SKETCHNBUILD SNB-12A User manual

MACHINERY

SKETCHNBUILD

CONTENTS

Ⅰ.Usage andFeature of Structure…………….………………………1

Ⅱ.TechnicalParameter..…………………………………...……..……1

Ⅲ.SafetyPrecautions………………………………………....…..……1

Ⅳ.Machine Installation……………………...…………………..…..…2

4.1 Mounting Safety Cover on Riving Knife………………………………….....……2

4.2 Extension of Table…………………………...………………………………...…..3

4.3 Pressure Utensil …………………………………………………………...……....3

4.4 Workpiece Push Parts…………………………...…………………………...…….4

4.5 Assembly…………………………….……………………………………….……4

4.6. Adjustment after Installation………………………………………………….…..5

Ⅴ.Operation of Machine……………………………………..…….…6

5.1 Adjustment of Saw Blade……………………………...……………………....…..7

5.2 Replacement of Saw Blade……………………………...……………………....…7

5.3 Setting of Main Saw Blade Speed…...………………………..………………..….7

5.4 Lock of Moving Table……...……………………………………………...…....…8

5.5 Main Switch……………………...………………………………….…….......…..8

5.6 Reaction of Motor to Overload………………..…………………………....……..9

5.7 Scoring Saw………………………………………………………………..………9

5.8 Replacement of Scoring Saw Blade………………………………………...……10

Ⅵ.Maintenance ( Trouble Shooting)…………………………....……11

Ⅶ.Service…………………………………………………………...….13

Ⅷ.Easily DamagedParts……………………………………………..13

Ⅸ.Descriptionof Service Spare Parts for Customers……...….……13

Ⅹ.Circuit Diagram……………………………………………………25

1

Ⅰ.Usage and Featureof Structure

This saw is destined to cut solid wood panel, chipboard, ABS board, PVC board,

organic glass board and other board which have the similar structure and hardness. It

is the necessary working tool for furniture production and decoration industry.

It is made of the body, sliding table, support for sliding table, fixed table, main saw

blade, scoring blade, up & down system, the transverse and vertical guide plate, etc.

The sliding table carriage is linear structure, exact and durable and made of

high-strength extruded aluminum alloy, sliding table is high in strength and won’t be

bent. With oxidation treatment, sliding table surface is beautiful and enduring.

Ⅱ.TechnicalParameter

Power Source

380V+3Ph/50HZ

Sliding Table Length

3200mm

Max. Cutting Height

80mm

Saw Group Tilting Angle

45°-90°

Main Saw Diameter

300mm

Main Saw Arbor Diameter

30mm

Main Saw Speed

4000/6000r.p.m

Scoring Saw Diameter

120mm

Scoring Saw Arbor Diameter

20mm

Scoring Saw Speed

8000r.p.m

Motor Power(Main Saw + Scoring Saw)

4+0.75kw

Diameter of Dust Suction Below the Table

100mm

Net/Gross Weight

650/750kgs

Ⅲ.SafetyPrecautions

All equipment tools, especially the woodworking machinery fed manually, all will

cause a certain danger if not operated properly, therefore, it is required to comply with

the safety precautions and other industrial safety stipulations and requirements

summarized in this chapter forever.

Regulations on accident prevention:

*Before operation, ensure the safety and operating facilities are installed properly

without any damage.

*Before replacing saw blade, removing trouble and repairing, ensure the power

supply has been switched off and it is necessary to lock the main power supply

with lock for preventing accident.

*It is only allowed to use the saw blade and grooving saw blade supplied by the

manufacturer.

*Wear close-fitting work clothes, and do not wear ring, bracelet or wrist watch.

*The work place shall be clean, skidproof and has good illumination.

*Do not cut overlarge or too small workpiece that exceeds the equipment

characteristics.

2

*Stand out of the bounce area of saw blade side and workpiece when operating and

do not stand in middle of saw blade.

*Remove the loose matters around saw blade before starting the machine.

*Cutting shall not be started until the saw blade up to full speed.

*Use safety cover forever!

*Except cross-cutting long and thin wood into pieces, the riving knife shall be used

forever and the riving knife shall not be thicker than the cut width and thinner than

the main saw blade.

Whencross-cutting long and thin wood into pieces cutting, use the anti-bounce device,

such as fix it in the sliding table groove with striker plate against moving. After

cross-cutting long and thin wood into pieces, remount the riving knife and safety

cover immediately.

*When narrow wood is cut longitudinally, the feeding parts shall be used.

*For the purpose of avoiding the cut wood from being brought upward and

bounced out by the uprising tooth ring, an offsetting wedge may be used for

instance.

*Do not cut round log with saw using standard feed auxiliary device or check plate.

*Fix the workpiece on the sliding table with striker plate when trimming.

*When using feed device, it at lease needs to use the longitudinal knife as the

anti-bounce device.

*Worn and torn sliding table strip shall be replaced promptly.

*Do not use wobble saw or cutting device.

*Wear hearing protection when operating because the noise in work place is more

than 85dB (A).

*The saw dust produced in cutting may affect the sight line and be also harmful to

health, so the two dust collector openings of saw shall be connected with the

suction system. When the suction force is not enough, no operation shall be done,

and proper measures must be taken to ensure when the equipment is started, the

suction system also is started.

