Accucraft trains FORNEY LIVE STEAM User manual

Other Accucraft trains Toy manuals

Accucraft trains

Accucraft trains Baldwin 4-4-0 1:20.3 Scale User manual

Accucraft trains

Accucraft trains Lilly Belle User manual

Accucraft trains

Accucraft trains D&RGW C-25 2-8-0 COAL FIRED User manual

Accucraft trains

Accucraft trains RUBY #5 User manual

Accucraft trains

Accucraft trains Colorado User manual

Accucraft trains

Accucraft trains WHITCOMB 45T SIDE ROD DIESEL ELECTRIC User manual

Accucraft trains

Accucraft trains DECAUVILLE 0-4-0T User manual

Accucraft trains

Accucraft trains D&RGW C-25 2-8-0 User manual

Accucraft trains

Accucraft trains Lilly Belle User manual

Accucraft trains

Accucraft trains SP 2-10-2 F4/F5 User manual

Accucraft trains

Accucraft trains SOUTHERN PACIFIC 2-10-2 F4 User manual

Accucraft trains

Accucraft trains Shay Electric User manual

Accucraft trains

Accucraft trains L&B LEW User manual

Accucraft trains

Accucraft trains Climax User manual

Accucraft trains

Accucraft trains AL97-372 User manual

Accucraft trains

Accucraft trains Ruby 0-4-0T Kit User manual

Accucraft trains

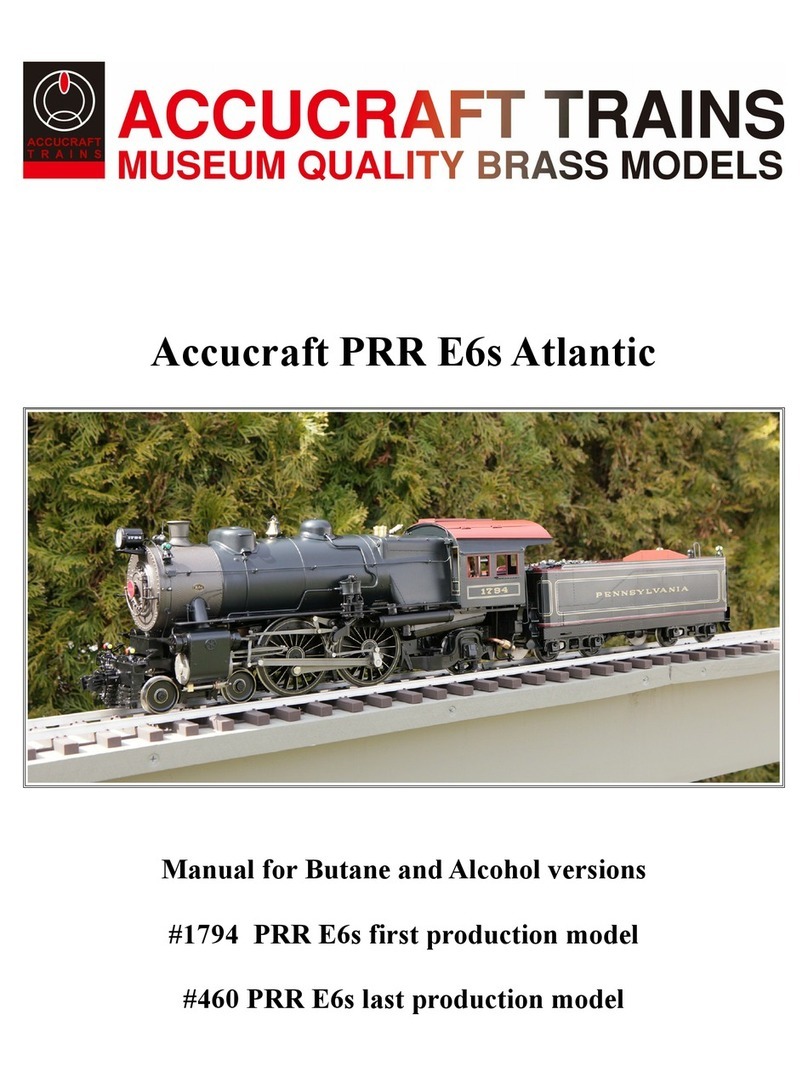

Accucraft trains PRR E6s Atlantic User manual

Accucraft trains

Accucraft trains Mogul User manual

Accucraft trains

Accucraft trains C.P. Royal Hudson Live Steam - Alcohol Fired User manual

Accucraft trains

Accucraft trains UNION PACIFIC 4-8-8-4 BIG BOY User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions