SKS Sweden Bonfiglioli Vectron Agile Use and care manual

www.bonfiglioli.com

Bonfiglioli Riduttori S.p.A.

Via Giovanni XXIII, 7/A

40012 Lippo di Calderara di Reno

Bologna, Italy

tel: +39 051 647 3111

fax: +39 051 647 3126

bonfiglioli@bonfiglioli.com

www.bonfiglioli.com

VEC 676 R0

Agile

CANopen Communication manual

Frequency inverter 230V / 400V

Bonfiglioli has been designing and developing innovative

and reliable power transmission and control solutions

for industry, mobile machinery and renewable energy

applications since 1956.

CANopen Agile 306/2010

General Information on the Documentation

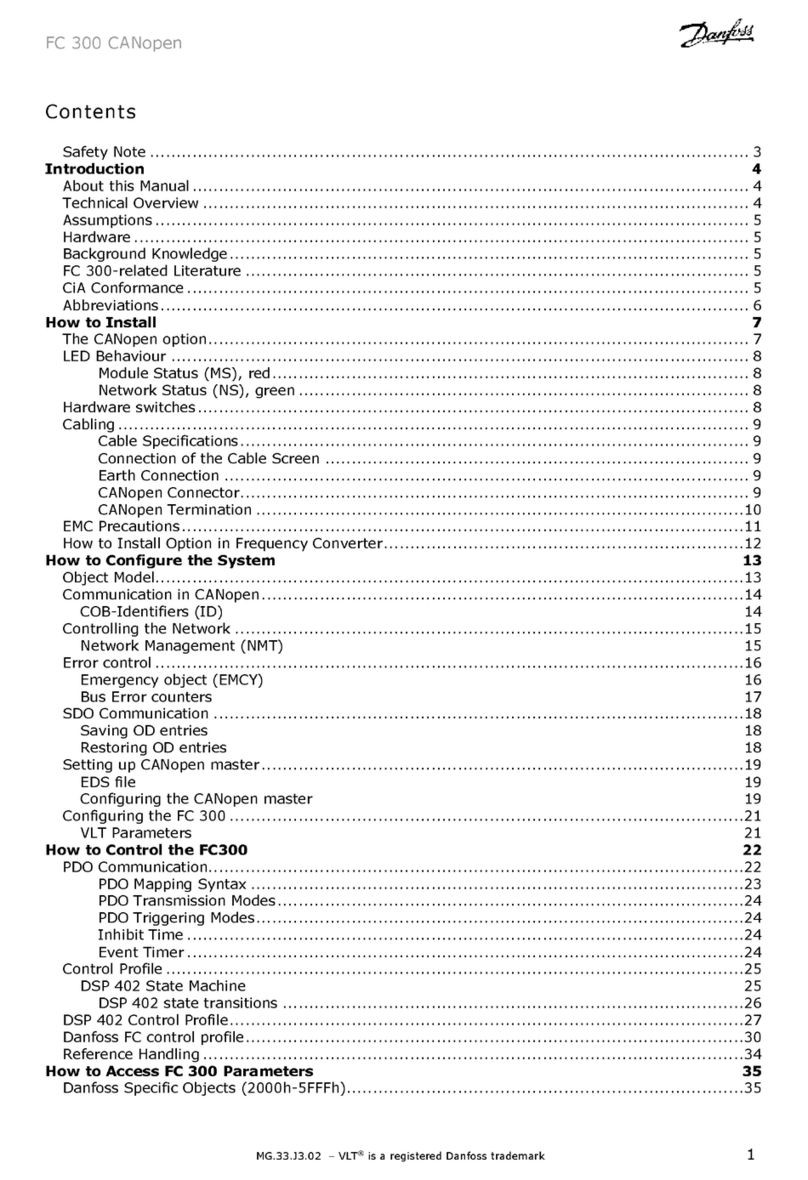

CONTENTS

1General Information on the Documentation.................................................................. 6

1.1 Instruction Manuals................................................................................................. 6

1.2 Used Pictograms and Signal Words......................................................................... 7

2General Safety Instructions and Information on Use.................................................... 8

2.1 General Information ................................................................................................ 8

2.2 Purpose of the Frequency Inverters........................................................................ 8

2.3 Transport and Storage............................................................................................. 8

2.4 Handling and Installation ........................................................................................ 9

2.5 Electrical Installation............................................................................................... 9

2.6 Information on Use................................................................................................ 10

2.6.1 Using external products.......................................................................................... 10

2.7 Maintenance and Service....................................................................................... 10

2.8 Disposal ................................................................................................................. 10

3Communication Option ................................................................................................ 11

3.1 VPlus PC-Software................................................................................................. 12

4Installation of an optional Communication Module..................................................... 13

4.1 Assembly................................................................................................................ 13

4.2 Disassembly........................................................................................................... 14

5Connection ................................................................................................................... 14

5.1 Connection to the Terminals.................................................................................. 14

5.2 Module Connection ................................................................................................ 14

6Commissioning via the Operator Panel........................................................................ 16

6.1 Menu for setting up the Communication ............................................................... 16

6.2 Select the Protocol................................................................................................. 17

6.3 Set the Communication Parameters...................................................................... 17

6.4 Set the Protocol for the Terminals and Communication Module........................... 18

7CANopen....................................................................................................................... 19

7.1 Baud Rate Setting / Line Lengths.......................................................................... 19

7.2 Setting the Node Address ...................................................................................... 20

7.3 Operational Behavior on Bus Failure ..................................................................... 20

8Protocol ........................................................................................................................ 22

8.1 Communication Objects......................................................................................... 22

8.2 Application Objects................................................................................................ 22

8.3 SDO Function ......................................................................................................... 22

8.3.1 Read Access.......................................................................................................... 23

8.3.2 Write Access ......................................................................................................... 23

8.3.3 Error Code Table ................................................................................................... 23

8.4 PDO Function ......................................................................................................... 24

CANopen Agile 06/20104

General Information on the Documentation

8.5 Emergency Function .............................................................................................. 25

8.6 SYNC ...................................................................................................................... 25

8.7 NMT Functions ....................................................................................................... 26

8.7.1 NMT Statemachine................................................................................................. 26

8.7.2 Boot-Up Message................................................................................................... 27

8.7.3 NMT Commands .................................................................................................... 27

8.8 Guarding ................................................................................................................ 28

8.9 Heartbeat............................................................................................................... 29

