SkyAzúl Greer MG514 Use and care manual

Greer – MG514

Retrofit

Installation, Calibration, and Service Manual

Greer – MG514 Retrofit Installation, Calibration, and Service Manual

SkyAzúl, Equipment Solutions www.skyazul.com 301-371-6126

NOTICE

SkyAzúl makes no warranty of any kind with regard to this material, including, but not limited to, the

implied warranties of merchantability and/or its fitness for a particular purpose.

SkyAzúl will not be liable for errors contained in this manual or for incidental or consequential

damages in connection with the furnishing, performance, or use of this manual. This document

contains proprietary information, which is protected by copyright, and all rights are reserved.

No part of this document may be photocopied, reproduced, or translated to another language without

the prior written consent of SkyAzúl.

SkyAzúl reserves proprietary rights to all drawings, photos and the data contained therein. The

drawings, photos and data are confidential and cannot be used or reproduced without the written

consent of SkyAzúl. The drawings and/or photos are subject to technical modification without prior

notice.

All information in this document is subject to change without notice.

SkyAzúl, Inc.

16 Walnut Street

Middletown, MD 21769

Fax 301-371-0029

info@skyazul.com

2

TABLE OF CONTENTS

1.0 Introduction ................................................................................................................................. 5

1.1 System Information.................................................................................................................. 5

1.2 Upgrade Parts ......................................................................................................................... 6

1.2.1 A450862 Computer Assembly .......................................................................................... 6

1.2.2 A450300 RCI 514 Display Module .................................................................................... 6

1.2.3 A240690 Reeling Drum .................................................................................................... 6

1.3 Computer Wiring...................................................................................................................... 7

1.4 Units with Swing Switches ....................................................................................................... 9

1.5 Removal and Installation ....................................................................................................... 10

2.0 Calibration................................................................................................................................. 12

2.1 Required Tools ...................................................................................................................... 12

2.2 Number Conversion............................................................................................................... 12

2.3 The MicroGuard 514 Display ................................................................................................. 13

2.3.1 Command Entry.............................................................................................................. 13

2.3.2 Number Entry ................................................................................................................. 13

2.4 Preliminary Checks and Measurements................................................................................. 15

2.4.1 Boom Pivot Dimensions.................................................................................................. 15

2.4.2 Winch Dimensions.......................................................................................................... 16

2.4.3 Boom Cylinder Dimensions............................................................................................. 17

2.4.4 Span Dimensions ........................................................................................................... 17

2.4.5 Auxiliary Head Dimensions............................................................................................. 18

2.4.6 Stowed Jib Dimensions .................................................................................................. 18

2.5 Installation Checks................................................................................................................. 19

2.5.1 Attaching the Anti-Two-Block (ATB) Cable and Extension Sensor Zero.......................... 19

2.6 Entering Calibration Data....................................................................................................... 20

2.6.1 Menu 00 –Error Codes .................................................................................................. 21

2.6.2 Menu 01 –Crane Data ................................................................................................... 22

2.6.3 Menu 02 - Dimensions.................................................................................................... 23

2.6.4 Menu 03 - Zero Sensors ................................................................................................. 24

2.6.5 Menu 04 - Span Sensor.................................................................................................. 25

2.6.5.1 Angle Span.............................................................................................................. 26

2.6.6 Menu 05 - Swing Potentiometer (If Equipped) ................................................................ 27

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

3

2.6.7 Menu 06 - Pressure ........................................................................................................ 28

2.6.8 Menu 07 - Radius/Moment.............................................................................................. 31

2.6.9 Menu 08 - Boom Deflection ............................................................................................ 37

2.6.10 Menu 09 - Head Angle.................................................................................................... 39

2.6.11 Menu 10 - Erected Attachments ..................................................................................... 40

2.6.12 Menu 11 - Enable Winches............................................................................................. 41

2.6.13 Menu 12 - Digital Inputs.................................................................................................. 42

2.6.14 Menu 13 - Pressure Monitor ........................................................................................... 43

2.6.15 APPENDIX A –Measurement Records .......................................................................... 44

3.0 Troubleshooting ........................................................................................................................ 48

3.1 Overview & Preparation......................................................................................................... 48

3.2 System Self-Test ................................................................................................................... 49

3.2.1 Display Console Problems.............................................................................................. 50

3.3 Fault Reporting and Fault Codes ........................................................................................... 51

3.3.1 Group “A” Fault Codes.................................................................................................... 52

3.3.2 Group “B” Fault Codes.................................................................................................... 53

3.3.3 Group “C” Fault Codes ................................................................................................... 54

3.3.4 Group “D” Fault Codes ................................................................................................... 55

3.3.5 “No Fault Code” Problems .............................................................................................. 56

3.3.5.1 Anti-Two-Block Alarm (ATB) .................................................................................... 56

3.3.5.2 Displayed Load or Radius Errors ............................................................................. 57

3.4 Computer Unit Overview........................................................................................................ 59

3.4.1 Computer Unit Layout..................................................................................................... 59

3.4.2 Internal Status Indicators ................................................................................................ 60

