www.skf.com/lubrication 7English

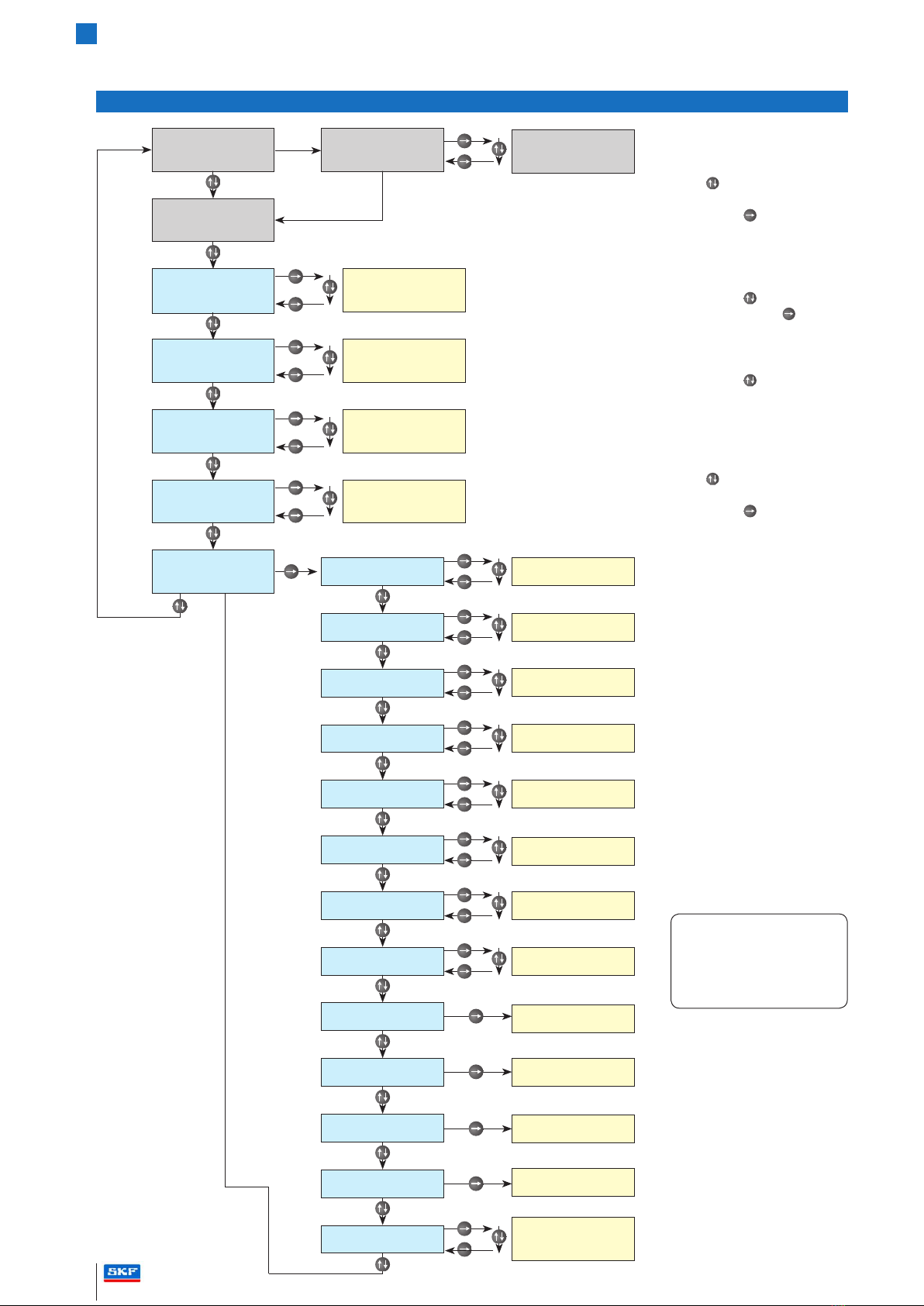

Menu functions for pressure switches with 2 switch points

First menu level

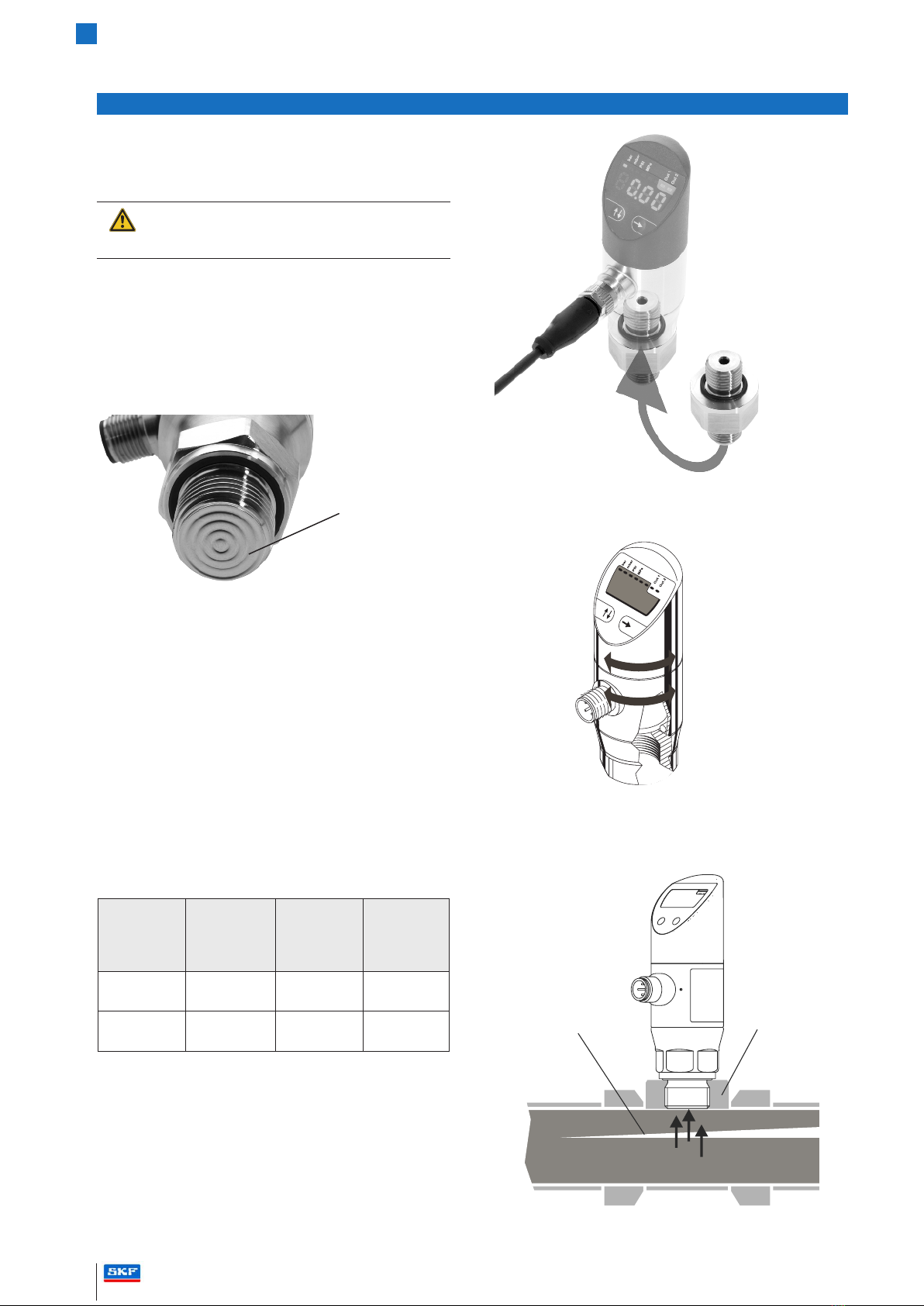

SP 1

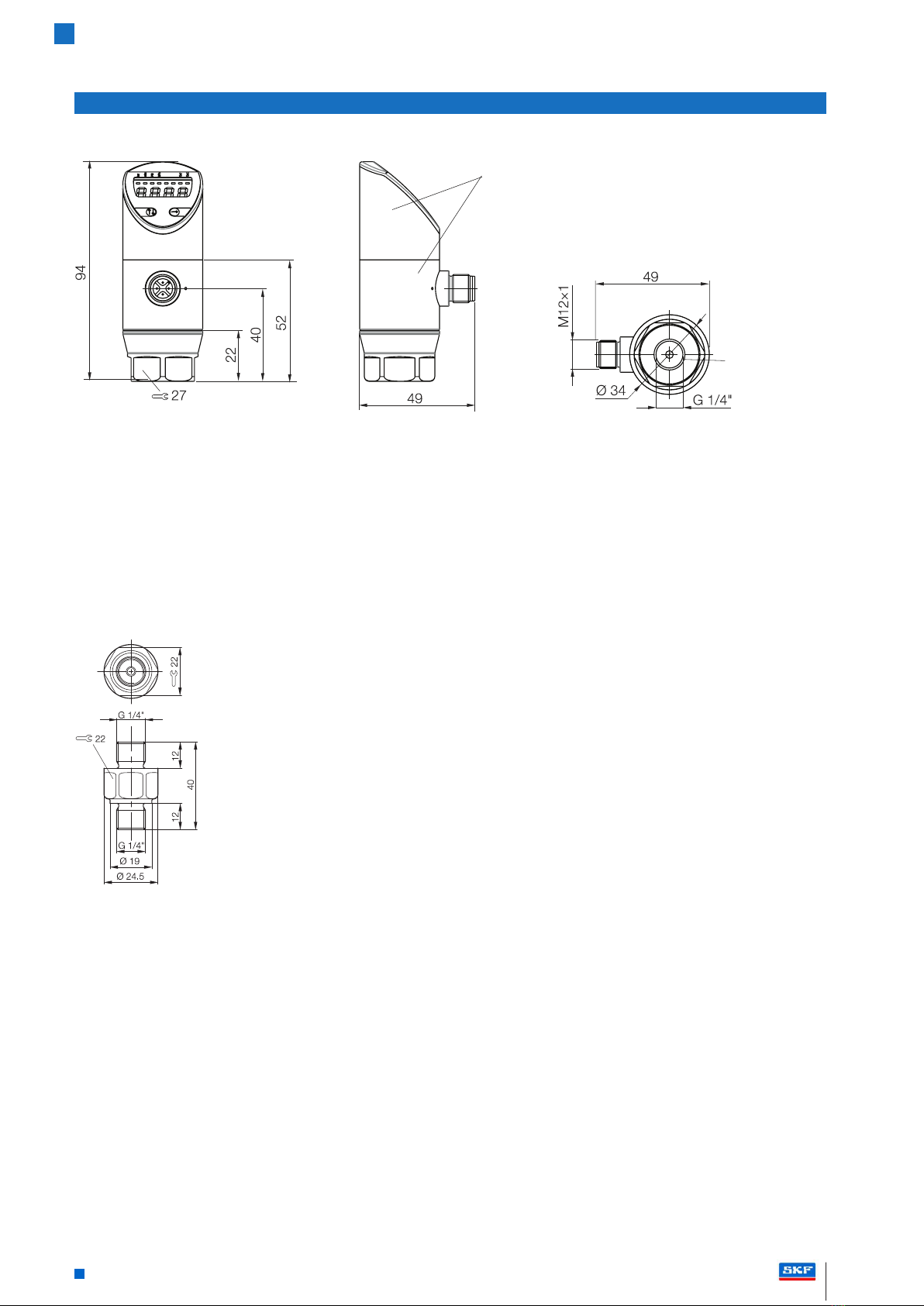

FH 1

Menu 1 – Setting for switch point 1, setting for

the relevant value from which switch point 1

shall be activated.

If the window function in menu 5:6 is activated,

the value for switch point 1 represents the

upper pressure limit in the window (FH).

rP 1

FL 1

Menu 2 – Setting for return switch point 1,

setting for the relevant value from which return

point 1 shall be activated.

If the window function in menu 5:6 is activated,

the return value for switch point 1

represents the

lower pressure limit in the window (FL).

SP 2

FH 2

Menu 3* – Setting for switch point 2, setting for

the relevant value from which switch point 2

shall be activated.

If the window function in menu 5:7 is activated,

the value for switch point 2 represents the

upper pressure limit in the window.

rP 2

FL 2

Menu 4 – Setting for return switch point 2,

setting for the relevant value from which return

switch point 2 shall be activated.

If the window function in menu 5:7 is activated,

the value for switch point 2 represents the

upper pressure limit in the window.