8.10 OS Synchronization ............................................................................................ 30

9Objects ......................................................................................................................... 32

9.1 Tabular Object Overview ....................................................................................... 32

9.1.1 Communication Objects.......................................................................................... 32

9.1.2 Manufacturer Objects............................................................................................. 35

9.1.3 Device Profile Objects ............................................................................................ 35

9.2 Communication Objects (0x1nnn)......................................................................... 38

9.2.1 0x1000/0 Device Type............................................................................................ 38

9.2.2 0x1001/0 Error Register ......................................................................................... 39

9.2.3 0x1005/0 COB-ID SYNC Message ............................................................................ 40

9.2.4 0x1006/0 Communication Cycle Period .................................................................... 40

9.2.5 0x1007/0 Synchronous Window Length ................................................................... 41

9.2.6 0x1008/0 Manufacturer Device Name ...................................................................... 42

9.2.7 0x1009/0 Manufacturer Hardware Version ............................................................... 42

9.2.8 0x100A/0 Manufacturer Software Version ................................................................ 42

9.2.9 0x100C/0 Guard Time ............................................................................................ 43

9.2.10 0x100D/0 Lifetime Factor ....................................................................................... 43

9.2.11 0x1010/n Store Parameters .................................................................................... 44

9.2.12 0x1011/n Restore default Parameters...................................................................... 45

9.2.13 0x1014/0 COB-ID Emergency Message .................................................................... 46

9.2.14 0x1016/n Consumer Heartbeat Time ....................................................................... 47

9.2.15 0x1017/0 Producer Heartbeat Time ......................................................................... 47

9.2.16 0x1018/n Identity Object........................................................................................ 48

9.2.17 0x1029/n Error Behavior ........................................................................................ 48

9.2.18 0x1200/n SDO Server Parameter............................................................................. 49

9.2.19 0x1400/n, 0x1401/n, 0x1402/n RxPDO Communication Parameter............................. 50

9.2.20 0x1600/n, 0x1601/n, 0x1602/n, RxPDO Mapping Parameters .................................... 52

9.2.21 0x1800/n, 0x1801/n, 0x1802/n, TxPDO Communication Parameters ......................... 54

9.2.22 0x1A00/n, 0x1A01/n, 0x1A02/n, TxPDO Mapping Parameters.................................... 57

9.3 Manufacturer Objects (0x2nnn) – Parameter Access ........................................... 59

9.3.1 Handling of Data Sets / Cyclic Writing...................................................................... 59

9.3.2 SDO Examples ("expedited" transfer only) ............................................................... 60

9.3.3 Examples of Writing Parameters.............................................................................. 61

9.3.4 Examples of Reading Parameters ............................................................................ 62

9.4 Manufacturer Objects (0x3000 … 0x5FFF) ........................................................... 64

9.4.1 0x3000/0 SYNC Jitter ............................................................................................. 64

9.4.2 0x3001/0 Digital In Actual Value ............................................................................. 65

9.4.3 0x3002/0 Digital Out Actual Value ........................................................................... 65

9.4.4 0x3003/0 Digital Out set values (Sources for Digital Outputs) .................................... 66

9.4.5 0x3004/0 Boolean Mux........................................................................................... 67

9.4.6 0x3005/0 Boolean DeMux....................................................................................... 68

9.4.7 0x3006/0 Percentage set value ............................................................................... 69

9.4.8 x3007/0 Percentage actual value............................................................................. 70

9.5 Device Profile Objects (0x6nnn)............................................................................ 71

9.5.1 0x6007/0 Abort Connection option code .................................................................. 71

9.5.2 0x603F/0 Error Code.............................................................................................. 73

9.5.3 0x6040/0 Control Word .......................................................................................... 74

CANopen Agile 506/2010

General Information on the Documentation

8.5 Emergency Function .............................................................................................. 25

8.6 SYNC ...................................................................................................................... 25

8.7 NMT Functions ....................................................................................................... 26

8.7.1 NMT Statemachine................................................................................................. 26

8.7.2 Boot-Up Message................................................................................................... 27

8.7.3 NMT Commands .................................................................................................... 27

8.8 Guarding ................................................................................................................ 28

8.9 Heartbeat............................................................................................................... 29

8.10 OS Synchronization ............................................................................................ 30

9Objects ......................................................................................................................... 32

9.1 Tabular Object Overview ....................................................................................... 32

9.1.1 Communication Objects.......................................................................................... 32

9.1.2 Manufacturer Objects............................................................................................. 35

9.1.3 Device Profile Objects ............................................................................................ 35

9.2 Communication Objects (0x1nnn)......................................................................... 38

9.2.1 0x1000/0 Device Type............................................................................................ 38

9.2.2 0x1001/0 Error Register ......................................................................................... 39

9.2.3 0x1005/0 COB-ID SYNC Message ............................................................................ 40

9.2.4 0x1006/0 Communication Cycle Period .................................................................... 40

9.2.5 0x1007/0 Synchronous Window Length ................................................................... 41

9.2.6 0x1008/0 Manufacturer Device Name ...................................................................... 42

9.2.7 0x1009/0 Manufacturer Hardware Version ............................................................... 42

9.2.8 0x100A/0 Manufacturer Software Version ................................................................ 42

9.2.9 0x100C/0 Guard Time ............................................................................................ 43

9.2.10 0x100D/0 Lifetime Factor ....................................................................................... 43

9.2.11 0x1010/n Store Parameters .................................................................................... 44

9.2.12 0x1011/n Restore default Parameters...................................................................... 45

9.2.13 0x1014/0 COB-ID Emergency Message .................................................................... 46

9.2.14 0x1016/n Consumer Heartbeat Time ....................................................................... 47

9.2.15 0x1017/0 Producer Heartbeat Time ......................................................................... 47

9.2.16 0x1018/n Identity Object........................................................................................ 48

9.2.17 0x1029/n Error Behavior ........................................................................................ 48

9.2.18 0x1200/n SDO Server Parameter............................................................................. 49

9.2.19 0x1400/n, 0x1401/n, 0x1402/n RxPDO Communication Parameter............................. 50

9.2.20 0x1600/n, 0x1601/n, 0x1602/n, RxPDO Mapping Parameters .................................... 52

9.2.21 0x1800/n, 0x1801/n, 0x1802/n, TxPDO Communication Parameters ......................... 54

9.2.22 0x1A00/n, 0x1A01/n, 0x1A02/n, TxPDO Mapping Parameters.................................... 57

