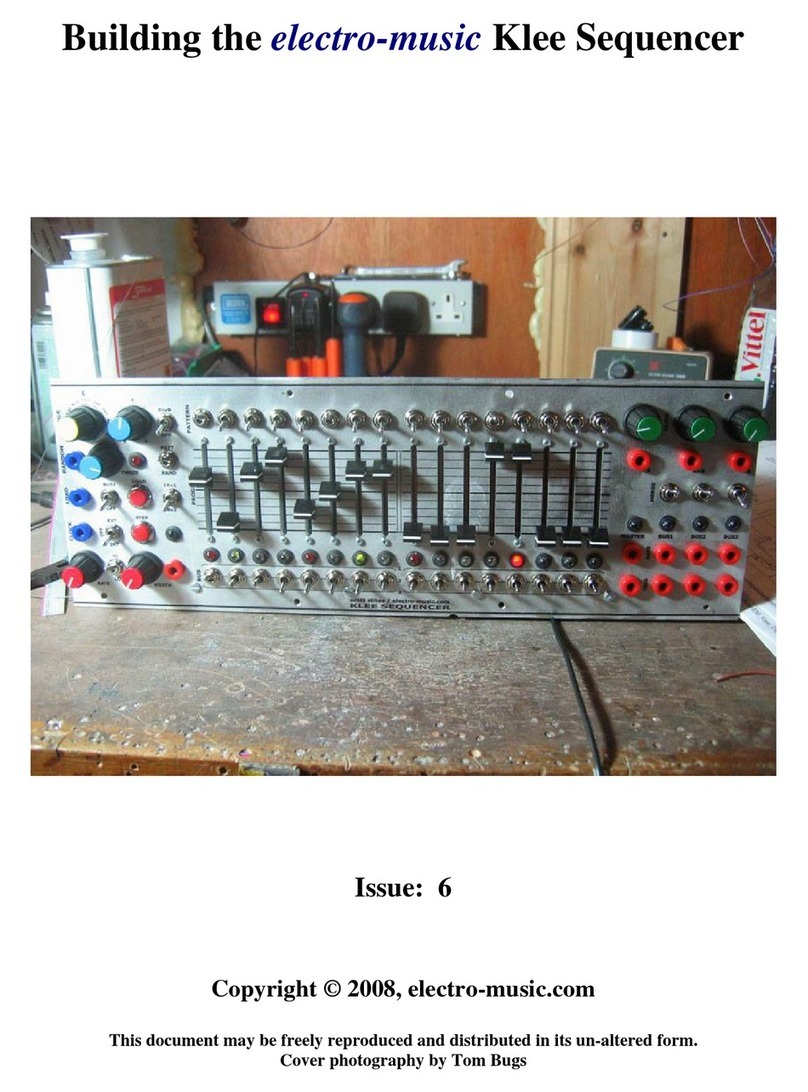

Building Guide

12HP Eurorack Module Built & designed in E.U. www.shakmat.com

Table of contents

www.shakmat.com •

Preamble

Component list & necessary tools

PCB details

Top PCB assembly

4.1 Front

4.1.1 Electrolytic capacitors

4.2 Back

4.2.1

Male headers (1x4 pin)

4.2.2

Power header (2x8 pin)

Tactical Plan assembly

Top PCB final assembly

6.1 Front

6.1.1 Jack connectors

6.1.2

Potentiometers & nuts

PCB stacking

Bottom PCB assembly

8.1 Front

8.1.1 Push buttons & display

Front panel preparation

LED mounting

Finish

First startup routine

Debug

.................................................................................................................................. 2

................................................................................... 3

............................................................................................................................4-5

................................................................................................................ 6

.............................................................................................................................. 6

.................................................................................... 6

.............................................................................................................................. 7

................................................................................ 7

............................................................................... 8

......................................................................................................... 9

..................................................................................................... 10

............................................................................................................................ 10

............................................................................................. 10

................................................................................ 11

......................................................................................................................... 12

....................................................................................................... 13

............................................................................................................................ 13

................................................................................ 13

..................................................................................................... 14

.................................................................................................................. 15-16

........................................................................................................................................ 17

.............................................................................................................. 18

....................................................................................................................................... 19

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

www.shakmat.com •

02/19

Thank you for purchasing a Shakmat DIY kit !

We spare no effort in our kit packing process to prevent any mistakes or

missing parts. In this document as well, we do our best to describe the assem-

bly process in the most practical and comprehensive way. If by any chance

there is a missing/damaged part in your kit or if you have any suggestion, feel

free to contact us via shakmat.com.

We strongly advise you NOT to spill all the bags open and mix their

components. Some of them are virtually indistinguishable (like LEDs that

all appear clear when inactive). We recommend to only take the neccesary

component out of its bag, or to empty the bags in separate & marked contai-

ners. For each step, next to the component’s graphic representation, there is a

reference indicating where to find it (i.e. P1 for Pack 1, or LP for Loose Part).

The assembly process will be dramatically simplified if you follow the order

defined by this building guide. We tested various orders of steps before finding

the most convenient, and the one presented here is the best!

1. Preamble

www.shakmat.com •

03/19

Pack 1

4x Amber LEDs

1x 7 segment display

8x Push buttons

8x Round push button caps

4x M3 metal screws

2x M3 nylon screws

2x 14mm nylon spacers

6x Jack connector nuts

4x Metal potentiometer nuts

Pack 2

2x 20 pin male header

2x 20 pin female header

1x 2x8 pin power header

4x 4 pin male header

4x WhiteLEDs

4x Green LEDs

3x 22 µF electrolytic capacitors

4x Metal potentiometers

6x Jack connectors

2. Component list & necessary tools

Pack 3

1x Top PCB

1x Bottom PCB

1x Tactical Plan

Loose parts

1x Front Panel

4x Black rubber knobs

1x Power cable

1x User manual

1x Cheat Sheet

Necessay tools

Soldering iron

Solder

Cutting pliers

Masking tape

www.shakmat.com •

04/19

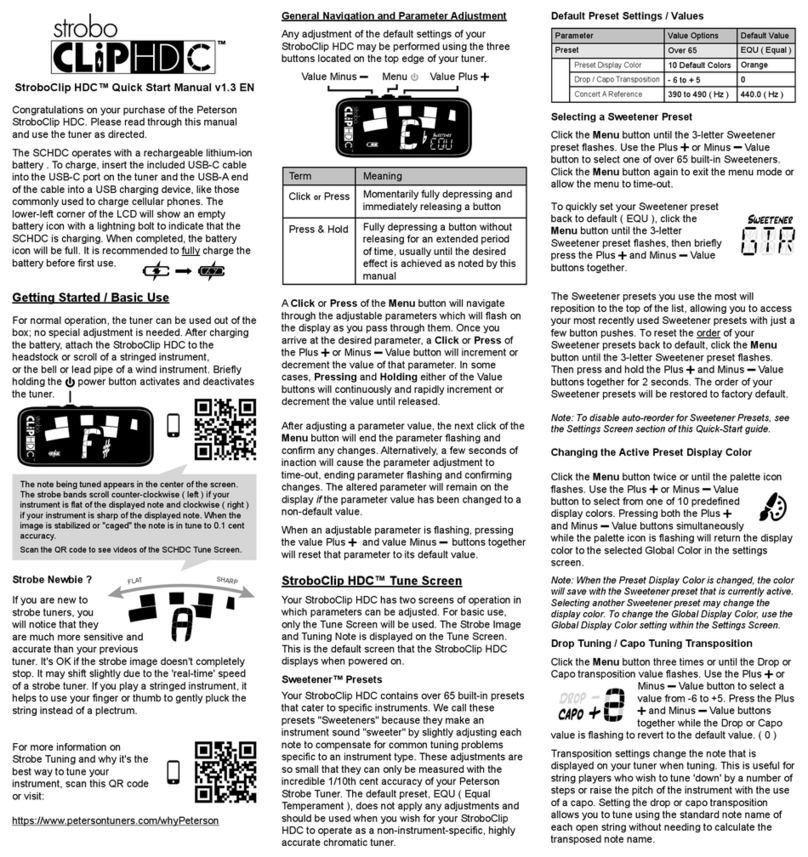

3. PCB details

Top PCB

Front & back

Bottom PCB

Front & back

C1

C2

C3

-12V

www.shakmat.com •

05/19

Tactical Plan

Front & back

www.shakmat.com •

06/19

C1

C2

C3

4. Top PCB assembly

Solder the three 22µF capacitors.

You must pay attention to the orienta-

tion of these components. The long

leg indicates the positive side,

therefore it has to match the + sign

on the PCB silkscreen.

