Skywalker X-8 User manual

Skywalker X8

Assembly manual January 2013

ThisManualWasCreatedbyRayGraubergerwww.raygrauberger.com

Technical Data

This is the X-8 FPV wing from Skywalker Technology. The BIG FPV wing!

The X-8 has been specifically designed for FPV and UAV, customized for F-Tek stabilizer

systems.

An awesome looking and fantastic flying FPV / UAV platform, molded out of EPO so it's nearly

indestructible!

This model offers a huge amount of under canopy space, excellent glide performance, and fast

low power cruise speeds in the region of 80-90 kph.

The airframe was designed from the outset to take FPV and other video devices, the equipment

bays have been laid out to suit FPV / UAV applications, there is a camera mount in the nose

and there's a forward oblique mount to suit a Gopro. Transporting the airframe is easy, both

the wing panels and the vertical stabs are bolt on affairs.

Nice design points are the molded in wing reflex, removable vertical stabilizers, ventral

launching grips, nose camera bay, canopy retained via strong magnets , molded battery and

FPV trays and 2 through fuselage spars - plus a molded in spar in each wing panel.

It's an impressive airframe that spans 2120mm and has a rather imposing silhouette!

Specs:

Wingspan: 2120 millimeters

Dry Weight: 880 grams

Take Off Weight: 3200 grams

Motor: 400 – 800 watts dependent on payload

Suggested Motor: 2820 KV730 with 60 amp Esc

Prop: 12 x 6 – 13 x 8 – 13 x 7

Battery: 4s 3000 mA - 6S 5000 mAh

Esc: 40-70 amp

Maximum Weight: 3500 grams

Not Included But Required:

3 or more channel radio system

2 x standard size servos

Propeller and adapter

Brushless out runner

Brushless ESC

Lipo battery

FPV or UAV system

FLIGHT CHARACTERISTICS

When flying your Skywalker X8, please keep in mind these manufacturer guidelines. As everything,

there are exceptions to the rule but these are good points to start with.

Please note that you should, control the Skywalker X8 flight speed within 85 km/H.

If you need a high speed flight you should strengthen wings, otherwise the wings support structure

may fail. Try to keep the Skywalker X8 within 3200 grams. If your build exceeds the 3200 gram

limit, you should strengthen the wings.

If there are technical problems or suggestions, please email or consult your local dealer or distributor

that you purchased your model from.

If you have any questions about this document or anything I can help you with, please email

AFTER BUILD

Skywalker suggests you use brand name quality propeller such as CAM or APC. The design of the Skywalker X8

makes it easy to break down and carry to a field, or store in a smaller space.

CENTER OF GRAVITY

The position of the center of gravity for the Skywalker X8 is 440 millimeters away from the nose, a 5 millimeter

correction either forward or backwards from this point may be needed. The design of the Skywalker X8 puts the

Center of Gravity point and the rear edge of the hand hold slots on the bottom of the model, so measuring is not

needed.

