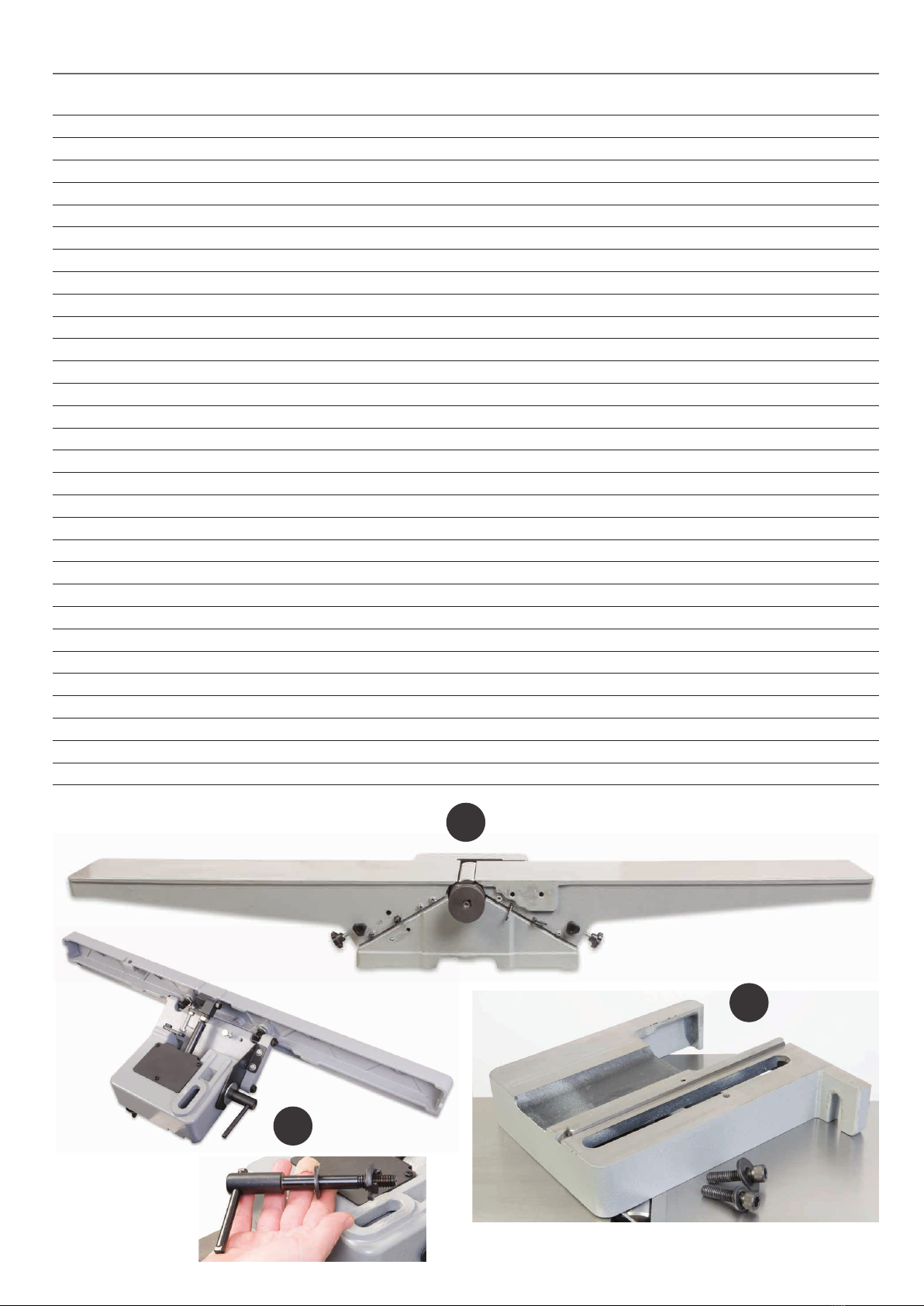

Specific Safety Instructions for Planers

7

• Keep the cutting blades sharp and free from resin and

other residue

• Always use a push stick or push block to keep your

fingers away from the cutting block.

• When planing narrow timber ensure that the exposed

part of the Cutterblock is fully guarded.

• Do not attempt to process timber less than 200mm long,

20mm wide or 6mm thick.

• Maintain the correct relationship between the infeed

table, outfeed table and cutterblock as described in the

operating instructions.

• Always feed the work from infeed to outfeed table

(i.e. from right to left), not the reverse.

• Always plan your work in advance, particularly with

respect to the method of holding and feeding the work

through the machine. Unusual jobs need particular care

and forethought.

• DO NOT make cuts deeper than 1/8” (3mm) in a single

pass. On cuts more than 1/2” (12.7mm) wide, adjust

depth of cut to 1/16” (1.6mm) or less to avoid the wood

from tearing.

• Do not try to cut more than 3mm deep in one pass. The

wider the material, the thinner the cut should be in order

to minimise the load on the motor and the risk of kick

back.