4.1 Front

4.1.1 Electrolytic capacitors (x3) P2

-12V

www.shakmat.com •

07/19

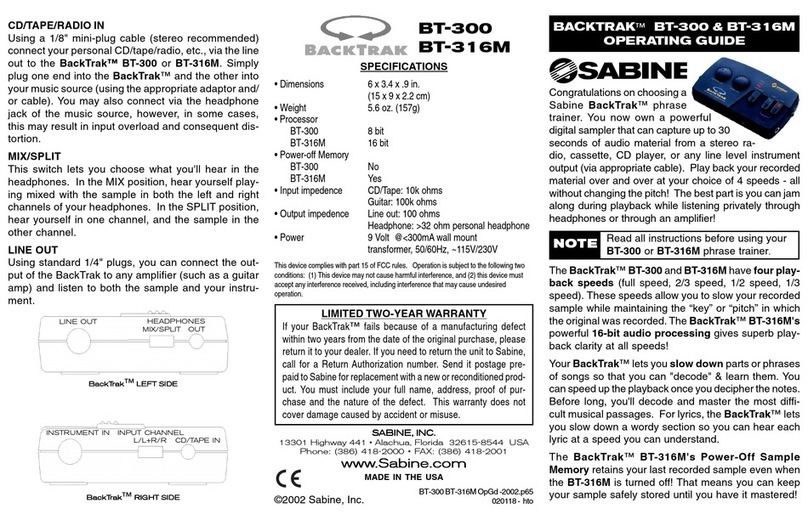

Flip the PCB and place a 4 pin male

header, with the short pin side

through the hole. We will solder these

four headers one by one. Be sure to

lay them flat and upright. Those

headers will later join the two PCBs

together so they need to be perfectly

perpendicular.

We recommend you only solder one

of the pins. Then reheat your solde-

red point and simultaneously press

the plastic part of the header against

the PCB until it’s flat. Take off the

soldering iron but keep pressing.

Avoid touching the pins themselves

because they will become hot very

quickly and move out of alignment

within their plastic bracket. Once you

are satisfied with you placement,

solder the remaining pins.

4.2 Back

4.2.1 Male headers (4pin) (x4) P2

www.shakmat.com •

08/19

Place the power header, the short pin

side in the holes and solder only one

of the pins. Check the alignment and

correct with the same method as for

a single row header. Then, once your

component is upright and flat on the

PCB, solder the remaining pins.

4.2.2 Power header P2

-12V

www.shakmat.com •

09/19

2x

5. Tactical Plan assembly

5.1 Male & Female headers (x2) P2

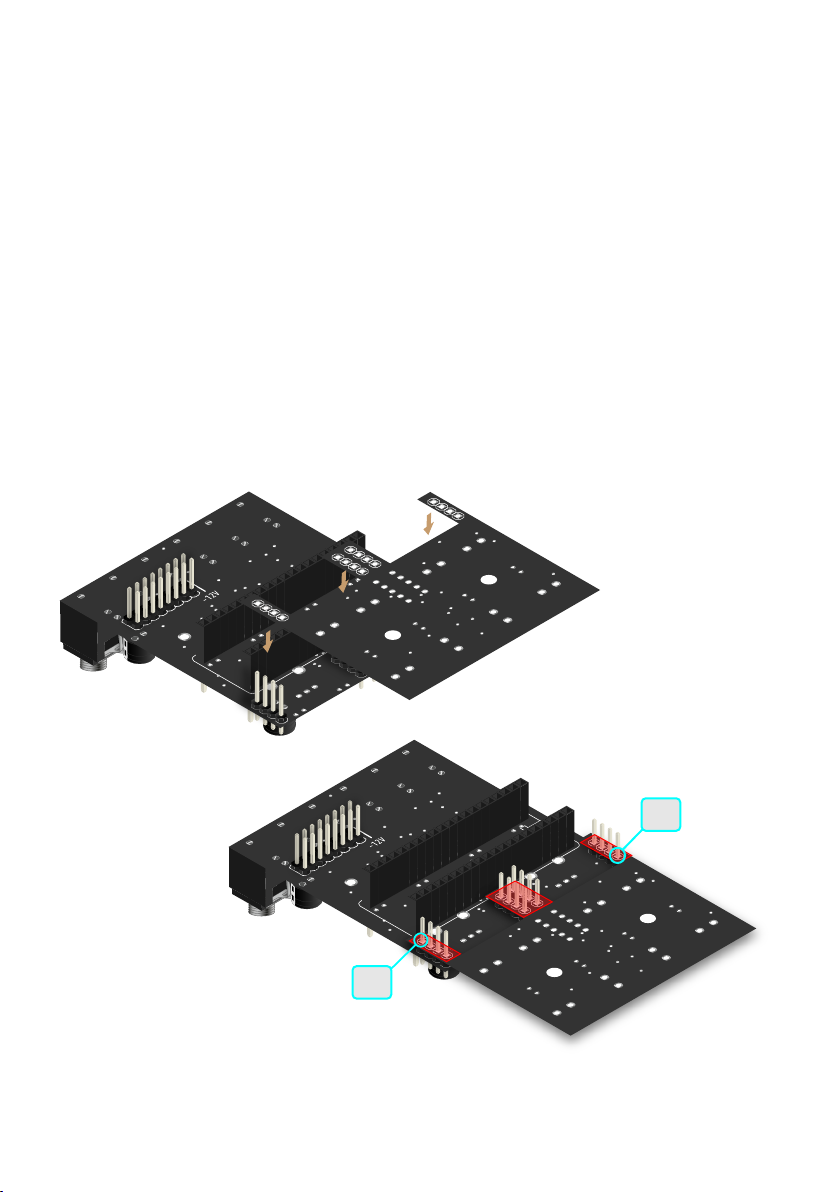

Now, we are going to stack the Tactical Plan with the top PCB. For this we

use two 20 pin pairs of male & female headers. First assemble the headers,

then place them on the Tactical Plan, female side down. Then assemble the

two boards toghether and solder one pin, on each side, for each header. Once

the PCBs are held together and correctly aligned, you can solder all the remai-

ning points.

Be VERY careful with the soldering of the female part of the headers. Once

the potentiometers will be in place, those solder points will be inaccessible.

After everything is well soldered, disconnect the Tactical Plan and proceed to

the next step with the top PCB.

www.shakmat.com •

10/19

Flip the PCB around and solder the

six jack connectors. Be sure to lay

them completely flat on the PCB

before soldering. If those jacks aren’t

perpendicular, the front panel will be

very hard to mount.

If one of the jacks is not perfectly

perpendicular with the PCB, you can

reheat the pads and push it down

with your thumb to re-align.

6.1 Front

6.1.1 Jack connectors (x6) P1

6. Top PCB final assembly

C1

C2

C3

www.shakmat.com •

11/19

C1

C2

C3

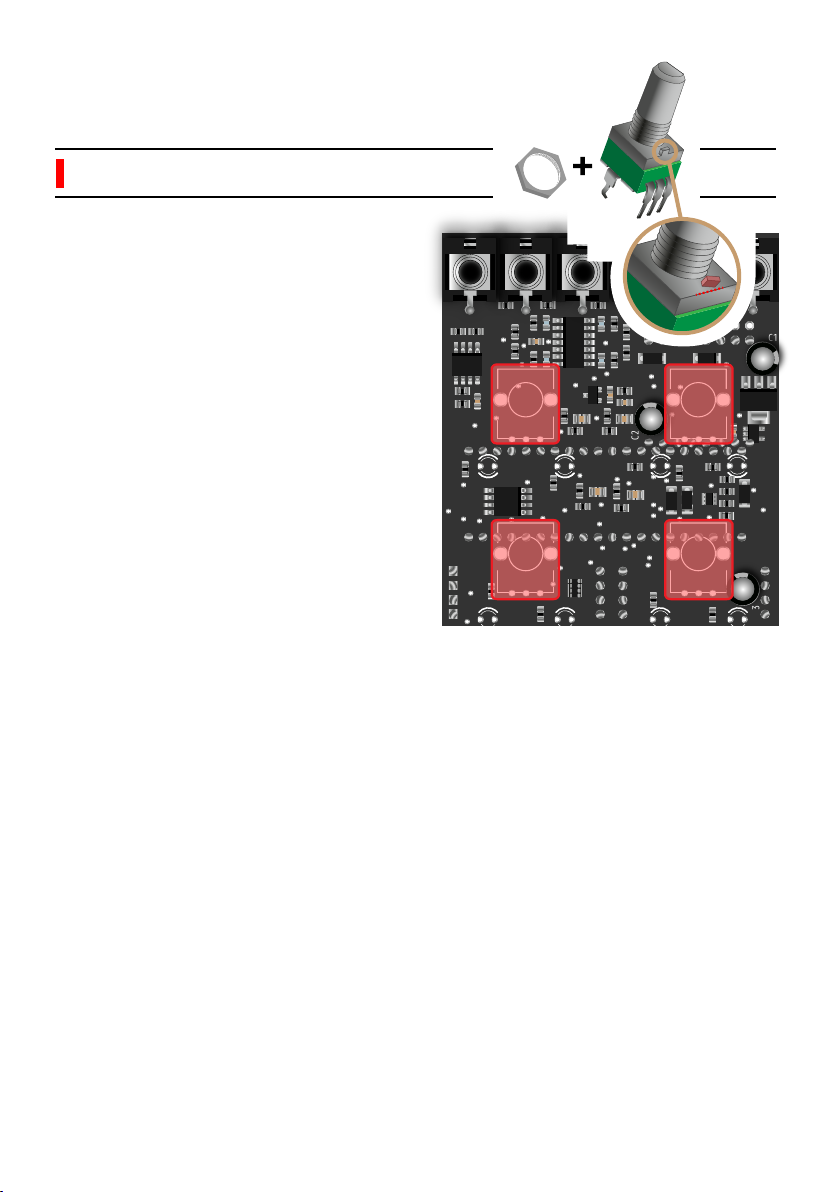

Before soldering, you will have to cut

a little metal piece off the top of each

potentiometer, as shown in the

picture. This little stud prevents the

front panel from sitting properly. Use

some small & sharp cutting pliers for

this task.

Then, place the 4 potentiometers on

the PCB. Be sure that no metal part

of the potentiometer touches a

soldering point from the previous

step. Mount the front panel and

tighten the potentiometers nuts (this

will ensure a proper placement of

the pots) and then solder them.

Once you have soldered everything,

remove the nuts, the front panel and

proceed to the next step.

6.1.2 Potentiometers & nuts (x4) P1&P2

Cut!

4x

www.shakmat.com •

12/19

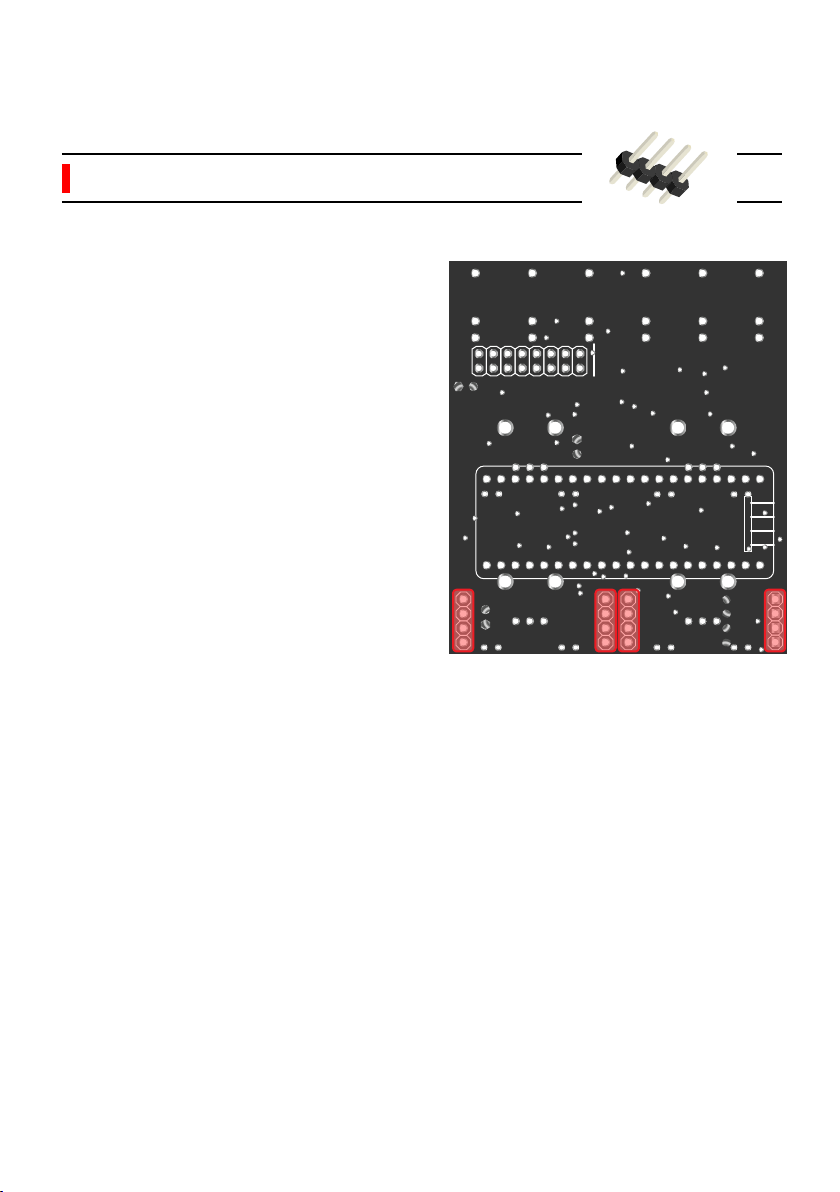

7. PCB stacking

It’s now time to join and solder the two PCBs together. Be very careful during

this step. If you solder every pin and the PCBs arn’t well aligned, you will likely

not be able to correct it and will encounter all sorts of problems on your way to

the end of this build.

The first step is to assemble the two PCBs as shown above, and only solder

the first pin of the small vertical header. It is vey important that you firmly hold

the two PCBs against each other while soldering this point. There must be no

gap between the PCBs and the header’s black plastic part between them.

Once you’ve soldered the first point, you can move on to the second header

as shown below. Repeat the same procedure as for the first point for all of the

four points listed. Once they are all perfect, without any gap between the

PCBs and headers, you can solder every remaining point.

02

01

www.shakmat.com •

13/19

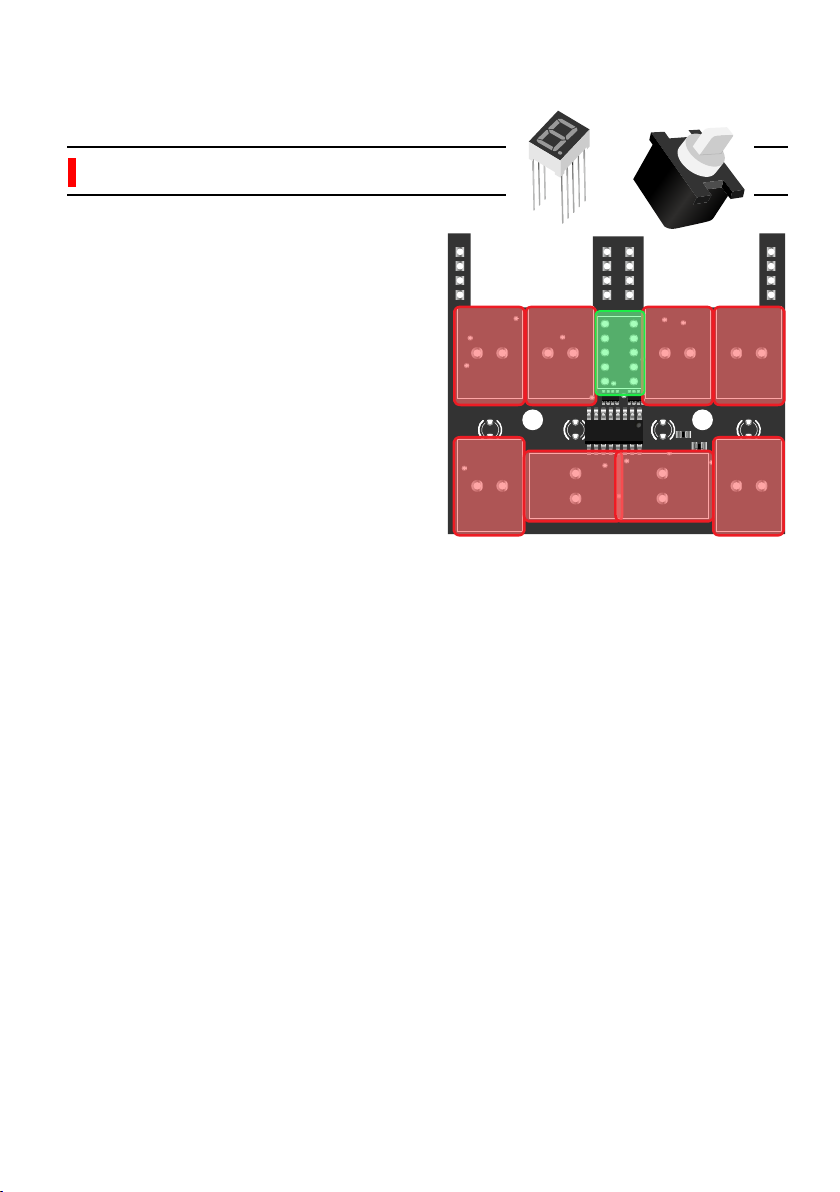

8.1 Front

8.1.1 Push buttons (x8) & display P1

8. Bottom PCB assembly

Before placing and soldering the

push buttons, place the 7 segment

display on the PCB. Pay attention to

the orientation, the dot is on the

bottom line. Sometimes, its legs can

be a little bent thus hard to get

through the holes. So place the

display but don’t solder it and then

the buttons.