MY CONFIGURATION

Motor: Hacker A40-12S V2

ESC: HACKER X-70 SB PRO

BATTERY: ZIPPY Flightmax 8000 mAh 6S1P 30C

Turnigy nano-tech 8000 mAh 5S 25~50C Lipo Pack

ZIPPY Flightmax 8000 mAh 5S1P 30C

PROPELLER: Graupner CAM Folding Propeller 13 X 7

SPINNER: Aeronaut 2-Blade Black Spinner for Folding Propellers

BLADE STOPPER: Aeronaut Fiberglass Blade Stopper for 2-Blade Spinners

YOKE: Aeronaut Yoke for 2-Blade Spinners

PARTS LIST

QUANTITY DESCRIPTION

1 2PartEPO(expanded polyolefin) SplitFuselage

1 EPOFuselageHatch

2 EPOMainWings

2 EPOMainWingAccessPanels

2 EPOWinglets

1 590.55millimeterFrontCarbonFiberWingTube

1 889millimeterRearCarbonFiberWingTube

1 WoodenOvalMotorMount

4 WoodenMainWingButt‐Plate

2 WoodenUpperWingletButt‐Plate(usedontheWinglets)

2 WoodenLowerWingletButt‐Plate(markedwithaT)(UsedontheMainWings)

2 Standard3WireServoExtensions

2 WireControlArms

2 PressureFitRudderControlHorns

8 NeodymiumMagnets

8 MagnetMountingSurfaces

8 Screws

2 BlackPushrodConnectorScrews

2 PushrodConnectors

2 SqueezeTubesofGlue

Skywalker X8 Assembly Procedure

1. Gluethewingletbutt‐platetothewingletPHOTOS1A,1B,1C,1D

2. Gluethemagneticholddownstructurestogether PHOTOS2A,2B

3. GluethemagneticholddownstructuresintothewingbodyPHOTOS3A,3B,3C

4. GluingtherudderhornsPHOTOS4A,4B

5. Trialfittingtheservoandelevonconfiguration

6. AdvancedwingconfigurationusingDragRudders(seeAppendixA)

7. GluingtheservosinplacePHOTOS7A,7B

8. Mountingthepushrodandpushrodconnector PHOTO8A

9. Gluingthemainwingwingletbutt‐platePHOTOS9A,9B

10. Separatingthecontrolsurfacefromthewing PHOTO10A

11. WingplatebondingwithservoextensionInstallation PHOTOS11A,11B,11C,11D

12. Addingthewingbutt‐platetothemainwings PHOTOS12A,12B,12C,12D

13. Runningtheservoextensionintothemainfuselagebody PHOTOS13A,13B

14. Installingthemotormountintothefuselage PHOTOS14A,14B,14C,14D

15. GluingthefuselagehalvesPHOTOS15A,15B,15C,15D

16. Installingthewingbutt‐plateontothefuselage PHOTOS16A,16B,16C

17. WingletfinalassemblyPHOTO17A

18. AttachingthemotorPHOTOS18A,18B

19. RecessedcameramountPHOTOS19A,19B19C

20. TheSkywalkerX8finalassemblyPHOTOS20A,20B,20C,

21. SkywalkerX8centerofgravityPHOTO21A

22. AssemblyandDisassemblyforTransportation PHOTOS22A,22B,22C,22D,22E

23. FinishedSkywalkerX8PHOTO23A

APPENDIXA–ConvertingStandardElevonToDragRudderConfiguration

Assembly Instructions

1. Gluethewingletbutt‐platetothewinglet

Spreadthesuppliedglueevenlyoverthewingletbottom.Alsospreadthesuppliedglueononesideofthe

woodenbutt‐plate,(makesurethisisNOTthebutt‐platemarkedwitha“T”).Waitapproximately5minutesfor

thegluetodryuntilitisnolongersticky.Dothisforbothpiecesbeforepressingthemtogether,thiswillallow

youtobetteralignthewingletandthebutt‐plate.SeePhotos:1A,1B,1C,and1D.

PHOTO1A

PHOTO1B

PHOTO1C

PHOTO1D

2. Gluethemagnetsandtheholddownstructuretogether

Assemblethehatchmagnetsintothemagnetholdersbyforcingthemintotheprecutholesinthewooden

magnetholders.Makesureyouhave4Northand4SouthPolesets,marktheholdersinawaythatyoudon’t

mixthemup.Doingthisincorrectlywillreversethemagneticforce,thewrongmagneticdirectioncouldcause

anunwantedfailureorhatchlossinflight.Afteryouhaveforcedthemagnetsintoplace,useCyanoacrylateor

(CA)toaffixthemagnetspermanentlyinthewoodenmagnetholders.Justadropwillbeplentytoholdthe

magnets.SeePhotos2Aand2B.

PHOTO2A

PHOTO2B

3. Gluethemagneticholddownstructureintothewingbody

Usingthesuppliedglueapplyliberallytothemagneticholddowns,allowthegluetodryforapproximately5

minutes.Applygluetothewingshatchandfuselagewaitapproximately5minutesforthegluetodry.Afterthe

gluehasdried,payingcloseattentiontotheNorthandSouthpolesofthemagnetsinsertthemintothewing

andfuselage.IfyoupreviouslymarkedtheNorthandSouthpolesofyourmagnetholddownsasmentionedin

Step2,thisassemblyprocedurewillgomucheasier.Afterthegluehassetinboththefuselageandhatchput

thetwopiecestogetherandinspectthefit,makeanyadjustmentsatthistimetoinsurethereisasolidfit

betweenthehatchandthewing.Paycarefulattentiontothespacingbetweenthetwoholddownpartsandthe

wingandhatch.SeePhotos3A,3B,and3C.

