SKS Sweden Bonfiglioli Vectron ACTIVE CUBE ACU 201... User manual

www.bonfiglioli.com

Bonfiglioli Riduttori S.p.A.

Via Giovanni XXIII, 7/A

40012 Lippo di Calderara di Reno

Bologna, Italy

tel: +39 051 647 3111

fax: +39 051 647 3126

bonfiglioli@bonfiglioli.com

www.bonfiglioli.com

VEC 521 R3

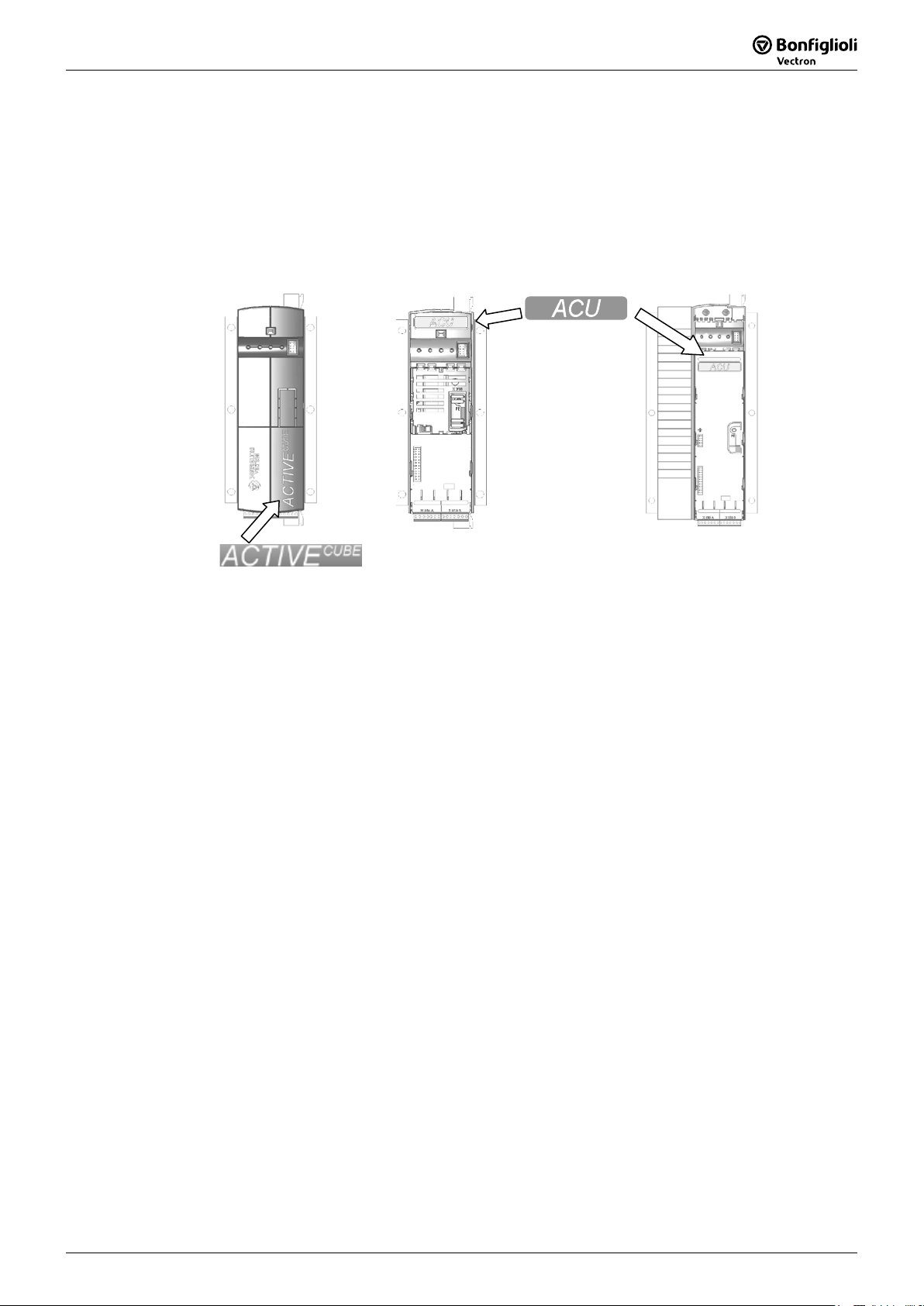

ACTIVE CUBE

Operating Instructions

Frequency Inverter 230V / 400V

0.25 kW ... 132 kW

Bonfiglioli has been designing and developing innovative

and reliable power transmission and control solutions

for industry, mobile machinery and renewable energy

applications since 1956.

09/08 Operating Instructions ACU 1

General Information about the Documentation

The present documentation refers to the frequency inverters ACTIVE Cube 201 and

ACTIVE Cube 401 series. With their factory settings, both series of devices are suited

for a wide range of applications. The modular hardware and software structure

enables customer-specific adaptation of the frequency inverters. Applications with

high functionality and dynamics requirements can be realized easily.

The ACTIVE Cube series can be recognized by its label on the case and the identifica-

tion below the top cover.

(Position of ID

depends on size)

For better clarity, the documentation is structured according to the customer-specific

requirements made on the frequency inverter.

Quick Start Guide

The Quick Start Guide describe the basic steps required for mechanical and electrical

installation of the frequency inverter. The guided commissioning supports you in the

selection of necessary parameters and the configuration of the frequency inverter by

the software.

Operating Instructions

The Operating Instructions describe and document all functions of the frequency

inverter. The parameters required for adapting the frequency inverter to specific ap-

plications as well as the wide range of additional functions are described in detail.

Application Manual

The application manual supplements the documentation for purposeful installation

and commissioning of the frequency inverter. Information on various subjects con-

nected with the use of the frequency inverter are described specific to the applica-

tion.

Installation Instructions

Complementing the Brief Instructions and the Operating Instructions, the Installation

Instructions provide information on how to install and use the additional/optional

components.

If you need a copy of the documentation or additional information, contact your na-

tional representative of BONFIGLIOLI.

Operating Instructions ACU 109/08

2 Operating Instructions ACU

09/08

The following pictograms and signal words are used in the documentation:

Danger!

Danger refers to an immediate threat. Non-compliance with the precaution described

may result in death, serious injury or material damage.

Warning!

Warning refers to a possible threat. Non-compliance with the warning may result in

death, serious injury or material damage.

Caution!

Caution refers to an indirect threat. Non-compliance may result in personal or ma-

terial damage.

Attention!

Attention refers to a possible operational behavior or an undesired condition that can

occur in accordance with the reference text.

Note

Note marks information that facilitates handling for you and supplements the corres-

ponding part of the documentation.

