ROWAN ELETTRONICA SRL page 2 out of 24

INDEX

Boarddescription:

Technical characteristics - Dimensions............................................................................................page. 3

Operating principal .............................................................................................................................page. 4

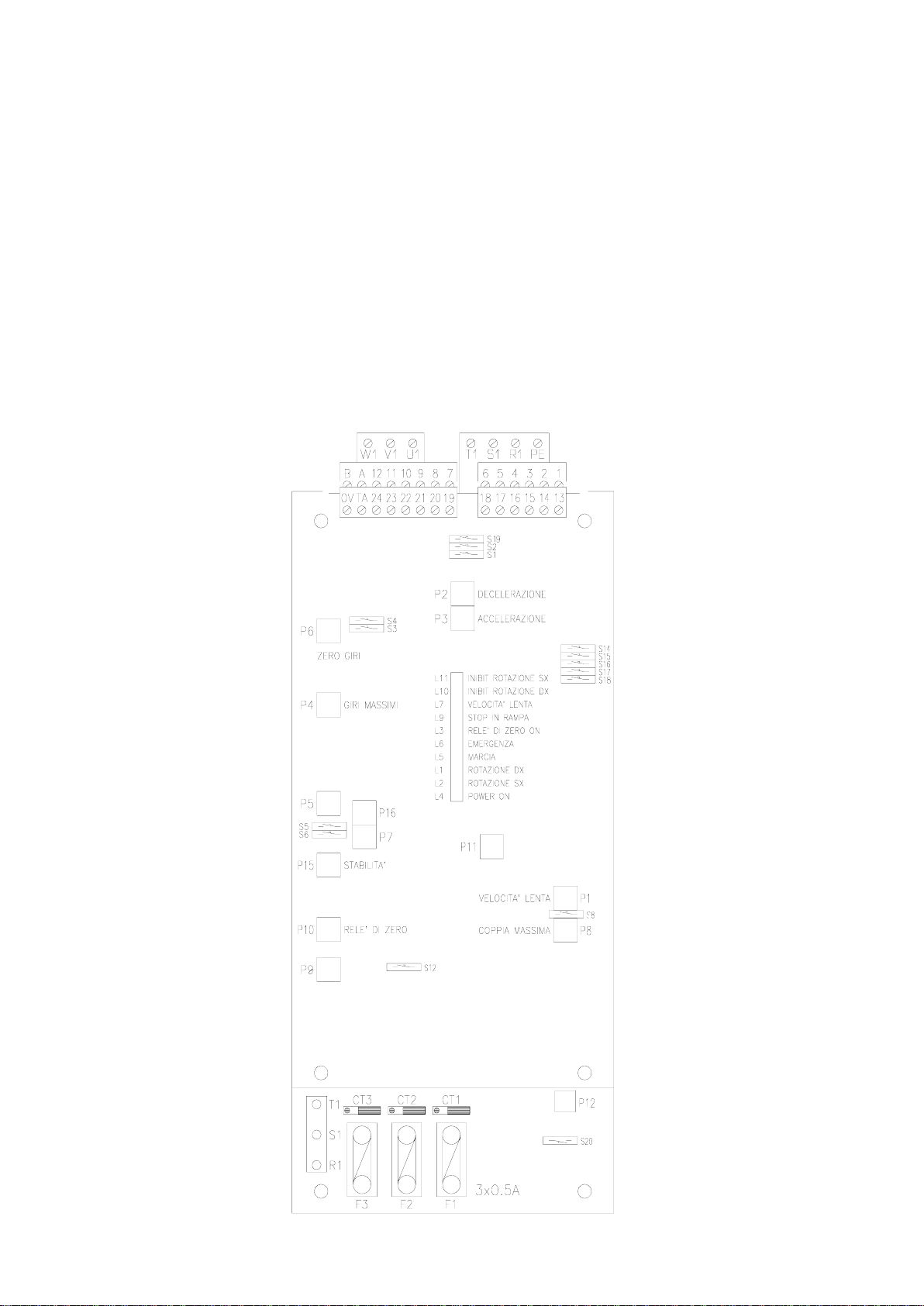

Led,trimmer, dip-switchpositions.................................. .....................................................................page. 4

Connection diagrams.........................................................................................................................page. 5

Led signal description ........................................................................................................................page. 6

Trimmer description ...........................................................................................................................page. 6

Dip-switch description ........................................................................................................................page. 6

Command and power connectors description .................................................................................page. 7

380S board setting and command instructions:

Board presetting for the number of motor poles ...............................................................................page. 8