*Only qualified electrician can operate the electrical equipment of the machine.

*Clean the equipment periodically, especially the saw bench, sliding table and

check plate, which is an important safety factory, and before operation start, it

must be ensured that the equipment cannot be started without cause.

Ⅳ.Machine Installation

4.1 Mounting Safety Cover on Riving Knife

For the purpose of keeping the saw blade on the saw bench, we recommended

separated adjustable protective device.

4.1.1 Mounting Safety Cover

3

4.1.2 Setting of Riving Knife

With respect to safety, the accurate setting of riving knife plays a very important

role. The distance between riving knife and toothed ring in cut height area shall be

more than 8mm, and the distance in most common use is about 5mm and that of the

lower part is 3mm.

When setting riving knife, the power supply must be cut off, for setting riving knife,

move the upper bracket to terminal position of unlocking device, fold the orange

check plate downwards, subsequently, loosen the set screws on the holder of riving

knife with special spanner, then move it in the fixed groove to adjust its height,

remove the whole riving knife holder along the track to adjust the distance between

riving knife and saw blade, and observe the scale on the riving knife at the same time,

then tighten up the set screws and shut to the guard.

4.2 Extension of Table

The worktable attached to the table may prevent workpiece from inclining

backward in cutting and improve the safety. The attached worktable is a necessary

part of a standard machine.

4.3 Pressure Utensil

The pressure utensil is used for pressing workpiece on the sliding table.

4

4.4 Workpiece Push Parts

4.4.1 Push Knife

When the wood less than 120mm to be cut, the push knife shall be used to prevent

hand from approaching to the saw blade.

Push Knife Push Knife Seat

4.4.2 Push Knife Seat

When cutting narrow workpiece, lean the workpiece against the rip fence with push

knife seat that may be self-made by the operator.

5.5 Assembly

4.5.1 Installation of Panel Saw

The panel saw shall be on hardened and flat floor than is enough to bear the weight

of machine without necessity of special foundation. There shall be enough space on

the installation site, as shown in figure, so as to install the equipment and operate

large-size wood. There shall be a certain safety distance betweenother parts and other

machines indoor to prevent hurting other personnel.

5

4.5.2 Installation of Sliding Table

Put the sliding table on the position of machine body, align the three set screws

with the screw holes and tighten them up.

Mount the rear stop plate, check if it is up to the requirement and adjust it otherwise.

Before start-up, check each link.

4.5.3 Electrical Connection

Only qualified electrician can install the electrical equipment, including connection

with power supply. Before electrical installation, the power supply must be cut off.

Only when the main power supply is cut off, each contact may be closed or opened.

The distribution box of panel saw is mounted on the electrical box of machine body

and has output line. There is a terminal box on the side and it only needs to connect

according to the mark.

Electrical Box Terminal box Running Direction

After finishing connection of power cord, start the machine just a little to check the

running direction of main saw motor, if it is necessary to correct, just change the

direction of two cord ends, and write the running direction down on the saw blade

cover with arrow.

4.6. Adjustment after Installation

In final assembly, the basic settings have been done in the factory. But adjusting the

basic settings of machine is necessary because of disassembly, transportation and

assembly on site.

4.6.1 When adjustment, make the sliding table slide smoothly from one end to the

other and can be made slide with a little force from stationary state.

Check the moving table, put a rule on the moving table, move the moving table to

the middle position and move the moving table backward and forward, the aluminum

6

worktable shall be a little lower about 1/10mm.

Setting the moving table, unscrew the lock screws on the four stud bolts, adjust the

worktable, tighten up the set screws, then put the rule on the fixed table to be parallel

with the moving table, if the surface is sunken, adjust the pressure screw for

compensation.

4.6.2 Adjust the saw blade to max cutting position, use it to cut out a small piece (it

may as well be MDF board) along cross-cutting guiding rule, judge if the setting of

moving table is correct through the sound difference between saw teeth cutting and

not cutting, when the uprising saw teeth passing through, there is only a little swing,

but saw teeth have noise in cutting.

Setting: loosen the mounting pieces on both ends of moving table and in the middle,

unscrew the lock nuts of stop screws for adjusting properly and then lock them,

afterward, adjust the moving table and tighten up each set screw.

4.6.3 Parallel Check Plate Cutting

Adjust the saw blade to the max cutting position to cut a piece of 300×450mm

sample, if the setting of moving table is correct can be judged from the sound of

uprising saw teeth.

