SLAGKRAFT SH125 User manual

Artikelnummer 5017 743-R4

English, User manual in original

Copyright

All rights reserved, including the right to reproduce this manual, or parts thereof, in any form, without the

written permission of Cranab AB.

Instruction manual

Horizontal Flail

Model:

SH125 / SH150 / SH170 / SH190 / SH210

SH110-TW / SH150-TW

EuroTest

Certificate

Read through the entire instruction

manual before beginning operation.

2

Products sold after 1995-01-01 are to be CE-marked and in conformance with

the machine directive confirmed by EU.

The manufacturer (importer) holds responsibility for this in the EU and/or EES

area.

EuroTest

Certificate

The EUROTEST mark indicates that the product has been inspected by a

testing station that is independent of the maker of the product, ie, third party

certification.

The EUROTEST mark shows that the product is independently inspected with

regard to common European requirements concerning safety and health related

to this product

To enable a testing station to issue certificates it must fulfil confirmed quality

requirements and its experts inspect the product on the basis of safety and

quality.

SMP Svensk Maskinprovning AB is approved to carry out this third party

certification.

SMP puts its ET-mark on the product when it considers that the product

conforms to EU’s machine directive.

3

C

ONTENTS

1 .................................................................................................................................................................. Introduction 5

Limitation of application.................................................................................. 5

Range of use.................................................................................................. 5

2 .................................................................................................................................................... General description 7

Identification................................................................................................... 7

Direction of rotation ........................................................................................ 8

3 ................................................................................................................................................. Technical description 9

Hydraulic fluids............................................................................................... 9

Filter ............................................................................................................... 9

Hub .............................................................................................................. 10

Safety cover ................................................................................................. 10

Hydraulic motor ............................................................................................ 10

Flail chain..................................................................................................... 10

Chain magazine and chain locks.................................................................. 11

Protective rubber mat................................................................................... 11

Chain curtain................................................................................................ 11

Wear plates and back plate.......................................................................... 11

4 ............................................................................................................................................................. Technical data 12

Standard models .......................................................................................... 12