EF Menu 5 – Extended functions

Second menu level

rES Menu 5:1 – Reset

Restores all adjustable parameters to their

default settings and deletes the Min. and Max.

values,

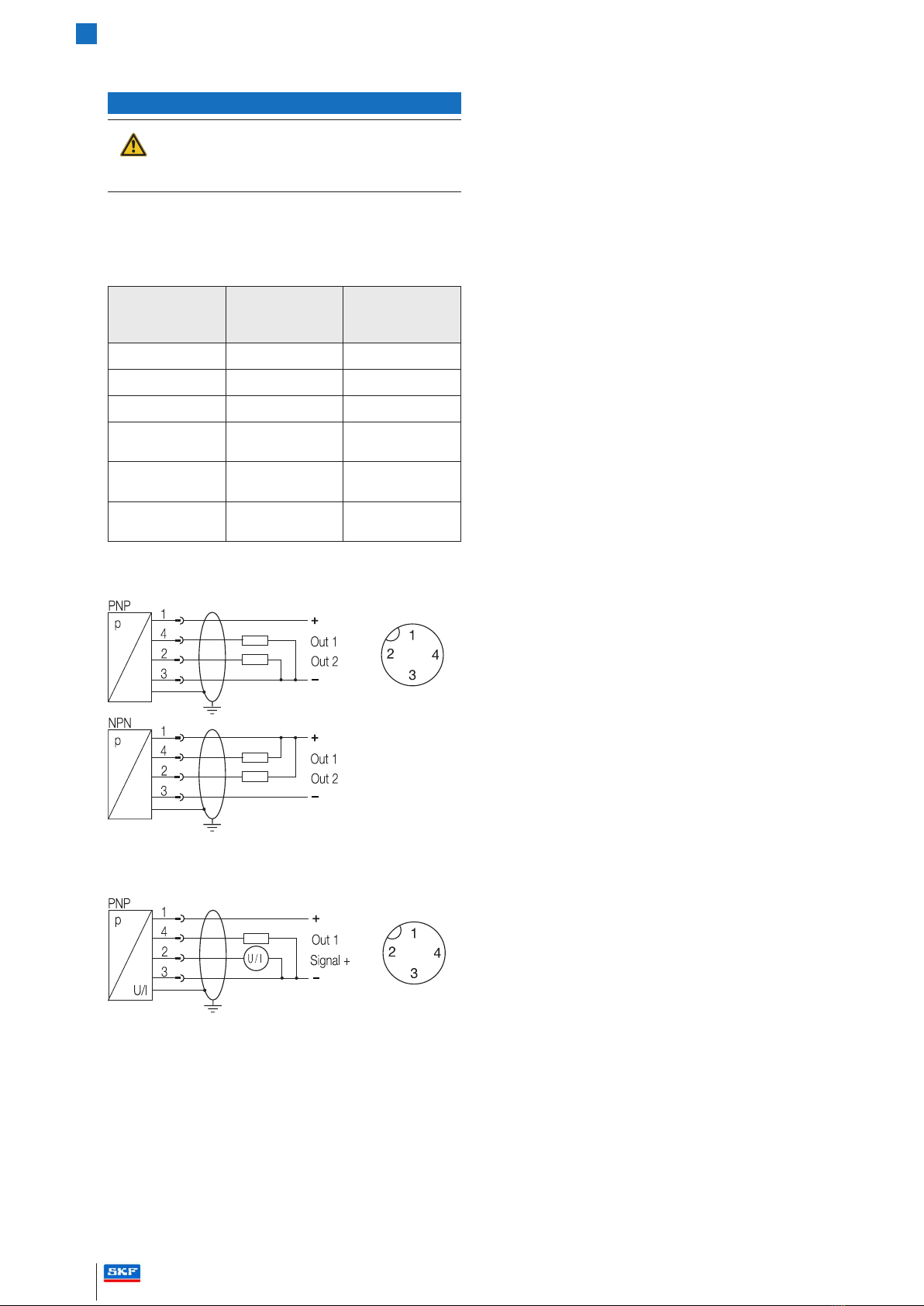

dS 1 Menu 5:2 – Switching delay time 1

Setting for the value of switching delay time 1,

which starts after switch point 1 is reached

(time range 0...50 seconds)

dr 1 Menu 5:3 – Return switching delay time 1

Setting for the value of return switching delay

time 1, which starts after return switch point 1

is reached (time range 0...50 seconds)

dS 2 Menu 5:4*– Switching delay time 2

Setting for the value of switching delay time 2,

which starts after switch point 2 is reached

(time range 0...50 seconds)

dr 2 Menu 5:5*– Return switching delay time 2

Setting for the value of return switching delay

time 2, which starts after return switch point 2

is reached (time range 0...50 seconds)