9.3 Manufacturer Objects (0x2nnn) – Parameter Access ........................................... 59

9.3.1 Handling of Data Sets / Cyclic Writing...................................................................... 59

9.3.2 SDO Examples ("expedited" transfer only) ............................................................... 60

9.3.3 Examples of Writing Parameters.............................................................................. 61

9.3.4 Examples of Reading Parameters ............................................................................ 62

9.4 Manufacturer Objects (0x3000 … 0x5FFF) ........................................................... 64

9.4.1 0x3000/0 SYNC Jitter ............................................................................................. 64

9.4.2 0x3001/0 Digital In Actual Value ............................................................................. 65

9.4.3 0x3002/0 Digital Out Actual Value ........................................................................... 65

9.4.4 0x3003/0 Digital Out set values (Sources for Digital Outputs) .................................... 66

9.4.5 0x3004/0 Boolean Mux........................................................................................... 67

9.4.6 0x3005/0 Boolean DeMux....................................................................................... 68

9.4.7 0x3006/0 Percentage set value ............................................................................... 69

9.4.8 x3007/0 Percentage actual value............................................................................. 70

9.5 Device Profile Objects (0x6nnn)............................................................................ 71

9.5.1 0x6007/0 Abort Connection option code .................................................................. 71

9.5.2 0x603F/0 Error Code.............................................................................................. 73

9.5.3 0x6040/0 Control Word .......................................................................................... 74

General Information on the Documentation

9.5.4 0x6041/0 Status Word ........................................................................................... 75

9.5.5 0x6042/0 Target Velocity........................................................................................ 76

9.5.6 0x6043/0 Target velocity demand (Ramp Output) .................................................... 77

9.5.7 0x6044/0 Control effort (current Speed) .................................................................. 77

9.5.8 0x6046/n Velocity min max amount......................................................................... 78

9.5.9 0x6048/n Velocity acceleration................................................................................ 79

9.5.10 0x6049/n Velocity deceleration ............................................................................... 80

9.5.11 0x604A/n Velocity quick stop .................................................................................. 81

9.5.12 0x6060/0 Modes of operation ................................................................................. 82

9.5.13 0x6061/0 Modes of operation display ...................................................................... 82

9.5.14 0x6071/0 Target Torque ........................................................................................ 83

9.5.15 0x6077/0 Torque actual value................................................................................. 83

9.5.16 0x6078/0 Current actual value ................................................................................ 84

9.5.17 0x6079/0 DC link circuit voltage.............................................................................. 84

10 Frequency Inverter Control.......................................................................................... 85

10.1 Control via Contacts/Remote-Contacts ............................................................. 86

10.1.1 Device state machine ............................................................................................. 88

10.2 Control via Statemachine ................................................................................... 89

10.2.1 Statemachine diagram ........................................................................................... 91

10.3 Operation Mode Velocity Mode........................................................................... 93

10.3.1 Behavior in Quick Stop ........................................................................................... 93

10.3.2 Behavior in Transition 5 (Disable Operation) ............................................................ 94

10.3.3 Reference Value / Actual Value ............................................................................... 95

10.3.4 Example Sequence................................................................................................. 95

11 Parameter List.............................................................................................................. 96

11.1 Actual Values ...................................................................................................... 96

11.2 Parameters ......................................................................................................... 96

12 Appendix ...................................................................................................................... 98

12.1 Control Word Overview ...................................................................................... 98

12.2 Status Word Overview........................................................................................ 98

12.3 Warning Messages.............................................................................................. 99

12.4 Warning Messages Application......................................................................... 100

12.5 Error Messages ................................................................................................. 101

Index................................................................................................................................ 102

CANopen Agile 06/20106

General Information on the Documentation

1General Information on the Documentation

This documentation describes the communication with

Agile

device series frequency inverters using

the CANopen protocol. The modular hardware and software structure allows the user-friendly custo-

mization of the frequency inverters. Applications, which demand high functionality and dynamics can

be comfortably implemented.

1.1 Instruction Manuals

For better clarity, the user documentation is structured according to the customer-specific demands

made on the frequency inverter.

Quick Start Guide

The "Quick Start Guide"brief instructions manual describes the basic steps for the mechanical and

electrical installation of the frequency inverter. The guided commissioning supports you with the selec-

tion of the necessary parameters and the software configuration.

Operating Instructions

The Operating Instructions documents the complete functionality of the frequency inverter. The pa-

rameters necessary for specific applications for adaptation to the application and the extensive addi-

tional functions are described in detail.

Application Manual

The application manual supplements the documentation for purposeful installation and commissioning

of the frequency inverter. Information on various subjects connected with the use of the frequency

inverter is described specific to the application.

The documentation and further information can be requested from the local BONFIGLIOLI representa-

tive.

The following instruction manuals are available for the

Agile

device series:

Agile

Operating Instructions Frequency inverter functionality.

Agile

Quick Start Guide Installation und commissioning. Supplied with the device.

Communication

Application Manuals

Communication via the RS485 Interface on the X21-Connection (RJ45):

Instructions for Modbus and VABus.

Communication via the X12.5 and X12.6 Control Terminals:

Instructions for Systembus and CANopen®1.

Communication via the Communication Modules:

CM-232/CM-485: Instructions for Modbus and VABus.

CM-CAN: Instructions for Systembus und CANopen®.

CM-PDPV1: Instructions for Profibus-DP-V1

PLC Application Manual Logical interconnections of digital signals. Functions for analog signals

such as comparisons and mathematical functions. Graphical support for

the programming of functional components.

Service Instructions For service personnel. Service work, monitoring of service intervals and

replacement of ventilators.

This documentation has been produced with the greatest of care and extensively and repeatedly

checked. For reasons of clarity, not all the detailed information on all types of the product and also

not every imaginable case of installation, operation or maintenance has been taken into account. If

you require further information or if specific problems which are not dealt with extensively enough in

the documentation exist, you can request the necessary information from the local BONFIGLIOLI rep-

resentative.

1The CANopen®-Communication products fulfill the specifications of the CiA® (CAN in Automation)

user organization.

CANopen Agile 706/2010

General Information on the Documentation

1General Information on the Documentation

This documentation describes the communication with

Agile

device series frequency inverters using

the CANopen protocol. The modular hardware and software structure allows the user-friendly custo-

mization of the frequency inverters. Applications, which demand high functionality and dynamics can

be comfortably implemented.

