Ski-Daddler 5811-0000 User manual

.

MODELS

5811

-0000,

-0100

5812-0

000

I

-0200

PA

TS AND SERVICE

MANUAL

AMERICAN

MACH

INE

&

FDUNDRY

CDMPANY

CONSUMER

PRODUCTS

SALES

DIVISION

PARTS

&

SERV

I

CE

DEPARTMENT

Whiteford

Road

,

York.

Pennsy

lv

an

ia

17402.

Area

Code

717

848-

11

77

PART

NO

.

37949

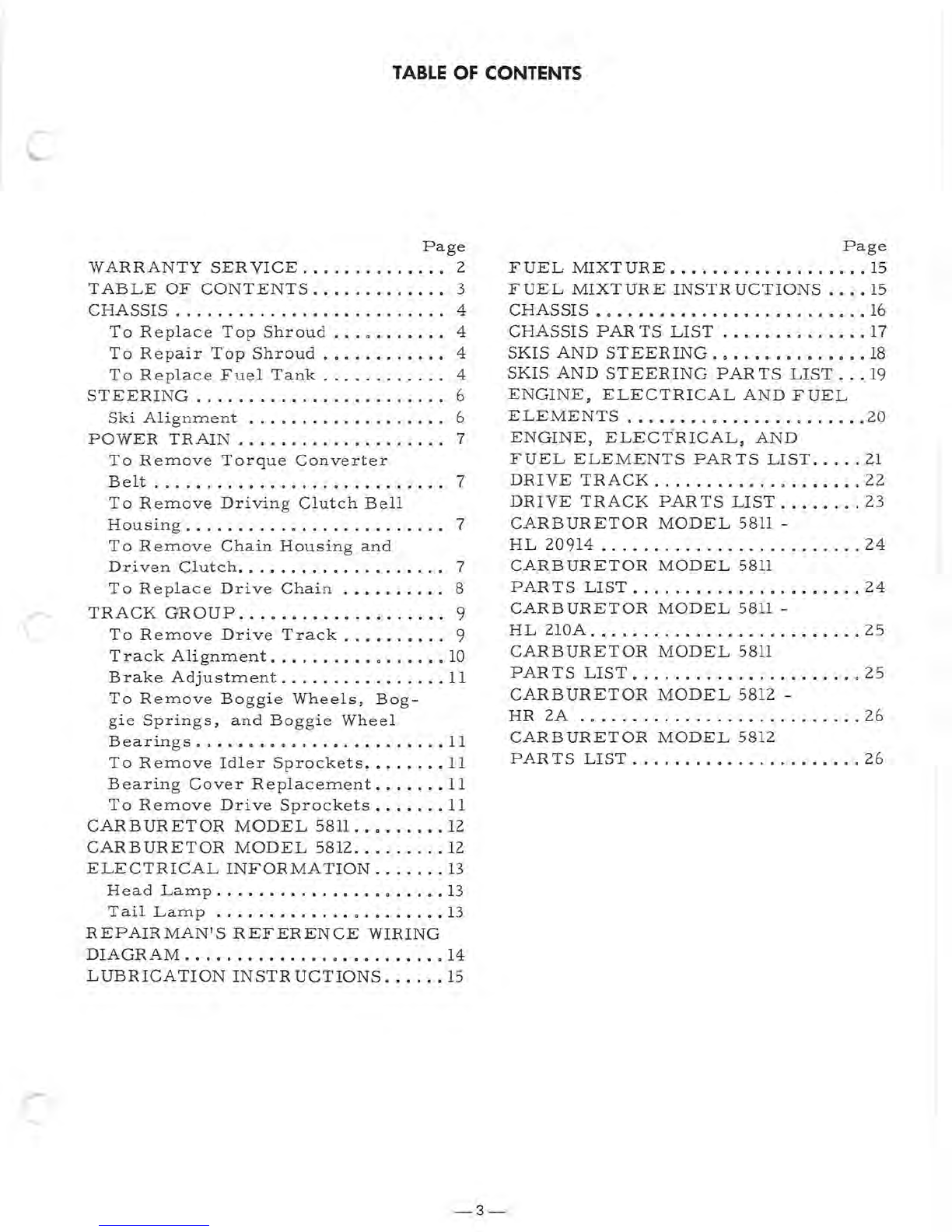

TABLE

OF

CONTENTS

Page

WARRANTY

SER

VICE

..............

2

TABLE

OF

CONTENTS

.............

3

CHASSIS

..........................

4

To

R

epl

ace

Top

Shroud

...........

4

To

Repa

ir

Top

Shroud

............

4

To

Replace

Fuel

Tank

............

4

STEERING

........................

6

Ski

Alignment

.

..................

6

POWER

TRAIN

...................

, 7

To

Remove

Torque

Converter

Belt

............

.

...............

7

To

Remove

Driving

Clutch

Bell

Housing

.........................

7

To

Remove

Chain

Housing

and

Driven

Clutch

....................

7

To

Replace

Drive

Chain

..........

8

TRACK

OROUP

....................

9

To

Remove

Drive

Track

..........

9

Track

Alignment

.................

10

Brake

Adjustment

................

11

To

Remove

Boggie

Wheels,

Bog

-

gie

Springs,

and

Boggie

Wheel

Bearings

.....•..................

11

To

Remove

Idler

Sprockets

........

11

Bearing

Cover

Replacement

.......

11

To

Remove

Drive

Sprockets

.......

11

CARBURETOR

MODEL

5811

..

0

••••••

12

CARB

URETOR

MODEL

5812

.........

12

ELECTRICAL

INFORMA

TION

.......

13

Head

Lamp

......................

13

Tail

Lamp

......................

13

REPAIRMAN'S

REFERENCE

WIRING

DIAGRAM

..............•..........

14

LUBRICATION

INSTRUCTIONS

......

15

-3-

Page

FUEL

MIXTURE

•..................

15

FUEL

MIXTURE

INSTR

UCTIONS

....

15

CHASSIS.

0

••••••••••••••••••••••••

16

CHASSIS

PAR

TS

LIST

..............

17

SKIS

AND

STEERING.

0

•••••••••••••

18

SKIS

AND

STEERING

PAR

TS

LIST

...

19

ENGINE,

ELECTRICAL

AND

FUEL

ELEMENTS

........

0

••••••••••••••

20

ENGINE,

ELECTRICAL,

AND

FUEL

ELEMENTS

PAR

TS

LIST

.....

21

DRIVE

TRACK

............

...•....

22

DRIVE

TRACK

PARTS

LIST

........

23

CARBURETOR

MODEL

5811 -

HL

20914

.........................

24

CARB

URETOR

MODEL

5811

PARTS

LIST

......................

24

CARB

URETOR

MODEL

5811 -

HL

210A

..........................

25

CARB

URETOR

MODEL

5811

PAR

TS

LIST

...........

..

.........

25

CARB

URETOR

MODEL

5812

-

HR

2A

...

.

.......................

26

CARBURETOR

MODEL

5812

PAR

TS

LIST

......................

26

CHASSIS

TO

R

EPL

ACE

TOP

SHROUD

1.

Remove

right

and

left

half

end

caps

from

the

aluminum

trim

s

tr

ip

by

removing

two

screws

and

two

lock

nuts.

2.

Remove

rubber

bumper

s

trip

from

trim

strip

around

top

shroud

by

prying

out

with

a

screw

dr

i

ver

.

3.

Remove

pop

rivets

by

drilling

them

out.

4.

Remove

aluminum

trim

strip.

5.

Remove

bracket

holding

st

ee

ring

col

-

umn

to

the

top

sh

roud

by

removing

two

screws,

t\\"O

nuts

and

a

holding

plate

.

Remove

fasteners

from

inside

storage

compartment

on

top

shroud

.

6.

Remove

gas

cap

and

sup

port

angle

wh

ic

h

ho

lds

the

fuel

intake

to the

top

shroud

.

To

release

the

support

an

gle

remove

one

scre\v

and

one

nut

from

the

top

shroud

.

7.

Disconnect

wiring

loom

at

connector

plug

.

8.

Remove

light

switch

by

removing

two

nuts

from

the

outside

of

the

s\v

itch

.

Then

push

switch

out.

9.

Remove

ignition

s

witch

by

removing

nut

on

the

backs

ide of

the

s

witch

.

Then

push

switch

out.

10.

Remove

wire

holding

clips

from

the

edge

of the

access

hole

on

the

top

shroud.

11.

Remove

headlamp

assembly

from

the

front

of the

top

shroud

by

removing

two s

crews

.

and two

nuts.

12

.

Use

reverse

procedure

from

that

s

tated

above

to

install

new

top

shroud.

13

.

Use

either

a

pop

rivet

gun

and

pop

rivets

or

fla

t

head

screws

and

lock

nuts

to

se

cure

new

top

shroud.

If

flat

head

screws

are

u

sed,

work

thro

ugh

the

acces

s

opening

.

14

.

If

you

have

difficulty

in

replacing

rub-

berbumper

strip,

use

a

small

amount

of

trim

cement

to

keep

it

in

place.

TO

REPAIR

TOP

SHROUD

If

the

top

shroud

is

fractured

or

punctured,

repair

with

polyester

resin

and

fibre

gl

ass

cloth.

See

CHASSIS

parts

list

for

pa

int

in-

format

ion.

NOTE:

The

repair

materials

are

not

sup-

plied

or

kept

in

stock

by

the

manufacturer

.

However,

they

can

be

purchased

locally

through

auto

part

s

or

marine

supply

com

-

panies.

TO

REPLACE

FUEL

TANK

1.

Remove

access

cover

on

top

shroud

.

2.