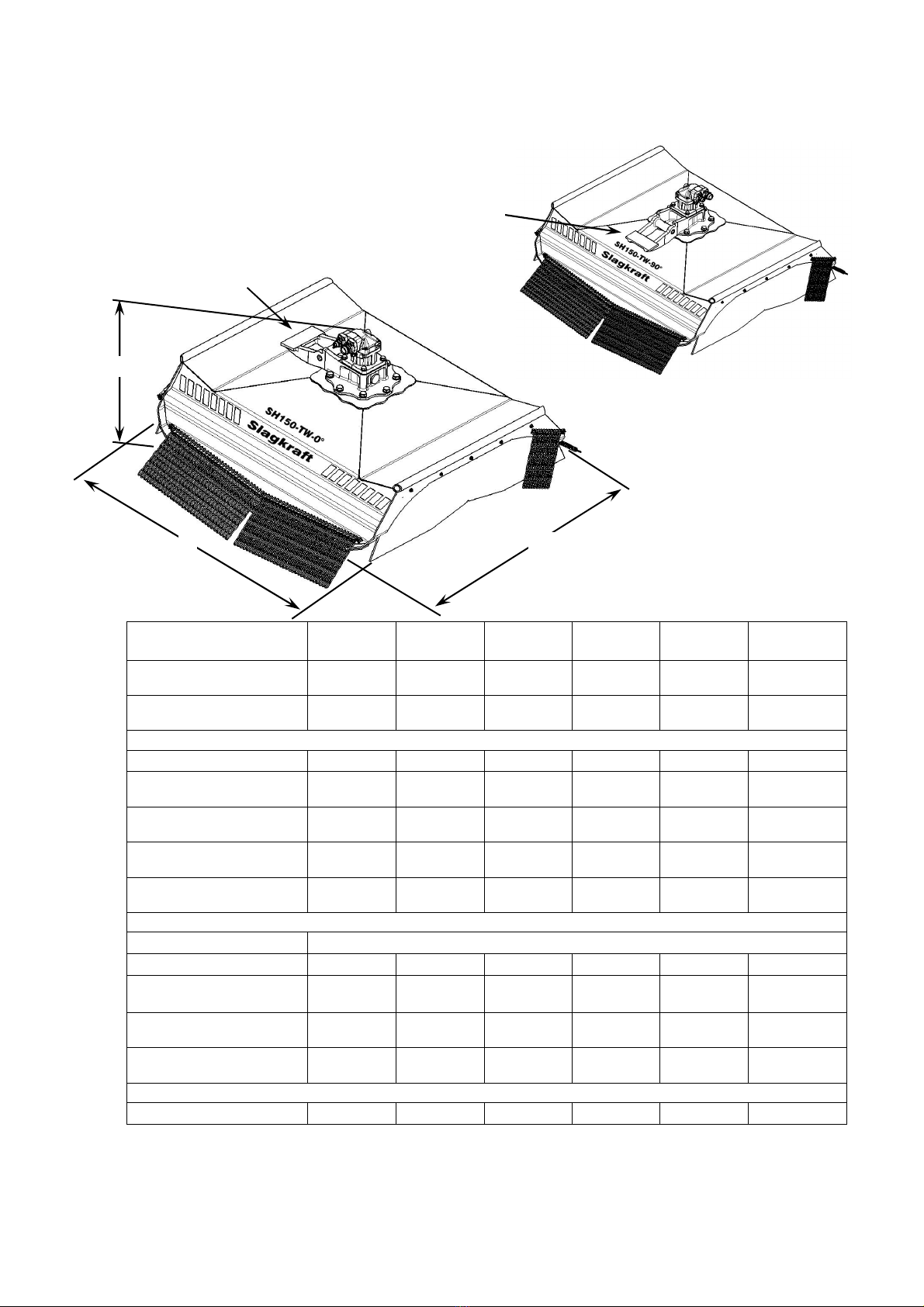

TW models................................................................................................... 13

5 ..................................................................................................................................................................Safety rules 14

General safety rules ..................................................................................... 14

Safety instructions........................................................................................ 15

Warning decal .............................................................................................. 17

Lifting points................................................................................................. 19

Type plate .................................................................................................... 19

6 .................................................................................................................................................. Connecting to carrier 20

Hoses........................................................................................................... 20

Connecting................................................................................................... 20

7 ................................................................................................................................................ Operating instructions 22

Before starting.............................................................................................. 22

Starting......................................................................................................... 22

Mode of operation ........................................................................................ 22

Hints for light clearing................................................................................... 23

Chain curtain................................................................................................ 23

Flail chain, chain locks and chain magazine ................................................ 23

After operation, general instructions............................................................. 23

Long-term parking / storage..................................................................... 23

Check after long-term parking / storage................................................... 24

8 ......................................................................................................................................................................... Service 25

Electric welding ............................................................................................ 26

Maintenance schedule / Lubrication schedule ............................................. 27

Retightening of bolted joints - Table............................................................. 28

4

Lubrication schedule .................................................................................... 29

Lubricating the drive axle ............................................................................. 30

Cleaning the chain magazine....................................................................... 30

Loading chain into the magazine.................................................................. 31

Changing the protective rubber mat............................................................. 32

Changing the chain curtain .......................................................................... 32

Retightening bolted joints............................................................................. 33

Inspecting slot-and-wedge bolt joints ........................................................... 33

Inspecting bearings ...................................................................................... 34

Inspecting vibration damper under tilt mount ............................................... 34

9 ............................................................................................................................................................ EC Declaration 35

5

1

I

NTRODUCTION

This instruction manual contains information that you should be conversant with

to operate and maintain the horizontal flail in the best way. Study the contents

carefully before putting the flail into operation and carefully follow the

instructions provided. This will ensure the best conditions for long useful life and

interference-free operation.