Operating Instructions ACU 09/082

09/08 Operating Instructions ACU 3

TABLE OF CONTENTS

1General Safety Instructions and Information on Use.................................................. 10

1.1General Information ................................................................................. 10

1.2Purpose of the Frequency Inverters ......................................................... 11

1.3Transport and Storage .............................................................................. 11

1.4Handling and Installation ......................................................................... 11

1.5Electrical Connection ................................................................................ 12

1.6Information on Use................................................................................... 12

1.7Maintenance and Service .......................................................................... 12

1.8Safety Instructions on Function „Safe Torque Off“ (STO)........................ 13

2Scope of Supply............................................................................................................ 15

2.1ACU 201 (up to 3.0 kW) and 401 (up to 4.0 kW)...................................... 15

2.2ACU 201 (4.0 to 9.2 kW) and 401 (5.5 to 15.0 kW).................................. 16

2.3ACU 401 (18.5 to 30.0 kW) ....................................................................... 17

2.4ACU 401 (37.0 to 65.0 kW) ....................................................................... 18

2.5ACU 401 (75.0 to 132.0 kW) ..................................................................... 19

3Technical Data.............................................................................................................. 20

3.1General technical data .............................................................................. 20

3.2Technical Data – Control Electronic Equipment ....................................... 21

3.3ACU 201 (0.25 to 1.1 kW, 230 V).............................................................. 22

3.4ACU 201 (1.5 to 3.0 kW, 230 V)................................................................ 23

3.5ACU 201 (4.0 to 9.2 kW, 230 V)................................................................ 24

3.6ACU 401 (0.25 to 1.5 kW, 400 V).............................................................. 25

3.7ACU 401 (1.85 to 4.0 kW, 400 V).............................................................. 26

3.8ACU 401 (5.5 to 15.0 kW, 400 V).............................................................. 27

3.9ACU 401 (18.5 to 30.0 kW, 400 V)............................................................ 28

3.10ACU 401 (37.0 to 65.0 kW, 400 V)............................................................ 29

3.11ACU 401 (75.0 to 132.0 kW, 400 V).......................................................... 30

3.12Operation diagrams .................................................................................. 31

4Mechanical Installation................................................................................................ 32

4.1ACU 201 (up to 3.0 kW) and 401 (up to 4.0 KW) ..................................... 32

4.2ACU 201 (4.0 to 9.2 kW) and 401 (5.5 to 15.0 kW).................................. 33

4.3ACU 401 (18.5 to 30.0 kW) ....................................................................... 34

4.4ACU 401 (37.0 to 65.0 kW) ....................................................................... 35

4.5ACU 401 (75.0 to 132.0 kW) ..................................................................... 36

5Electrical Installation ................................................................................................... 37

5.1EMC Information....................................................................................... 38

5.2Block diagram ........................................................................................... 39

5.3Optional Components ............................................................................... 40

5.4Connection of Unit .................................................................................... 41

Operating Instructions ACU 309/08

4 Operating Instructions ACU

09/08

5.4.1Dimensioning of conductor cross-section ........................................................... 41

5.4.1.1Typical cross-sections ...................................................................................... 41

5.4.2Mains Connection............................................................................................ 42

5.4.3Motor Connection............................................................................................ 43

5.4.3.1Length of motor cables, without filter................................................................ 43

5.4.3.2Motor cable length, with output filter dU/dt ....................................................... 43

5.4.3.3Motor cable length, with sinus filter .................................................................. 43

5.4.3.4Group drive .................................................................................................... 44

5.4.3.5Speed sensor connection ................................................................................. 44

5.4.4Connection of a Brake Resistor......................................................................... 44

5.5Connection of types .................................................................................. 45

5.5.1ACU 201 (up to 3.0 kW) and 401 (up to 4.0 kW)................................................ 45

5.5.2ACU 201 (4.0 to 9.2 kW) and 401 (5.5 to 15.0 kW) ............................................ 47

5.5.3ACU 401 (18.5 to 30.0 kW) .............................................................................. 49

5.5.4ACU 401 (37.0 to 65.0 kW) .............................................................................. 51

5.5.5ACU 401 (75.0 to 132.0 kW) ............................................................................ 53

5.6Control Terminals...................................................................................... 55

5.6.1External DC 24 V power supply......................................................................... 57

5.6.2Relay Output .................................................................................................. 57

5.6.3Motor Thermo-Contact..................................................................................... 57

5.6.4Control terminals – Connection diagrams of configurations ................................. 58

5.7Configurations overview........................................................................... 58

5.7.1Configuration 110 – Sensorless Control ............................................................. 59

5.7.2Configuration 111 – Sensorless Control with Technology Controller...................... 59

5.7.3Configuration 410 – Sensorless Field-Oriented Control........................................ 60

5.7.4Configuration 411 – Sensorless Field-Oriented Control with Technology ..................

Controller ....................................................................................................... 61

5.7.5Configuration 430 – Sensorless Field-Oriented Control, Speed and Torque ..............

Controlled....................................................................................................... 62

5.7.6Configuration 210 – Field-Oriented Control, Speed Controlled ............................. 63

5.7.7Configuration 211 – Field-Oriented Control with Technology Controller ............... 63

5.7.8Configuration 230 – Field-Orientated Control, Speed and Torque Controlled ......... 64

5.7.9Configuration 510 – Field-Oriented Control of Synchronous Machine, ......................

Speed Controlled............................................................................................. 65

5.7.10Configuration 530 – Field-Orientated Control of a Synchronous Machine, ................

Speed and Torque Controlled ........................................................................... 66

6Control Unit KP500 ...................................................................................................... 67

6.1Menu Structure ......................................................................................... 68

6.2Main Menu................................................................................................. 68

6.3Actual Value Menu (VAL) .......................................................................... 69

6.4Parameter Menu (PARA)........................................................................... 70

6.5Copy Menu (CPY) ...................................................................................... 71

6.5.1Reading the Stored Information........................................................................ 71

6.5.2Menu Structure ............................................................................................... 72

6.5.3Selecting the Source........................................................................................ 72

6.5.4Selecting the Destination ................................................................................. 73

6.5.5Copy Operation............................................................................................... 73

6.5.6Error Messages ............................................................................................... 74

6.6Reading Data From Control Unit............................................................... 75

6.6.1Activation ....................................................................................................... 75

6.6.2Data transfer .................................................................................................. 76

6.6.3Resetting to Normal Operation ......................................................................... 77

6.7Control Menu (CTRL) ................................................................................ 77

6.8Controlling the Motor via the Control Unit ............................................... 78

Operating Instructions ACU 09/084

09/08 Operating Instructions ACU 5

7Commissioning of the Frequency Inverter................................................................... 81

7.1Switching on Mains Voltage...................................................................... 81

7.2Setup Using the Control Unit .................................................................... 81

7.2.1Configuration.................................................................................................. 82

7.2.2Data Set......................................................................................................... 83

7.2.3Motor Type..................................................................................................... 84

7.2.4Machine Data.................................................................................................. 84

7.2.5Plausibility check ............................................................................................. 85

7.2.6Parameter identification ................................................................................... 87