1.1 Instruction Manuals

For better clarity, the user documentation is structured according to the customer-specific demands

made on the frequency inverter.

Quick Start Guide

The "Quick Start Guide"brief instructions manual describes the basic steps for the mechanical and

electrical installation of the frequency inverter. The guided commissioning supports you with the selec-

tion of the necessary parameters and the software configuration.

Operating Instructions

The Operating Instructions documents the complete functionality of the frequency inverter. The pa-

rameters necessary for specific applications for adaptation to the application and the extensive addi-

tional functions are described in detail.

Application Manual

The application manual supplements the documentation for purposeful installation and commissioning

of the frequency inverter. Information on various subjects connected with the use of the frequency

inverter is described specific to the application.

The documentation and further information can be requested from the local BONFIGLIOLI representa-

tive.

The following instruction manuals are available for the

Agile

device series:

Agile

Operating Instructions Frequency inverter functionality.

Agile

Quick Start Guide

Installation und commissioning. Supplied with the device.

Communication

Application Manuals

Communication via the RS485 Interface on the X21-Connection (RJ45):

Instructions for Modbus and VABus.

Communication via the X12.5 and X12.6 Control Terminals:

Instructions for Systembus and CANopen®1.

Communication via the Communication Modules:

CM-232/CM-485: Instructions for Modbus and VABus.

CM-CAN: Instructions for Systembus und CANopen®.

CM-PDPV1: Instructions for Profibus-DP-V1

PLC Application Manual

Logical interconnections of digital signals. Functions for analog signals

such as comparisons and mathematical functions. Graphical support for

the programming of functional components.

Service Instructions For service personnel. Service work, monitoring of service intervals and

replacement of ventilators.

This documentation has been produced with the greatest of care and extensively and repeatedly

checked. For reasons of clarity, not all the detailed information on all types of the product and also

not every imaginable case of installation, operation or maintenance has been taken into account. If

you require further information or if specific problems which are not dealt with extensively enough in

the documentation exist, you can request the necessary information from the local BONFIGLIOLI rep-

resentative.

1The CANopen®-Communication products fulfill the specifications of the CiA® (CAN in Automation)

user organization.

General Information on the Documentation

We would also point out that the contents of this documentation are not part of a previous or existing

agreement, assurance or legal relationship and are not intended to amend the same. All obligations of

the manufacturer result from the underlying purchase contract, which also contains the complete and

solely valid warranty regulation. These contractual warranty provisions are neither extended nor li-

mited by the production of this documentation.

The manufacturer reserves the right to correct or amend the contents and the product information as

well as omissions without prior notification and assumes no kind of liability for damage, injuries or

expenditure to be put down to the aforementioned reasons.

These instructions are not to be understood as fundamental information on CANopen. They presup-

pose underlying knowledge of the CANopen protocol.

1.2 Used Pictograms and Signal Words

The following pictograms and signal words are used in the documentation:

Danger!

Danger refers to an immediate threat. Non-compliance with the precaution described will

result in death, serious injury or material damage.

Warning!

Warning refers to a possible threat. Non-compliance with the warning may result in death,

serious injury or material damage.

Caution!

Caution refers to an immediate hazard. Non-compliance may result in personal or material

damage.

Attention!

Attention and the related text refer to a possible behavior or an undesired condition which can occur

during operation.

Note

Marks information that facilitates handling for you and supplements the corresponding part of the

documentation.

CANopen Agile 06/20108

General Safety Instructions and Information on Use

2General Safety Instructions and Information on Use

Warning!

The specifications and instructions contained in the documentation must be complied with

strictly during installation and commissioning. Before starting the relevant activity, read the

documentation carefully and comply with the safety instructions. The term "Qualified Staff"

refers to anybody who is familiar with the installation, assembly, commissioning and opera-

tion of the frequency inverter and has the proper qualification for the job.

2.1 General Information

Warning!

The DC-link circuit of the frequency inverter is charged during operation, i.e. there is al-

ways the risk of contact with high voltage. Frequency inverters are used for driving moving

parts and they may become hot at the surface during operation.

Any unauthorized removal of the necessary covers, improper use, wrong installation or op-

eration may result in serious injuries or material damage.

In order to avoid such injuries or damage, only qualified technical staff may carry out the

transport, installation, commissioning, setup or maintenance work required. The standards

EN 50178, IEC 60364 (Cenelec HD 384 or DIN VDE 0100), IEC 60664-1 (Cenelec HD 625

or VDE 0110-1) as well as the applicable national regulations must be complied with. The

term „Qualified Staff“ refers to anybody who is familiar with the installation, assembly,

commissioning and operation of the frequency inverter as well as the possible hazards and

has the proper qualification for the job.

Persons who are not familiar with the operation of the frequency inverter and children

must not have access to the device.

2.2 Purpose of the Frequency Inverters

Warning!

The frequency inverters are electrical drive components intended for installation in indus-

trial plants or machines. Commissioning and start of operation is not allowed until it has

been verified that the machine meets the requirements of the EC Machinery Directive

2006/42/EEC and EN 60204. In accordance with the CE marking requirements, the fre-

quency inverters comply with the Low Voltage Directive 2006/95/EC as well as EN 61800-

5-1. The user shall be responsible for making sure that the requirements of the EMC Direc-

tive 2004/108/EEC are met. Frequency inverters are only available at specialized dealers

and are exclusively intended for professional use as per EN 61000-3-2.

Purposes other than intended may result in the exclusion of warranty.

The frequency inverters are also marked with the UL label according to UL508c, which

proves that they also meet the requirements of the CSA Standard C22.2-No. 14-95.

The technical data, connection specifications and information on ambient conditions are

indicated on the name plate and in the documentation and must be complied with in any

case. Anyone involved in any kind of work at the device must have read the instructions

carefully and understood them before starting the work.

2.3 Transport and Storage

The frequency inverters must be transported and stored in an appropriate way. During transport and

storage the devices must remain in their original packaging.

The units may only be stored in dry rooms which are protected against dust and moisture. The units

may be exposed to little temperature deviations only. Observe the conditions according to EN 60721-

3-1 for storage, EN 60721-3-2 for transport and the marking on the packaging.

The duration of storage without connection to the permissible nominal voltage may not exceed one

year.

CANopen Agile 906/2010

General Safety Instructions and Information on Use

2.4 Handling and Installation

Warning!

Damaged or destroyed components must not be put into operation because they may be a

health hazard.