Ⅴ.Operation of Machine

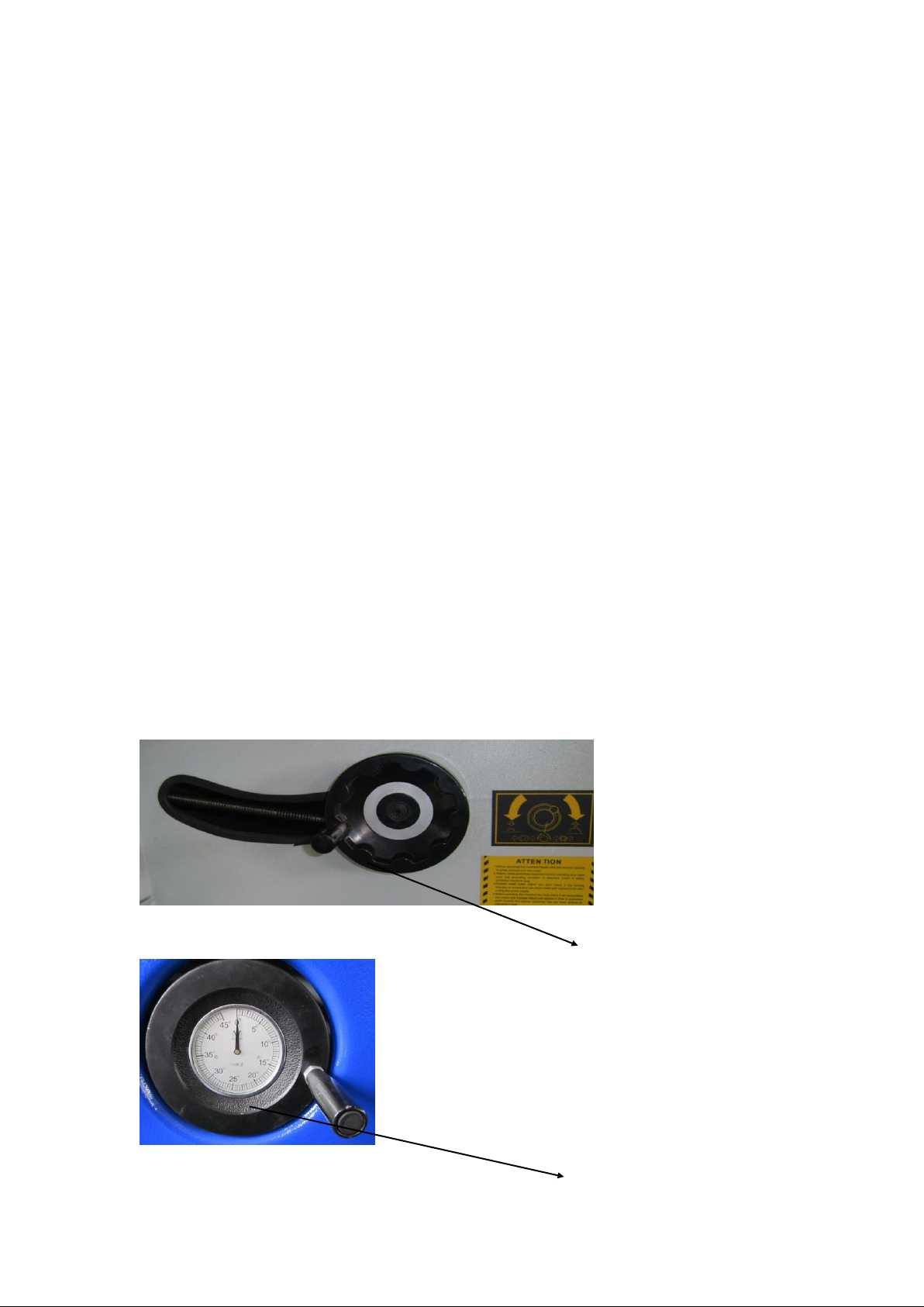

To raise or lower the saw blade: it just needs to adjust the Up/Down hand wheel on

the right side of the machine body.

To reduce or enlarge the angle: adjust the angle hand wheel in the front of machine.

Height Control Handle

Angle Control Handle

7

5.1 Adjustment of Saw Blade

It shall comply with the following requirements by all means:

*Don’t mount the cracked or damaged saw blade.

*Make a check, the rotary speed of saw blade shall not be too high, and the

maximum rotary speed is marked on the saw blade.

*Pay attention to choosing proper saw blade, open the clamp nut, and clockwise

mount the main saw blade on arbor, put the saw clamp on, then tighten up the

clamp nut, for scoring saw, mount anticlockwise the saw blade, tighten up the nut

at last.

Mount the Main Saw Blade Mount the Scoring Saw Blade

Cut off the power supply, adjust the saw blade to the top height with the

obliquity of 0°, press down the emergency button to move the upper moving table

towards the cutting direction until the forefront, and then lift the orange damper,

afterward clockwise screw off the saw arbor nuts with special spanner.

5.2 Replacement of Saw Blade

Prior to mount the new saw blade, remove the sawdust on flange firstly. Mount the

saw blade and front flange on saw arbor. Anticlockwise tighten up the saw arbor nuts

with specialspanner; afterward check if the thickness and space of the riving knife are

matching with the saw blade.

Close the safety cover, and take a simple trial run to see if the saw blade operates

correctly, lower the safety cover of upper saw blade to the designated position for

checking if the saw blade is protected completely.

Important suggestion: After saw blade is replaced, check if the riving knife is

mounted correctly by all means.

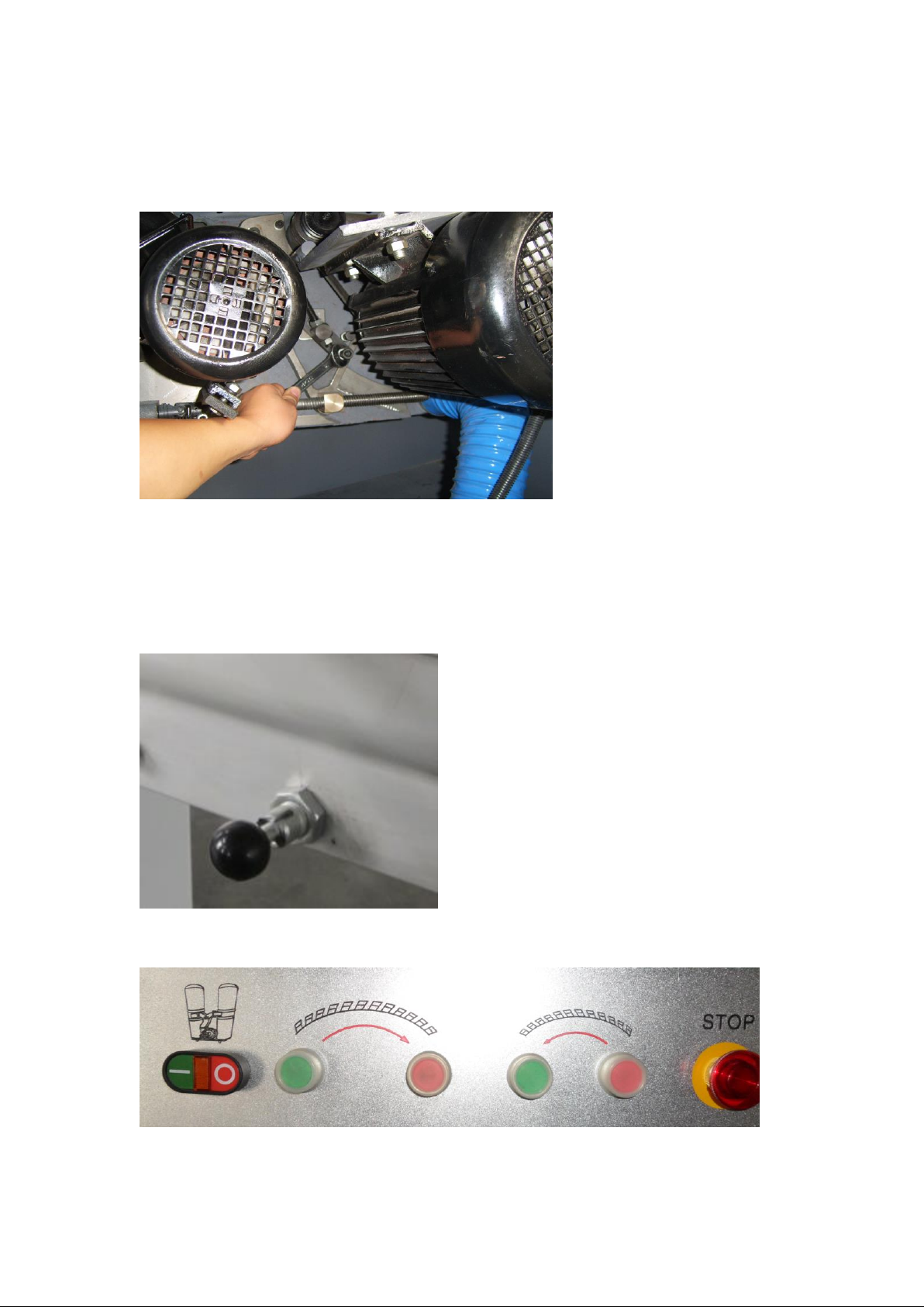

5.3 Setting of Main Saw Blade Speed

Our panel saw is of two speeds, i.e. the rotary speeds of main shaft are 4,000 and

8

6,000, which can be reached by moving the V-belt.

Shut down the driving, cut off all the power supplies, unscrew the V-belt tension

screws on the lift board, and raise it to the left, then the belt position can be adjusted,

please refer to the following pictures for operation.

Explanatory of Belt Replacement

5.4 Lock of Moving Table

The moving table is locked manually at the backend against moving casually so as

to prop the wood to cut against the cross-cutting guiding rule, and it may be unlocked

with the handle at the backend of the moving table.