7.2.7Application data .............................................................................................. 89

7.2.7.1Acceleration and deceleration deceleration deceleration...................................... 89

7.2.7.2Set points at multi-functional input ................................................................... 90

7.2.8Quitting commissioning.................................................................................... 90

7.2.9Selection of an actual value for display.............................................................. 91

7.3Check direction of rotation ....................................................................... 91

7.4Speed sensor............................................................................................. 92

7.4.1Speed sensor 1 ............................................................................................... 92

7.4.2Speed sensor 2 ............................................................................................... 93

7.5Set-up via the Communication Interface ................................................. 94

8Inverter Data ............................................................................................................... 97

8.1Serial Number ........................................................................................... 97

8.2Optional Modules ...................................................................................... 97

8.3Inverter Software Version ........................................................................ 97

8.4Set Password ............................................................................................ 97

8.5Control Level ............................................................................................. 98

8.6User Name................................................................................................. 98

8.7Configuration ............................................................................................ 98

8.8Language ................................................................................................ 101

8.9Programming .......................................................................................... 101

9Machine Data ............................................................................................................. 102

9.1Rated Motor Parameters......................................................................... 102

9.2Further motor parameters ...................................................................... 103

9.2.1Stator Resistance .......................................................................................... 103

9.2.2Leakage Coefficient ....................................................................................... 103

9.2.3Magnetizing Current ...................................................................................... 104

9.2.4Rated slip correction factor ............................................................................ 104

9.2.5Voltage constant ........................................................................................... 105

9.2.6Stator inductance .......................................................................................... 105

9.2.7Peak current ................................................................................................. 105

9.2.8Change sense of rotation ............................................................................... 106

9.3Internal values........................................................................................ 106

9.4Speed Sensor 1 ....................................................................................... 107

9.4.1Operation Mode Speed Sensor 1..................................................................... 107

9.4.2Division marks, speed sensor 1....................................................................... 109

9.4.3Gear factor speed sensor 1 ............................................................................ 110

9.5Sensor evaluation ................................................................................... 111

Operating Instructions ACU 509/08

6 Operating Instructions ACU

09/08

10System Data ............................................................................................................... 112

10.1Actual System Value ............................................................................... 112

10.2Volume Flow and Pressure...................................................................... 112

11Operational Behavior ................................................................................................. 113

11.1Starting Behavior .................................................................................... 113

11.1.1Starting Behavior of Sensorless Control System................................................ 113

11.1.1.1Starting Current ............................................................................................ 115

11.1.1.2Frequency Limit ............................................................................................ 115

11.1.1.3Brake release time ........................................................................................ 115

11.1.2Flux Formation.............................................................................................. 116

11.2Stopping Behavior................................................................................... 117

11.2.1Switch-Off Threshold ..................................................................................... 119

11.2.2Holding Time ................................................................................................ 119

11.3Direct current brake................................................................................ 119

11.4Auto Start................................................................................................ 120

11.5Search Run.............................................................................................. 121

11.6Positioning .............................................................................................. 122

11.6.1Reference Positioning .................................................................................... 123

11.6.2Axle Positioning............................................................................................. 126

12Error and warning behavior ....................................................................................... 129

12.1Overload Ixt ............................................................................................ 129

12.2Temperature ........................................................................................... 129

12.3Controller status ..................................................................................... 130

12.4IDC Compensation Limit ......................................................................... 130

12.5Frequency Switch-Off Limit .................................................................... 131

12.6Motor Temperature................................................................................. 131

12.7Phase Failure........................................................................................... 132

12.8Automatic Error Acknowledgment.......................................................... 133

13Reference Values........................................................................................................ 134

13.1Frequency Limits..................................................................................... 134

13.2Slip Frequency......................................................................................... 134

13.3Percentage Value Limits ......................................................................... 134

13.4Frequency reference channel.................................................................. 135

13.4.1Block diagram............................................................................................... 136

13.5Reference percentage channel ............................................................... 138

13.5.1Block diagram............................................................................................... 138

13.6Fixed reference values............................................................................ 140

13.6.1Fixed Frequencies ......................................................................................... 140

13.6.2JOG frequency .............................................................................................. 141

13.6.3Fixed Percentages ......................................................................................... 141

13.7Frequency ramps .................................................................................... 142

13.8Percentage Value Ramps ........................................................................ 145

13.9Block Frequencies ................................................................................... 145

Operating Instructions ACU 09/086

09/08 Operating Instructions ACU 7

13.10Motor Potentiometer .............................................................................. 146

13.10.1Motorpoti (MP).............................................................................................. 147

13.10.2Motorpoti (KP) .............................................................................................. 147

13.10.3Controlling the Motor via the Control Unit........................................................ 148

13.11PWM-/repetition frequency input .......................................................... 149

14Control Inputs and Outputs ....................................................................................... 151

14.1Multi-Function Input MFI1 ..................................................................... 151

14.1.1Analog input MFI1A....................................................................................... 151

14.1.1.1Characteristic................................................................................................ 151

14.1.1.2Scaling ......................................................................................................... 153

14.1.1.3Tolerance Band and Hysteresis....................................................................... 153

14.1.1.4Filter Time Constant ...................................................................................... 154

14.1.1.5Error and warning behavior............................................................................ 155

14.2Multi-Function Output MFO1 .................................................................. 156

14.2.1Analog output MFO1A.................................................................................... 156

14.2.1.1Output Characteristic..................................................................................... 157

14.2.2Frequency Output MFO1F .............................................................................. 157

14.2.2.1Scaling ......................................................................................................... 157

14.3Digital Outputs........................................................................................ 158

14.3.1Digital Signal ................................................................................................ 161

14.3.2Setting Frequency ......................................................................................... 162

14.3.3Reference value reached................................................................................ 163

14.3.4Flux Forming finished .................................................................................... 164

14.3.5Brake release................................................................................................ 164

14.3.6Current Limitation ......................................................................................... 164

14.3.7External Fan ................................................................................................. 164

14.3.8Warning Mask............................................................................................... 165

14.3.9Application warning mask .............................................................................. 167

14.4Digital inputs........................................................................................... 168

14.4.1Start command ............................................................................................. 173

14.4.23-wire control ............................................................................................... 173

14.4.3Error Acknowledgment .................................................................................. 174

14.4.4Timer........................................................................................................... 174

14.4.5Thermo contact............................................................................................. 174

14.4.6n-/M Control Change-Over ............................................................................. 174

14.4.7Data Set Change-Over................................................................................... 175

14.4.8Fixed Value Change-Over............................................................................... 176

14.4.9Motor Potentiometer...................................................................................... 176

14.4.10Handshake Traverse Function ........................................................................ 177

14.4.11External error ............................................................................................... 177

14.5Function Modules.................................................................................... 178

14.5.1Timer........................................................................................................... 178

14.5.1.1Timer – Time Constant .................................................................................. 179