3.4.3 Pressure Sensors ........................................................................................................... 60

3.4.4 Replacing the Computer Unit Computer Removal .......................................................... 61

3.5 Display Console Overview ..................................................................................................... 62

3.5.1 Unresponsive Buttons..................................................................................................... 62

3.5.2 Connectors ..................................................................................................................... 62

3.5.3 Horn ............................................................................................................................... 62

3.5.4 Moisture.......................................................................................................................... 62

3.5.5 Replacing the Display Console ....................................................................................... 63

3.6 Remote Bar Graph Overview................................................................................................. 64

3.6.1 Checking the Remote Bar Graph.................................................................................... 64

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

4

3.6.2 LEDs .............................................................................................................................. 64

3.6.3 Brightness Control .......................................................................................................... 64

3.6.4 Cable and Connector...................................................................................................... 65

3.6.5 Moisture.......................................................................................................................... 65

3.6.6 Remote Bar Graph Replacement.................................................................................... 65

3.7 Reeling Drum Overview......................................................................................................... 66

3.7.1 Checking the Reeling Drum Cable Layering ................................................................... 67

3.7.2 Checking the Extension Sensor Drive Voltage................................................................ 68

3.7.3 Checking the Boom Extension Sensor Voltage............................................................... 68

3.7.4 Physical Zero.................................................................................................................. 69

3.7.5 Checking the Angle Sensor Pendulum ........................................................................... 70

3.7.6 Checking the Angle Sensor Drive Voltage ...................................................................... 71

3.7.7 Checking the Angle Sensor Voltage ............................................................................... 71

3.7.8 Reeling Drum Replaceable Parts.................................................................................... 71

3.7.8.1 Reeling Drum Cable ................................................................................................ 72

3.7.8.2 Slip-Ring Assembly ................................................................................................. 74

3.7.8.3 Sensor Baseplate Assembly.................................................................................... 75

3.7.8.4 Signal Cable Assembly............................................................................................ 77

3.8 Anti Two-Block Function Overview ........................................................................................ 79

3.8.1 Checking the Reeling Drum Cable.................................................................................. 80

3.8.2 Checking the Anti-Two-Block Circuit............................................................................... 80

3.9 Swing Sensor Overview......................................................................................................... 81

3.9.1 Checking the Swing Sensor Drive Voltage...................................................................... 82

3.9.2 Checking the Swing Sensor Output Voltage ................................................................... 82

3.9.3 Checking the Swing Sensor Resistance ......................................................................... 82

3.9.4 Swing Sensor Setup and Checks.................................................................................... 82

4.0 Revision History ........................................................................................................................ 85

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

5

1.0 Introduction

The MicroGuard MG514 replaces the previous Link Belt MG404, 414, and 434 systems currently in

use. This chapter will cover information necessary for installing the MicroGuard 514 system.

Please read the Operator’s Manual before operating the system. The system installer must be

knowledgeable in safety guidelines, crane capacity information, and the crane manufacturer’s

specifications.

For questions about Installation, please contact Technical Support:

Greer Company Service:

Jenks, OK

Telephone: (918) 298-8300

FAX: (918) 298-8301

1.1 System Information

When installing the new computer and display system, Greer Company recommends the existing

rectangular shaped reeling drum be replaced with our current production reeling drum, A240690. The

rectangular shaped reeling drum has been classed obsolete. There is no longer field support for this

product.

Upgrading the reeling drum will ensure you have both field support and parts support in the future. The

A240690 Reeling Drum is equipped with the necessary parts to be a direct replacement for the

obsolete part.

The new computer uses Flash RAM technology for loading the Duty Files. If known at the time of

purchase, the proper Duty File will be loaded on your computer before installation.

If you are unfamiliar with preparing the computer for use, kit K758746 is available from Greer Company.

The kit contains a programming cable and a CD with software, drivers, and the “Greer Mini Loader”

program.