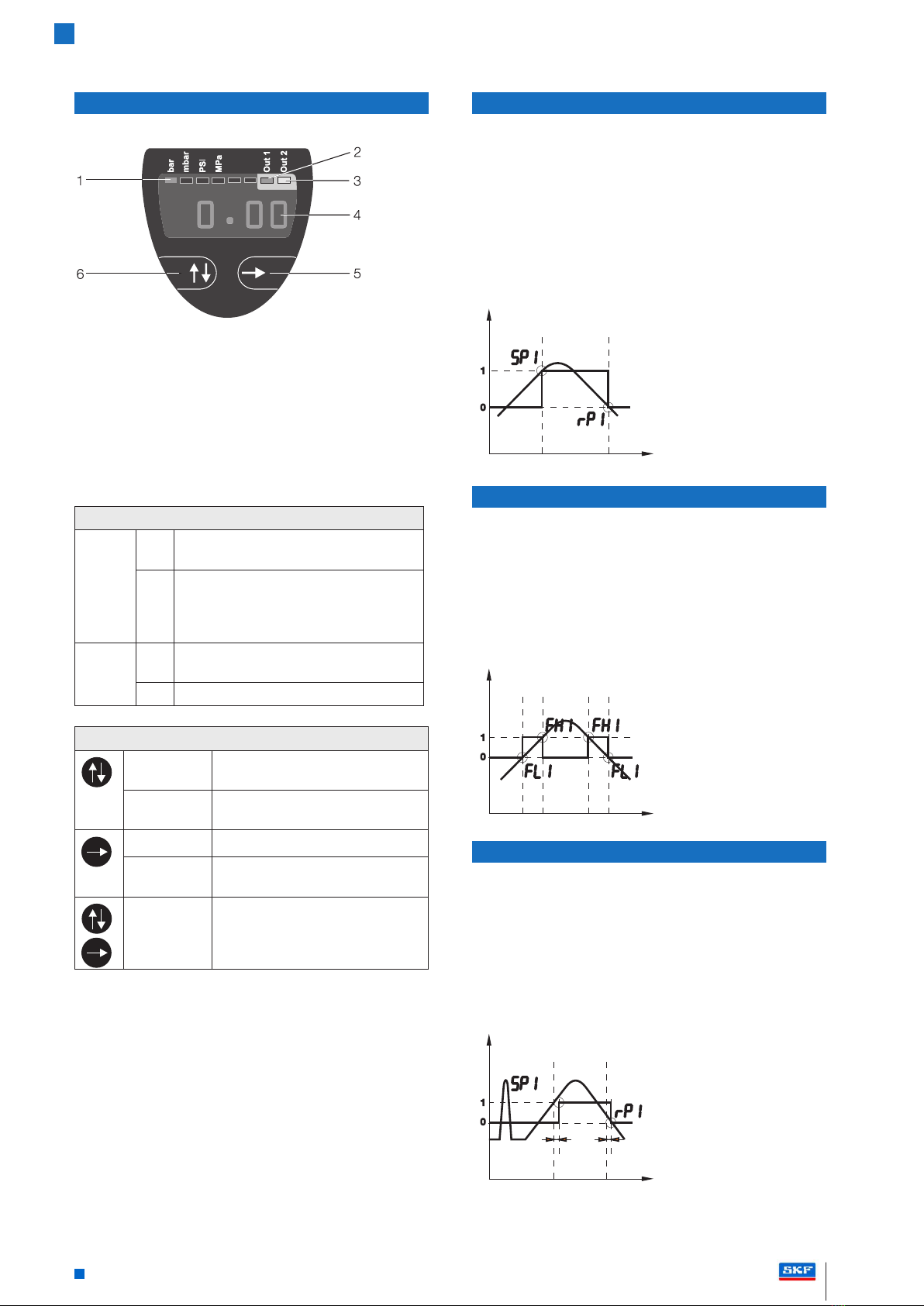

ou 1 Menu 5:6 – Output 1

Switching function of the switching output:

Hno = Hysteresis function, NO contact

Hnc = Hysteresis function, NC contact

Fno = Window function, NO contact

Fnc = Window function, NC contact

Menu functions (continued)

Second menu level (continued)

ou 2 Menu 5:7*– Output 2

Switching function of the switching output:

Hno = Hysteresis function, NO contact

Hnc = Hysteresis function, NC contact

Fno = Window function, NO contact

Fnc = Window function, NC contact

uni Menu 5:8 Change units

Selection of physical unit of measurement for

displayed and preset pressure values:

bAr = bar,

nnBa = mbar,

PSi = PSI,

mPA = MPa

FLiP Menu 5:9 – Rotate display

Rotate the display 180°

lo Menu 5:10 - Min value

Display of minimum pressure attained during

the measurement (the value is lost when the

power supply is interrupted)

Hi Menu 05:11 - Max value

Display of maximum pressure attained during

the measurement (the value is lost when the

power supply is interrupted)

--- Menu 5:12 – Deletion of Min and Max values

The display confirms that the process for

deleting the values has started

codE Menu 5:13 – Access protection

Setting the password for protecting access to

the menu

0000 = no password

0000...9999 adjustable

Legend

*Menus marked with an

asterisk do not appear if the

pressure switch has an analo-

gous output.