This instruction manual applies only to Slagkraft’s horizontal flail. Separate

instruction manuals are available for vertical flail, crane, bush clearing machine

type Compact and bush clearing machine with motor package.

Slagkraft reserves the right to freely alter the contents of instructions, directions

and specifications.

The spare parts catalogue is included as a supplement in this instruction

manual and it may contain several model variants than those dealt with in the

manual.

When ordering spare parts the serial number of the horizontal flail should be

stated (see type plate) in addition to the number of the spare part. The reason

for stating the serial number is that design changes may have been made that

could affect the choice of spare parts required.

A machine card accompanies the horizontal flail on delivery indicating the type,

serial number and year of manufacture. If the horizontal flail is part of a

complete bush clearing machine there will also be a machine card for the whole

unit.

Limitation of application

Slagkraft’s flails can be mounted on other carriers than Slagkraft cranes.

Slagkraft’s tilting mounts are therefore available in a variety of designs. It is

essential that the base machine is inspected after fitting to ensure satisfactory

stability. To inspect stability, run the crane boom and horizontal flail to maximum

tilting moment, ie, maximum extended mode at right angles to the direction of

travel for the machine, just above ground level. If the base machine is unstable

it can be balanced with counterweights or stabilising cylinder. Consult Slagkraft

for approval of base machine / combination of flail model.

Range of use

The horizontal flail is designed solely for clearing thickets and bush vegetation

and must be used and maintained in accordance with directions in this

instruction manual. It is especially important that safety rules are adhered to.

6

Study the entire instruction manual before using the flail.

Before mounting it, study the section “connecting to carrier” and section

“Safety rules.”

If the horizontal flail is included in bush clearing machine Compact or

Motor package study also the instruction manual for Compact, Motor

package and Crane respectively.

7

2

G

ENERAL DESCRIPTION

Identification

The horizontal flail consists mainly of safety cover, hub and hydraulic motor and

chain magazine, chain curtain, protective rubber mat, and wear plates.

The type designation of the horizontal flail consists of a number of parts

describing the configuration of the flail. How this designation is built up and what

it means is shown below. The type designation is required in some cases to

enable ordering of the right spare part.

Type designation SH150-80-TW-90 means:

SH150 Working width 150cm

80 Indicates size of hydraulic motor in cc

TW Flail with two open sides, ie, two-way flail.

90 Turning of hub in relation to standard version. This turning is used

mainly on backhoes and excavators. Other turning may also occur.

Saftey cover

Hub and hydraulic

motor, chain magazine

Wear plate

Chain curtain

Back plate with rubber mat

Location of warning decal

Protective rubber mat

Type plate

8

Direction of rotation

Flail have clockwise rotation seen from above. Wear plates, the hood and other

protections are designed for this rotation.

This rotation requires that the pressure line to the hydraulic motor is connected

to the hydraulic motor connection marked “A”.

9

3

T

ECHNICAL DESCRIPTION

The basic principle of the horizontal flail is two horizontally rotating chains.

Bushes and thickets are slashed and the vegetation is disintegrated into chips.

The horizontal flail can be operated using different chain diameters

recommended by Slagkraft, 10 or 13mm. Note that the chain magazine shall

only be filled with one dimension at a time. 10 and 13mm chain may never,

under any circumstances, be mixed in the same magazine.

For clearing with sweeping movement in terrain and for operation back and forth

a special flail is available with two open sides, ie, a two-way flail (type

designation TW). This flail is mainly used on excavators and other off road

machines. For use on roads a standard model is more suitable.

Hydraulic fluids

High requirements are put on the hydraulic fluid, which is the power-transmitting

component in a hydraulic system, to ensure the best possible efficiency and

useful life of the hydraulic system. The fluid, which is primarily intended for use

in equipment for outdoor use, must therefore be suitable for a wide temperature

range. The fluid shall contain additives to counteract foaming, improve film

strength and reduce viscosity temperature dependence.

Temperature range corresponding to the range for kinematic viscosity 1500-

10mm2/s(=cSt) for the standardised hydraulic fluids SHS ISO VG 46.