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

6

1.2 Upgrade Parts

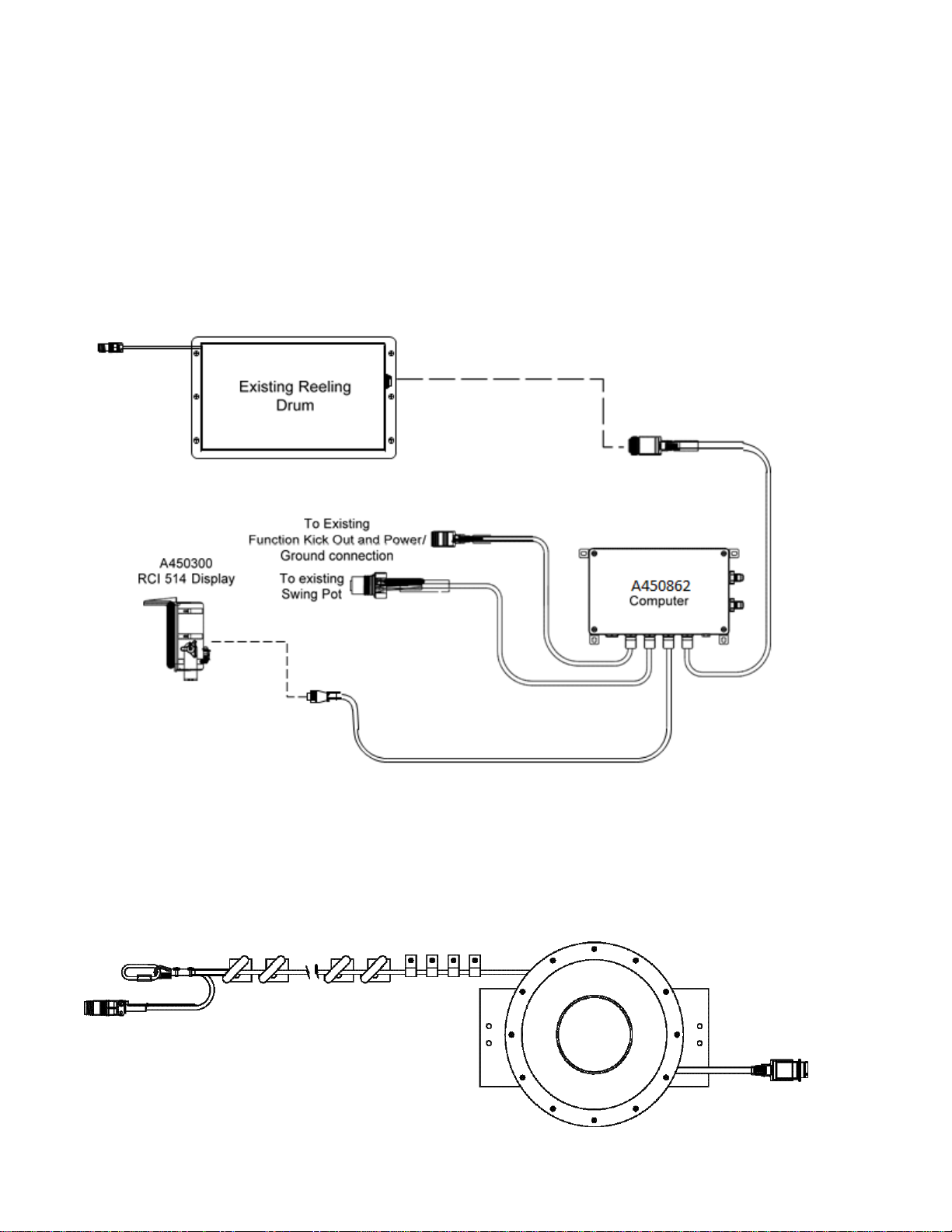

1.2.1 A450862 Computer Assembly

The computer assembly includes a wiring harness adapted to integrate with the existing Link Belt crane

wiring harness. Refer to the installation drawing below.

1.2.2 A450300 RCI 514 Display Module

This display module is designed specifically for upgrading Link Belt cranes and operates with Link Belt-

style menus.

1.2.3 A240690 Reeling Drum

If you replace the existing reeling drum with A240690, you must also replace the guides for the Anti-

Two-Block cabling. The guides support the level wind system of the reeling drum. The part number for

the guides is K056005. This kit contains a brochure, W056005, explaining how to install the guides and

obtain the best reeling drum performance.

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

7

1.3 Computer Wiring

The RCI 514 system wiring is based on the original wiring done by the factory. Greer Company cannot

assume responsibility for color codes used on wiring done at the time of origin.

We have identified the wiring inside and outside of our computer module to assist in the wiring

connections. It is the responsibility of the installer to identify the proper wire identifications and routings

on the crane for connecting to the MG514 computer. Please reference the wiring diagram below for

wiring designations

NOTICE: The white (WHT) wire on BLD7 is not required if the jumper wire between BLD3 and BLD7 is

present.

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

8

S450612

A450862

Work Instruction

Connection

Connection

JP3-1Battery 0V

BLD 1 Battery -VE

Connect to Frame Ground

System Power JP3-2

BLD 2 Battery +VE

Connect to Crane Power 12V - 36V (Fused at

10 Amp power source)

JP 5-1 Function Kick

Out (FKO) Feed

BLD 7 FKO Feed

Incoming Crane Power for Function Kickout

JP 5-2 Solenoid

Output

BLD 8 Solenoid

Output

Power to Function Kick Out Solenoids on

Crane

JP 5-3 Solenoid

Output

BLD 9 Boom Mode

Power to Boom Mode

Connection

Connection

Work Instructions

JP 12-1 (Data "A")

BLD 38 (Data "A")

Display Communication connection

JP 12-2 (Data "B")

BLD 39 (Data "B")

Display Communication connection

JP 12-3 Reset

BLD 40 Reset

Reset line…..Usually Blue

JP 12-4 Display

Power

BLD 41 Power

12V Power for Display

JP 12-5

BLD 42

Display Ground Wire

Connection

Connection

Work Instructions

JP9-1

BLD 26

Digital Input (12V)

JP9-2

BLD 27

Digital Input (12V)

JP9-3

BLD 28

Digital Input (12V)