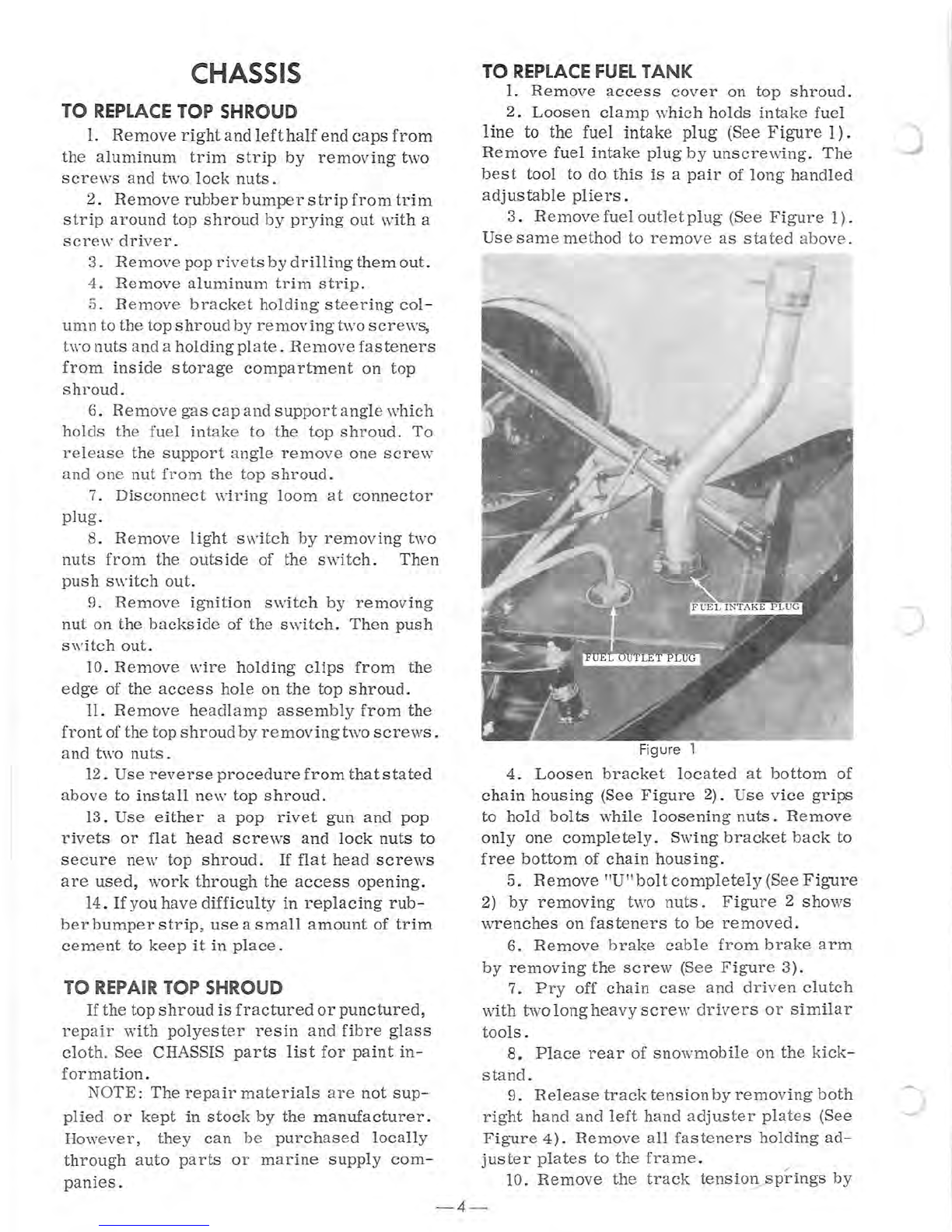

Loosen

clamp

which

hol

ds

intake

fuel

line

to the fuel intake

plug

(See

Figure

1) .

Remove

fuel

intake

plug

by

unscrewing

.

The

be

st

tool

to

do

this

is

a

pair

of

long

handled

adjustable

pliers

.

3.

Remove

fuel

outlet

plug

(See

Figure

1).

Use

s

ame

method

to

remove

as

stated

abo

ve .

F

igure

1

4.

Loo

s

en

bracket

located

at

bottom

of

chain

housing

(See

Figure

2).

Use

vice

grips

to

hold

bolt

s

while

loosening

nuts.

Remove

only

one

completely

.

Swing

bracke

t

back

to

free

bottom

of

chain

hous

ing

.

5.

Remove

"U"bolt

completely

(See

Figure

2)

by

removing

two

nuts.

Figure

2

shows

wrenches

on

fasteners

to

be

removed.

6.

Remove

brake

cabl

e

from

brake

arm

by

removing

the

screw

(See

Figure

3) .

7.

Pry

off

chain

case

and

driven

clutch

with

two

long

heavy

screw

drive

rs

or

similar

tools.

8.

Place

rear

of

snowmobile

on

the

kick

-

stand.

9.

Release

track

tension

by

removing

both

right

hand

and

left

hand

adjuster

pla

te

s (See

Figure

4).

Remove

all

fas

teners

holding

a

d-

juster

plates

to

the

frame.

.

10.

Remove

the

track

tensiol!-fip~ing

s

by

-4-

)

Figure

2

c

Figure

3

Figure

4

-5-

pushing

the

extended

top

end

toward

the

center

and

pulling

down.

Use

same

procedure

on

both

sides

(See

Figure

5).

Now

the

rear

support

arms

and

idler

sprockets

can

be

re

-

moved.

Figure

5

11.

Tip

snowmobile

up

on

its

right

side.

12.

Remove

the

three

boggie

assemblies

by

removing

a

bolt

and

a

washer

from

each

end

of

the

boggie

wheel

support

shaft.

Figure

6

shows

bolt

and

washer

to

be

removed.

13. Now

the

only

thing

holding

the

track

in

place

is

the

driving

sprockets

and

drive

shaft.

To

remove:

a.

With

a

screw

driver

carefully

pry

rubber

oil

seal

from

the

bearing

retainer

Figure

6

on

the

drive

shaft

(See

Figure

7)

on

both

right

and

left

hand

sides.

b .

Figure

8

shows

the

drive

shaft

and

driving

sprockets

being

removed.

Pull

shaft

towards

the

side

which

has

the

chain

housing

removed.

This

will

free

the

drive

shaft

and

sprockets

for

removal.

Figure 7

Figure 8

NOTE:

When

replacing

drive

sprockets

and

drive

shaft,

add

one

-two

ounces

of

oil

to

center

of

shaft.

Also

check

oil

level

in

chain

housing

after

it

is

reinstalled.

The

oil

level

shouldbe

approximately

2~

inches

deep

in

the

chain

housing

(approximately

5

ounces).

Do

not

overfill

as

overfilling

can

cause

leakage

at

vent

hole

and

possibly

get

oil

on

torque

con-

verter

belt.

14

.

Figure

9

shows

screws

and

nuts

to

be

removed

to

remove

fuel

tank

retainer

plate.

15.

Remove

retainer

plate

(See

Figure

10).

16.

Remove

bearing

retainer

which

holds

the

drive

sha

ftby

removing

four

nuts

and

bolts

(SeeFigure

8).RerrlOve

cha

in

case

bolt

on

the

opposite

side

of

theBearingR

etaine

r.

17.

Remove

fuel

tank.

18.

Reassemble

in

opposite

order

as

stated

Figure

9

Figure

10

above.

19.

During

reassembly

follow

instructions

un

d e r TRACK

TENSION

ADJUSTMENT,

TRACK

ALIGNMENT

AND

BRAKE

ADJUST

-

MENT.

STEERING

Skis

should

be

properly

aligned

so

they

are

parallel

to

each

other

and

parallel

with

the

drive

track

when

the

steering

handle

is

in

the

str

aight

ahead

position.

Figure

II

shows

skis

properly

aligned.

Measure

the

distance

be

-

tween

the

skis

at

the

front

and

at

the

rear.

The

distances

should

be

equal.

Figure

llshows

the

front

measuring

points.

SKI

ALIGNMENT

1.

Center

steering

handle,

check

to

see

that

right

hand

ski

is

parallel

with

the

drive

track.

2.

If

right

hand

ski

is

not

parallel

to

drive

track

adjust

drag

link.

If

a

large

amount

of

adjustment

appears

necessary,

remove

spin

-

dle

arm

retaining

bolt

with

zerk

fitting

(See

Figure

12).

Remove

the

spindl

e

arm

from

the

spindle.

3.

Align

right

hand

ski

so

that

it

is

parallel

-6

-

)

..

I

}(

.

'-

FRONT

MEASURING

POINTS

Figure

11

Figure

12

with

track

and

replace

spindle

arm

on

the

spindle

making

sure

that

the

splines

are

align

-

ed

and

securely

tighten

retaining

bolt.

4.

Measure

skis

front

and

rear

making

sure

that

both

skis

are

in

alignment.

If

the

skis

are

not

in

alignment

with

each

other,

ad-

just

tie

rod

by

loosening

the

lock

nuts

and

rotating

tie

rod.

POWER TRAIN

TO REMOVE TORQUE CONVERTER

BELT

Remove

the

belt

guard

and

use

a

screw

driver

or

similar

tool

to

pry

driven

sheaves

apart

as

shown

in

Figure

13

.

Pull

the

drive

belt

down

into

the

driven

sheave

halves.

This

will

make

enough

slack

in

the

drive

belt

to

easily

pull

it

up

over

the

driving

clutch.

Re

-

move

other

end

from

driven

clutch.

Replace

in

reverse

order.

Mter

replacing

the

belt

check

the

b

elt

tension

.

There

should

be

lOi

inches

between

the

center

of

the

driving

clutch

and

the

driven

clutch

(See

Figure

13).

If

ad

-

justment

is

neces

sary,

loosen

nuts

securing

engine

and

slide

it

backward.

The

engine

can

be

moved

backwards

a

total

of

i

inches.

Figure 13

TO REMOVE

DRIVING

CLUTCH

BELL

HOUSING

1.

Remove

the

bolt

assembly

from

the

out-

side

of

the

bell

clutch

housing

(See

Figure

13).

2.

Hold

the

two

halves

of

the

clutch

to-

getherwhen

removing

the

bell

clutch

housing.

IMPORTANT

:

Remove

housing

with

care

to

preven

t

any

possible

damage

to

the

clutch

assembly

.

3.

When

replacing

bell

clutch

housing

make

sure

the

weight

s

fit

into

the

notches

on

the

outer

sheave.

4.

Lubricate

bearing

and

spring

retainer

before

reassembly

.

TO REMOVE

CHAIN

HOUSING

AND

DRIVEN CLUTCH

1.

Remove

drive

belt

as

stated

above.

2.

Loosen

bracket

at

bottom

of

the

chain

housing

(See

Figure

14) .