Maximum speed setting - zero revolutions offset ..............................................................................page. 8

Acceleration and deceleration ramp regulation ................................................................................ page. 8

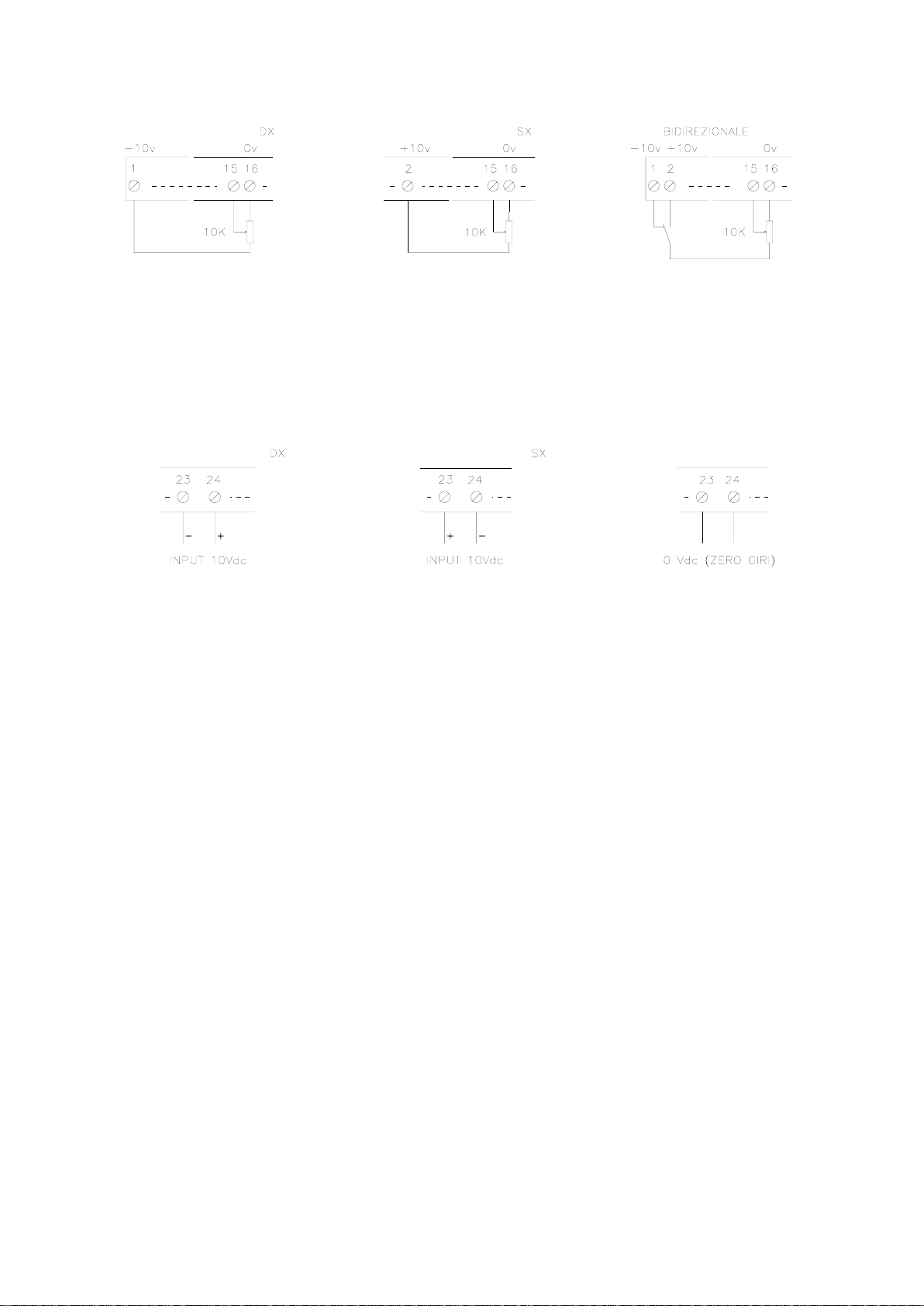

DC signal or potentiometer speed regulation................................................................................... page. 9