JP9-4

BLD 29

Digital Input (12V)

BLD30

12V Power Supply

Connection

Connection

Work Instructions

JP11-1

BLD 34

Drive Voltage for Swing Pot

JP 11-2

BLD 35

Ground Signal for Swing Pot

JP 11-3

BLD 36

Communication Connection

JP 11-4

BLD 37

Communication Connection

Connection

Connection

Work Instructions

JP8-1

BLD 20

Monitored Voltage Signal Anti 2 Block

JP8-2

BLD 21

Analog Signal from Ext. to Computer

JP8-3

BLD 22

Analog Signal from Angle to Computer

JP8-4

BLD 23

Monitored Voltage Signal Anti 2 Block

JP8-5

BLD 24

Protected 5 Volts (Drive Voltage)

JP8-6

BLD 25

Internal Ground (Drive Voltage)

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

9

1.4 Units with Swing Switches

Some older units in the field may use swing switches instead of swing potentiometers, use the

appropriate work area schematic.

Description

Connection

A450763

Work Instruction

Rear

BLD 26

DIN 0

Over Rear

Side

BLD 27

DIN 1

Over Side Chart

Front

BLD 28

DIN 2

Over Front Chart

Between Tires

BLD 29

DIN 3

Between Tires Chart

Power

BLD 30

VP+

Switched Power

BLD 26

BLD 27

BLD 30

BLD 29

BLD 26

BLD 27

BLD 30

DIN 0

DIN 1

+VP

NO

NC

CBLD 28

BLD 27

BLD 30

DIN 2

DIN 1

+VP

NO

NC

C

DIN 3

DIN 0

DIN 1

NO

NC

CNO

NC

C

+VP

BLD 29

BLD 28

BLD 27

BLD 30

DIN 3

DIN 2

DIN 1

NO

NC

CNO

NC

C

+VP

OVER REAR / 360 OVER FRONT / 360

INLINE / OVER REAR / 360 INLINE / FRONT / 360

/

/

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

10

1.5 Removal and Installation

1. Place the crane in rigging mode and raise the boom. This will allow access to the hose fittings

and wiring harness connections.

NOTE: Leave the Power and FKO cable connected to allow movement of the boom during the removal

and installation process.

2. Disconnect the reeling drum cable.

3. Disconnect the swing sensor.

4. Remove the display.

5. Remove the display cable.

6. Unscrew the four bolts and remove the old computer from its mounting and place computer on

the deck.

NOTE: Do not disconnect the power and FKO cables.

7. The new computer is smaller than the existing one. Mount the new computer using one of the

existing bolt holes. Use the new computer as a template to drill three new mounting holes.