The frequency inverters are to be used in accordance with the documentation as well as the applica-

ble directives and standards.

They must be handled carefully and protected against mechanical stress.

Do not bend any components or change the isolating distances.

Do not touch electronic components or contacts. The devices are equipped with components which

are sensitive to electrostatic energy and can be damaged if handled improperly. Any use of damaged

or destroyed components shall be considered as a non-compliance with the applicable standards.

Removal of seal marks may cause restrictions on warranty.

Do not remove any warning signs from the device.

2.5 Electrical Installation

Warning!

Before any assembly or connection work, discharge the frequency inverter. Verify that the

frequency inverter is discharged.

Do not touch the terminals because the capacitors may still be charged.

Comply with the information given in the operating instructions and on the frequency in-

verter label.

Comply with the rules for working on electrical installations.

Rules for working on electrical installation:

−Separate completely (isolate the installation from all possible sources of electrical power.

−Fix (protect against reconnection). Reconnection must be carried out by suitably qualified persons.

−Verify there is no electrical power. Verify that there is no voltage against earth on the plant com-

ponent by measuring with measurement device or voltage tester.

−Ground and connect in a short circuit. Connect earth conductors.

−Protect against nearby power sources and delimit the working zone.

1)

In plants with a nominal power up to 1 kV deviation from description may be possible.

When working at the frequency inverters, comply with the relevant accident prevention regulations,

the applicable standards, standards governing work on systems with dangerous voltages (e.g. EN

50178), directives for electrical and mechanical equipment erection and other national directives.

Comply with the electrical installation instructions given in the documentation as well as the relevant

directives.

Responsibility for compliance with and examination of the limit values of the EMC product norm EN

61800-3 for variable-speed electrical drive mechanisms is with the manu-facturer of the industrial

plant or machine. The documentation contains information on EMC-conforming installation.

The cables connected to the frequency inverters may not be subjected to high-voltage insulation tests

unless appropriate circuitry measures are taken before.

Do not connect any capacitive loads.

CANopen Agile 06/201010

General Safety Instructions and Information on Use

2.6 Information on Use

Warning!

The frequency inverter may be connected to power supply every 60 s. This must be consi-

dered when operating a mains contactor in jog operation mode. For commissioning or after

an emergency stop, a non-recurrent, direct restart is permissible.

After a failure and restoration of the power supply, the motor may start unexpectedly if the

auto start function is activated.

If staff is endangered, a restart of the motor must be prevented by means of external cir-

cuitry.

Before commissioning and the start of the operation, make sure to fix all covers and check

the terminals. Check the additional monitoring and protective devices according to EN

60204 and applicable the safety directives (e.g. Working Machines Act, Accident Prevention

Directives etc.).

No connection work may be performed, while the system is in operation.

2.6.1 Using external products

Please note, that Bonfiglioli Vectron does not take any responsibility for the compatibility of

external products (e.g. motors, cables, filters, etc.).

To ensure the best system compatibility, Bonfiglioli Vectron offers components which sim-

plify commissioning and provide the best tuning with each other during operation.

Using the device in combination with external products is carried out at your own risk.

2.7 Maintenance and Service

Warning!

Unauthorized opening and improper interventions can lead to personal injury or material

damage. Repairs on the frequency inverters may only be carried out by the manu-facturer

or persons authorized by the manufacturer.

Check protective equipment regularly.

Any repair work must be carried out by qualified electricians.

2.8 Disposal

The dispose of frequency inverter components must be carried out in accordance with the local and

country-specific regulations and standards.

CANopen Agile 1106/2010

Communication Option

3Communication Option

Interface See

Control Terminals for CAN-Connection Instructions for Systembus or CANopen®

2

CM-CAN

.

X21 Communication Interface

3

Instructions for VABus or Modbus.

CM-232 Instructions for VABus or Modbus.

CM-485 Instructions for VABus or Modbus.

CM-PDPV1 Instructions for Profibus DP-V1.

Combinations of Systembus and CANopen® communication on the two interfaces:

Optional Communication

Module (CM)

Frequency Inverter

Terminals X12.5 and X12.6

CANopen® as well as Systembus

Systembus as well as CANopen®

2The CANopen®-Communication products fulfill the specifications of the CiA® (CAN in Automation)

user organization.

3Install an interface adapter for connection to a PC. This enables parameterization und monitoring via

the VPlus PC-Software.

CANopen Agile 06/201012

Communication Option

3.1 VPlus PC-Software

The USB-Interface of a PC can be connected to the X21 Communication Interface via an optional USB

adapter. This enables parameterization and monitoring with the help of the VPlus PC-Software.

X21 (RJ45)

VPlus

USB

RJ45

Adapter

CANopen Agile 1306/2010

Communication Option

3.1 VPlus PC-Software

The USB-Interface of a PC can be connected to the X21 Communication Interface via an optional USB

adapter. This enables parameterization and monitoring with the help of the VPlus PC-Software.

X21 (RJ45)

VPlus

USB

RJ45

Adapter

Installation of an optional Communication Module

4Installation of an optional Communication Module

4.1 Assembly

The communication module is pre-assembled in a casing. Additionally, a PE spring is enclosed for PE

connection (shield).

Caution!

The frequency inverter must be disconnected from the power supply before installation of

the communication module.

Installation under voltage is not permitted and will destroy the frequency inverter and/or

the communication module.

Do not touch the PCB visible on the back of the module, otherwise components may be

damaged.

•Remove the cover of the module slot.

1

•Attach the PE spring (1) using the screw provided on

the frequency inverter.

2

3

•Insert the Communication Module (2).

•Screw the communication module (2) onto the fre-

quency with the screw (3).

•Break off the pre-punched cut-out from the cover.

•Replace the cover.

CANopen Agile 06/201014

Connection

4.2 Disassembly

•Remove the cover of the module slot.

2

1

•Loosen the screw (1) on the communication module.

•Using a small screwdriver, firstly unlock the right and then the

left snap-in hook (2).

•Remove the communication module from the slot.

•Unscrew the PE spring.

•Replace the cover onto the frequency inverter.

5Connection

The CAN-Connection of the Systembus is physically laid out according to ISO-DIS 11898 (CAN High

Speed).

Caution!

The frequency inverter must be disconnected from the power supply before installation and

connection work. Make sure that the frequency inverter is de-energized.

Installation under voltage is not permitted and can lead to the destruction of the frequency

inverter and/or the communication module.