PHOTO3A

PHOTO3B

PHOTO3C

4. GluingtheRudderHorns

Spreadjustenoughglueontothewingscontrolsurfacetoaccepttheruddercontrolhorn.Makesureyou

spreadtheglueevenlyandallowittodry.Dothesameforthecontrolhornitself.Afterboththecontrol

surfaceandcontrolhornhavedried,insertthecontrolhornintothepre‐markedholesinthecontrolsurface.

SeePhotos4Aand4B.

PHOTO4A

PHOTO4B

5. Trialfittingtheservoandelevonconfiguration

Thisisthestandardradioset‐upfortheSkywalkerX8.Atthispointyoushouldhaveyourradiosetupforadelta

wing,elevonconfiguration.Ifyouhavenotset‐upyourradioyet,dothisnowbeforecontinuing.Withallof

yourelectronicsturnedonlettheservosself‐centerthemselves.Turnoffyourelectronicsandattachtheservo

hornstoyourservosatarightangletothelongestsurfaceoftheservo.

6. AdvancedWingConfigurationusingDragRudders

Thereisamoreadvancedflyingconfigurationthatrequirescontrolsurfaceandwingmodificationwith

advancedradioset‐updiscussedlaterinthisdocument.SeeAppendixA.

7. Gluingtheservosinplace

Useastandardsizeservooraservothathasmorethan2.5KGofforcefortheSkywalkerX8.Plugintheservo

extensioncablesuppliedwiththekit.Applygluetoonesideoftheservoandalsoapplygluetotheservocut‐

outinthewings.Waitforthegluetodry(approximately5minutes)thenplacetheservointothewing.Place

theservoextensionwireintothepreformedchannelinthewing.SeePhotos7Aand7B.

PHOTO7A

PHOTO7B

8. MountingthePushrodandPushrodConnector

Insertthepushrodintotheuppermostholeintheservoarm.Slidethepushrodconnectorontothepushrodand

attachthepushrodconnectorwithoneofthesuppliedblackscrews.Cutoffanyexcesslengthoffthepushrod.

Thepushrodshouldnotextendmorethan1/8”ofaninchpastthepushrodconnector.SeePhoto8A.

PHOTO8A

9. GluingtheMainWingWingletButt‐Plate

Liberallyapplyasmoothlayerofgluetothewingletbutt‐platethesebutt‐platesaremarkedwitha“T”.Applya

smoothlayerofgluetothemainwingaswell.Allowthegluetodryonboththewingandbutt‐plate(about5

minutes),thenpressthemtogetheraligningthemaccurately.SeePhotos9Aand9B.

PHOTO9A

PHOTO9B

10. SeparatingtheControlsurfacefromtheWing

Useaneworextremelysharpbladetocutthecontrolsurfacesidesfromthewing.YouwillNOTberemoving

thecontrolsurfacecompletely,justallowingittomoveupanddownwiththelongestsideuncut.Itis

recommendedtoleavea1.5millimetergapbetweenthewingandthecontrolsurface.SeePhoto10A.

PHOTO10A

11. WingPlateBondingwithServoExtensionInstallation

Ifyouareusingdragrudders,doNOTdothisstepuntilyouhavereadandcompletedAppendixA.Spreadglue

ontotherecessinthewingwherethewingplatewillsit.MakesureyoudoNOTcovertheWingTubeareawith

glue.Carefullyinserttheservoextensionintothewingpanelcut‐outchannel,makesurethattheservowireis

firmlyinplaceandtheextensionistightfromtheservo.Spreadglueevenlyontothewingplateallowingthe

wingglueandwingplatetodry(about5minutes).Carefullycompressthewingpaneltothewingadjustingfor

fit.Trytomakesurethatthebuttendofthewingplateisevenwiththeendofthewing.SeePhotos11A,11B,

11Cand11D.

PHOTO11A

PHOTO11B

PHOTO11C

PHOTO11D

12. AddingtheWingButt‐PlatetotheMainWing

Applythesuppliedgluetotheinnerwingedge,makesurenottogetanyglueintothewingtubehole.Also

applygluetothebutt‐plate,allowthegluetodryonbothpiecesforabout5minutes.Afterthegluehasdried

insertthewingtubeintoitthewingtubecavitytohelpalignthebutt‐plateforthemostaccuratefit.Nextinsert

thewingtubeintothewingtubeholeinthebutt‐plate,andattachthebutt‐platetothewing.

SeePhotos12A,12B,12C,and12D.

PHOTO12A

PHOTO12B

PHOTO12C

PHOTO12D

13. RunningtheServoExtensionintotheMainFuselageBody

Youwillneedtowidentheslotinthefuselagesothattheplugendoftheservoleadwillfitthroughthehole

afterthefuselagehasbeengluedtogether.SeePhotos13Aand13B.

PHOTO13A

PHOTO13B

14. InstallingtheMotorMountintotheFuselage

Optionallyyoucanattachyourmotortothemotormountbeforegluingitintothefuselage.Ifyoudonotattach

yourmotoratthistimeyoushouldhavenoproblemsmountingthemotorafterfurtherconstruction.See

Photos14A,14B,14C,and14D

Other manuals for X-8

2

Table of contents

Other Skywalker Toy manuals

Popular Toy manuals by other brands

Fisher-Price

Fisher-Price Power Wheels Cruiser M0412 Assembly and owner's manual

ROBBE

ROBBE Edge 540 ARF Assembly and operating instructions

Canon

Canon Creative Park Rabbit Assembly instructions

Mega Bloks

Mega Bloks HALO ONI REAP-X manual

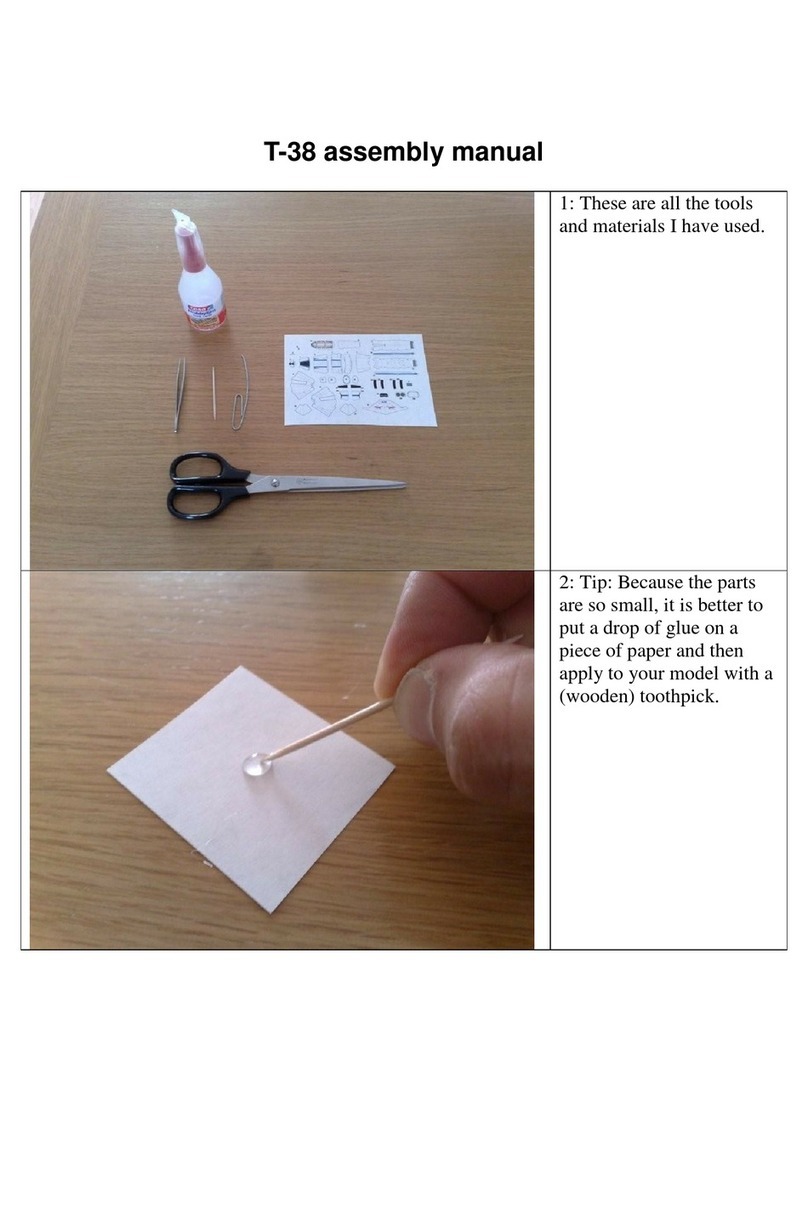

AXM Paper Space Scale Models

AXM Paper Space Scale Models T-38 Assembly manual

Tower Hobbies

Tower Hobbies Turbo Vee 2 Assembly and operation manual

RTS

RTS 3P2 Assembly instructions

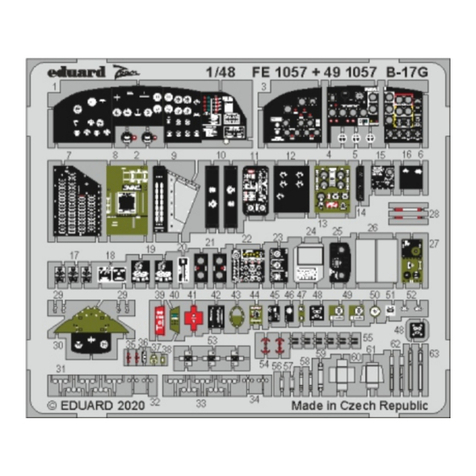

Eduard

Eduard ZOOM FE 1057 manual

MD Helicopters

MD Helicopters MD900 with PW206E Flight manual

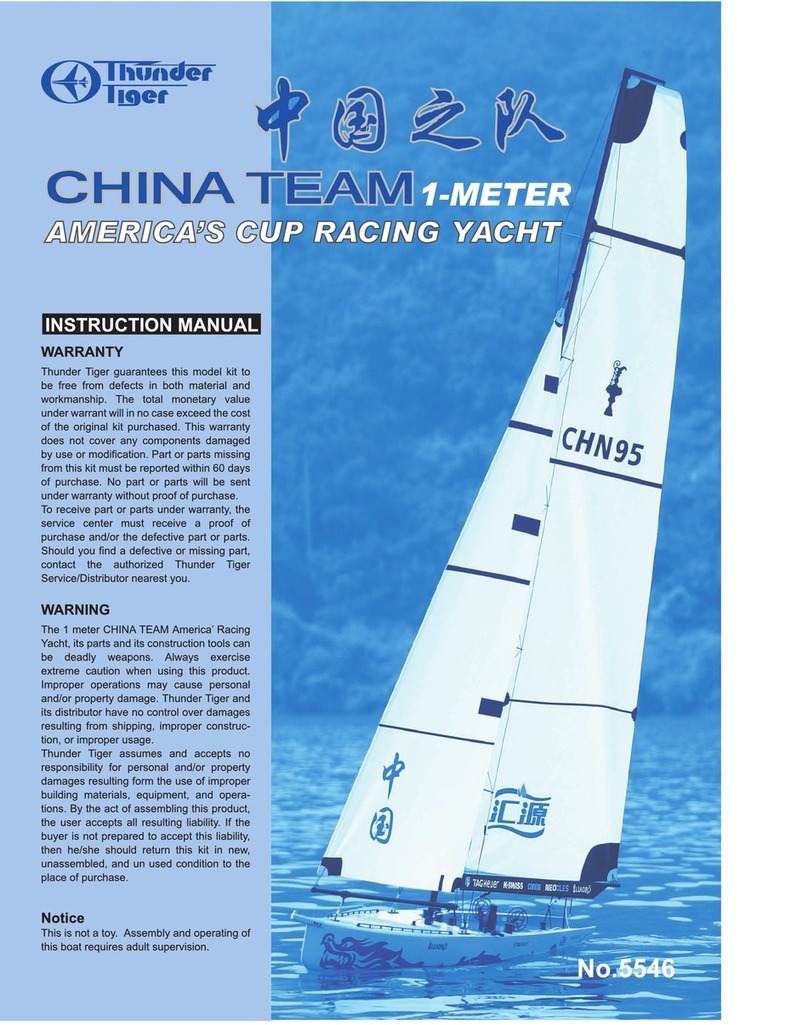

THUNDER TIGER

THUNDER TIGER 5546 instruction manual

Accucraft trains

Accucraft trains FORNEY LIVE STEAM instruction manual

Kazan Helicopters

Kazan Helicopters Mi-17-1V Flight manual