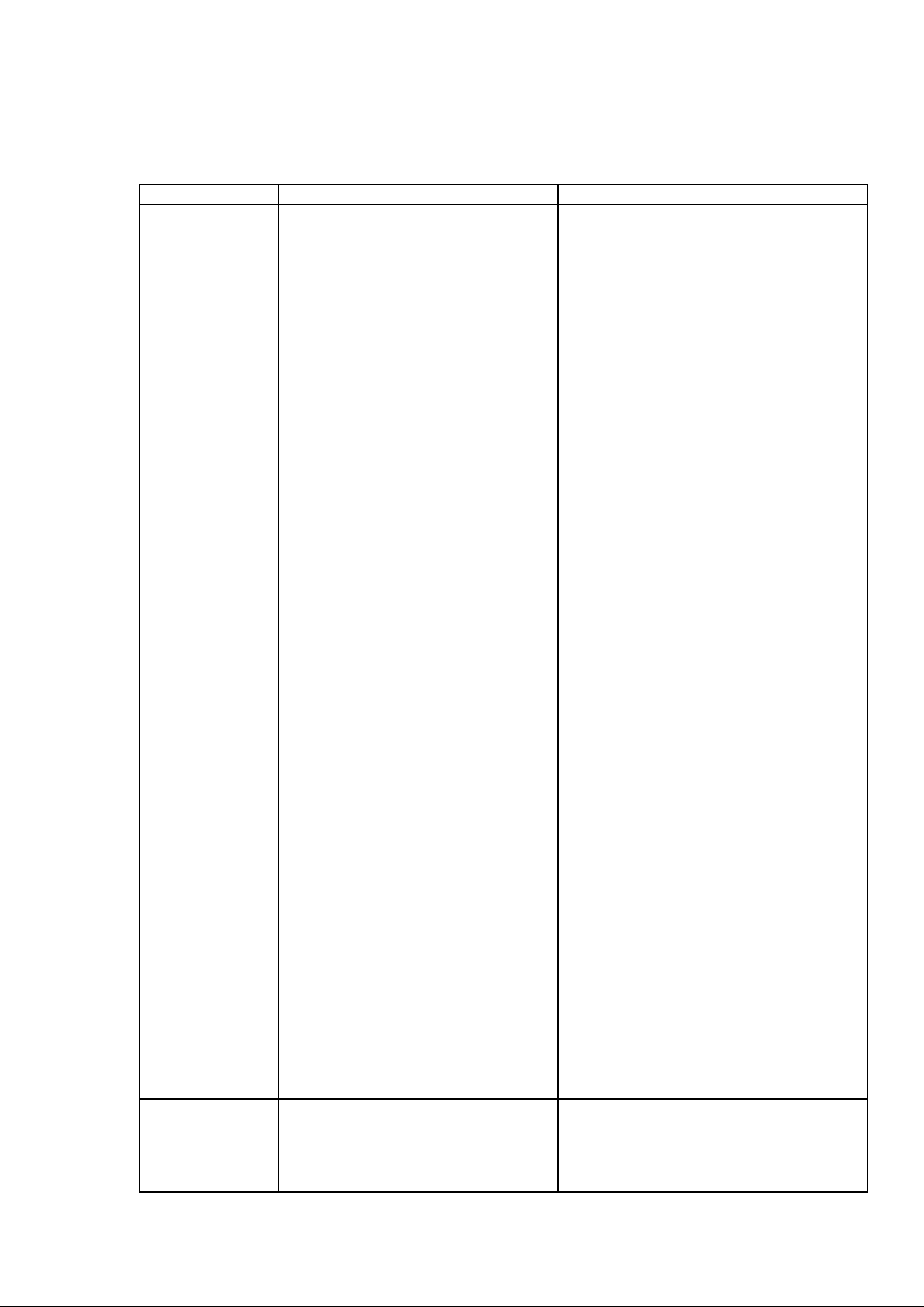

5.5 Main Switch

Button Panel

9

5.5.1 Start:

Before closing the main power supply switch, the emergency stop switch must be

in open condition. Then turn the emergency stop switch to left, and turn on the green

button of main saw, hereby the main saw is started. The scoring saw can be started

only 5s after main saw starting.

5.5.2 Stop:

The red button on the right of green button is the stop button of main saw. Press

down this button, the main saw will be stopped and the scoring saw will be stopped

accordingly.

5.5.3 Emergency Stop:

The machine can be stopped by the emergency stop switch, but this switch only can

be used in case of emergency.

5.6 Reaction of Motor to Overload

Reaction of motor to overload means the motor is over loaded, prior to restart,

causes shall be found out and trouble shall be removed by all means, there is a

thermal rounding protective device to protect the motor, if overheat, the motor will be

stopped automatically. Attention shall be paid in this situation that the motor of the

machine with a scoring saw attached will be stopped automatically even if the scoring

saw motor is not overheated. Only after the thermal relay cooling down, can the motor

be started again, and the thermal relay needs about 10min to cool down.

Electrical box shall be measured by the electrician every year.

5.7 Scoring Saw

The scoring saw is for the breakthrough in panel cutting that is to make the cutting

of both panel surfaces slippery and smooth. Scoring saw first cuts 1-2mm below the

panel, and then the main saw blade cuts it. Scoring saw blade and main saw blade

must be aligned with each other and with the same width.

This machine is furnished with stepped single-score saw blade, which can be

adjusted up and down or left and right by the regulating handle, cut of the scoringsaw

blade is 1/10mm wider than the main saw blade, that is to say 5/100mm of each side.

Cut height and left & right adjustments are all completed by the manual adjusting

handle and hand wheel.

10

Scoring SawAdjustment

Adjust Up & Down Adjust Left & Right

Use the handle of scoring saw on right side of panel saw to adjust, one is for

adjusting up and down and another is for left and right, turn the handle left and right

until aligning to a satisfactory height with the main saw blade.