8. Screw in the remaining 3 bolts and ensure the computer is firmly attached.

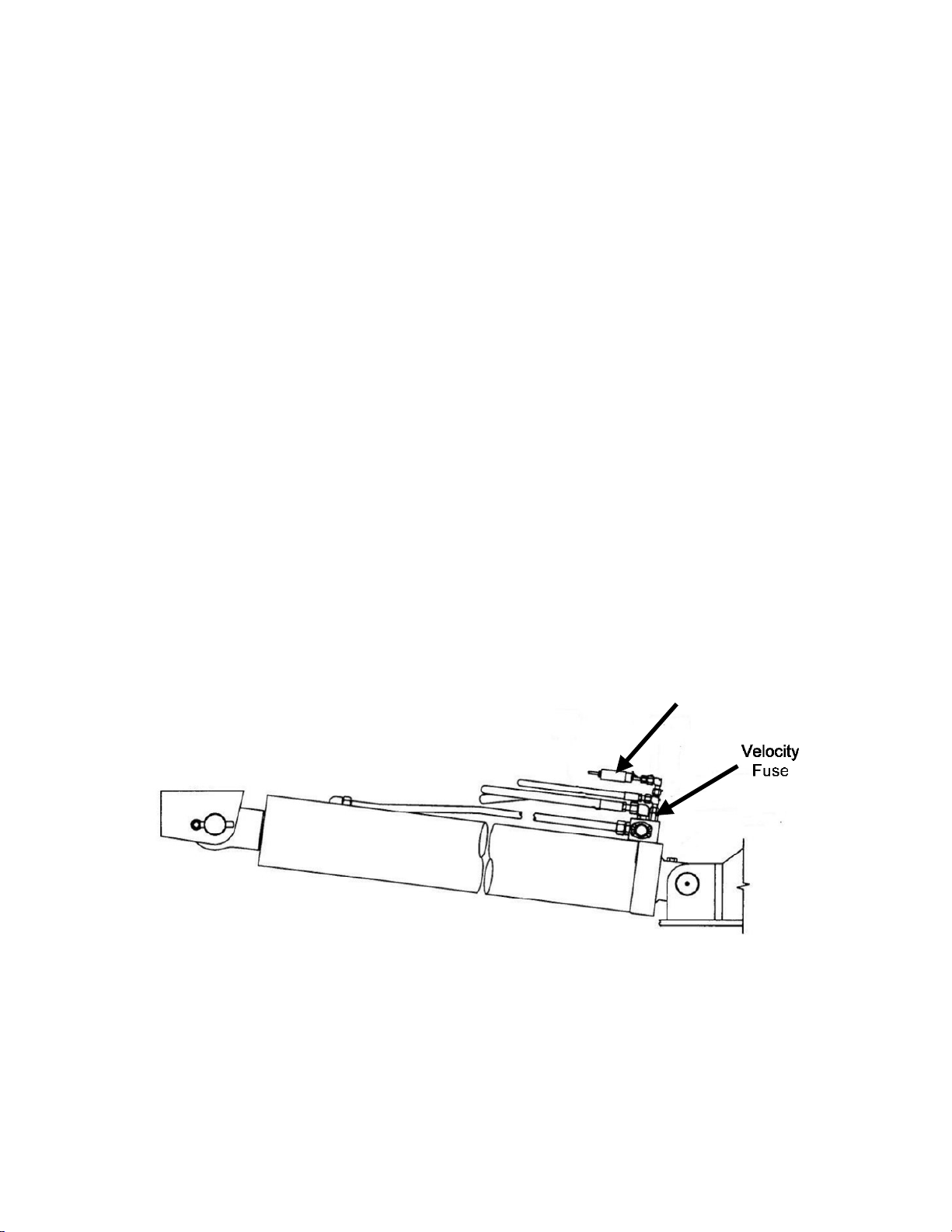

9. Lower the boom completely. Remove the existing pressure sensors.

10. Install the new pressure hoses and retain the velocity fuses.

NOTE: Install the velocity fuse In-line with base side pressure sensor. Ensure there is sufficient length

for boom travel without stretching or damaging hoses.

NOTE: Install bleeder fittings at the cylinder. Obtain the fittings from your hose dealer.

WARNING!

Failure to ensure the velocity fuse is correctly installed may cause a dangerous uncontrolled,

downward movement of the boom in the case of hose failure.

11. Connect the new pressure hoses to the new computer.

12. Raise the boom.

13. If using the existing reeling drum, disconnect the reeling drum cable and remove. The new

computer is wired with a new cable and only needs to be attached to the reeling drum. Install

the display.

14. Install the display cable.

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

11

15. Install the power and FKO cables to the new computer.

16. Slowly elevate the boom to its Maximum Angle to ensure the pressure hoses and electrical

cables are routed properly.

ATTENTION!

It is easy to misroute the pressure hoses and electrical cables. If misrouted, when the boom is

raised the 1st time the hoses/cables can be damaged or destroyed. Use caution.