14.5.2Comparator .................................................................................................. 181

14.5.3Function table............................................................................................... 182

14.5.4Multiplexer/Demultiplexer .............................................................................. 183

15V/f-Characteristic ...................................................................................................... 185

15.1Dynamic Voltage Pre-Control ................................................................. 186

16Control Functions ....................................................................................................... 187

16.1Intelligent current limits ........................................................................ 187

16.2Voltage controller ................................................................................... 188

16.3Technology Controller............................................................................. 193

Operating Instructions ACU 709/08

8 Operating Instructions ACU

09/08

16.4Functions of Sensorless Control.............................................................. 202

16.4.1Slip compensation ......................................................................................... 202

16.4.2Current limit value controller .......................................................................... 202

16.5Functions of Field-Orientated Control .................................................... 203

16.5.1Current Controller ......................................................................................... 203

16.5.2Torque Controller .......................................................................................... 205

16.5.2.1Limit Value Sources ....................................................................................... 205

16.5.3Speed controller............................................................................................ 206

16.5.3.1Limitation of Speed Controller ........................................................................ 208

16.5.3.2Limit Value Sources ....................................................................................... 209

16.5.3.3Integral time speed synchronization................................................................ 209

16.5.4Acceleration Pre-Control ................................................................................ 209

16.5.5Field Controller ............................................................................................. 210

16.5.5.1Limitation of field controller............................................................................ 211

16.5.6Modulation Controller .................................................................................... 212

16.5.6.1Limitation of Modulation Controller ................................................................. 213

17Special Functions ....................................................................................................... 214

17.1Pulse Width Modulation.......................................................................... 214

17.2Fan .......................................................................................................... 215

17.3Bus controller.......................................................................................... 215

17.4Brake Chopper and Brake Resistance..................................................... 217

17.4.1Dimensioning of Brake Resistor ...................................................................... 218

17.5Motor Protection Switch ......................................................................... 219

17.6V-belt Monitoring.................................................................................... 221

17.7Functions of Field-Orientated Control .................................................... 221

17.7.1Motor Chopper.............................................................................................. 221

17.7.2Temperature Adjustment ............................................................................... 222

17.7.3Speed Sensor Monitoring ............................................................................... 224

17.8Traverse function.................................................................................... 225

18Actual Values.............................................................................................................. 227

18.1Actual Values of the Frequency Inverter ................................................ 227

18.1.1STO Status ................................................................................................... 229

18.2Actual Values of the Machine.................................................................. 230

18.3Actual value memory .............................................................................. 231

18.4Actual Values of the System ................................................................... 232

18.4.1Actual System Value...................................................................................... 232

18.4.2Volume Flow and Pressure ............................................................................. 233

19Error Protocol ............................................................................................................. 234

19.1Error List ................................................................................................. 234

19.1.1Error Messages ............................................................................................. 234

19.2Error Environment .................................................................................. 237

20Operational and Error Diagnosis................................................................................ 239

20.1Status Display ......................................................................................... 239

20.2Status of Digital Signals.......................................................................... 239

20.3Controller Status..................................................................................... 240

20.4Warning Status and Warning Status Application ................................... 241

Operating Instructions ACU 09/088

09/08 Operating Instructions ACU 9

21Parameter List............................................................................................................ 243

21.1Actual Value Menu (VAL) ........................................................................ 243

21.2Parameter Menu (PARA)......................................................................... 246

Index ................................................................................................................................ 254

Functions of the control terminals (table) ....................................................................... 256

Operating Instructions ACU 909/08

10 Operating Instructions ACU

09/08

1General Safety Instructions and Information on Use

Warning! The specifications and instructions contained in the documentation

must be complied with strictly during installation and commissioning.

Only qualified staff who has read the documentation and, in particular,

the safety instructions carefully is allowed to carry out installation or

commissioning work or to operate the frequency inverters. The term

„Qualified Staff“ refers to anybody who is familiar with the installation,

assembly, commissioning and operation of the frequency inverter and

has the proper qualification for the job.

The present documentation was prepared with great care and it was subjected to

extensive and repeated reviews. For reasons of clarity, it was not possible to include

all details of all types of the product in the documentation. Neither was it possible to

consider all conceivable installation, operation or maintenance situations. If you re-

quire further information or if you meet with specific problems which are not dealt

with in sufficient detail in the documentation, contact your national BONFIGLIOLI

agent.

We would also like to point out that the contents of this documentation do not form

part of any previous or existing agreement, assurance or legal relationship. Neither

are they intended to supplement or replace such agreements, assurances or legal

relationships. The manufacturer's obligations are exclusively specified in the relevant

purchase contract. This contract also contains all and any warranty regulations which

may apply to the relevant scope of supply. These contractual warranty provisions are

neither extended nor limited by the specifications contained in this documentation.

The manufacturer reserves the right to correct or amend the specifications, product

information and omissions in these operating instructions without notice. The manu-

facturer shall not be liable for any damage, injuries or costs which may be caused by

the aforementioned reasons.

1.1 General Information

Warning! The DC-link circuit of the frequency inverter is charged during opera-

tion, i.e. there is always the risk of contact with high voltage. Frequency

inverters are used for driving moving parts and they may become hot at

the surface during operation.

Any unauthorized removal of the necessary covers, improper use,

wrong installation or operation may result in serious injuries or material

damage.

In order to avoid such injuries or damage, only qualified staff may carry

out the transport, installation, setup or maintenance work required. The

standards EN 50178, IEC 60364 (Cenelec HD 384 or DIN VDE 0100),

IEC 60664-1 (Cenelec HD 625 or VDE 0110-1), BGV A2 (VBG 4) as well

as the applicable national regulations must be complied with. The term

„Qualified Staff“ refers to anybody who is familiar with the installation,

assembly, commissioning and operation of the frequency inverter as

well as the possible hazards and has the proper qualification for the job.

Operating Instructions ACU 09/0810

09/08 Operating Instructions ACU 11

1.2 Purpose of the Frequency Inverters

Warning! The frequency inverters are electrical drive components intended for

installation in industrial plants or machines. Commissioning and start of

operation is not allowed until it has been verified that the plant meets

the requirements of the EC Machinery Directive 98/37/EEC and EN

60204. In accordance with the CE marking requirements, the frequency

inverters also comply with the Low Voltage Directive 2006/95/EC as

well as EN 50178/DIN VDE 0160 and EN 61800-2. The user shall be

responsible for making sure that the requirements of the EMC Directive

89/336/EEC are met. Frequency inverters are only available at specia-

lized dealers and are exclusively intended for professional use as per EN

61000-3-2.

The frequency inverters are also marked with the UL label according to

UL508c, which proves that they also meet the requirements of the CSA

Standard C22.2-No. 14-95.

The technical data, connection specifications and information on am-

bient conditions are indicated on the name plate and in the documenta-

tion and must be complied with in any case. Anyone involved in any

kind of work at the device must have read the instructions carefully and

understood them before starting the work.