5.8 Replacement of Scoring Saw Blade

*When stopping the machine, adjust the scoring saw blade to the highest position,

move the moving table to the cutting direction to expose all scoring saw blades,

lock up the moving table, open the safety cap, and clockwise screw off the fixing

nuts with special spanner. Take out the front flange and dismount the scoring saw

blade.

*Remove the stickers in the two flanges before mounting the new saw blade.

Mount the saw blade and the front flange on the saw arbor, and then clockwise

tighten up the nut.

*When using the scoring saw set with stepless cut width, it shall strictly comply

with the following items, and disobeying the requirements of operation manual

will endanger the production, the lose caused by which is not in the claim range:

◆Max. rotary speed of the saw blade is 8,000rpm, and allowable cut width is

2.8-3.2mm.

◆Open and pack the adjusting devices with special care against injury.

◆The adjusting devices can only be stored in the original packing!

◆All connecting parts shall be mounted properly by all means.

◆If the connecting component fittings being lost or damaged, the original

fittings shall be used for replacement.

5.8.1Setting of Scoring Saw Blade Width

*Use spacer to set the width of double saw blade to make it 0.1mm wider than the

main saw blade.

*At first, align the scoring saw with the main saw at one side of the machine, and

carry on a trial cutting.

*Align them in left and right by means of increasing or decreasing spacer.

5.8.2 Setting of the Single Grooving Saw Blade

Use the handle of scoring saw on right side of panel saw to adjust, one is for

adjusting up and down and another is for left and right, turn the handle left and right

until aligning to a satisfactory height with the main saw blade.

11

Ⅵ.Maintenance (Trouble Shooting)

In trouble shooting process, please operate complying with the following descriptions:

Trouble

Cause

Solution

Machine can’t

be started

Machine stops

automatically.

Main switch is not started up;

Interruption occurs in electric

circuit or some phase;

Protection for over load trips,

however, thermal relay is still not

cold that can’t reset;

Ends of the moving table exceed

the middle part of saw blade that

results in saw cut length is not

enough.

Emergency switch is pressed

down;

Saw blade front plate guard or

machine back door is not closed;

Fuse for controlling the current

circuit is blown out.

Power supply interruption occurs

in one or more phases, e.g.

because the fuse is blown out.

Saw blade is too blunt or saw

cutting speed is too fast that results

in over load protection trips;

Fuse for controlling current circuit

is blown out;

Close the main switch knife “I”

Wait for recovery of the electric

circuit, or find out and remove the

cause for power failure. (e.g.: fuse is

blown out)

Solve the over load problem of

machine, and wait for the thermal

relay cooling down;

Pull the moving table back to the front

end of the saw blade middle part

again.

Turn emergency switch to right to

original position;

Close the door, and cover the plate

guard;

Open the electrical cabinet (prior to

which close the main switch), and find

out which fuse is damaged among F1,

F2 & F3. Find out the cause and

remove the trouble. Then, replace the

burned fuse. Pay attention to that the

fuse with same load can only be used;

Remove the cause for power failure in

phase, and re-start the machine.

Replace the saw blade or reduce the

saw cutting speed; wait for the thermal

relay cooling down, then re-start the

machine;

Open the electrical cabinet (prior to

which close the main switch), and find

out which fuse is damaged among F1,

F2 & F3. Find out the cause and

remove the trouble. Then, replace the

blown fuse. Pay attention to that the

fuse with the same load can only be

used;

Motor is

running, but the

workpiece does

not run.

Saw blade becomes blunt;

Riving knife blade does not match

with the saw blade

Mount the new saw blade;

Replace with proper riving knife

blade, and the thickness of which shall

be a little narrower than that of the

main saw blade;

12

Trouble

Cause

Solution

Width of the workpiece cut

by saw is not corresponding

with the width regulated on

the parallel check plate

Scale of saw cut width shifts

Re-regulate the ruler. Cut a

workpiece on parallel check plate

with saw, and measure out the

saw cut width, and then adjust the

scale of aluminum ruler to this

measurement;

Width of the workpiece cut

by saw is not corresponding

with the width regulated on

the cross-cutting check plate

Scale of saw cut width ruler shifts

Adjust the ruler again. Cut a piece

of workpiece on cross-cutting

check plate with saw, and

measure out the saw cut width,

then adjust the scale of aluminum

ruler to this measurement;

Operation of oscillating arm

is unstable.

Telescopic arm or guide pulley is

dirty

Wash the telescopic arm and

guide pulley;

The moving table wonders.

Improper installation of lower

guide pulley

Adjust the lower guide pulley of

moving table

Ends of the moving table is

higher than the worktable

Improper installation of lower

guide pulley

Adjust the lower guide pulley of

moving table

Saw blade is scorched on the

moving table surface

Adjustment to the free saw cutting

of moving table is insufficient;

adjustment to the free saw cutting

of parallel check plate is too

large;

Adjust the free saw cutting;

Adjust the parallel check plate;

Saw blade is scorched on the

parallel check plate surface

Adjustment to the free saw cutting

of parallel check plate is

insufficient.

Adjust the free saw cutting;

Both sides of the saw blade

are scorched.