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

12

2.0 Calibration

2.1 Required Tools

•1/4” nut driver or T15 Torx driver

•Digital or bubble level calibrated and accurate to 0.1° at level

•Digital volt/Ohm Meter capable of measurements to three decimal places

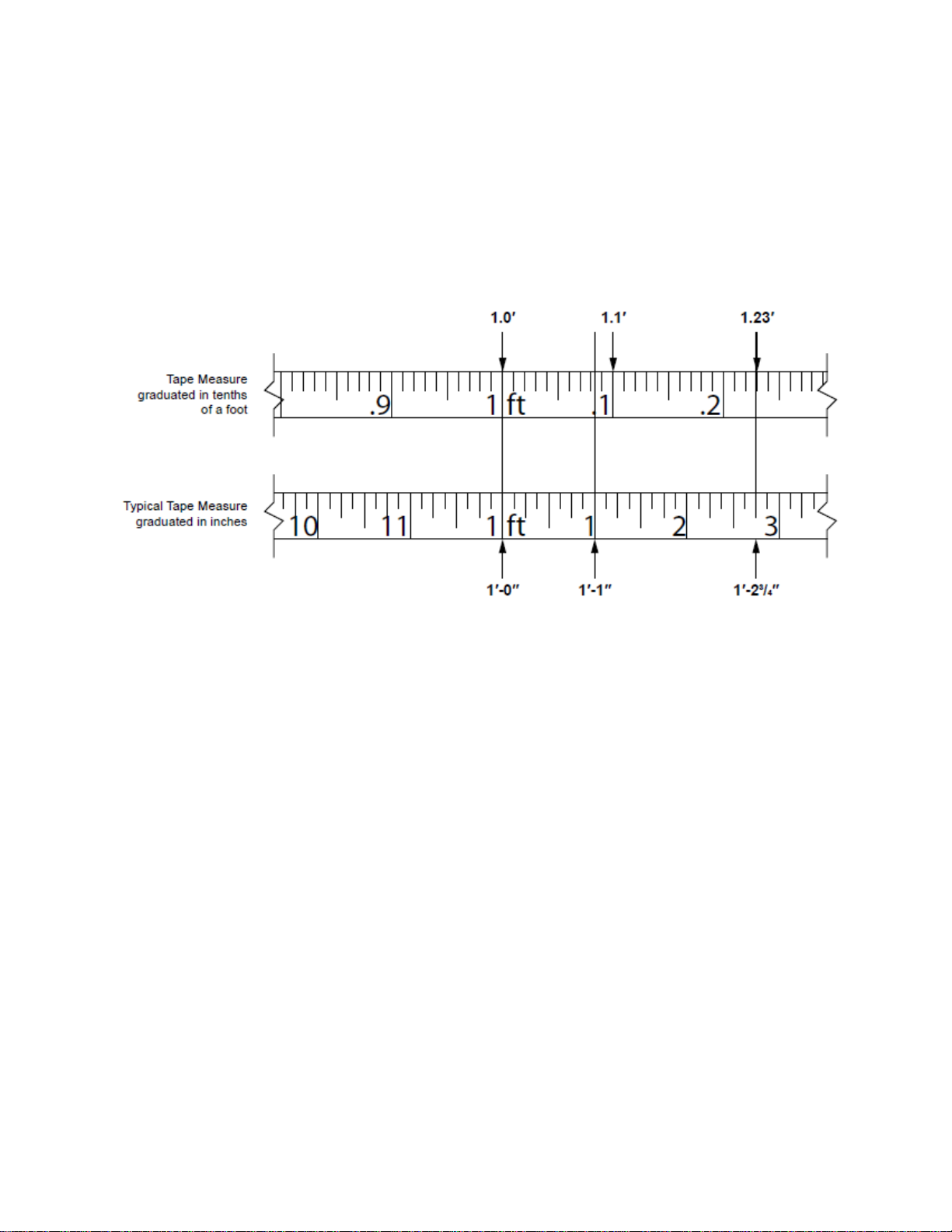

•100 foot measuring tape: fiber type graduated in tenths of feet

NOTE: The computer calculates measurements in feet and tenths of a foot, so using the correct tape

measure is essential for entering the measurements.

2.2 Number Conversion

If a standard tape measure is being used, convert the measurement into feet and tenths of a foot. For

example: a distance of 35’–6” would be entered into the system as 35.5 feet. Whole inches can be

easily converted by dividing by 12 (6/12=.5). Fractions of an inch are converted by dividing the

numerator by the denominator.

For example: 1/4 inches would be entered as .25 (1/4=.25). Conversion of whole inches and fractions

of an inch (for example 6-1/4”) are converted by first converting the fraction to a decimal and then

dividing by 12. In this case 6-1/4” is converted to 6.25 and then divided by 12 which equals 0.520. Refer

to the Fraction to Decimal Conversion Chart.

When entering weights, convert the number by moving the decimal three places to the left. For

example: enter 1,400 pounds as 1.4, enter 300 pounds as .300.