Use

vice

grips

to

hold

bolts

while

loosening

nuts.

Remove

only

one

completely.

S\\'ing

bracket

back

to

free

bottom

of

chain

housing.

3.

Remove

"U"bolt

completely

(See

Figure

14)

by

removing

two

nuts

.

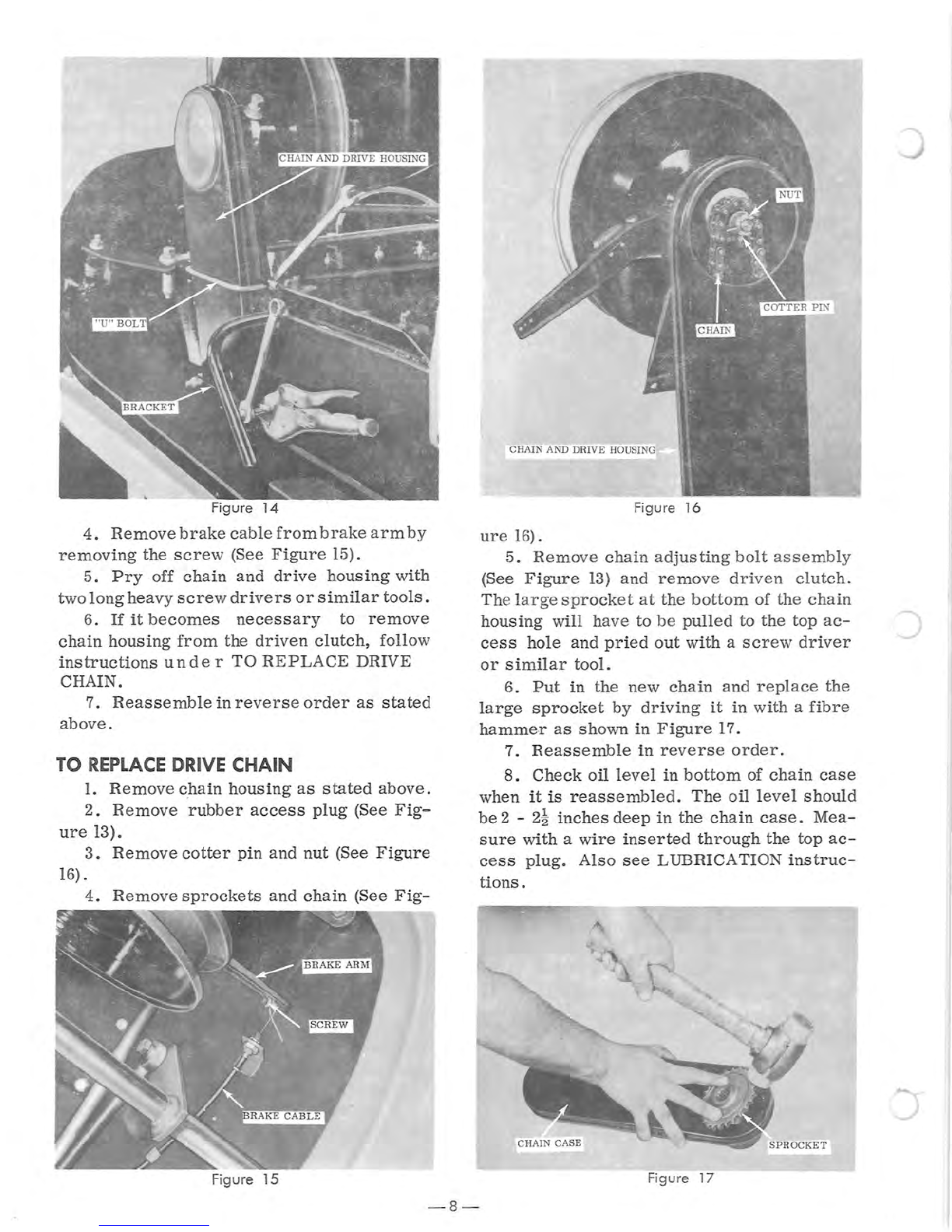

Figure

14

shows

wrenches

onfasteners

to

be

loosened

and

re-

moved.

- 7 -

Figure

14

4.

Remove

brake

cable

from

brake

armby

removing

the

screw

(See

Figure

15).

5.

Pry

off

chain

and

drive

housing

with

two

long

heavy

screw

drivers

or

similar

tools.

6.

If

it

becomes

necessary

to

remove

chain

housing

from

the

driven

clutch,

follow

instructions

unde

r

TO

REPLACE

DRIVE

CHAIN.

7.

Reassemble

in

reverse

order

as

stated

above.

TO

REPLACE

DRIVE

CHAIN

1.

Remove

chain

housing

as

stated

above.

2.

Remove

rubber

access

plug

(See

Fig-

ure

13).

3.

Remove

cotter

pin

and

nut

(See

Figure

16)

.

4.

Remove

sprockets

and

chain

(See

Fig-

Fi

gure

15

CHAIN AND DRIVE HOUSING

Fi

gu

re

16

ure

16

).

5.

Remo

ve

chai

n

adjus

ting

bo

lt

as

sem

bly

(See

Figure

13)

and

remo

ve d

riv

en

c

lu

tch.

Th

e

la

r ge

sp

rocket

at

the

bottom

of

t

he

ch

ain

housing

will

ha

ve

to

be

pulled

to

the

top

ac-

cess

hole

and

pried

out

with

a

scr

ew

driver

or

similar

tool.

6.

Put

in

t

he

new

chain

and

repl

a

ce

the

large

sprocket

by

driving

it

in

wit

h a

fibre

hammer

as

shown

in

Figure

17.

7.

Reassemble

in

reverse

order.

8.

Check

oil

level

in

bottom

of

chain

case

when

it

is

reassembled.

The

oil

level

should

be

2 - 2!

inches

deep

in

the

chain

case.

Mea

-

sure

with

a

wire

inserted

through

the

top

ac-

cess

plug.

Also

see

LUBRICATION

instruc

-

tions.

Figure 17

- 8 -

)

c

-r

'--

TRACK GROUP

TO

REMOVE

DRIVE

TRACK

1.

Loosen

bracket

located

at

bottom

of

chain

housing

(See

Figure

18).

Use

vice

grips

to

hold

bolts

while

loosening

nuts.

Remove

only

one

completely.

Swing

bracket

back

to

free

bottom

of

chain

housing.

2.

Remove

"U"bolt

completely

(See

Figure

18)

by

removing

two

nuts.

Figur

e

18

shows

wrenches

on

fasteners

to

be

loosened

and

re-

moved.

Figure 18

3.

Remove

brake

cable

from

brake

arm

by

removing

the

screw

(See

Figure

19)

.

4.

Pry

off

cha

in

and

drive

hous

ing

\\lith two

long

heavy

screw

drivers

or

similar

tools.

5.

Place

rear

of

snowmobile

on

the

kick-

stand.

Figure 19

- 9 -

6.

Release

track

tension

by

removing

both

right

hand

and

left

hand

adjuster

plates

(See

Figure

20).

Remove

all

fasteners

holding

ad

-

juster

plates

to

the

frame.

7.

Remove

the

track

tension

springs

by

pushing

the

extended

top

end

toward

center

pulling

down.

Use

same

procedure

on

both

sides

(See

Figure

21). Now

the

rear

support

arms

and

idler

sprockets

can

be

removed.

8.

Lay

snowmobile

on

its

right

side.

9.

Remove

the

three

boggie

assemblies

by

removing

a

bolt

and

a wa

sher

from

each

end

of

the

b

rt

shaft.

F

~.;;..;;..;-,;

Figure

20

Figure

21

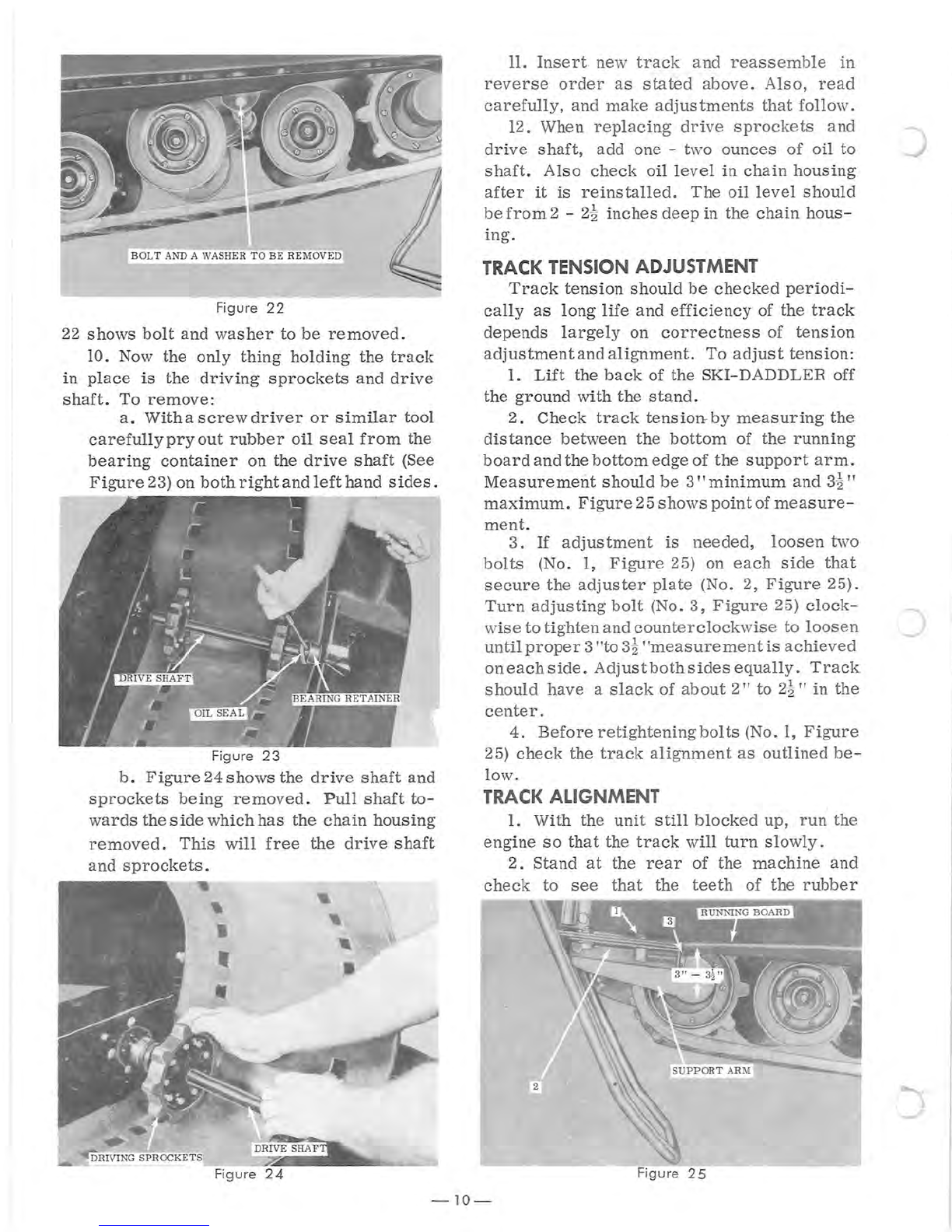

BOL

T AND A WASHER

TO

BE

REMOVED

Figure

22

22

shows

bolt

and

washer

to

be

removed.