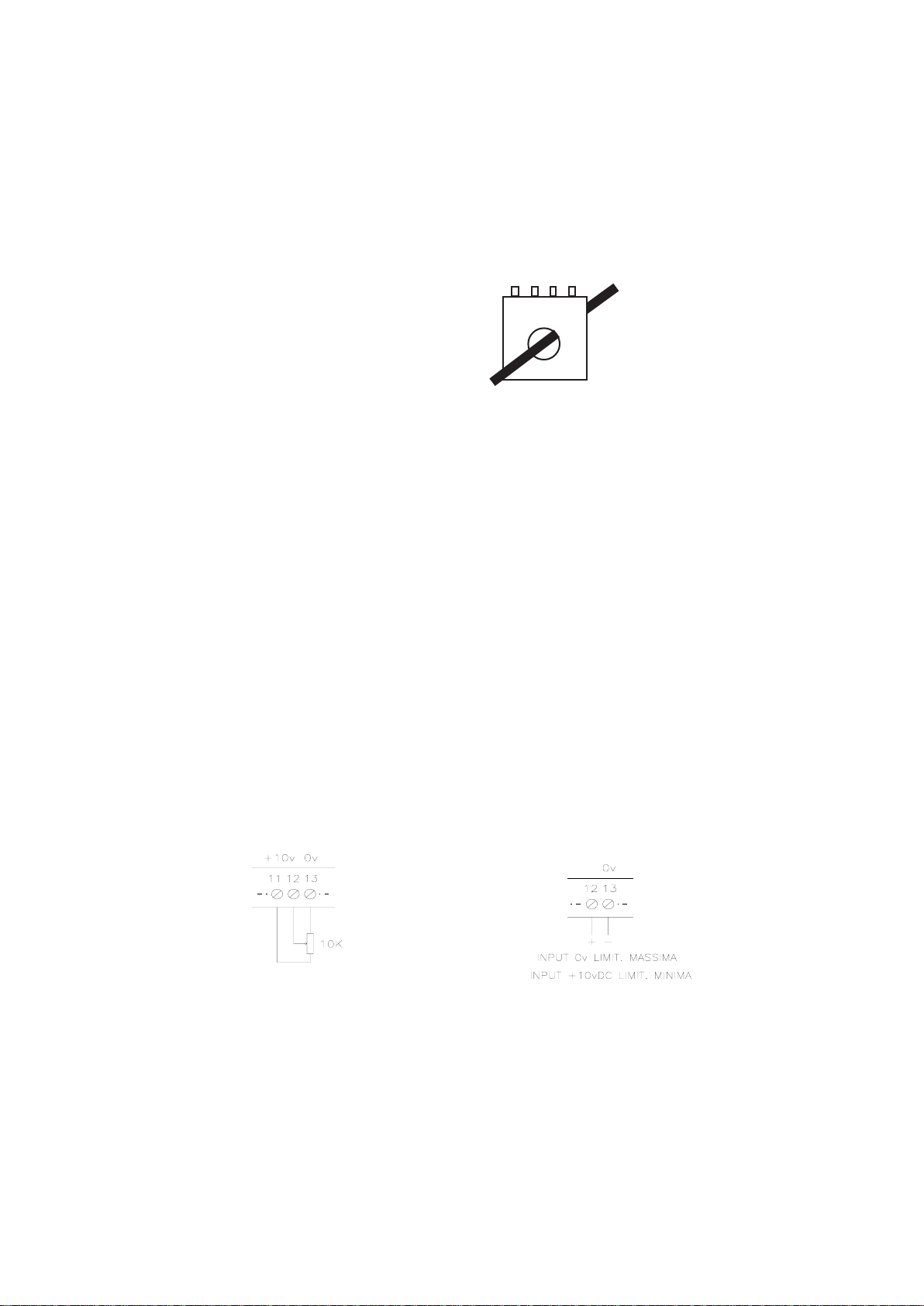

Rowan high speed motor couple regulation..................................................................................... page. 10

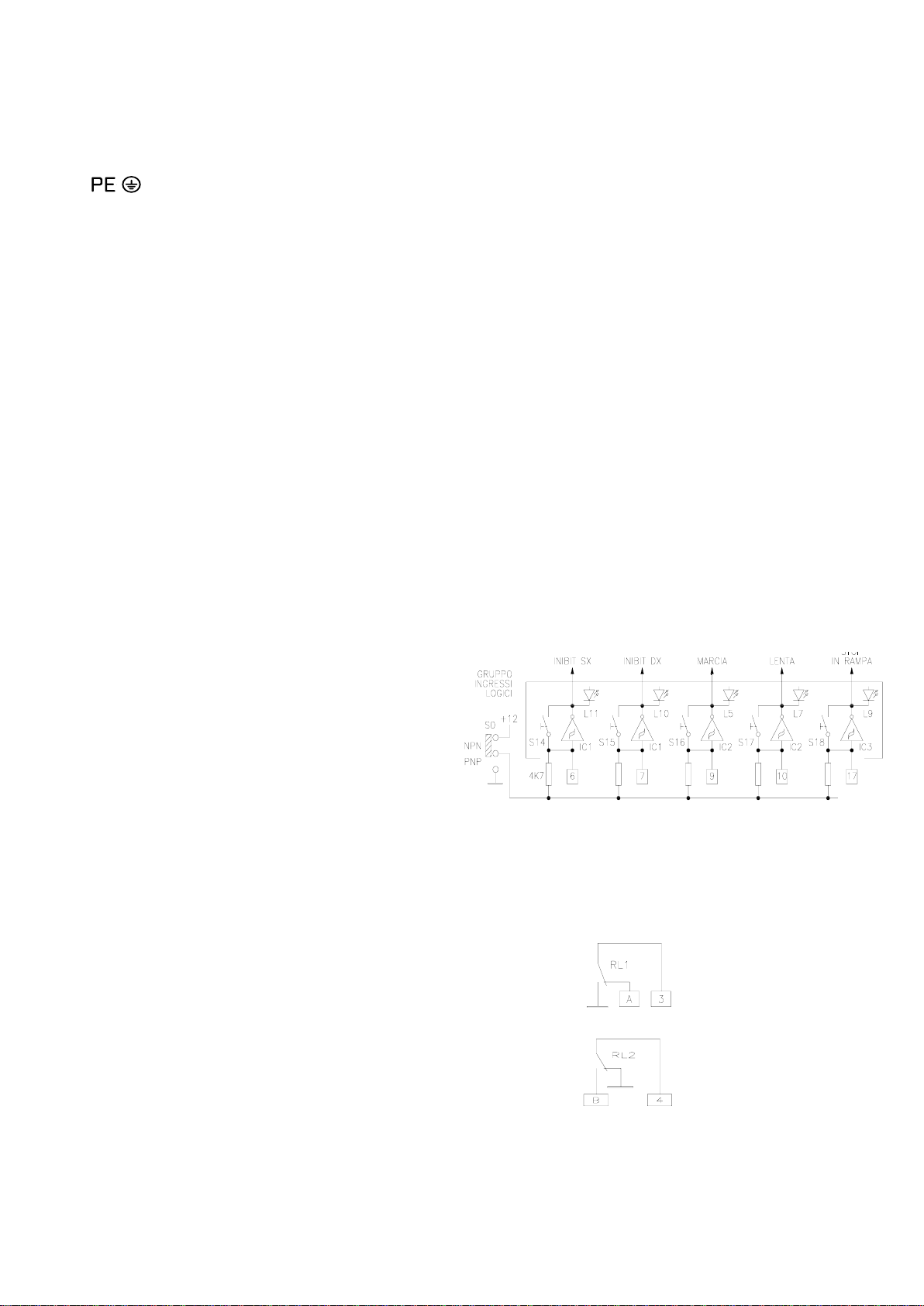

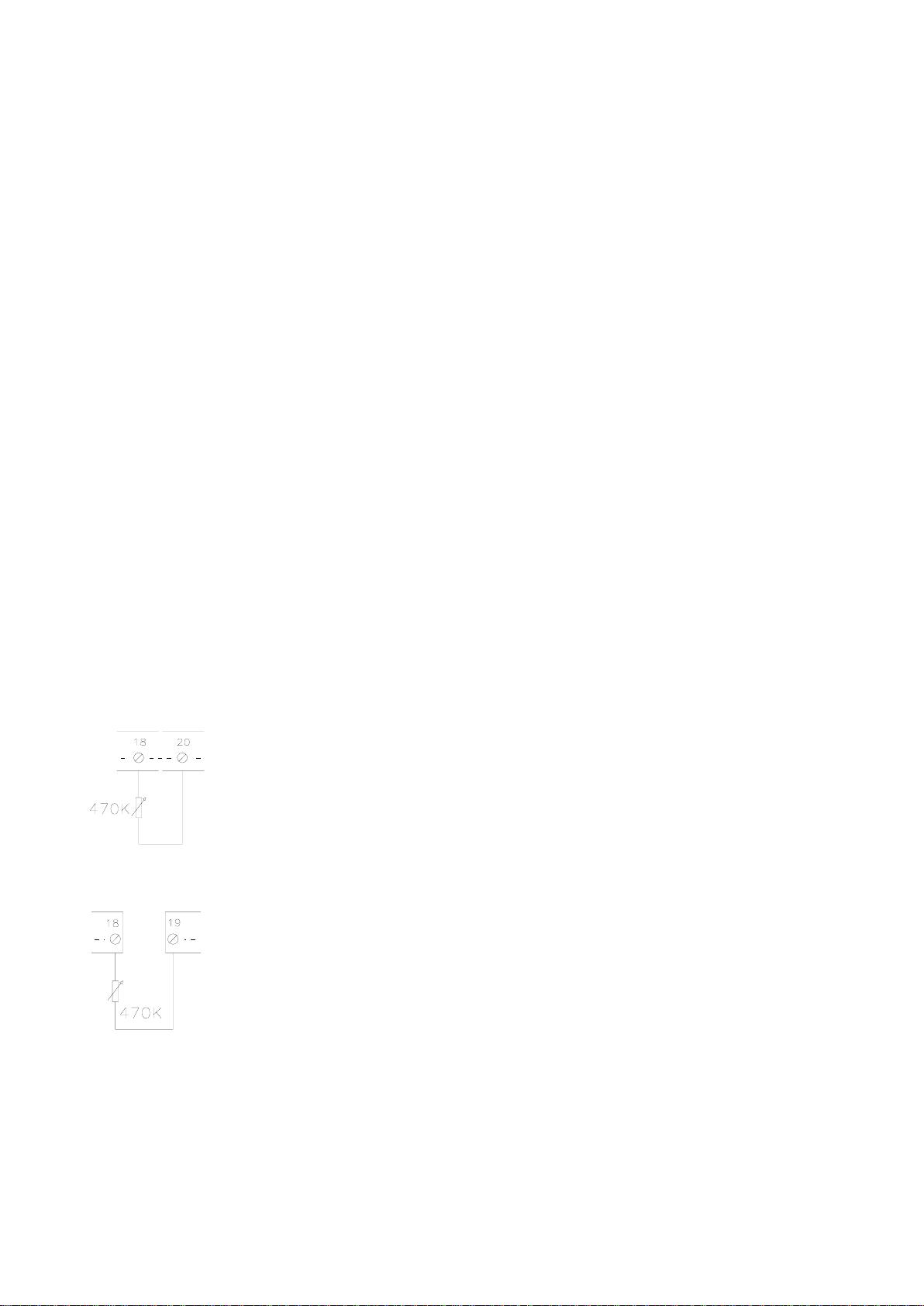

Command inputs description ............................................................................................................page. 11-12

Output description ..............................................................................................................................page. 13

Rowan S series motor connection instructions:

Motor power connector connection ....................................................................................................page. 14

Electrical characteristics table of the motors applicable to the 380S board...................................page. 14

Motor service connector connection...................................................................................................page. 15

Brake connection; table of the power consumption of the 24VDC brake......................................... page. 15

Installationinstructions:

Mechanical installation .......................................................................................................................page. 16

Electrical protection ............................................................................................................................page. 16

Wiring and electromagnetic compatibility..........................................................................................page. 16

Start up ................................................................................................................................................page. 17-18

Troubleshooting..................................................................................................................................page. 18

Default settings and standard settings .............................................................................................page. 18

Applicable diagrams:

Forward/backward movement with pre-stop slowing for precise stopping with the brake command.. page. 19

How to substitute the previous (out of production) boards:

Substitution of Cod. 280S.B/0 and 280R with Cod. 380S................................................................page. 5

Block diagrams .................................................................................................................................. page. 20

Componentslayout............................................................................................................................ page. 21

Maintenance instructions for the S series Rowan motors (high slip type) ................................. page. 22-23

TRANSLATION OF THE TEXT IN THE DRAWINGS ........................................................................pag. 24

Warning!

- ROWAN ELETTRONICA s.r.l. declines any responsibility for any inaccuracies contained in this manual, due to

printing and/or transcription errors. ROWAN ELETTRONICA s.r.l. reserves the right to make any variations that

it considers necessary for better functioning of the product, without prior notification.

- Regarding the data and characteristics mentioned in the manual, a maximum tolerance of 10% has been

allowed, if not otherwise indicated.

- Theproductguarantyisconsideredex-worksandisvalid 6monthsfromthedateofleavingROWANELETTRONICA

s.r.l.

- The electrical equipment could create dangerous situations for the safety of both personnel and objects; the user

is responsible for the installation of the equipment and for the conformity of the installation with the regulations

in force.

- The diagrams contained in this manual are mere examples and should be perfected by the customer according

to their specific needs.

-The equipment must be installed only by qualified personnel, after having read and understood this manual. In

case of doubt, the supplier should be contacted.