5.1 Connection to the Terminals

Connect the bus to the X12.5 and X12.6 terminals of the frequency inverter.

X12

56

CAN High

CAN Low

Cable

•For the bus line use a twisted and shielded cable.

•Implement the shield as a braided shield (not a foil shield).

•Connect the cable shield surfaces to PE at both ends.

Bus Termination

Connect the bus termination, necessary on one cable, at the first and last physical participant.

CAN High

120

CAN Low

Data line

Data line

CANopen Agile 1506/2010

Connection

4.2 Disassembly

•Remove the cover of the module slot.

2

1

•Loosen the screw (1) on the communication module.

•Using a small screwdriver, firstly unlock the right and then the

left snap-in hook (2).

•Remove the communication module from the slot.

•Unscrew the PE spring.

•Replace the cover onto the frequency inverter.

5Connection

The CAN-Connection of the Systembus is physically laid out according to ISO-DIS 11898 (CAN High

Speed).

Caution!

The frequency inverter must be disconnected from the power supply before installation and

connection work. Make sure that the frequency inverter is de-energized.

Installation under voltage is not permitted and can lead to the destruction of the frequency

inverter and/or the communication module.

5.1 Connection to the Terminals

Connect the bus to the X12.5 and X12.6 terminals of the frequency inverter.

X12

56

CAN High

CAN Low

Cable

•For the bus line use a twisted and shielded cable.

•Implement the shield as a braided shield (not a foil shield).

•Connect the cable shield surfaces to PE at both ends.

Bus Termination

Connect the bus termination, necessary on one cable, at the first and last physical participant.

CAN High

120

CAN Low

Data line

Data line

Connection

5.2 Module Connection

S1 X310

The X310 (9-pin D-

Sub) bus plug has been designed according

to DS102 Version 2.0 (Bus node, option A).

Details can be seen from the following table on the occupancy of

the bus plug.

The bus termination necessary on a phase in the physically first

and last subscriber can be activated via DIP switch S1

on the

communication module.

The factory setting for the bus termination is OFF.

As an alternative, this is also possible via corresponding circuits in the bus connection plugs.

CA N high ( Pin 7)

120

CAN low (Pin 2)

Data lin e

Data lin e

Attention!

Make absolutely sure that only one of the two possibilities for the bus termination is used and the bus

termination is only switched on with the first and last subscriber. Otherwise, operation of the CANo-

pen® communication is not possible.

Bus Connector X310

Pin Name Function

Housing Shield connected with PE.

1 CAN_L CAN-Low Bus-Interface

short-circuit resistant and function-insulated, max. current 60 mA

2 CAN_L CAN-Low Bus-Interface

short-circuit resistant and function-insulated, max. current 60 mA

3 CAN_GND Earth/GND

4n.c. not used.

5n.c. not used.

6CAN_GND Earth/GND

7 CAN_H CAN-High Bus-Interface

short-circuit resistant and function-insulated, max. current 60 mA

8 CAN_H CAN-High Bus-Interface

short-circuit resistant and function-insulated, max. current 60 mA

9 - do NOT connect.

For the bus line, use twisted cable with harness shield (no foil shield).

Attention!

The harness screen of the data lines is to be connected to ground (PE) on both sides on a large area.

CANopen Agile 06/201016

Commissioning via the Operator Panel

6Commissioning via the Operator Panel

A communication interface can be set up in the "Setup"menu of the operator panel. Further commu-

nication parameters can be set in the "Para"menu.

6.1 Menu for setting up the Communication

The communication interface can be set up quickly and simple via the Operator Panel.

CANopen Agile 1706/2010

Commissioning via the Operator Panel

6Commissioning via the Operator Panel

A communication interface can be set up in the "Setup"menu of the operator panel. Further commu-

nication parameters can be set in the "Para"menu.

6.1 Menu for setting up the Communication

The communication interface can be set up quickly and simple via the Operator Panel.

Commissioning via the Operator Panel

6.2 Select the Protocol

•Select CANopen.

Display

Select the "Setup"menu using the arrow keys.

EN T

Using the arrow keys select:

Setting up a Communication Interface (Bus Configuration)

asd

EN T

Select a protocol using the arrow keys:

CANopen

Profibus

4

Systembus

Modbus

VABus

EN T

6.3 Set the Communication Parameters

Parameter Display

387 Node Number

385 Baud Rate

276 CAN Interface (CM-CAN/X12). Interface setting.

−Set the X12.5 and X12.6 Terminals to the CANopen

Protocol

Or:

−Set an optional CM-CAN Communication Module to

CANopen.

4The selection is only possible if an optional CM-PDPV1 Communication Module is installed.

CANopen Agile 06/201018

Commissioning via the Operator Panel

6.4 Set the Protocol for the Terminals and Communication Module

276 CAN Interface (CM-CAN/X12)

With Parameter CAN Interface (CM-CAN/X12) 276 the terminals of the frequency inverter and an

optional Communication Module (CM) can be set to a communication protocol. In the factory setting

(1 - CANopen/CAN-Systembus) the terminals of the frequency inverter are set to CAN-Systembus.

CM-CAN/CAN-Terminals

Function

1- CANopen/CAN-Systembus Optional Communication Module:

Frequency Inverter Terminals X12.5 and X12.6:

CANopen®

Systembus

2- CAN-Systembus/CANopen Optional Communication Module:

Frequency Inverter Terminals X12.5 und X12.6:

Systembus

CANopen®

CM-CAN: Optional Communication Module

CAN-Terminals: Terminals X12.5 and X12.6 of the frequency inverter.

Simultaneous CANopen®-Communication via the Terminals of the frequency inverter and via a Com-

munication Module is not possible.

Simultaneous Systembus-Communication via the Terminals of the frequency inverter and via a Com-

munication Module is not possible.

CANopen Agile 1906/2010

Commissioning via the Operator Panel

6.4 Set the Protocol for the Terminals and Communication Module

276 CAN Interface (CM-CAN/X12)

With Parameter CAN Interface (CM-CAN/X12) 276 the terminals of the frequency inverter and an

optional Communication Module (CM) can be set to a communication protocol. In the factory setting

(1 - CANopen/CAN-Systembus) the terminals of the frequency inverter are set to CAN-Systembus.