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

13

2.3 The MicroGuard 514 Display

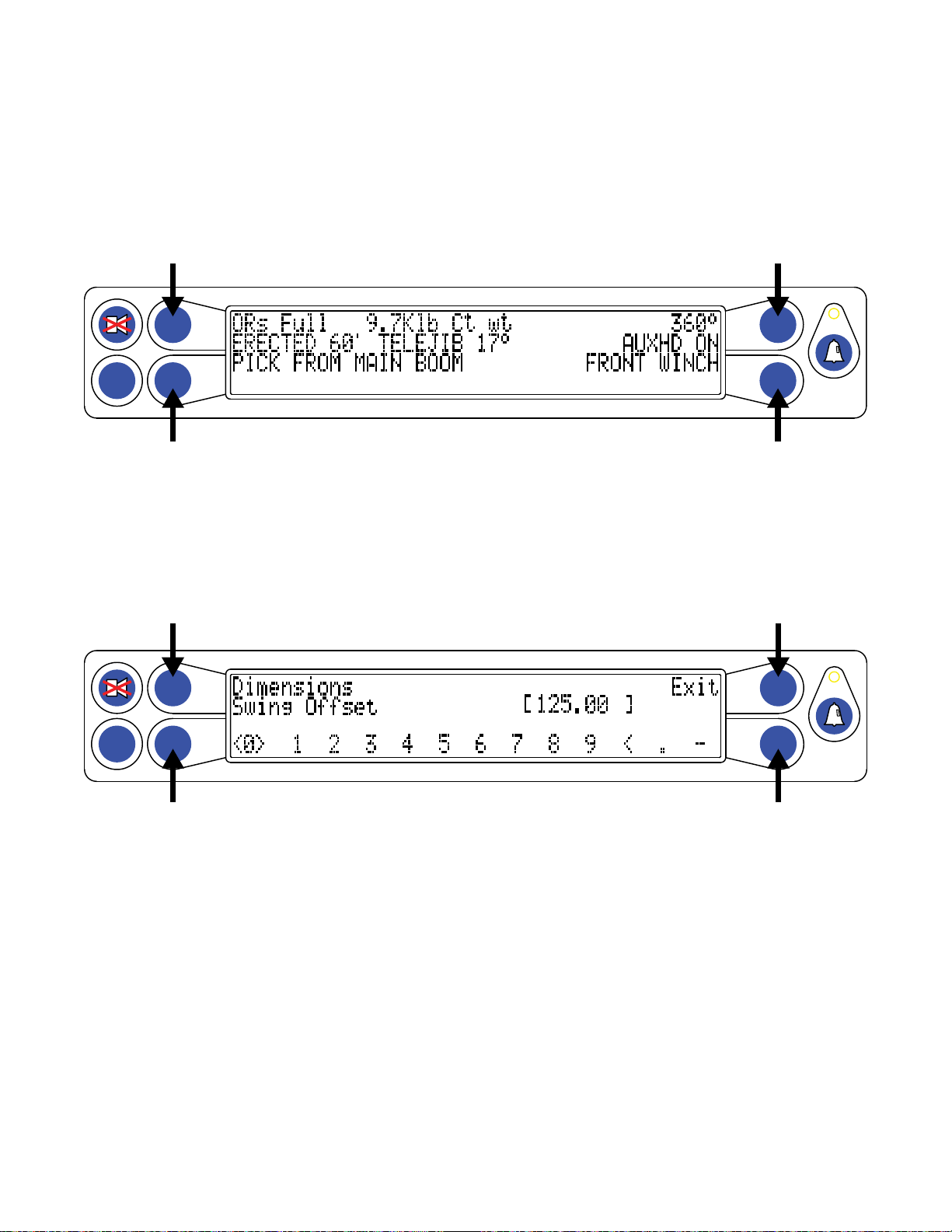

2.3.1 Command Entry

The A, B, C, and Dbuttons are used most for the procedures described in this document and their

function will vary depending on the routine being performed. Commands for each routine will show in

the information window as text adjacent to the buttons. Follow the directions for each routine carefully.

2.3.2 Number Entry

The display does not have a numerical keypad so when numbers are required, the display will change

to enable number entry.

Buttons Band Dare used to scroll left and right. The “cursor” will appear as flashing < > brackets on

either side of the number. Button Ais used to enter the number. Button Cis used to exit the number

entry subroutine.

As each number is selected, press Button Ato enter it into the system. The number will then appear in

the [ ] brackets. Up to five numbers may be entered. When entering a negative value, enter the minus

sign first, then enter the numbers and decimal. When all numbers are correct, press the Cbutton to

calibrate the complete number.

Example: To enter the value “-2.98”:

1. Press button Bor Duntil the number “2” is selected (indicated by flashing < > brackets) and

then press button A to enter the number.

TEST

SET

A

B

C

D

TEST

SET

A

B

C

D

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

14

NOTE: If a number is entered incorrectly, select the backspace “<” and press button A.

2. Select the decimal “.” then press button A.

3. Repeat steps 1 and 2, to enter the numbers “9” and “8”.

4. After the numbers are entered, press button Bor Duntil the minus sign “-” is selected and then

press button A.

5. If the value is correct, press button Cto exit.

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

15

2.4 Preliminary Checks and Measurements

Record the following measurements and enter them into the system. Validate any data supplied by the

crane manufacturer before calibration begins. Enter all dimensions into the computer in feet and tenths

of a foot.

2.4.1 Boom Pivot Dimensions

The boom must be in a horizontal position (0°) when taking the following measurements. Use the space

provided in Appendix A to record the measurements.

Dimension “L” – The horizontal distance between the center of the boom pivot and the center of the

boom hoist cylinder upper pivot.

Dimension “J” – The vertical distance between the center of the boom pivot and the center of the

boom hoist cylinder upper pivot.

NOTE: If the boom pivot is above the boom hoist cylinder upper pivot the dimension is negative (-).

Dimension “G” – The horizontal distance between the center of the boom pivot and the center of the

boom hoist cylinder lower pivot.

Dimension “H” – The vertical distance between the center of the boom pivot and the center of the

boom hoist cylinder lower pivot.

USE THE SPACE PROVIDED IN APPENDIX A TO RECORD THE MEASUREMENTS.

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

16

2.4.2 Winch Dimensions

Dimension “G0” and “G1” – The horizontal distance between the center of the front and rear winch,

and the center of the boom pivot.

Dimension “H0” and “H1” – The vertical distance between the center of the front and rear winch and

the center of the boom pivot.

Dimension “J0” and “J1” – The distance between the top sheave and the centerline of the boom

pivot parallel to the horizontal boom plane, (measurement may be identical).

NOTE: If the boom pivot is above the boom hoist cylinder upper pivot as shown in the illustration,

dimension “J” will be negative. It is important to indicate a positive (+) or negative (-) value.

Dimension “L0” and “L1” – The distance between the centerline of the boom pivot perpendicular to

the horizontal boom plane and the center of the bottom sheave (measurement may be identical).

Dimension “N” Swing Offset – The horizontal distance between the center of the boom pivot and the

centerline of rotation.

NOTE: If the centerline of rotation is ahead of the boom pivot as shown in the illustration, the dimension

will be negative. It is important to indicate a positive (+) or negative (-) value.

Dimension “R” Sheave Radius – The distance between the center and the outside edge of the

bottom sheave.

USE THE SPACE PROVIDED IN APPENDIX A TO RECORD THE MEASUREMENT.