10. Now

the

only

thing

holding

the

track

in

place

is

the

driving

sprockets

and

drive

shaft.

To

remove

:

a.

With

a

screwdriver

or

similar

tool

carefully

pry

out

rubber

oil

seal

from

the

bearing

container

on

the

drive

shaft

(See

Figure

23)

on

both

right

and

left

hand

sides.

Figure

23

b.

Figure

24 shows the

drive

shaft

and

sprockets

being

removed.

Pull

shaft

to-

wards

the

side

which

has

the

chain

housing

removed.

This

will

free

the

drive

shaft

and

sprockets.

•

• ,

,

11.

Insert

new

track

and

reassemble

in

reverse

order

as

stated

above.

Also,

read

carefully,

and

make

adjustments

that

follow.

12. When

replacing

drive

sprockets

and

drive

shaft,

add

one -two

ounces

of

oil

to

shaft.

Also

check

oil

level

in

chain

housing

after

it

is

reinstalled.

The

oil

level

should

be

from

2 -

2~

inches

deep

in

the

chain

hous-

ing.

TRACK

TENSION

ADJUSTMENT

Track

tension

should

be

checked

periodi-

cally

as

long

life

and

efficiency

of

the

track

depends

largely

on

correctness

of

tension

adjustmentandalignment.

To

adjust

tension:

1.

Lift

the

back

of

the

SKI-DADDLER off

the

ground

wi

th

the

s

ta

nd .

2.

Check

track

tension-

by

measuring

the

distance

between

the

bottom

of

the

running

board

and

the

bottom

edge

of

the

suppor

t

arm.

Measurement

should

be

3"

minimum

and

3~"

maximum.

Figure

25

shows

point

of

measure-

ment.

3.

If

adjustment

is

needed,

loosen

two

bolts

(No.1,

Figure

25) on

each

side

that

secure

the

adjuster

plate

(No.2,

Figure

25).

Turn

adjusting

bolt

(No.3,

Figure

25)

clock-

wise

to

tighten

and

counterclockwis

e to

loosen

J

until

proper

3"to

3~

"measurement

is

achieved

oneachside.

Adjustbothsides

equally.

Track

should

have

a

slack

of

about

2"

to

2

~"

in

the

center.

4.

Before

retightening

bolts

(No.1,

Figure

25)

check

the

track

alignment

as

outlined

be

-

low.

TRACK

ALIGNMENT

1.

With

the

unit

still

blocked

up,

run

the

engine

so

that

the

track

will

turn

slowly.

2.

Stand

at

the

rear

of

the

machine

and

check

to

see

that

the

teeth

of

the

rubber

Figure

25

-10-

c

c

c

sprocket

are

centered

in

the

slots

in

the

track

and

also

that

the

distance

between

the

track

and

the

adjuster

plate

is

the

same

on

each

side

.

3.

If

the

track

is

not

centered

tighten

the

adjusting

bolt

(No.3,

Figure

25)

on

the

side

where

the

track

is

closest

to

the

adjuster

plate

until

track

is

centered

.

4.

When

adjustment

and

alignment

of

track

is

completed,

retighten

the two

bolts

(NO

.

1,

Figure

25) on

each

side.

BRAKE

ADJUSTMENT

The

brake

on

this

unit

is

applied

agains

t

the

outside

of

the

driven

pulley

.

If

it

need

s

ad

-

justing

take

the

following

steps:

1.

Loosen

the

outer

nut

(No.1,

Figure

26)

on

the

cable

housing

a

turn

.

2.

Tighten

the

inner

nut

(No.

2,

Figure

26)

tight

against

the

bracket.

3.

Check

to

see

that

brake

pad

(No. 1

Fig-

ure

27)

is

just

free

of

the

pulley

with

the

brake

Figure

26

not

applied

.

If

it

is

too

loose

tighten

further

as

outlined

above.

TO

REMOVE

BOGGlE

WHEELS

BOGGlE

SPRINGS

AND

REPLACE

BOGGlE

WHEEl

BEARINGS

1.

Remove

a

set

of

boggie

wheels

by

re

-

movinga

bolt

and

a

washer

from

each

end

of

the

boggie

wheel

support

shaft.

Figure

22

shows

one

bolt

and

washer

to

be

removed.

2.

Pull

out

the

set

of

boggie

\",heels .

3.

To

replace

or

repair

any

part

of

a

boggie

wheel,

remove

the

Eiix

screws

and

nutsholding

the

boggie

wheel

halves

and

the

boggie

tire

together.

4.

With

a

steel

tube

just

Ie

s s

than

an

in

ch

in

diameter,

ca

r

efully

hamme

rout

the

wheel

support

from

the

bear

in

g.

In-

stall

a

new

bearing,

then

str

i

ke

lightly

with

a

hamme

r

to

flare

out

the

end

of

the

wheel

support.

5.

Reassemble

in

the

opposite

order

.

6.

Release

the

extended

ends

of

the

boggie

springs

by

bending

the

tabs

on

the

boggie

support

assembly

outward.

'7

.

Remove

the

suppor

t

shaft

which

holds

the

boggie

wheel

support

assembly

halves

to-

gether.

8.

Pull

the

boggie

wheel

support

halves

apart

and

replace

or

repair

springs.

9.

Reassemble

in

the

opposite

order

as

s

ta

ted

above.

TO

REMOVE

IDLER

SPROCKETS

1.

Place

the

snowmobile

on

the

kickstand

.

2.

Release

track

tension

by

removing

both

right

and

left

ha

nd

adj

us

ter

pIa

tes

(See

Figure

20).

Remove

all

fasteners

holding

the

adjuster

plates

to

the

frame.

3.

Remove

the

tension

springs

by

pushing

the

extended

top

end

toward

the

center

and

pulling

down (

See

Figure

21). Now

the

rear

support

arms

and

idler

sprockets

can

be

re-

moved.

4.

Pull

the

supportarmoff

the

idler

shaft.

5.

Pull

off

the

press

on

bearing

and

rubber

bearing

cover

.

6.

Remove

the

nine

screws.

and

nuts

which

hold

the

sprocket

plates

and

the

rubber

nine

tooth

sprocket

in

place

.

7.

Reassemble

in

opposite

order

as

stated

above.

BEARING

COVER

REPLACEMENT

This

rubber

cover

is

important

because

it

holds

in

the

lubrication

for

the

bearing.

To

replace

follow

instructions

under

TO

RE-

MOVE

IDLER

SPROCKETS.

TO

REMOVE

DRIVE

SPROCKETS

Figure

27

-

11-

FollO\v

the

instructions

under

(TO

RE-

PLACE

DRIVE

BELT).

Then

remove

drive

sprock

ets

the

same

as

outlined

un

der

(TO

REMOVE

IDLER

SPROCKETS).

CARBURETOR

5811

IT

IS

IMPORTANT

NOT

TO

FORCE

AD-

JUSTMENTSINTOSEATS.

The

dual

carbure-

tors

used

are

Tillotson

Model

HL-209

and

HL-

210

carburetors.

For

best

results

the

engine

shouldbe

warm

when

final

ca

r

buretor

adjust-

ments

are

made.

Figure

28

shows

the

left

side

of

the

dual

carburetors,

and

Figure

29shows

the

right

side.

1.

STARTING

A

COLD

ENGINE -

Close

choke

and

crank

engine.

After

the

engine

starts

move

the

choke

to the

open

position.

Do

not

move

throttle

lever

far

enough

to

allow

bottom

carburetor

to

be

open.

The

choke

is

on the

top

carburetor

only,

and

any

opening

on the

bottom

carburetor

will

cause

fuel

starvation

and

hard

starting.

2.STARTING

A WARM ENGINE

It

should

be

started

with

the

choke

open

as

shown

in

Figure

28.

3.

TO

ADJUST

CARBURETOR

-

Turn

in

the

high

speed

jet

all

the

way, (do

not

force),

then

open

l~

turns

as

shown

in

Figure

28.

Turn

in

the

idle

mixture

screw

all

the

way,

(do

not

force).

Open one

full

turn,

as

shown

in

Fig-

ure

29.

This

adjustment

controls

the

mixture

at

idling

speeds.

Lean

idle

mixture

will

cause

poor

acceleration.

Adjust

the

idle

speed

screw

shown

in

Figure

28.

Keep

idle

speed

slower

than

clutch

engaging

speed

(Approximately

1750

-2

000

RPM).

NOTE:

Figure

28

also

shows

a

throttle

Figure

29

wire

adjustment

collar

and

screw.

Remove

carburetor

air

cleaner.

Depress

the

throttle

control.

If

this

does

not

open

the

throttle

plate

completely,

loosen

throttle

wire

adjustment

screw

and

readjust

to

open

throttle.

CARBURETOR

5812

IT

IS

IMPORTANT

NOT

TO

FORCE

AD-

JUSTMENTS

INTO

SEATS.

The

single

car

-

buretor

used

is

a

Tillotson

Model

HR

carbure

-

tor.

For

bes

t

resul

ts

the

engine

should

be

warm

when

final

carburetor

adjustments

are

made.

