Page 6

I5 INSTALL ● REV0

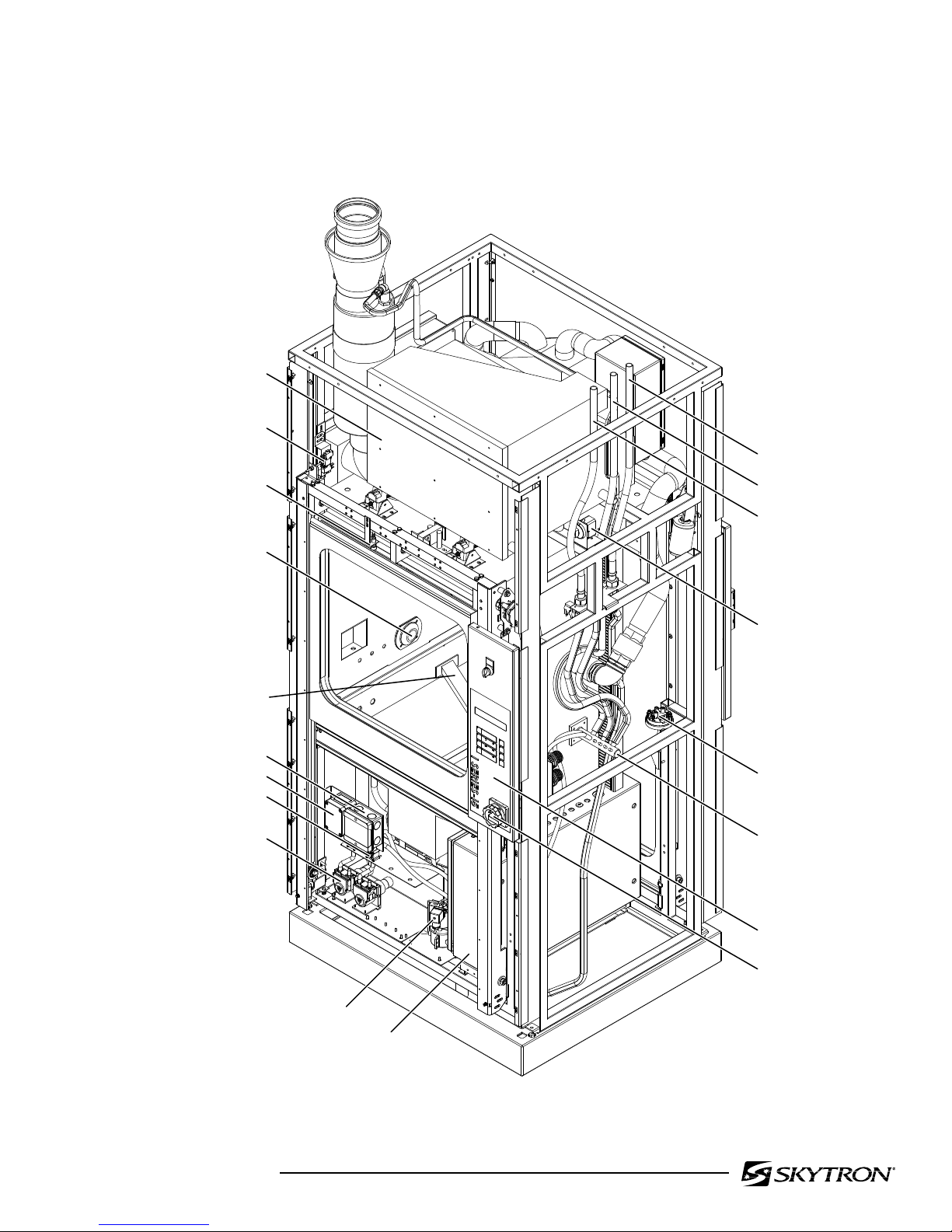

1-1. General Specications

Weight: 800lbs.(363Kg)

Dimensions: 35.5”Wx33”Dx79”H

(900x840x2000mm)*

*Alldimensionsrefertonishedoorandnished

wall.

- Packaged Unit Dimensions & Weight

• Size: 40"Wx30"Dx40"H

• Weight: 460lbs.

- Package Contents

• Unit

• DrainPlumbingpackage

• HeaderRack

• I-SeriesPerformanceKit

FortheconnectionoftheSKYTRON I5 Washer-

Disinfector to the facility water supply, all local/

nationalregulationsmustbefollowed.

Installalltheelectricalconnectionsinaccordancewith

theNECstandardsandlocal/nationalregulations.