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

17

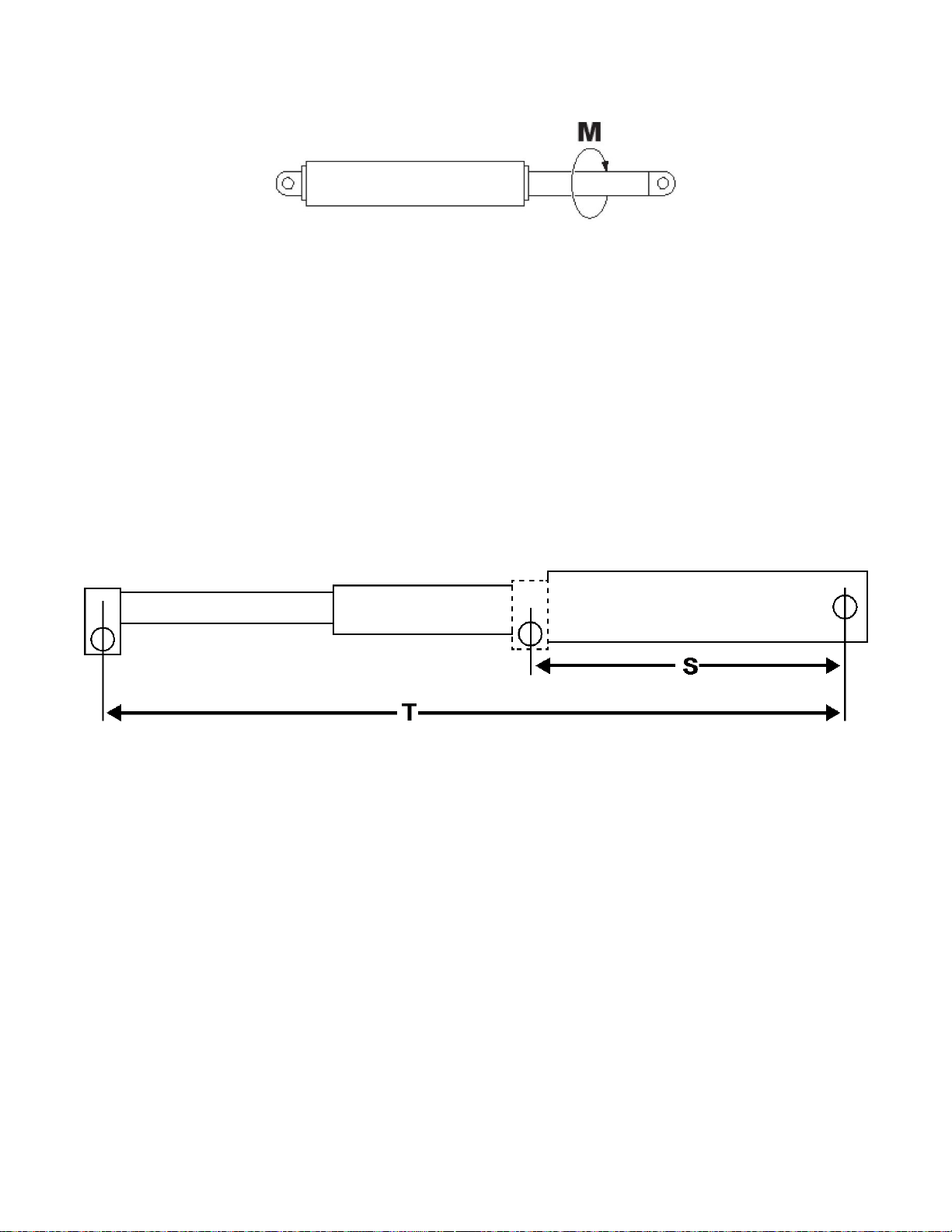

2.4.3 Boom Cylinder Dimensions

Dimension “M” – This is the distance measured around the outside of the cylinder rod, divided by 12.

Then divide this number by 3.14. Record this number for entry into the system.

USE THE SPACE PROVIDED IN APPENDIX A TO RECORD THE MEASUREMENT.

2.4.4 Span Dimensions

WARNING!

SETTING SPANS ON THE CRANE WILL REQUIRE FULL EXTENSION OF THE BOOM. ENSURE

THE CRANE IS SETUP ACCORDING THE MANUFACTURER’S OPERATION MANUAL TO

ENSURE MAXIMUM STABILITY. ENSURE ALL BOOM EXTENSIONS AND LOADS ARE LIFTED

WITHIN THE APPROPRIATE LOAD CHARTS AND LIMITS. FAILURE TO COMPLY WITH THESE

LIMITS MAY RESULT IN SERIOUS INJURY OR DEATH.

Dimension “S” – This is the distance between the center of the boom pivot and the center of the

sheave with the boom fully retracted.

Dimension “T” – This is the dimension between the center of the boom pivot and the center of the

sheave with the boom fully extended.

The span of the boom is calculated by subtracting Dimension “S” from Dimension “T” (T - S = span).

USE THE SPACE PROVIDED IN APPENDIX A TO RECORD THE MEASUREMENT.

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

Table of contents

Other SkyAzúl Music Mixer manuals