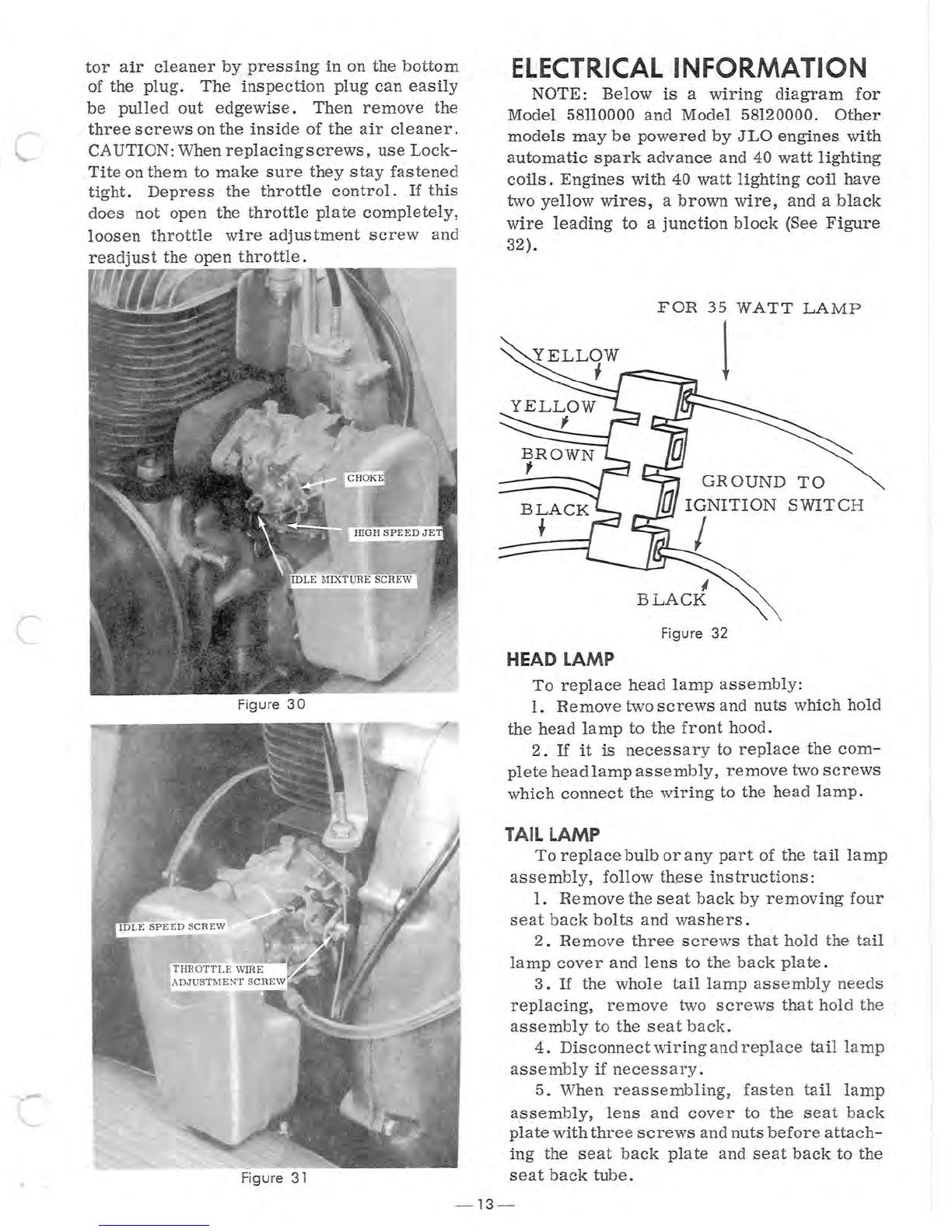

Figure

30

shows

the

left

side

of

the

carburetor

.

and

Figure

31

shows

the

right

side.

1.

STARTING

A

COLD

ENGINE -

Close

choke

and

crank

engine.

After

the

engine

starts

move

the

choke

to

the

open

position.

2.STARTING

A WARM ENGINE

It

should

be

started

with

the

choke

open.

The

choke

is

shown

in

Figure

30.

3.

TO

ADJUST

CARBURETOR

-

Turn

in

the

high

speed

jet

all

the

way,

(do

not

force),

then

open

l

~

turns

as

shown

in

Figure

30

Turn

in

the

idle

mixture

screw

all

the

way,

(do

not

force),

Open 1

full

turn,

as

shown

in

Figure

30.

This

adjustment

controls

the

mix-

ture

at

idling

speeds.

A

lean

idle

mixture

will

cause

poor

acceleration.

Adjust

the

idle

speed

screw

shown

in

Figure

31.

Keep

idle

speed

slower

than

clutch

engaging

speed.

(approxi-

mately

1750-2000

RPM).

NOTE:

Figure

31

also

shows

a

throttle

wire

adjustment

collar

and

screw.

Remove

carbure

-

-12

-

)

c

tor

air

cleaner

by

pressing

in

on

the

bottom

of

the

plug.

The

inspection

plug

can

easily

be

pulled

out

edgewise.

Then

remove

the

_

three

screws

on

the

inside

of

the

air

cleaner

.

CAUTION:

When

replacingscrews,

use

Lock

-

Tite

on

them

to

make

sure

they

stay

fastened

tight.

Depress

the

throttle

control.

If

this

does

not

open

the

throttle

plate

completely,

loosen

throttle

wire

adjustment

screw

and

readjust

the

open

throttle

.

Figure

30

Figure

31

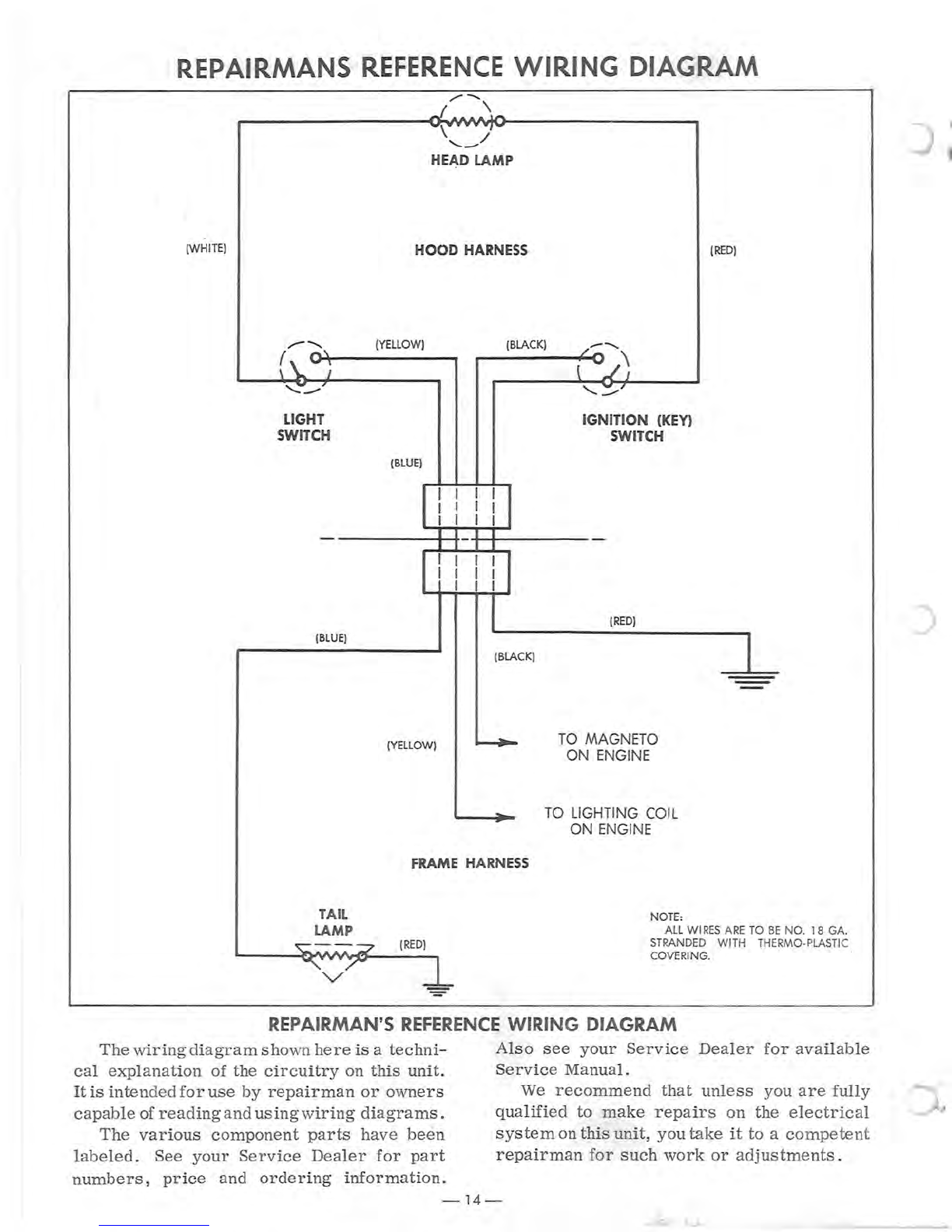

ELECTRICAL

INFORMATION

NOTE

:

Below

is

a

wiring

diagram

for

Model

58110000

and

Model

58120000.

Other

models

may

be

powered

by

JLO

engines

with

automatic

spark

advance

and

40

watt

lighting

coils.

Engines

with

40

watt

lighting

coil

have

two

yellow

wires,

a

brown

wire,

and

a

black

wire

leading

to

a

junction

block

(See

Figure

32)

.

HEAD LAMP

FOR

35

WATT

LAMP

I

GROUND

TO

IGNITION

SWITCH

I

Figure

32

To

replace

head

lamp

assembly:

1.

Remove

two

screws

and

nuts

which

hold

the

head

lamp

to

the

front

hood.

2.

If

it

is

necessary

to

replace

the

com

-

plete

head

lamp

assembly,

remove

two

screws

which

connect

the

wiring

to

the

head

lamp.

TAIL LAMP

To

replace

bulb

or

any

part

of

the

tail

lamp

assembly,

follow

these

instructions:

1.

Remove

the

seat

back

by

removing

four

seat

back

bolts

and

washers.

2.