Do not connect any capacitive loads.

1.3 Transport and Storage

The frequency inverters must be transported and stored in an appropriate way. Dur-

ing transport and storage the devices must remain in their original packaging. The

units may only be stored in dry rooms which are protected against dust and moisture

and are exposed to little temperature deviations only. Observe the climatic conditions

according to EN 50178 and the marking on the packaging. The frequency inverters

must not be stored for more than one year without connecting them to nominal vol-

tage.

1.4 Handling and Installation

Warning! Damaged or destroyed components must not be put into operation

because they may be a health hazard.

The frequency inverters are to be used in accordance with the documentation as well

as the applicable directives and standards. They must be handled carefully and pro-

tected against mechanical stress. Do not bend any components or change the isolat-

ing distances. Do not touch electronic components or contacts. The devices are

equipped with components which are sensitive to electrostatic energy and can easily

be damaged if handled improperly. Any use of damaged or destroyed components

shall be considered as a non-compliance with the applicable standards. Do not re-

move any warning signs from the device.

Operating Instructions ACU 1109/08

12 Operating Instructions ACU

09/08

1.5 Electrical Connection

Warning! Before any assembly or connection work, discharge the frequency in-

verter. Verify that the frequency inverter is discharged.

Do not touch the terminals because the capacitors may still be charged.

Comply with the information given in the operating instructions and on

the frequency inverter label.

When working at the frequency inverters, comply with the applicable standards BGV

A2 (VBG 4), VDE 0100 and other national directives. Comply with the electrical instal-

lation instructions given in the documentation as well as the relevant directives. The

manufacturer of the industrial machine or plant is responsible for making sure that

the limit values specified in the EMC product standard EN 61800-3 for electrical vari-

able-speed drives are complied with. The documentation contains information on

EMC-conforming installation. The cables connected to the frequency inverters may

not be subjected to high-voltage insulation tests unless appropriate circuitry meas-

ures are taken before.

1.6 Information on Use

Warning! The frequency inverter may be connected to power supply every 60 s.

This must be considered when operating a mains contactor in jog oper-

ation mode. For commissioning or after an emergency stop, a non-

recurrent, direct restart is permissible.

After a failure and restoration of the power supply, the motor may start

unexpectedly if the AutoStart function is activated.

If staff is endangered, a restart of the motor must be prevented by

means of external circuitry.

Before commissioning and the start of the operation, make sure to fix

all covers and check the terminals. Check the additional monitoring and

protective devices according to EN 60204 and applicable the safety

directives (e.g. Working Machines Act, Accident Prevention Directives

etc.).

No connection work may be performed, while the system is in opera-

tion.

1.7 Maintenance and Service

Warning! Unauthorized opening and improper interventions can lead to personal

injury or material damage. Repairs on the frequency inverters may only

be carried out by the manufacturer or persons authorized by the manu-

facturer. Check protective equipment regularly.

Operating Instructions ACU 09/0812

09/08 Operating Instructions ACU 13

1.8 Safety Instructions on Function „Safe Torque Off“ (STO)

The function „Safe Torque Off“ (STO) is a functional safety provision, i.e. it protects

staff from damage, provided that projecting, installation and operation are performed

properly. This function does not disconnect the plant from power supply.

To disconnect the plant from power supply (for example for service purposes) an

„Emergency Stop“ circuit according to EN 60204 has to be installed.

For maintenance work, a provision must be provided for disconnecting the plant from

power supply.

Warning! Improper installation of the safety circuitry may result in uncontrolled

starting of the drive. This may cause death, serious injuries and signifi-

cant material damage.

Safety functions may only be installed and commissioned by qualified

staff.

The STO function is not suitable for emergency stop as per EN 60204.

An emergency stop can be realized by installing a mains contactor.

An emergency stop according to EN 60204 must be functioning in all

operation modes of the frequency inverter. Resetting of an emergency

stop must not result in uncontrolled starting of the drive.

The drive is started again when the function STO is no longer required.

In order to comply with EN 60204, it must be ensured by taking exter-

nal measures that the drive does not start without prior confirmation.

Without a mechanical brake, the drive will not stop immediately but

coast to a standstill. If this may result in personal or material damage,

additional safety measures must be taken.

If persons may be endangered after disconnection of the motor power

supply by STO, access to the hazard areas must be prevented until the

drive has stopped.

Check the safety function at regular intervals according to the results of

your risk analysis.

BONFIGLIOLI VECTRON recommends that the check is performed after

one year, at the latest.

The STO function is fail-safe. However, on rare occasions, the occur-

rence of component defects may cause jerking of the motor shaft (max.

180°/pole pair, e.g. jerk by 90° with 4-pole motor, 180°/2). It must be

checked if this causes a dangerous movement of the plant.

If the STO function is used, the special safety, installation and instruc-

tions on use instructions shall be complied with.

Operating Instructions ACU 1309/08

14 Operating Instructions ACU

09/08

Warning! Dangerous voltage!

The safety function “Safe Torque Off ” may only be used if mechanical

work is to be performed on the driven machines, not for work on live

components.

After disconnection of an external DC 24 V power supply, the DC link of

the frequency inverter is still connected to mains supply.

Even if power supply to the motor is disconnected, and the motor is

coasting to a standstill or has already stopped, high voltages may still

be present on the motor terminals.

Before working (e.g. maintenance) on live parts, the plant must always

be disconnected from mains supply (main switch). This must be docu-

mented on the plant.

When the function “Safe Torque Off ” is triggered, the motor is not

isolated from the DC link of the frequency inverter. High voltage levels

may be present at the motor.

Do not touch live terminals.