We recommend fluid with characteristics in conformance with Swedish

Standard for hydraulic fluids SS 15 54 34. This standard includes conventional

hydraulic fluids that have a mineral oil base and also biologically decomposable

hydraulic fluids conforming to the standard and strict environment requirements.

Note. Some suppliers of pumps or components may have other

requirements regarding hydraulic fluids than those noted above. Ensure

therefore that the hydraulic fluid is approved prior to use.

Filter

For maximum useful life and performance the fluid must conform with regard to

cleanliness to ISO-norm 17/13 or better (ISO 4406). A 10µm (absolute) filter is

recommended. The hydraulic system must also be clean in general.

10

Hub

The hub consists of a housing with a spherical bearing in the lower part of the

housing. The lower part of the drive axle between the hydraulic motor and the

chain magazine is carried by the spherical bearing and at the upper end the

bearing is aligned by the outgoing axle of the hydraulic motor. A spline coupling

interconnects the drive axle and hydraulic motor.

Safety cover

The safety cover is made of hardened high-strength steel sheet. The wear

runners are replaceable. The protective rubber mat protects the front edge. The

TW type flail has two protective rubber mats. The cover also has a chain curtain

on the sides not fitted with a protective rubber mat. The chain curtain works as a

flexible extension of the cover and thus reduces the risk of flying stones.

Hydraulic motor

The hydraulic motor is of the bent-axis type with fixed displacement. The

outgoing axle is supported by bearings.

Flail chain

The flail chain is hardened and tempered in conformance with special

requirements for bush clearing. Flail chains are available in two sizes 10 and

13mm. Article number 1046 010 and 1046 002 respectively.

To facilitate identification of flail chain from Slagkraft it is painted blue and

identification marked according to Slagkraft’s instructions. When buying chain,

save the identification marking until the chain is used up.

Use only genuine flail chain to ensure that the guarantees and product

responsibility appertaining to the machine are not impeded

11

Chain magazine and chain locks

The chain magazine has a circular base plate. Two separate chain channels run

on the upper face of the base plate. Chain locks are fitted in the channel

openings to keep the chain in place. The chain magazine is made and heat-

treated to withstand hard wear. The flail chain is fed out manually.

Protective rubber mat

The protective rubber mat is fitted in the opening of the safety cover in the

direction of travel as protection against flying stones and other objects. The

protective rubber mat has several layers of cord.

Chain curtain

The chain curtain consists of chain links. This guard is fitted to the lower part of

the cover as a flexible extension of the cover.

Wear plates and back plate

The purpose of the wear plates is to protect the lower part of the safety cover

against wear. The wear plates are fastened by slot-and-wedge bolts. Wear

plates should be replaced at the latest when they are 6mm around the slot-and-

wedge bolts. If wear plates become unevenly worn they can suitably be moved

over to the opposite side to prolong their useful life. The back plate and the

safety cover are screwed into position and can be replaced as a single unit.

Replace the back plate when there is 2mm metal left at the thinnest position.

The responsibility of Slagkraft (CE and ET-markning) is not available if

there is used other flailchain, chainlock or chainmagazine or other not

genuine parts who direct affect the saftey.

12

4

T

ECHNICAL DATA

Standard models

Model SH125 SH150 SH170 SH190 SH210

Working width (mm) 1250

49”

1500

59”

1700

67”

1900

75”

2100

82”

Hydraulic motor (cc) 60

3,66 cu.in

80

4,88 cu.in

90

5,62 cu.in

110

6,71 cu.in

125

7,63 cu.in

Outer dimensions (mm)

Length 1795

70”

1970

77”

2330

92”

2560

100”

2770

109”

Width 1550

61”

1760

69”

2000

78”

2200

86,5”

2390

94”

Height (above superstructure) 910

36”

910

36”

910

36”

920

36”

970

37”