Remove

three

screws

that

hold

the

tail

lamp

cover

and

lens

to

the

back

plate.

3.

If

the

whole

tail

lamp

assembly

needs

replacing,

remove

two

screws

that

hold

th

e

assembly

to

the

seat

back.

4.

Disconnect

wiring

and

replace

tail

la

mp

assembly

if

necessa

r

y.

5.

When

reassembling,

fasten

tail

lamp

assembly,

lens

and

cover

to

the

seat

back

plate

with

three

screws

and

nuts

before

attach

-

ing

the

seat

back

plate

and

seat

back

to

the

seat

back

tube.

-13 -

REPAIRMANS R

EFERE

NCE

WIRING

DIAGRAM

/'"

-....

( \

\ /

'--

HEAD LAMP

(WHIT

E)

HOOD

H

ARNESS

{

RED

}

LIGHT

SWI

TC

H

I

BLUE)

(

YE

LLOW)

(

BLUE

)

(YEL

L

OW)

{BLACK}

{BLACK}

IG

NI

TION (

KE

Y)

S

WIT

CH

{

RED

}

TO

M

AG

N

ETO

ON ENGINE

TO

LI

GHTING COIL

ON

ENGINE

FRAME HARN

ESS

TAIL

LAMP

NOT

E:

ALL WIRES

ARE

TO

BE

NO.

18

GA.

ST

RANDED

WITH

THERMO·PLASTIC

COVERING.

REPAIRMAN'S

REFERENC

E

WIRING

DIAGRAM

The

wiring

diagram

shown

here

is

a

techni

-

cal

explanation

of

the

circuitry

on

this

unit

.

It

is

intended

for

use

by

repairman

or

owners

capable

of

reading

and

using

wiring

diagrams

.

Als o

see

your

Service

Dealer

for

available

Ser

vice

Manual.

We

recommend

that

unless

you

are

fully

qualified

to

make

repairs

on

the

electrical

sy

s

tem

on

this

unit,

you

take

it

to a

competent

repairman

for

such

work

or

adjustments

.

The

variou

s

component

parts

have

been

labeled.

See

your

Service

Dealer

for

part

numbers

,

price

and

order

ing i

nformation.

-

14

-

J

)

)

c

LUBRICATION INSTRUCTIONS

PART

LOCATION

TYPE

OF

LUBRICATION

FREQUENCY

Steering

Spindles

Grease

zerk

on

spindles

Low

Temperature

grease

50

hours

(See

Figure

2)

Boggie

Wheels

Grease

zerk

in

center

of

Low

temperature

grease

50

hours

Boggie

Wheel

(See

Figure

22)

Steering

End

of

handle

column

Light

engine

oil

50

hours

Driving

Clutch

Remove

"U"

bolt

for

Light

engine

oil

Every

25

hours

lubrication

(See

FIgure

13)

Driven

Clutch

End

of

pully

shaft

Light

engine

oil

25

hours

(

See

Figure

18)

Chain

Housing

With

access

plug

removed

Light

engine

oil

50

hours

(See

Figure

16)

FUEL

MIXTURE

JLO

252-292

First

25

Hours

Mag

Type

2054-SRB

x

18

20

- 1

First

40

Hour

s

20

-1

After

25

Hours

25

-1

After

40

Hours

25 - 1

FUEL

MIXTURE INSTRUCTIONS

The

correct

oil-gasoline

ratio

is

24:1

or

1/3

pint

oil

to a

gallon

of

gasoline.

Too

much

oil

will

cause

carbon

deposits.

Too

little

oil

will

cause

insufficient

lubrication.

WARNING:

Gasoline

and

oil

should

be

mixed

at

temperatures

above

freezing.

Below

freez-

ing,

gas

and

oil

mix

with

difficulty.

Mix

with

care

or

damage

to

engine

could

result.

Use

only

a good

grade

of

SAE

30

non-

detergent

automotive

engine

or

outboard

motor

oil.

Do

not

use

light

duty

oils

for

multi-

visc

o

sity

oils.

Use

a good

grade

of

r e

gular

gasoline.

Use

fr

e

sh

gasoline

only.

Do

not

use

gasoline

left

over

from

summer

uses.

Mix

the

gasoline

and

oil

thoroughly

in

a

separate

clean

container

kept

for

this

purpose

only.

Bes

t

way

to

insure

good

mix

is

to

add

oil

to

an

empty

or

about

half

-

fuli

container

and

then

fill

with

gas

oline.

Mix

thorough

ly.

Fill

gasoline

tank

on

Ski

-

Daddler

from

this

separate

container

of

mixed

fuel.

Use

a

funnel

with

a

fine

screen

strainer

when

fill-

ing

tank.

OILS AND ADDITIVES

We do

not

recommend

the

use

of

additives

for

the

fuels

to

be

used

in

the

engines

of

the

Ski

-

Daddler

or

Snow

Clipper.

We

have

re-

ceived

comments

from

the

field

that

STP

and

Mercury

outboa

rd

oils

have

caused

problems.

Some

outboard

motor

oils

contain

a

deter-

gent

that

works

well

in

an

outboard,

however,

an

outboard

operates

ata

much

lower

temper

-

ature

because

it

is

water

co

o

led

and

for

this

reason

we do

not

recommend

outboard

oil.

Use

an

oil

for

air

cooled

2

cycle

engines

such

as

Ca

strol

or

a good no

n-detergent

#30

or

#40

motor

oil.

If

you

experience

a

problem

with

moisture

in

the

fuel

system

a

small

amount

of

Dri-Gas

or

equivalent

may

be

used.

-15 -

~

0-

I

For Parts

Li

st -

Se

e Page 17

ALL

UNN

UM

BE

R

ED

PARTS

INTER-CHANGEABLE

WIT

H OPPOSITE SIDE

7

44

40

46

'e

3 / \

43

()

~

~

'--..

-?,®

\

~e

@

~

\%

~~-

-~

\

42

OF'

39

38

l°

te

31

,---

I

19

*' G

\\

l~

_

II

r,II

...

1-

11'

-

19

17

17

_

1I11

v

-2

3

.ft

U

~

~

~

26

~,

18

23

..

AMF SKI-DADDLER

SNO

WM

OB

ILE

12

I

0--

I

74

_________

11

76-1

~

/\

l

~26

1)

______

~

8

o 0

.....

g

II>

26

~

BODY

PARTS

o

oJII..Q

o

=fi

73

d1

~

26

o

36

FIGURE

1

u

22

~

.,,",d

o 0

I)

,,0.::3

o 0

49

04

22

I

.","""

34

35

33

J

72

5~

'"

28

~

47

55

\..

I

68

,-

22

2\9

~

"

29

' "

26~

"1l-

70

::

Q

~

~--

9

<8'

64

75

B

El

El

IJ

U

I \

~

• • ' 2

5

~

8

~

J~

-

30

o

~

U

~

64

59

~

53

_-------

-y

~

0/

61

, __

________-

•

63

~

6

~6

0

II .

'

~l

y

~

65

.

~~

---

o .

. . •

62

,

......

6)'

....--,;,....

;

~~,

o

Ii~

~

~

"

16

25

-@

,/

"

"

3

~m

'\

,

~

24

27

67

T

'~~~

I

67

-~~~

..

~

~

58

32

69

c

c

Key

No

.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

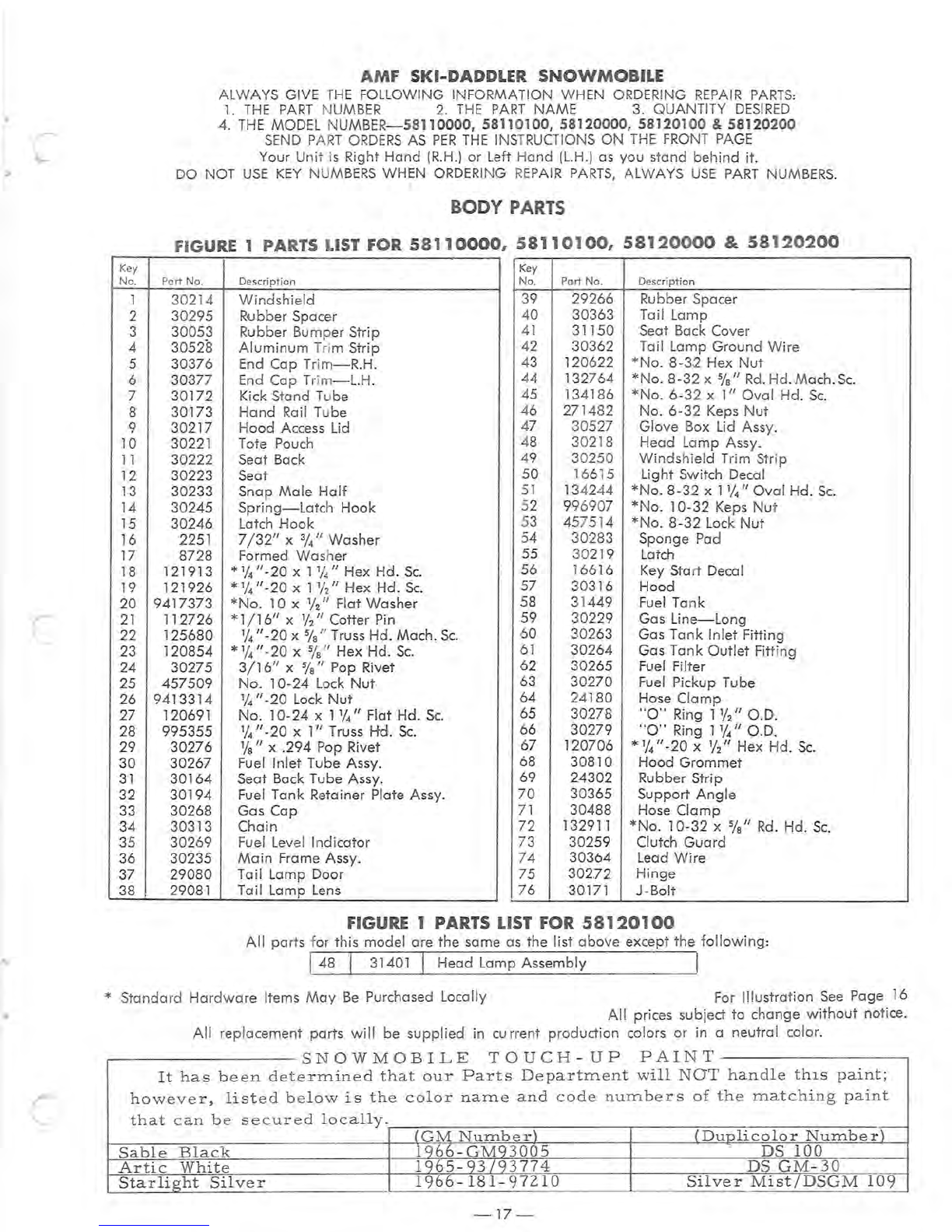

AMF

SKI-DADDLER

SNOWMOBILE

ALWAYS GIVE T

HE

FOLLOWING INFORMATION WHEN ORDERING

REPAIR

PARTS:

1.