Operating Instructions ACU 09/0814

09/08 Operating Instructions ACU 15

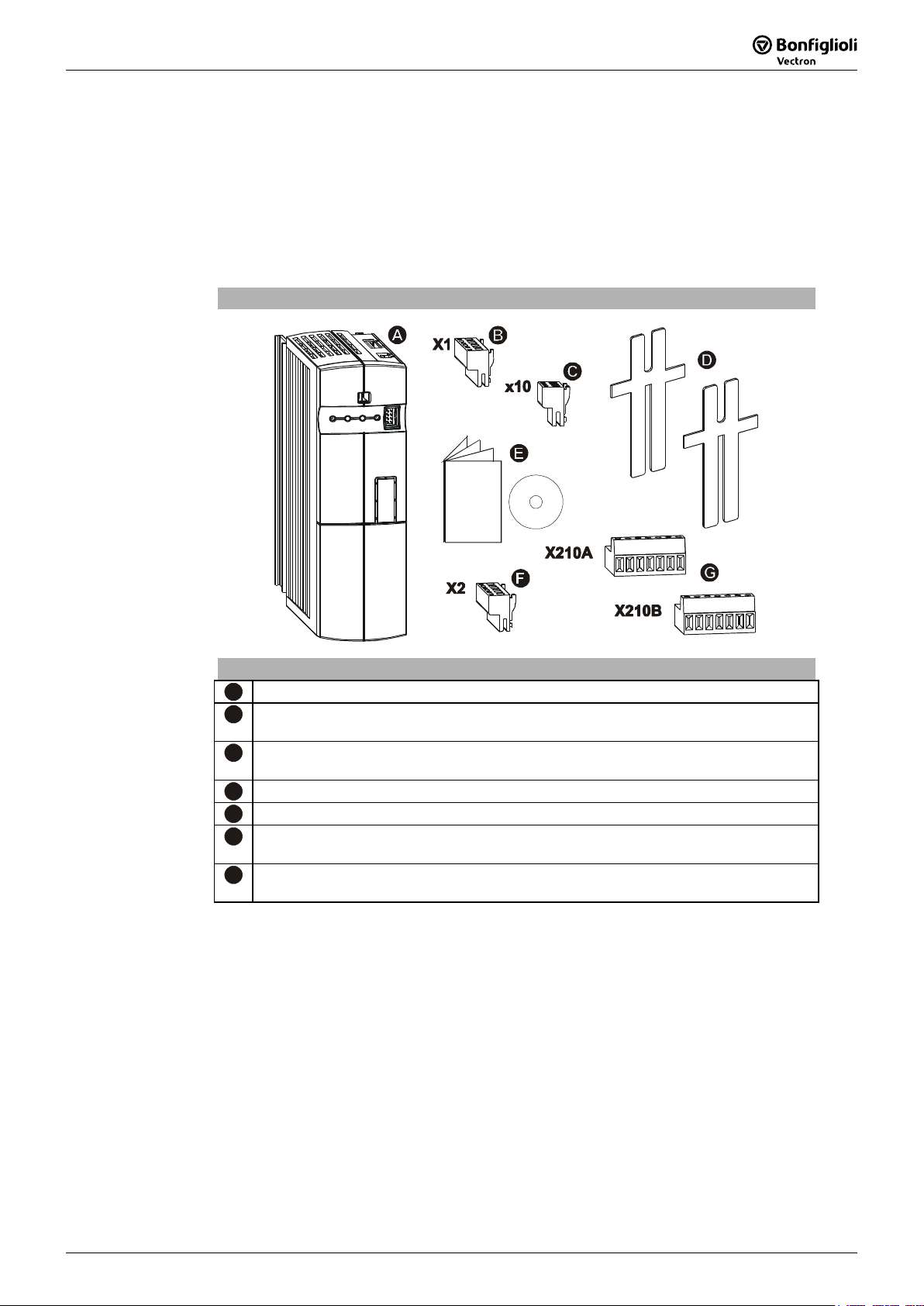

2Scope of Supply

Thanks to the modular hardware components, the frequency inverters can be inte-

grated in the automation concept easily. The scope of delivery described can be sup-

plemented by optional components and adapted to the customer-specific require-

ments. The plug-in type connection terminals enable a safe function and quick and

easy assembly.

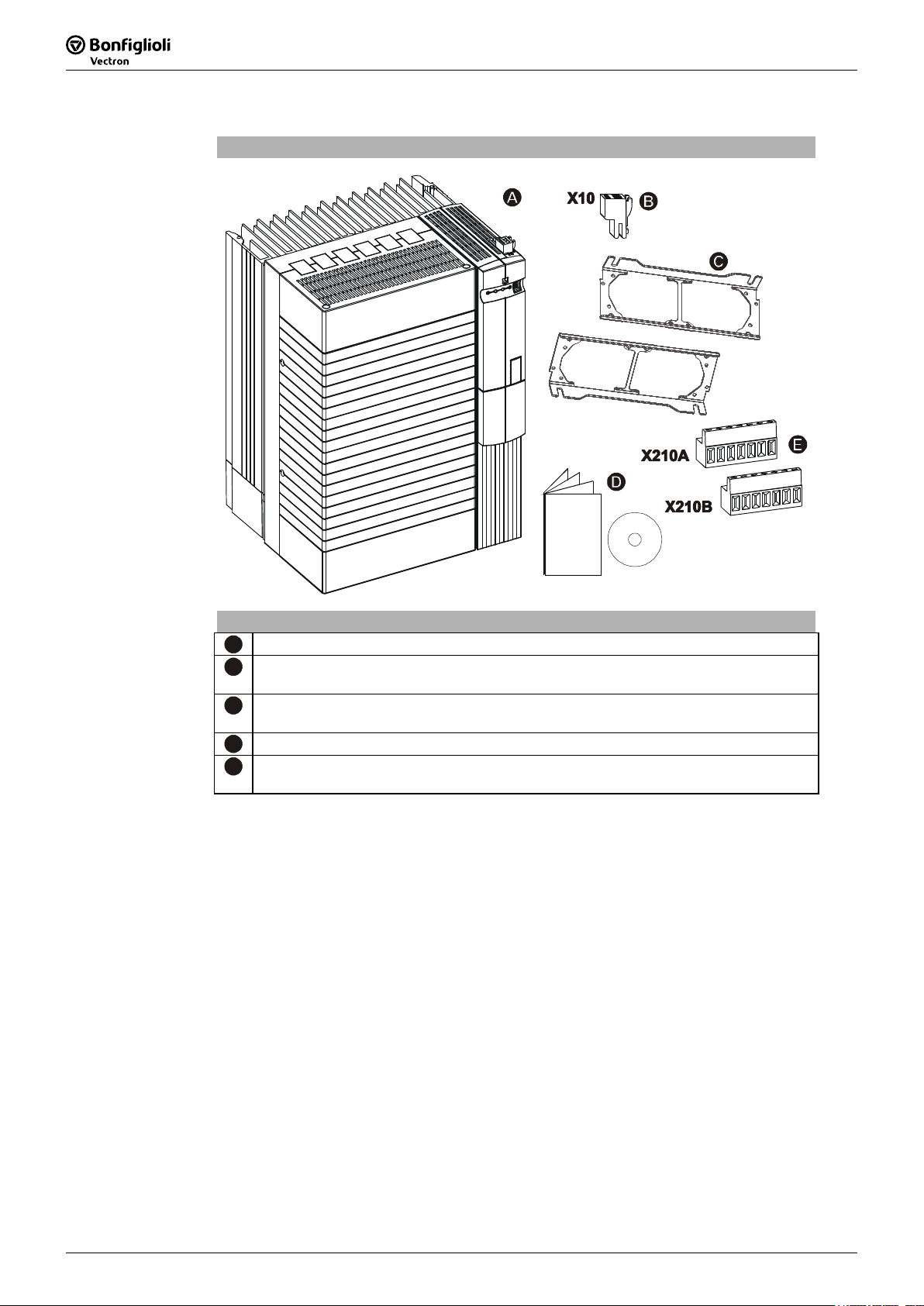

2.1 ACU 201 (up to 3.0 kW) and 401 (up to 4.0 kW)

Scope of Supply

Scope of Supply

A

Frequency inverter

B

Terminal strip X1 (Phoenix ZEC 1,5/ST7,5)

Plug-in terminals for mains connection and DC linking

C

Terminal strip X10 (Phoenix ZEC 1.5/3ST5.0)

Plug-in terminals for the relay output

D

Standard fixtures for vertical assembly

E

Brief Instructions and Operating Instructions on CD ROM

F

Terminal strip X2 (Phoenix ZEC 1,5/ST7,5)

Plug-in terminal for brake resistor and motor connection

G

Control terminals X210A / X210B (Wieland DST85 / RM3.5)

Plug-in terminal for connection of the control signals

Note: Please check incoming goods for quality, quantity and nature without

delay. Obvious defects such as exterior damage of the packing and/or the

unit must be notified to the sender within seven days for insurance rea-

sons.