The buttons need to be upright and

pushed well against the PCB. An

imprecise mounting will result in a

cap scrapping against the front

panel. We recommend you to place

the buttons, then flip the PCB

(holding the buttons in place with a

piece of cardboard) and press it

against a table.

At the final step, if a button is not well

aligned with the front panel, you can

gently re-heat its solder points and

push it into alignment.

www.shakmat.com •

14/19

9. Front panel preparation

Place some masking tape over every LED

hole on the front panel. Make sure not to

block any other component’s hole with the

tape. The LEDs are special flat top models

intended to be mounted flush with the front

panel. The masking tape will help you to

do this neatly.

You also need to screw the two nylon

spacers on each of the two studs at the

back of the front panel. Screw them until

the end of the thread. These spacers will

assure the stability & alignment of the

PCB’s bottom half.

Nylon spacer (x2) P1

www.shakmat.com •

15/19

10. LED mounting

Placing the LEDs requires a

specific orientation due to their

polarity. The long legs are the

positive side and they all go into

the left holes of the top PCB. For

the bottom PCB, place the long leg

in the upper hole.

Place all the LEDs through the

PCBs. Be aware of LED colors

(some of their legs can be coloured

to help you differenciate them).

LED POLARITY!

Green LEDs ( Ax4) P2

White LED ( Cx4) P2

Amber LEDs ( Bx4) P1

C1

C2

C3

www.shakmat.com •

16/19

Potentiometer nuts (x4) P1

Nylon screw (x2) P1

Assemble the PCBs & front panel with the four nuts on the potentiomers

and the two nylon screws through the bottom PCB into the spacers. Once

everything is well secured, push every LED through their hole until they sit

flush with the panel and stick to the tape. Once they are all in place, you

can solder and trim the legs.

Finally, solder only one leg of the 7 segment display and check that it sits

well against the front panel window. Triple check the display alignment

through the front panel window. When all of its legs are soldered, it is

imposible to correct its placement. Once it’s nicely placed, you can solder

the remaining legs of the display and trim them.