THE

PART

N

UMBER

2.

THE

PART

NAME 3. QUANTITY

DESIRED

4.

TH

E MODEL N

UMBER

-

58110000,

58110100,58120000,

58120100

&

58120200

SEND

P

AR

T

ORDERS

AS

PER

THE

INSTRUCTIONS

ON

THE

FRONT

PAGE

Your Unit is Right

Hand

(R

.H

.)

or Left H

and

(L.H

.) as you stand

behind

it

.

DO NOT

USE

KEY

NU

MBERS

WHEN

ORDERI

NG R

EPAIR

PARTS,

ALWAYS

USE

PART

NUMBERS.

I

BODY

PARTS

FI

GURE

1 PARTS

LIST

FOR

58110000, 58110100,

58120000

&

58

1

20200

Key

Part

No

. De

script

i

on

No. Part

No.

Description

30214

Windshield

39 29266 Rubber Spacer

30295 Rubber Spacer 40 30363 Tail Lamp

30053 Rubber Bumper St

rip

30528

Aluminum

Tr

im Strip

30376 End Cap Trim

-R

.H

.

30377 End Cap

Tr

i

m-L.H.

30172 Kick Stand Tube

41 31150 Seat Back Cover

42 30362

Ta

il Lamp

Ground

Wire

43 120622

*No

. 8-32 Hex

Nut

44 132764

*No.

8-32 x %

II

Rd.

Hd.

Mach.

Sc.

45 134186

*No.

6-32 x 1"

Oval

Hd.

Sc

.

30173

Hand

Rail Tube 46 27 1482 No. 6-32 Keps

Nut

30217

Hood

Access Lid 47 30527

Glove

Box Lid Assy.

30221 Tote Pouch 48 30218 Head La

mp

Assy.

30222 Seat Back 49 30250

Winds

hield Trim Strip

30223 Seat 50 16615 Light Switch Decal

30233 Snap

Male

Half

51

134244

*No.

8-32 x 11/4"

Oval

Hd

.

Sc.

30245 Spring-Latch

Hook

52 996907

*No.

10-32 Keps

Nu

t

30246 Latch

Hook

53 457514

*No

. 8-32 Lock

Nut

2251 7

/32"

x %

II

Washer 54 30283 Sponge Pad

8728 Formed

Was

her 55 30219 Latch

12191 3 *

1/4

"-20

x 11//' Hex

Hd

.

Sc.

56 16616 Key Start Decal

121926 *

1/4

"-20

x 1

1/

2" Hex Hd.

Sc.

57 30316 Hood

9417373

*No

. 10 x

1f2

" Flat

Wa

sher 58 31449 Fuel Tank

112726 * 1

/16"

X

1/2"

Cotter

Pin

59 30229 Gas Line-Long

125680

1/4

"-2

0 x %

II

Truss

Hd

.

Mach

.

Sc

. 60 30263 Gas Tank

Inlet

Fitting

120854 * 1

/4

"-20

x %

II

Hex Hd.

Sc.

61

30264 Gas Tank

Outlet

Fitti

ng

30275

3/16"

x %

II

Pop Rivet 62 30265 Fuel Filter

457509

No

. 10-24 Lock

Nut

63 30270

Fuel

Pickup Tube

9413314

1/4

"-20

Lock

Nut

64 24180 Ho'

se

Clamp

120691

No.

10-24 x 1%

II

Flat Hd.

Sc.

65 30278

"0"

Ring 1%

II

O.D.

995355 1/4"-20 x

1"

Truss

Hd

.

Sc.

66 30279

"0"

Ring 1

1/4

II

O.D.

30276

1fa

II

x .294 Pop Rivet 67 120706 *

1/4

"-20

X

1/2"

Hex

Hd

.

Sc.

30267 Fuel Inlet Tube Assy. 68 30810

Hood

Grommet

30164 Seat Back Tube Assy. 69 24302 Rubber

St

rip

30194 Fuel Tank Retainer Plate Assy. 70 30365 Support A

ngle

30268 Gas

Cap

71

30488 Hose

Clamp

30313

Chain

72

132911 *No. 10-32 x %

II

Rd

. Hd.

Sc

.

30269 Fuel

Leve

l

Indicator

73 30259 Clutch

Guard

30235

Main

Frame Assy. 74 30364 L

ead

Wir

e

29080 Tail Lamp Door 75 30272

Hinge

29081 Tail Lamp

Lens

76 30171 J -Bolt

FIGURE 1 PARTS

LIST

FOR

58120100

All

parts for this

mode

l are the same as the list

above

except the

following:

I48 I 31401 I Head Lamp Assem

bly

I

* Standard

Hardware

Items

May

Be

Purchased L

ocally

F

or

Illustration

See

Page 16

All

prices subject

to

change

without

notice.

All

replacement parts

will

be

supplied

in

cu

rrent production colors

or

in a neutral

co

lor.

SNOWMOBILE

TOUCH

UP

PAINT

-

It

has

been

determined

that

our

Parts

Department

will

NOT

handle

thIS

paint;

however,

li

st

e d b e

low

is

the

color

name

and

code

numbers

of

the

matching

paint

that

can

b e

secured

locally.

(GM

Number)

(Dunlicolor

Number)

Sable

Black

1966

-

GMg3005

DS

100

Artic

White

1965-g3/g3774

DS

GM

-

30

Starlight

Silver

1966

-

181

-

97210

Silver

Mist/DSGM

109

-1

7 -

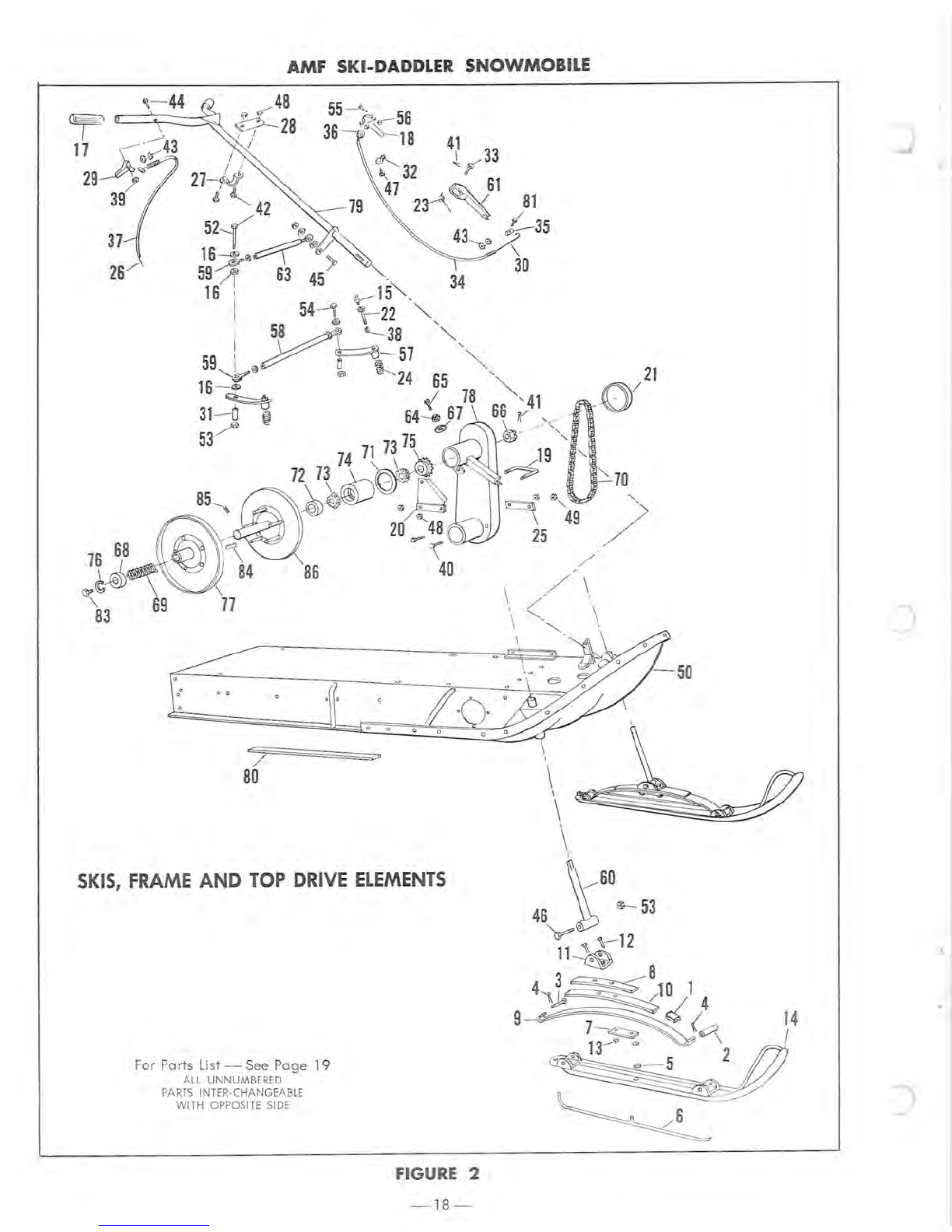

AMF

SKI-DADDLER

SNOWMOB

ILE

37

o 0

80

SKIS,

FRAME

AND

TOP

DRIVE

ELEMENTS

For Parts

List

-

See

P

age

19

A

LL

UNNUMBERED

PARTS

INTER·CHANGEABLE

WITH

OPPOSITE SIDE

FIGURE 2

-18 -

"

70

<3

~...