CM-CAN/CAN-Terminals

Function

1- CANopen/CAN-Systembus

Optional Communication Module:

Frequency Inverter Terminals X12.5 and X12.6:

CANopen®

Systembus

2- CAN-Systembus/CANopen

Optional Communication Module:

Frequency Inverter Terminals X12.5 und X12.6:

Systembus

CANopen®

CM-CAN: Optional Communication Module

CAN-Terminals: Terminals X12.5 and X12.6 of the frequency inverter.

Simultaneous CANopen®-Communication via the Terminals of the frequency inverter and via a Com-

munication Module is not possible.

Simultaneous Systembus-Communication via the Terminals of the frequency inverter and via a Com-

munication Module is not possible.

CANopen

7CANopen

CANopen®is used in a wide range of applications and is an especially favored communication system

for motion control applications. The CANopen®based standard DS402 "drives and motion control"

describes and defines the necessary objects and functions for motion control systems.

The available objects are subdivided into:

Communication Objects (0x1nnn) according to DS301 V4.02

Manufacturer Objects (0x2nnn)

Standardized Objects (0x6nnn) according to DS402 V2.0

The functions and objects are described here as far as is necessary. For further information refer to

the CiA Draft Standards.

The standards, referred to here, are DS102, DS301 und DS402. These can be obtained from:

CAN in AUTOMATION (CiA)

Kontumazgarten 3

D-90429 Nürnberg

Tel.: +49 911 928819 0

Fax: +49 911 928819 79

URL: www.can-cia.org

E-Mail: headquarters@can-cia.org

Attention!

With the help of the CM-CAN CANopen®communication module, it is possible to access ALL parame-

ters of the frequency inverter from the external control unit. Control of the access via the operation

level, as with the Operator Panel or the VPlus PC-Software, does not exist. A change of parameters

with an unknown meaning to the user can lead to the inoperability of the frequency inverter.

Attention!

If data is written cyclically comply with the instructions in Chapter 9.3.1 "Handling of Data Sets / Cyc-

lic Writing".

Note:

For the operation with a PLC in most cases an EDS file in required. You can find this EDS file on the

product documentation CD.

CANopen® and CiA® are registered trademarks of CAN in Automation e.V.

7.1 Baud Rate Setting / Line Lengths

385 CAN Baud rate

The transmission speed of the CANopen®communication module CM-CAN can be set via Parameter

CAN Baud rate 385.

Parameter Setting

No. Description Min. Max. Factory Setting

385 CAN Baud rate 1 8 6

The transmission rate is a function of a variety of application-specific parameters. The line length of

the communication network limits the transmission speed due to the signal propagation time of the

CANopen®protocols.

CANopen Agile 06/201020

CANopen

CANopen Interface

Operation Mode Function max. Line Length

1- 10 kBaud Transmission rate 10 kBaud 5000 Meter

2- 20 kBaud Transmission rate 20 kBaud 2500 Meter

3 - 50 kBaud Transmission rate 50 kBaud 1000 Meter

4 - 100 kBaud Transmission rate 100 kBaud 500 Meter

5- 125 kBaud Transmission rate 125 kBaud 500 Meter

6- 250 kBaud Transmission rate 250 kBaud 250 Meter

7- 500 kBaud Transmission rate 500 kBaud 100 Meter

8- 1000 kBaud Transmission rate 1000 kBaud 25 Meter

7.2 Setting the Node Address

387 CAN Node-Number

The CANopen®protocol supports a maximum of 127 nodes in a communication network. Each fre-

quency inverter is assigned a node ID, which may only exist once in the system, for its unambiguous

identification. The node number is set with parameter CAN Node Number 387.

Parameter Setting

No. Description Min. Max. Factory setting

387 CAN Node Number -1 127 -1

Note:

The factory setting CAN Node Number 387 = -1 means that the CANopen®interface has been deac-

tivated.

The value Can Node number 387 = 0 is not allowed and cannot be set.

Note:

Changing the node number causes a restart of the CANopen®system (NOT a reset of the inverter).

7.3 Operational Behavior on Bus Failure

388 CAN Error Behavior

The operational behavior if the CANopen® system fails due to BusOff, guarding, heartbeat, SYNC

error, RxPDO length error or NMT state change (leaving NMT state operational) can be paramete-

rized. The required behavior is set with parameter CAN Error Behavior 388.

CAN Error Behavior

388 Function

0 - No Reaction Operating point is maintained

1 - Error Immediate change of state to "Fault". Factory Setting.

2 - Switch-off Control command "Disable Voltage"and change of state to "Voltage

disabled".

3 - Quick-Stop Control command "Quick Stop"and change of state to "Switch-on dis-

abled".

4 - Ramp-Stop + Error Control command "Disable Operation"and change of state to "Fault",

after the drive has been stopped.

5 - Quick-Stop + Error Control command "Quick Stop"and change of state to "Fault"

, after the

drive has been stopped.

Attention!

The parameter settings CAN Error Behavior 388 = 2 … 5 are only relevant if parameter Lo-

cal/Remote 412 = "1 - Control via Statemachine"has been set.

Parameter CAN Error Behavior 388 corresponds to the device profile object 0x6007 Abort Connec-

tion option code.