Adjustment to the free saw cutting

is insufficient;

Workpiece is locked;

Operation mistake;

Adjust the free saw cutting;

Replace with a little thicker riving

knife blade;

Push the workpiece forward along

left or right. Use the moving table

for saw cutting, and don’t prop

against the parallel check plate.

Workpiece is cut by saw later

and has the mark of being

scorched.

Saw blade is too blunt;

Charging speed is too slow;

Too many saw teeth on the saw

blade;

Mistake in free saw cutting;

Replace the saw blade;

Be quicker in feeding; Replace

the saw blade;

Adjust the free saw cutting

Broken stubble (with

grooving saw)

Grooving saw is not aligned with

the main saw;

Grooving saw blade is too narrow;

Readjust the centerline;

Adjust the width of saw blade;

Workpiece upwarping in saw

cutting process.

Grooving saw blade is too blunt;

Saw cut height is insufficient;

Replace the saw blade;

Adjust the saw cut height;

13

Ⅶ.Service

Prior to any maintenance for the machine, the power supply shall be cut off to guarantee

the safety. Periodic cleaning can prolong the service life, and also is the precondition of

perfect cutting effect. Thus the sliding table shall be cleaned at least twice a week according

to the service condition. It is advisable to clean it once a day.

Clean the main parts, including fixed table, sliding table, guide shaft of sliding table, casting

iron piece of the rip fence,machine inside, and machine surroundings.

Use the dust collector to remove the paring and saw dust attached to the machine, when

removing the resin residue, it is advisable to use the cleaning agent that can dissolve the resin,

after treatment of parts is finished, it is necessary to use the cloth with oil to wipe them for

preventing rust.

7.1 SawArbor Lubrication

Bearings of the main saw arbor and grooving saw are closed and have been lubricated for

whole lifetime, so there is no needto add lubricant.

7.2 Other parts shall be lubricated at least twice a week as the case maybe.

Ⅷ.Easily DamagedParts

Name

Model

Specification

Number

Installation parts

Bearing

6206

Import

2

Main Saw Arbor

Bearing

6203

Import

1

Scoring Saw Arbor

Bearing

6204

Import

1

Scoring Saw Arbor

V-Belt

0 model

580

2

Main Saw

V-Belt

0 model

560

1

Scoring Saw

Ⅸ.Descriptionof Service Spare Partsfor Customers

We have the stock of main spare parts and wearing parts, which is a very important

precondition for keeping board-cutting efficiency and production capacity.

When ordering the fittings, please refer to the detailed list. And for more details, please

refer tothe explanatory notes in drawings in the specification.

We are only responsible for guaranteeing the original parts provided by our factory.

We are not responsible for any lose or result from using the unoriginal fittings and

accessories.

Attention: there are available materials of the specification for specialized production and

delivery of the fittings supplied by us that are up to the updating technological requirement

and legal rules all.

14

Chapter

1. Fixed Table And Supporting & Adjustment Mechanism

2. Main Saw

3. Auxiliary Saw

4. Machine Body & Turning Arm

5. Bracket

6. Crosscut Guide Plate

7. Straight-cut Guide Plate

8. Double Roller Carriage-Top Carriage

9. Double Roller Carriage-Middle Carriage

10. Double Roller Carriage-Bottom Carriage

15

1. Fixed Table And Supporting & Adjustment Mechanism

1. Fixed Table

2. Protection Board

3. Lift Board

4. Connection Board

5. The Cover of Anti-Dust

6. Saw Nipping Plate

7. Pulling Board

8. Longitudinal Cutting Knife

9. Fixed Board

10. Nut

11. Connection Board

12. Following Action Board

13. Bolt

14. Cushion

15. Plywood

16. Bolt

17. Protection Hood

18. Circumgyrating Base

19. Guide Track

20. Bolt

21. Pipe Block

22. Dust Collection Pipe

23. Guide Track

24. Circumgyrating Base

25. Cushion

26. Bolt

27. Lift Nut

28. Lift Screw

29. Gimbal

30. Hand Wheel

31. Handle

32. Bolt

33. Angle Bolt

34. Angle Nut

35. Lift Adjusting Spindle

36. Adjusting Base

16

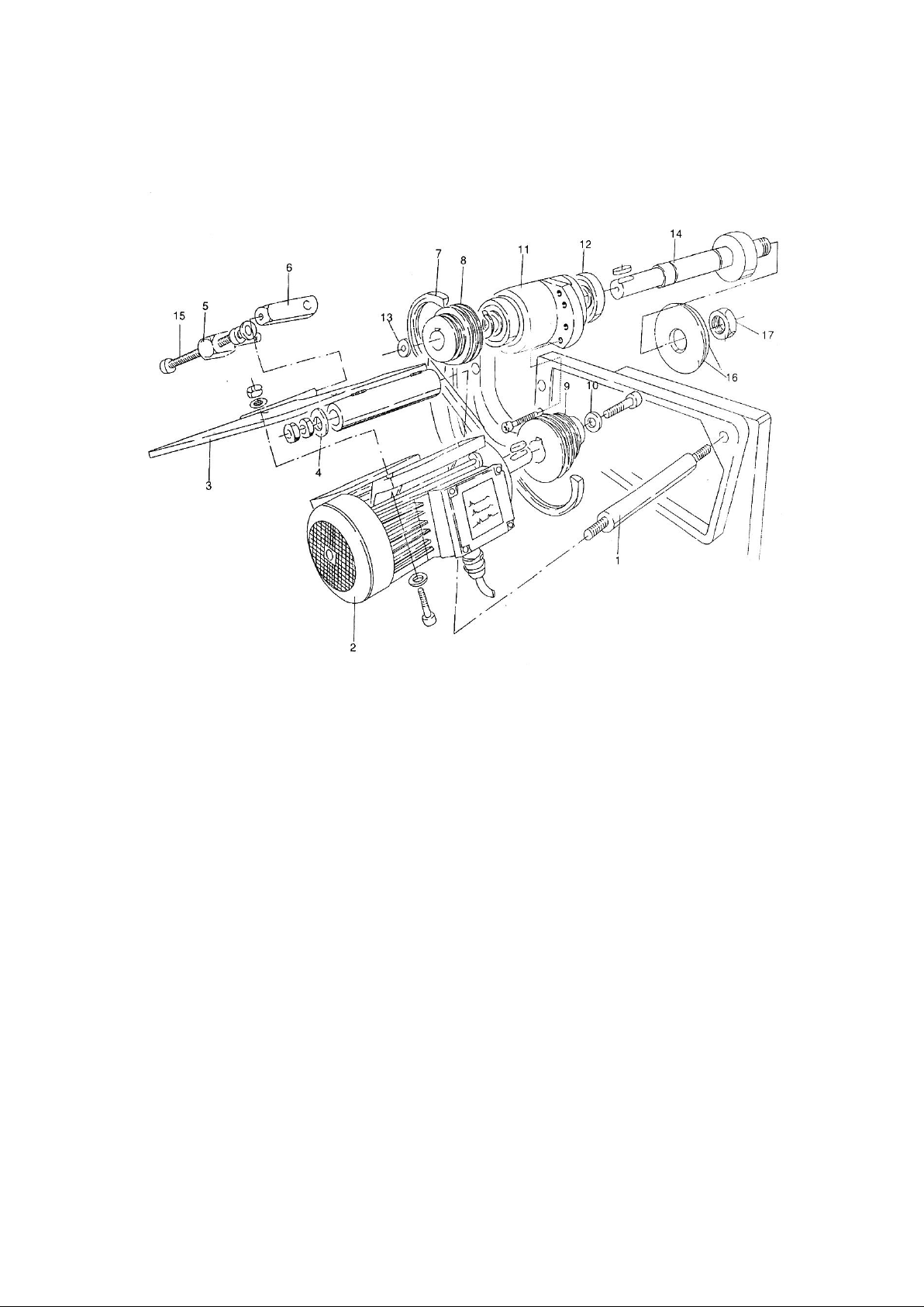

2. Main Saw

1. Motor Base Spindle

2. Motor

3. Motor Base

4. Cushion

5. Connection Board

6. Adjusting Sheath

7. Triangular Belt

8. Main Spindle Wheel

9. Motor Wheel

10. Pressure Cushion

11. Main Spindle Sheath

12. Bearing

13. Pressure Cushion

14. Main Spindle

15. Adjusting Screw

16. Saw Nip Plate

17. Nut

17

3. Auxiliary Saw

16. Inching handle

17. Lock nut

18. Fixed Sheath

20. Fixed Base

21. Feeding Block

22. Bolt

23. Scorning Saw Turning Base

24. Spring

25. Oriented Spindle

26. Motor Base

27. Nut

28. Pressure Cushion

29. Scoring Saw Spindle

30. Bearing

31. Scoring Saw Sheath

32. Bearing

33. Sheath

34. Driving Belt

35. Scoring SawWheel

36. Pressure Cushion

37. Motor Wheel

38. Pressure Cushion

39. Motor

40. TorsionSpring

18

4. Machine Body & Turning Arm

1. Machine Body

2. Door Cover

3. Bolt

4. Angle Adjusting Handle

5. Board Base

6. Operation Button

7. Nut

8. Sheath

9. Nut

10.Eccentric Spindle

11. Adjusting Spindle

12. Hair Brush

13. Stop Head

14. Roll Wheel

15. Bearing

16. Bearing

17. Spindle of Turning Arm

18. Hair Brush

19. The Pipe of Turning Arm

20. Lug

Table of contents

Popular Power Tools manuals by other brands

Axminster Trade

Axminster Trade AT150SP manual

Woodstock

Woodstock SHOP FOX W1667 owner's manual

Ingersoll-Rand

Ingersoll-Rand 1100PS4-EU instructions

Slime

Slime 40051 instructions

Swarts Tools

Swarts Tools SW2000 Instruction booklet and warranty information

Challenge

Challenge PADDY WAGON Instructions and parts manual

Meister

Meister MAS18W Translation of the original instructions

norbar

norbar EVOTORQUE 2 Quick reference guide

Grizzly

Grizzly H8118 instruction sheet

Worx

Worx Maker X WX743 Safety and operating manual original instructions

Milwaukee

Milwaukee M12 CHZ Original instructions

Scheer

Scheer HM 4 Maintenance manual