Operating Instructions ACU 1509/08

16 Operating Instructions ACU

09/08

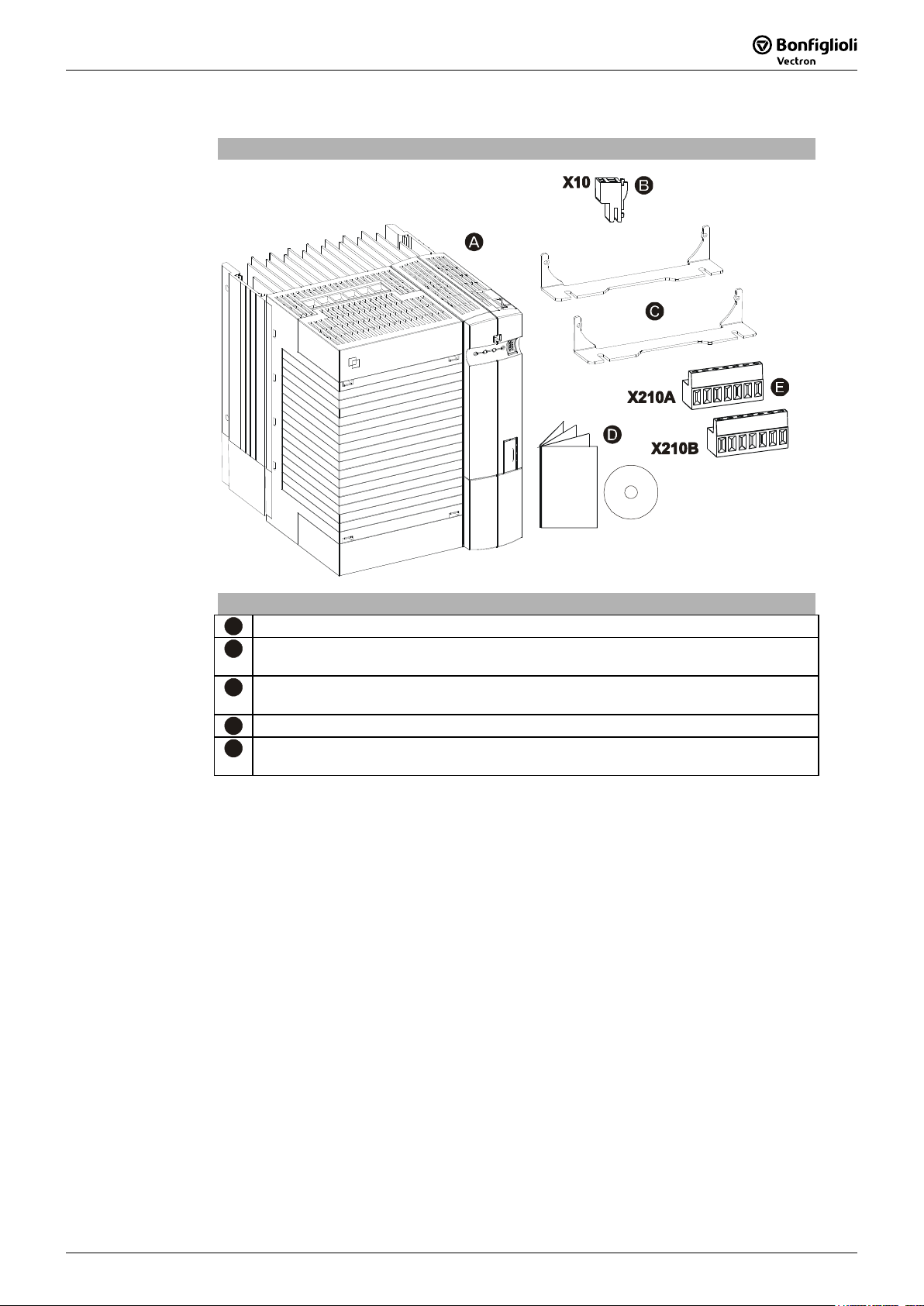

2.2 ACU 201 (4.0 to 9.2 kW) and 401 (5.5 to 15.0 kW)

Scope of Supply

Scope of Supply

A

Frequency inverter

B

Terminal strip X10 (Phoenix ZEC 1.5/3ST5.0)

Plug-in terminals for the relay output

C

Standard fittings with fitting screws (M4x20, M4x60)

for vertical assembly

D

Brief Instructions and Operating Instructions on CD ROM

E

Control terminals X210A / X210B (Wieland DST85 / RM3.5)

Plug-in terminal for connection of the control signals

Note: Please check incoming goods for quality, quantity and nature without

delay. Obvious defects such as exterior damage of the packing and/or the

unit must be notified to the sender within seven days for insurance rea-

sons.

Operating Instructions ACU 09/0816

09/08 Operating Instructions ACU 17

2.3 ACU 401 (18.5 to 30.0 kW)

Scope of Supply

Scope of Supply

A

Frequency inverter

B

Terminal strip X10 (Phoenix ZEC 1.5/3ST5.0)

Plug-in terminals for the relay output

C

Standard fittings with fitting screws (M4x20, M4x70)

for vertical assembly

D

Brief Instructions and Operating Instructions on CD ROM

E

Control terminals X210A / X210B (Wieland DST85 / RM3.5)

Plug-in terminal for connection of the control signals

Note: Please check incoming goods for quality, quantity and nature without

delay. Obvious defects such as exterior damage of the packing and/or the

unit must be notified to the sender within seven days for insurance rea-

sons.

Operating Instructions ACU 1709/08

18 Operating Instructions ACU

09/08

2.4 ACU 401 (37.0 to 65.0 kW)

Scope of Supply

Scope of Supply

A

Frequency inverter

B

Terminal strip X10 (Phoenix ZEC 1.5/3ST5.0)

Plug-in terminals for the relay output

C

Standard fittings with fitting screws (M5x20)

for vertical assembly

D

Brief Instructions and Operating Instructions on CD ROM

E

Control terminals X210A / X210B (Wieland DST85 / RM3.5)

Plug-in terminal for connection of the control signals

Note: Please check incoming goods for quality, quantity and nature without

delay. Obvious defects such as exterior damage of the packing and/or the

unit must be notified to the sender within seven days for insurance rea-

sons.