1-2. Utility Connection Specications

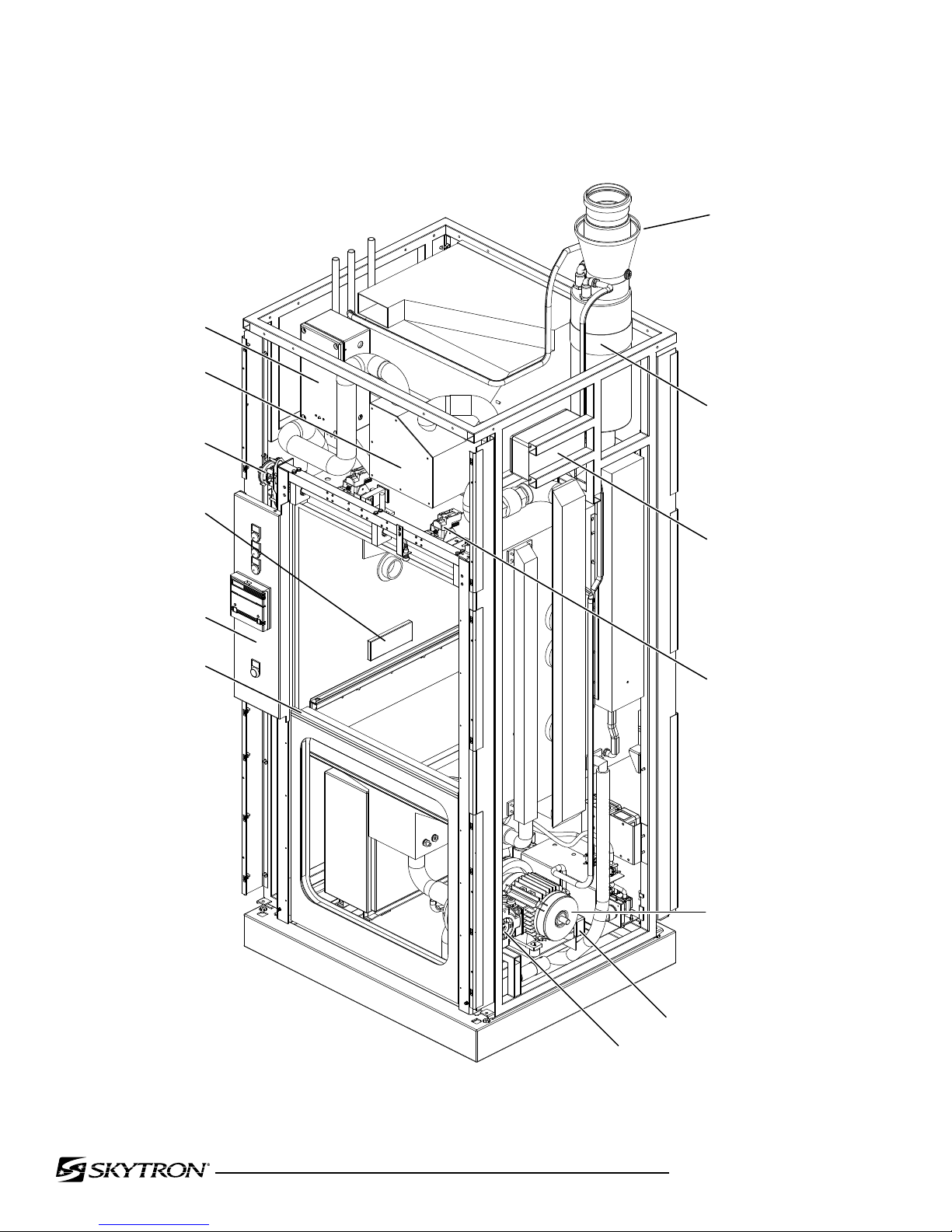

Itisrecommendedthatwatershut-offvalvesand

vacuum breakers (by others) be installed on all

servicelines.Flexiblehosesareprovidedforservice

connections. Hoses extend approximately 5 feet

fromthetopofthemachine.

- Waterline connection color code:

• Red: HW(hotwater)

• Blue: CW(coldwater)

• Yellow: DI(de-ionizedwater)

- Cold Water (CW)

• Connection: ¾”NPT

• Flowpressure: 29-75P.S.I.(2-5bar)

• Capacity: 5gal./min.

- Hot Water (HW)

• Connector: ¾”NPT

• Flowpressure: 29-75P.S.I.(2-5bar)

• Capacity: 5gal./min.

- De-Ionized Water (DI)

• Connector: ¾”NPT

• Flowpressure: 29-75P.S.I.(2-5bar)

• Capacity: 5gal./min.

NOTE

SKYTRONalsorecommendsReverse

Osmosis (RO) water or water from a

lteredsource.

- Compressed Air (AIR) (steam unit only)

• Connector: 3/8”Poly

• Flowpressure: 58-145P.S.I.(4-10bar)

• Capacity: 2.6gal./min.(10L/min.)

• Quality: Oilfree,ltered

- Steam (S) (steam unit only)

• Connector: ¾”NPT

• Capacity: 2lbs./min.(1Kg/min.)

• Consumptionpercycle:13-22lbs.(6-10Kg)

- Drain Service

SKYTRONstipulatesthatthecustomerprovidea

minimum12”x12”x12”(orequivalent)oorsink

withaminimum3”outlet.SKYTRONrecommends

thattheoorsinkbelocatedwithintheWasherbase

footprint.TheSKYTRONI5Washer-Disinfectoris

suppliedwithDrainHosesthatextendthree(3)feet

fromthebottomoftheWasher.TheDrainHoses

shouldextendintotheoorsinkforproperdraining.

• Capacity:7.92gal./min.

• 12”x12”x12”oorsinkwithminimum3”

gravityfed(byothers)

- Electrical Connection (EL)

• 208VAC,3Ph,L1+L2+L3+G

- Power consumption

• Steamdryerandsump:25Amp.,9KW

• Electricdryerandsump:50Amp.,16KW

SECTION I TECHNICAL SPECIFICATIONS / CONNECTIONS