www.shakmat.com •

17/19

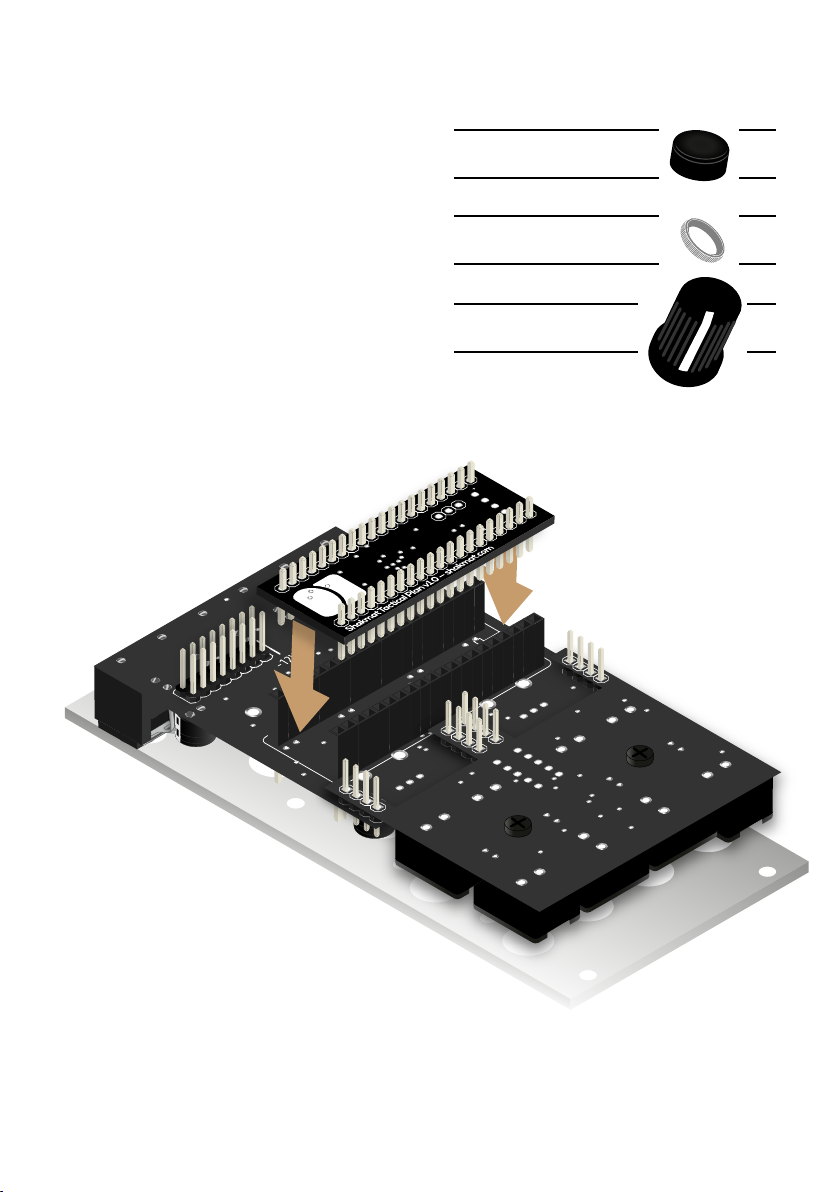

11. Finish

You’re almost done! The last thing

to do is to place the tactical plane

on the top PCB. Pay attention to

the orientation. The Shakmat logo

must be on the left side as shown

here.

Place all the push button caps.

Tighten the knurled nuts on the

jack sockets. Push the four knobs

onto their metal potentiometer.

Button caps (x8) P1

Jack nuts (x6) P1

Knobs (x4) LP

www.shakmat.com •

18/19

12. First startup routine

Make sure all the potentiometers are fully counterclockwise when turning

on your Harlequin’s Context for the first time. Plug in the power cable and

make sure the red side of the ribbon matches the -12V on the PCB. Now let's

plug the module into your system and test it. The module identifies the first time

it turns on and automatically starts the calibration, test and factory reset

routines.

Turn on your rack. The Harlequin’s display shows a “C” for calibration.

• Patch the channel A output into the CV input and press the Scene 1 button

• Patch the channel B output into the CV input and press the Scene 2 button

• Patch the channel C output into the CV input and press the Scene 3 button

• Patch the channel D output into the CV input and press the Scene 4 button

The calibration is now done and the Harlequin automatically switches to the

test routine :

• Each output produces a ramp (saw up LFO)

• CV input positive voltage values are displayed on the 7 segment display

• When an active gate is received in the gate input, the screen turns off

Therefore, patch each channel’s output into the CV input (the 7 segment

display will give values from 0 to F). Patch one of the outputs into the gate

input (the 7 segment display should slowly blink).

To test the white and amber LEDs, press each of the eight buttons of your

Harlequin’s Context. When pressed, each button lights an individual LED up.

The green LEDs show the potentiometer value by their intensity. Turn all the

potentiometers fully clockwise until all the green LEDs are fully on. You will exit

the test routine when all the potentiometers are fully clockwise.

Now hold the first Scene button until the display shows the letter “F”.

Press the Store button to start the Factory Reset routine. This operation will

clear all the non volatile memory, slot by slot, and the display will show the slot

currently being cleared (from 1 to G).

Once the Factory Reset routine is done, the module will start normally.

www.shakmat.com •

18/19

13. Debug

The module does not turn on

Check the orientation of the Tactical plan.

Re-check the electrolytic capacitors and power cable orientation.

The module is stuck in the calibration routine, or one or several outputs

are not working

Check the jack connectors & Tactical plan soldering.

One or several LEDs are not working

Check the LEDs solder points and LED orientation.

Check the Tactical Plan headers solder points.

For the amber LEDs, check the PCB to PCB headers solder points on both

PCBs.

One or several potentiometers are not working

Check the solder points and Tactical Plan headers solder points

One or several buttons are not working

Check the buttons solder points.

Check the PCB to PCB headers solder points on both PCBs.

The 7 segment display is not working

Check the display solder points.

Check the PCB to PCB headers solder points on both PCBs.

Table of contents

Other Shakmat Recording Equipment manuals