"-

o 9

49

)

25

/

•

•

c

c

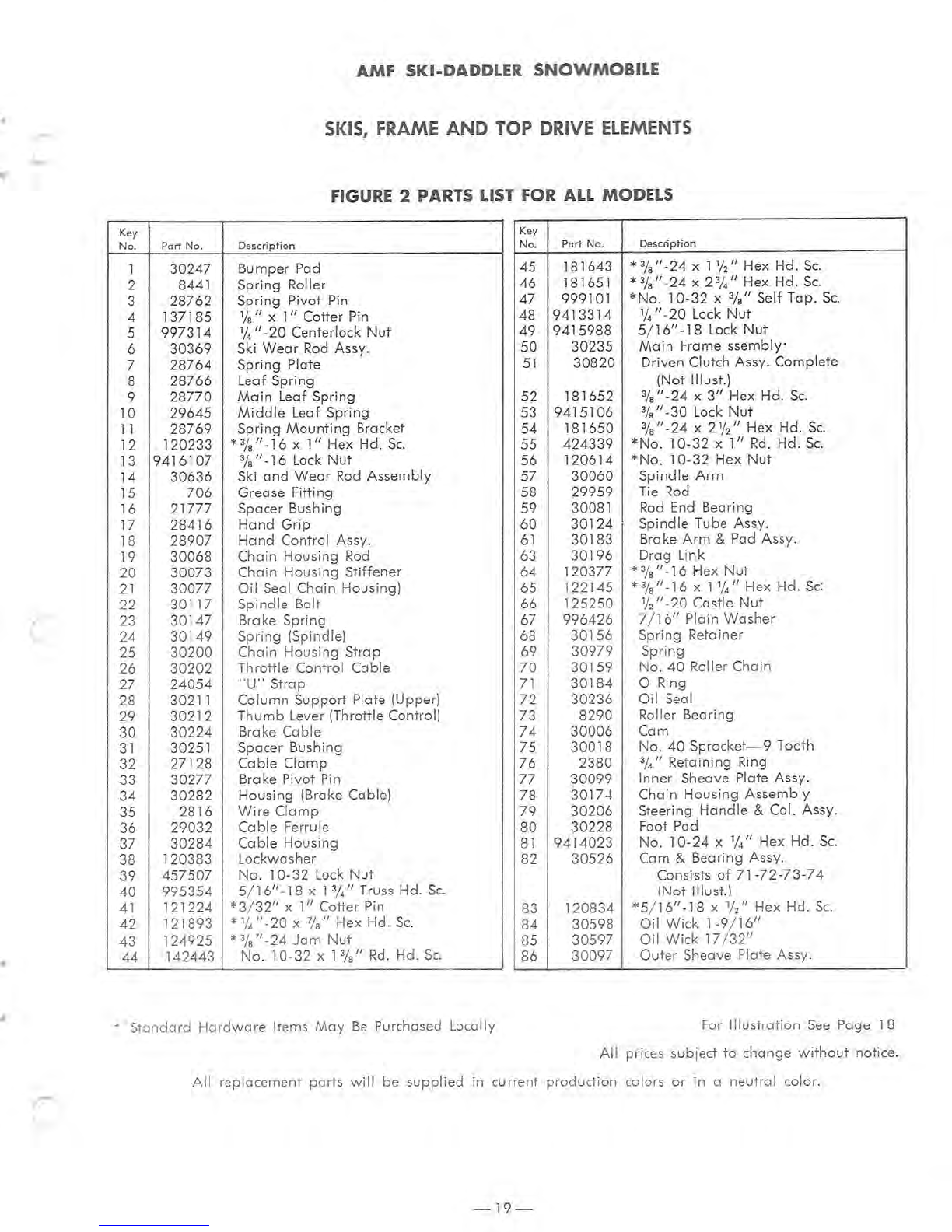

AMF

SKI-DADDLER

SNOWMOBILE

SKIS,

FRAME

AND

TOP DRIVE

ELEMENTS

FIGURE 2 PARTS LIST FOR

ALL

MODELS

Key

No

. Part No.

Description

Key

No

.

Part

No.

Description

1

30247

Bumper Pad

2 8441 Spring Roller

3

28762

Spring Pivot Pin

4

137185

1/8" X

1"

Cotter Pin

5

997314

1/4" -20 Centerlock

Nut

6

30369

Ski

Wear

Rod

Assy.

7

28764

Spring Plate

45

181643

*%"

-24 x

llj2"

Hex Hd.

Sc

.

46 181651

*%"-24

x

2%"

Hex Hd.

Sc

.

47 999101

*No

.

10-32

x

%"

Self Tap.

Sc.

48

9413314

1/4" -20 Lock

Nut

49

9415988

5/16"

-18 Lock

Nut

50

30235

Main

Frame

ssembly'

51

30820

Driven Clutch Assy. Complete

8

28766

Leaf Spring (Not !Ilust.)

9

28770

Main

Leaf Spring 52

181652

%"

-24 X

3"

Hex Hd.

Sc.

10

29645

Middle

Leaf Spring 53

9415106

%"

-30 Lock

Nut

11

28769

Spring

Mounting

Bracket

54

181650

%"

-24 x 21

/2" Hex Hd.

Sc.

12

120233

*3/

8

"-16

x

1"

Hex Hd.

Sc.

55

424339

*No.

10-32 x

1"

Rd.

Hd.

Sc

.

13

9416

107

%"

-16 Lock

Nut

56

120614

*No

. 10-32 Hex

Nut

14

30636

Ski

and

Wear

Rod

Assemb

ly

57

30060

Spindle

Arm

15

706

Grease Fitting 58

29959

Tie

Rod

16

21777

Spacer Bushing 59 30081

Rod

End

Bearing

17

28416

Hand

Grip

60

30124

Spindle

Tu

be Assy.

18

28907

Hand

Control Assy.

61

30183

Brake

Arm

& Pad Assy.

19

30068

Chain

Housing

Rod

63

30196

Drag Link

20

30073

Chain

Housing Stiffener 64

120377

*%"

-16 Hex Nut

21

30077

Oil

Seal Chain Housing) 65

122145

*

%"

-16 x 11

/4"

Hex Hd.

Sc:

22

30117

Spindle

Bolt

23

30147

Brake S

pring

66

125250

lj2"

-20 Castle

Nut

67

996426

7/

16"

Plain

Washer

24

30149

Spring (Spindle) 68

30156

Spring Retainer

25

30200

Chain Housing Strap

26

30202

Throttle Control Cable 69

30979

Spring

70

301

59

No

.

40

Roller Chain

27

24054

"U"

Strap

71

30184

o Ring

28 30211

Column

Support

Plate (Upper)

72

30236

Oil Seal

29

30212

T

humb

Lever (

Th

rottle Control)

73

8290

Roller Bearing

30

30224

Brake

Cable

74

30006

Cam

31

30251 Spacer Bushing 75

30018

No

.

40

Sprocke

t-

9 Tooth

32

271

28

Cable

Clamp

76

2380

3//'

Retaining Ring

33 30277 Brake Pivot

Pin

77

30099

Inner Sheave

Pl

at

e Assy.

34

30282

Housing (Brake Cable)

78

3017.+ Chain Housing

Assembly

35

2816

Wire

Clamp

79

30206

Steering Ha

ndle

& Col.

As-sy.

36

29032

Cable

Ferrule 80

30228

Foot Pad

37 30284

Cabl

e Housing

81

9414023

No

.

10-

24 X 1/4" Hex Hd.

Sc.

38 12

0383

Lockwasher 82 30

526

Cam & Bearing Assy.

39

457507

No.

10-32 Lock

Nut

Consists

of

71-

72

-

73-

74

40

995354

5/16"

-18 x 1

%"

Truss Hd.

Sc.

(Not I!lust

.)

41

121224

*3/

32"

x

1"

Cotter Pin 83

120834

*5

/

16"

-18 x

1//'

Hex Hd.

Sc.

42

121893

* 1/4"

-20

x

?fa"

Hex Hd.

Sc.

84

30598

Oil

Wick

1-9

/1

6"

43

124925

*%"-24

Jam

Nut

85 30597

Oil

Wick

17/

32"

44

142443

No

. 10-32 x 1

%"

Rd

. Hd.

Sc.

86

30097

Outer

Sheave Plate Assy.

*

Standard

Hardware

Items

May

Be

Purchased Locally For

Illustration

See

Page 18

All

prices subiect

to

change

without

notice.

Ali replacement parts

will

be

supplied

in current

production

colors

or

in a neutral color.

-19-

AMF

SKI-DADDLER

SNOWMOB

ILE

ENGINE,

ELECTRICAL

AND

FUEL

ELEMENTS

10

~

,

I I I

r...J

I I I I

~

~~

~

-

25

f D@ I

~

-

54

~

I I ,J

tf

: i

~

I

1-64

~-24

,

521

I I I

5

~

@

!

"-@!

@I

@

I I

Jepl;J;,

I

65

'

-

~~

.50,

I

,I

~

I I eo

'"

'5

I

...

1~.I~I9I

-

47

I , I _ 1

' I

~

I

! A ,!!

~

;

I !

f"1

51

i

a I

LJ

l)

Ll

___

1

2

-======6

e-

\

12

)9

FIGURE 3

-20

-

I

15

/

63

I

16

I

/

14

67

I

For Parts List -See

Page

21

ALL UNNUMBERED

PARTS

INTER-CHANGEABLE

WITH

OPPOSITE SIDE

67

18

[

17

/

-.~

I I J

62

61

66

•

)

This manual suits for next models

3

Table of contents

Other Ski-Daddler Offroad Vehicle manuals

Popular Offroad Vehicle manuals by other brands

Polaris

Polaris A12MH46AX Service manual

Polaris

Polaris Sportsman 9921309 owner's manual

Columbia ParCar

Columbia ParCar Gasoline and Electric Golf and Industrial Four Wheel... Service manual

Ducati Energia

Ducati Energia FREE DUCk Operating and maintenance manual

Yamaha

Yamaha KODIAK 700 YFM70KDXH owner's manual

Yamaha

Yamaha Apex RX10PA 2011 Supplementary service manual