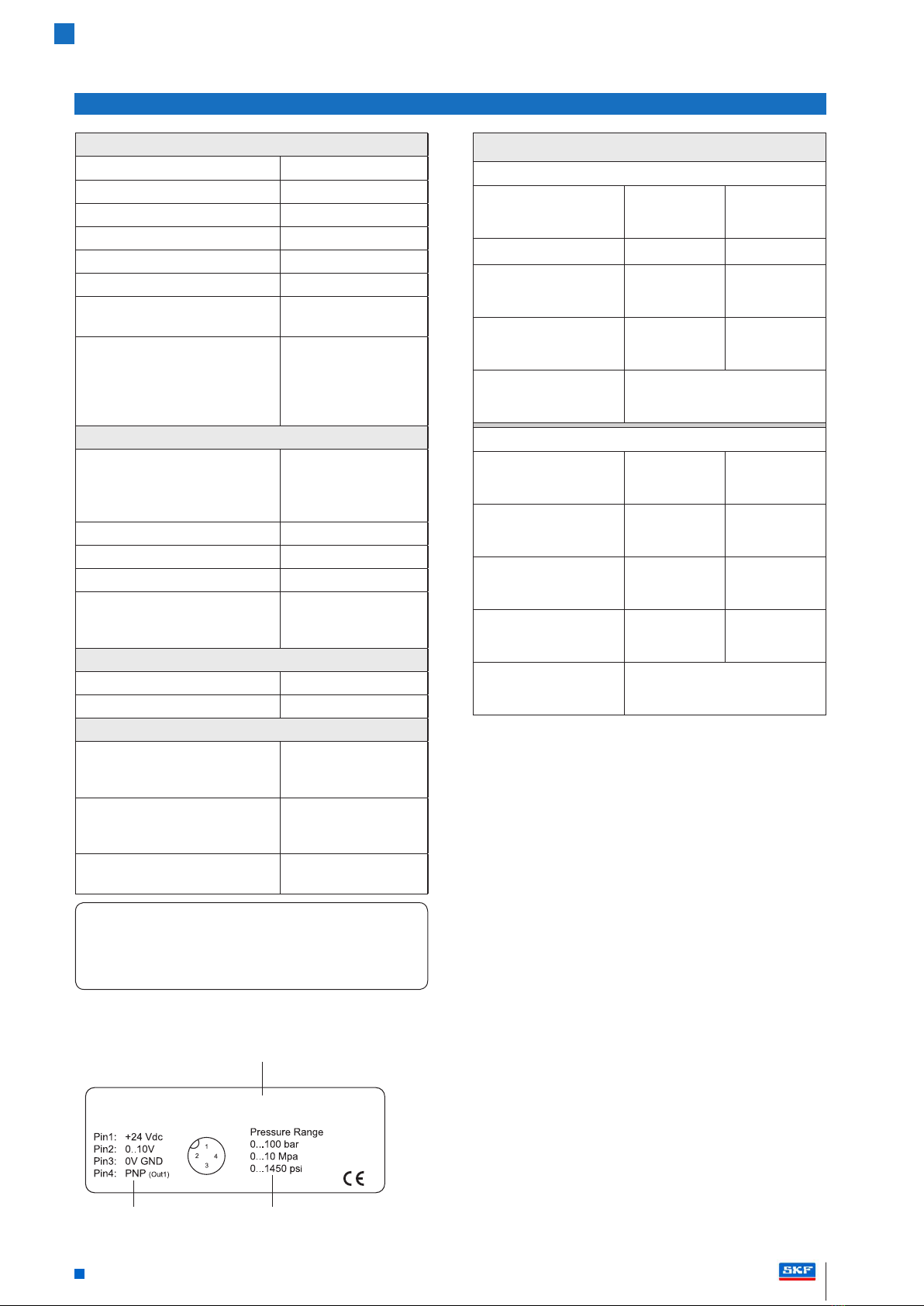

Standard, High-End and High-End Flush-Mounted Pressure Switches