Table of contents

Popular DC Drive manuals by other brands

Bosch

Bosch Rexroth Sytronix SvP 7020 PFC operating instructions

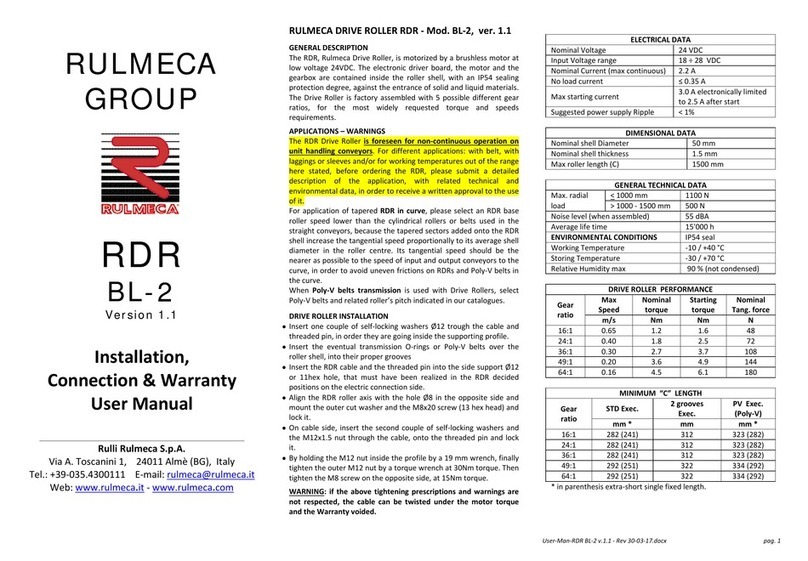

rulmeca

rulmeca RDR BL-2 user manual

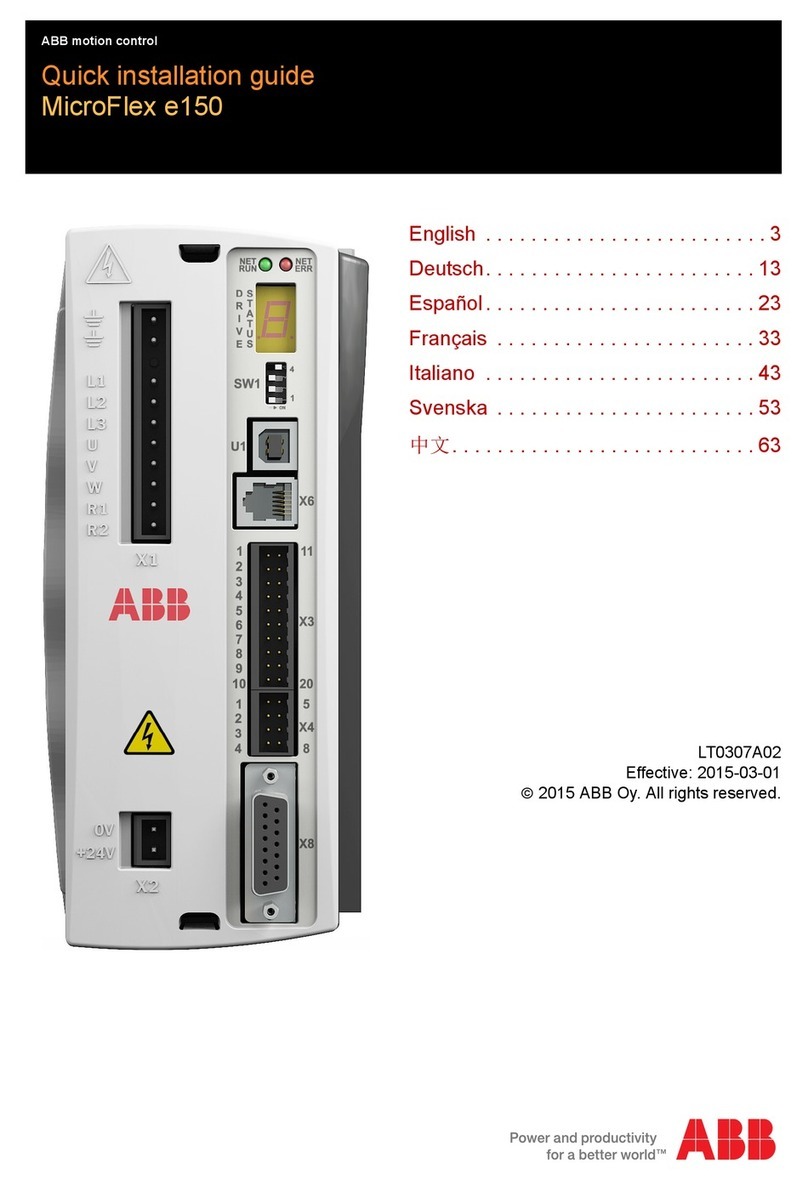

ABB

ABB MicroFlex e150 Quick installation guide

Leadshine

Leadshine EM422S user manual

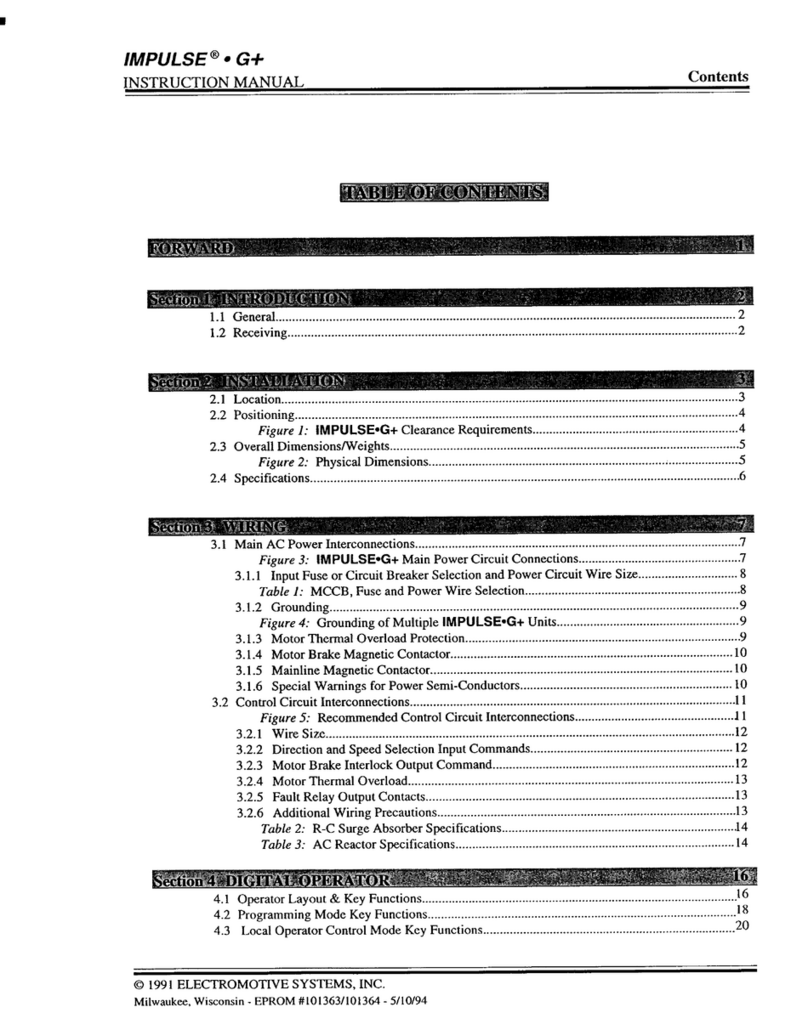

Electromotive Systems

Electromotive Systems impulse g+ instruction manual

Allen-Bradley

Allen-Bradley PowerFlex 70 installation instructions