Weight (kg) 525

1155 lbs

595

1309 lbs

665

1463 lbs

750

1650 lbs

780

1716 lbs

Hydraulic pressure Min. 210 bar (3045psi) / Max. 380 bar (5510psi)

Rate of hydraulic flow

Min. (l/min) 100

26,4 gpm

100

26,4 gpm

100

26,4 gpm

100

26,4 gpm

120

31,7 gpm

Preferably (l/min) 120

31,7 gpm

130

34,3 gpm

130

34,3 gpm

130

34,3 gpm

145

38,3 gpm

Max. (l/min) 140

37 gpm

150

39,6 gpm

160

39,6 gpm

160

42,3 gpm

170

45 gpm

Power requirement (kW) 40 (55hp) 45 (60hp) 70 (95hp) 75 (100hp)

80 (110hp)

The unit can be delivered with different tilt mounts.

Due to continual product development we reserve the right to make changes.

H

W

L

13

TW models

Model SH110-40-

TW-0°

SH110-40-

TW-90°

SH150-60-

TW-0°

SH150-60-

TW-90°

°°

°

SH150-80-

TW-0°

SH150-80-

TW-90°

°°

°

Working width (mm) 1100

43”

1100

43”

1500

59”

1500

59”

1500

59”

1500

59”

Hydraulic motor (cc) 40

2,44 cu.in

40

2,44 cu.in

60

3,66 cu.in

60

3,66 cu.in

80

4,88 cu.in

80

4,88 cu.in

Outer dimensions (mm)

Length 1565

61,5”

1565

61,5”

1890

75”

1890

75”

1890

75”

1890

75”

Width 1410

55,5”

1410

55,5”

1760

69”

1760

69”

1760

69”

1760

69”

Height 900

35,5”

900

35,5”

930

37”

930

37”

930

37”

930

37”

Weight (kg) 440

970 lbs

440

970 lbs

540

1190 lbs

540

1190 lbs

548

1210 lbs

548

1210 lbs

Hydraulic pressure Min 210 bar (3045psi) / Max 380 bar (5510psi)

Rate of hydraulic flow

Min. (l/min) 80

18,5 gpm

80

18,5 gpm

80

21 gpm

80

21 gpm

100

26,4 gpm

100

26,4 gpm

Preferably (l/min) 85

22,5 gpm

85

22,5 gpm

95

25 gpm

95

25 gpm

130

34,3 gpm

130

34,3 gpm

Max (l/min) 100

26,4 gpm

100

26,4 gpm

110

29 gpm

110

29 gpm

150

39,6 gpm

150

39,6 gpm

Power requirement (kW) 30 (40hp) 30 (40hp) 45 (60hp) 45 (60hp) 45 (60hp) 45 (60hp)

The unit can be delivered with different tilt mounts.

Due to continual product development we reserve the right to make changes.

TW Standard

Bracket forward

L W

H

TW 90°

Bracket sidemounted

14

5

S

AFETY RULES

See also safety rules for crane and where applicable also for Compact and

Motor package.

General safety rules

The contents of this chapter are a summary of rules that must always be

followed in connection with the horizontal flail. These rules do not, however, free

the operator from the obligation to observe statutory or other current national

regulations with regard to road safety and industrial safety. Acquaint yourself

with national and local rules and regulations governing the use of rotor mowers,

etc, and traffic rules and regulations, eg, road and traffic signs, work on roads,

marking of vehicles working on roads, and any other relevant regulations.

Safety rules that apply for various types of workplaces and regulations

according to the highway code must always be followed.

Consult the relevant authorities for information concerning current

instructions and regulations.

Observe great caution when driving in traffic and in built-up areas. There

is always a risk when meeting / contacting road-users or unprotected

persons.

15

Beware of the fire hazard when working in terrain that is dry and

flammable.

It is important to know the risks when using hot work processes (such as

grinding, welding, sawing/cutting) on products painted with polyurethane

colours. If heated above 200°C, dangerous amounts of isocyanates may be

released, and this will require personal protective equipment, and that the place

of work has a ventilation system that works well. All work with isocyanates is

regulated in national work environment directives.