Operating Instructions ACU 09/0818

This manual suits for next models

1

Table of contents

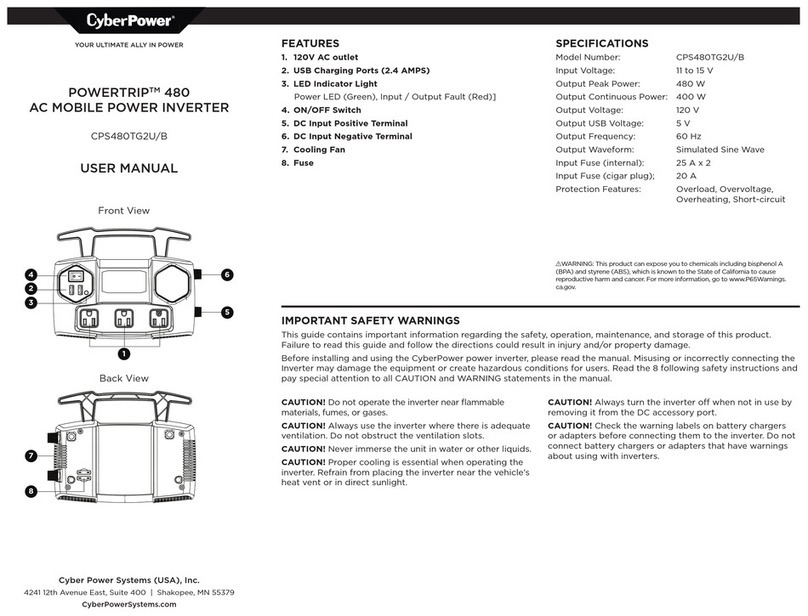

Popular Inverter manuals by other brands

CyberPower

CyberPower POWERTRIP 480 user manual

Pedal Power Generators

Pedal Power Generators Bike Stand Plate Attachment Procedure

Vector

Vector Maxx SST VEC043 Owner's manual & warranty

Omnik

Omnik Omniksol-2k-TL3-S user manual

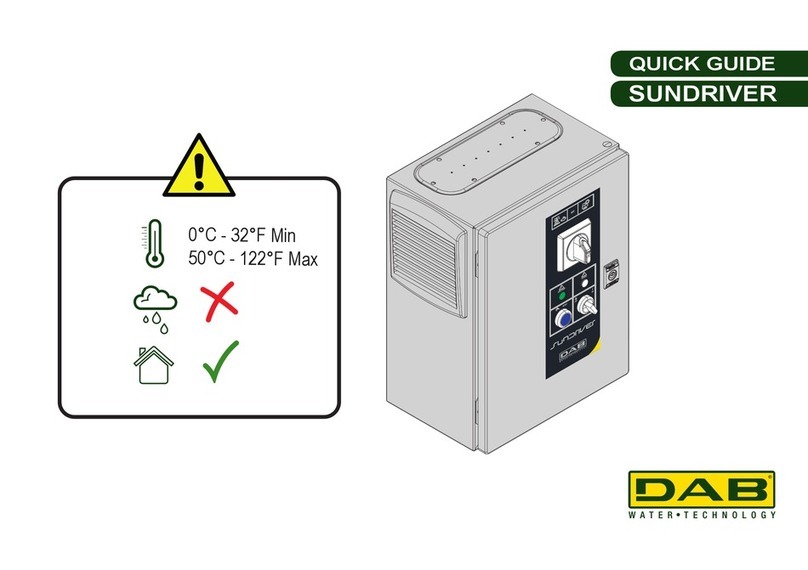

DAB PUMPS LTD.

DAB PUMPS LTD. SUNDRIVER quick guide

Solenso

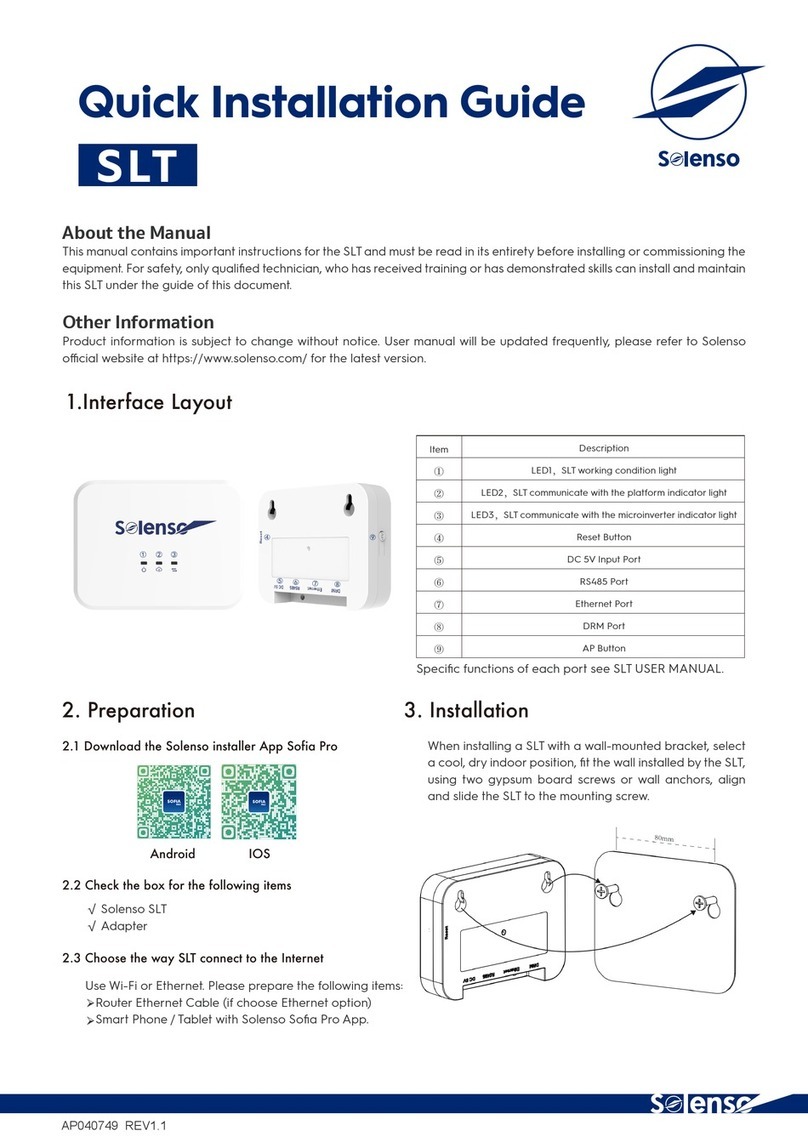

Solenso SLT Quick installation guide