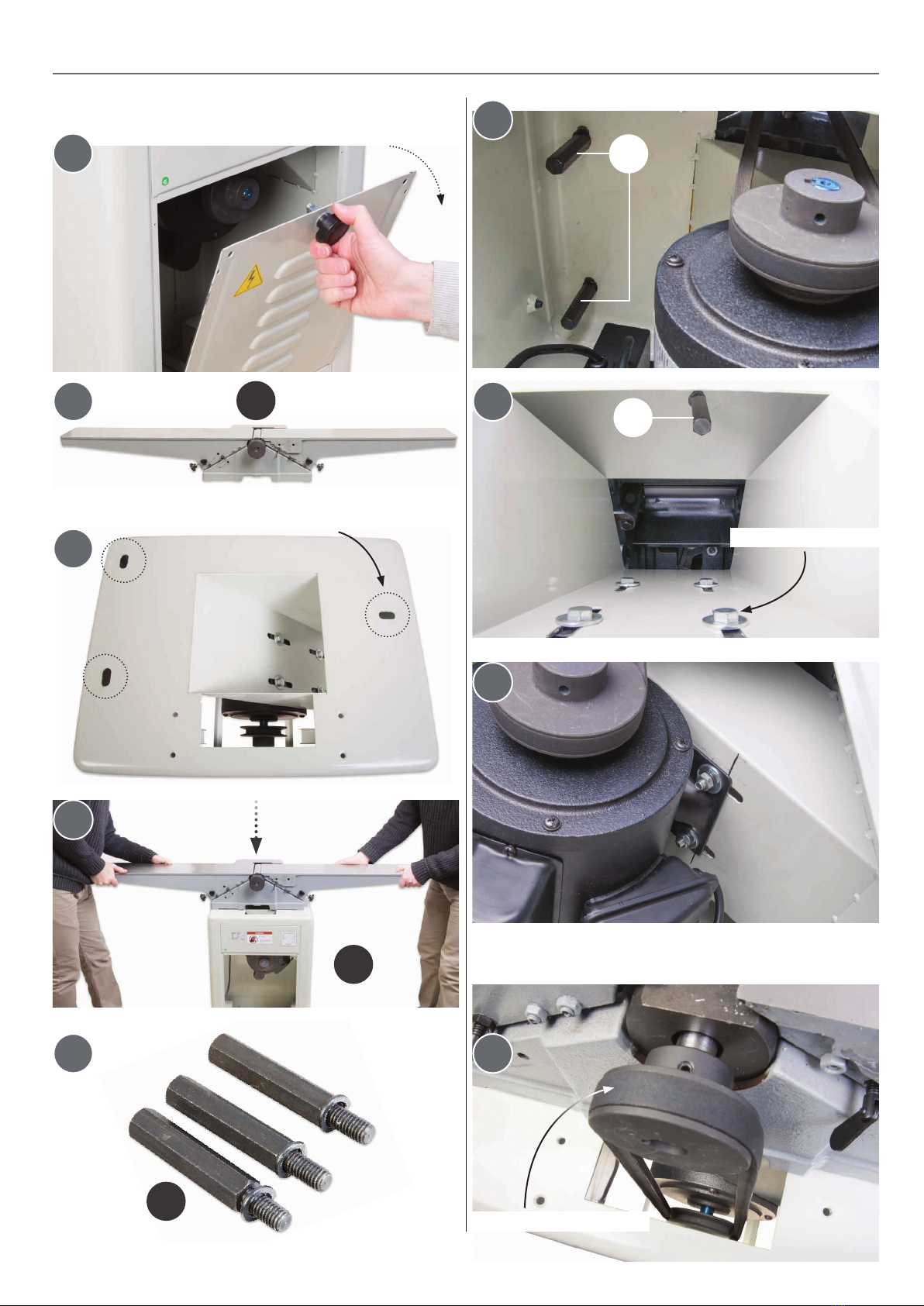

Code 104349

Model AT150SP

Rating Trade

Power 1,120W 230V

Cutterblock Speed 4,200 rpm

Cutterblock Diameter 60 mm

Max Planing Width 150 mm

Max Depth of Cut Planer 3 mm

Knives HSS (Resharpenable) x 3

Noise Level dB(A) 85dB(A)

Fence Size 705 mm x 100 mm

Length of Table 1,422 mm

Table Size 1,422 mm x 150 mm

Min Extraction Airflow Required 1,000 m³/hr

Dust Extraction Outlet 100 mm

Overall L x W x H 1,422 mm x 560 mm x 940 mm

Weight 80 kg

Specification

Code 106240

Model AT150SSP

Rating Trade

Power 1.2 kW

Cutterblock Speed 4,200 rpm

Cutterblock Diameter 60 mm

Max Planing Width 150 mm

Max Depth of Cut Planer 3.0 mm

Knives TC Spur Cutters x 28

Noise Level dB(A) 76dB(A)

Fence Size 705 mm x 100 mm

Length of Table 1,422 mm

Table Size 1,442 mm x 150 mm

Min Extraction Airflow Required 1,000 m³/hr

Dust Extraction Outlet 100 mm

Overall L x W x H 1,422 mm x 560 mm x 940 mm

Weight 80 kg