You may find more information about this at:

International:

www.isopa.org,

ISOPAhttp://en.wikipedia.org/w/index.php?title=ISOPA&action=edit&redlink=1ht

tp://en.wikipedia.org/wiki/Isocyanate - cite_note-3 the European Diisocyanate

and Polyol Producers Association

For Sweden:l

- The Swedish Work Environment Authority regulations on thermosetting

polymers, AFS 2005:18, phone: +46.8 730 90 00

- The pamphlet "Isocyanater är farliga" (Isocyanates are Dangerous) from the

Swedish Work Environment Authority, phone: +46.8 730 90 00

- The book "Härdplaster" (Thermosetting Polymers) from Prevent, phone:

+46.8.402 02 20

We can also supply data sheets on the paint in question on our web site

www.cranab.se or from the Cranab Quality & Environmental section, phone;

+46.933.135 00.

Safety instructions

Knowledge concerning function, maintenance and relevant safety rules is

required before using the horizontal flail.

•The ejection guard (chain curtain) must always be fitted and undamaged.

•The horizontal flail is always to be started and used with the wear plates

against the ground to ensure maximum safety. However, do not press the

horizontal flail against the ground with more than normal crane weight; an

excavator can easily damage the flail by its excavating force.

16

•Beware of the danger from flying objects, eg, stones, pieces of wood, etc.

•When reversing, re-running, or driving past obstacles reduce speed of the

horizontal flail to a minimum or stop it altogether.

•Running the horizontal flail vertically is prohibited.

•Operating the flail close to overhead electric power lines is prohibited.

•Being under a raised horizontal flail is prohibited.

•The flail shall in no circumstances whatsoever be used to lift any person.

•Observe great caution when operating the horizontal flail close to wheels of

the base machine. There is danger of the unit being run over by a wheel.

•Running the horizontal flail in a raised position is prohibited.

•Stop all motors before making an inspection or doing any maintenance work.

•Wear ear protectors and safety goggles and use other safety items required

when carrying out maintenance work.

•Remember the danger of fire, slipping and other injury or damage that may

be caused by leakage from the hydraulic system. Ensure that a fire

extinguisher is accessible.

•Ensure that the maximum rate of flow is not exceeded, see technical data.

•The horizontal flail must sufficiently balanced to avoid noticeable vibration.

•The operator must be observant during operation of any abnormal noise or

leakage. Detected faults are to be corrected before further operation so as to

avoid personal injury or material damage.

•Use only Slagkraft’s genuine spares and parts subjected to wear.

The outermost chain links are subjected to wear when operating the flail. When

a chain link becomes worn out the flail and its diesel engine must be stopped.

Position the flail suitably in a vertical mode, then lift the chain lock off from the

holder and pull out the chain to the right length. Then secure with the chain lock.

Ensure that the chain lock is seated in the holder.

Check that the chains are as long as possible without fouling the safety cover.

Both chains are to be equally long.

17

Warning decal

Observe the warning decal that is to be found undamaged on top of the cover. If

the warning decal is illegible, order a new one from Slagkraft and fix it on the

well-cleaned surface. Article number of the warning decal is 5013 889 for the

European markets and 5014 428 for the American market

The various parts of the decal are explained below

Read the entire instruction manual before

doing any work on the flail (including loading,

unloading and assembling).

Take care when operating on stoney ground.

Risk of flying stones.

Rotating flail chain. Risk of personal injury.

The flail must be stationary and the

engine switched off for service.

Be cautious when operating in the

vicinity of overhead cables

.

Don’t touch any mowing part untill

they have

stopped completely.

Don’t stay close when working with the flail.

18

Operate with the wear runners against the

ground to ensure maximum safety.

ALWAYS use genuine flail chain from

Slagkraft.

Replace the chain curtain if damaged.

Replace the protective rubber mat when

worn.

The engine of the wheel-

mounted

loader must be switched off when

connecting or disconnecting hydraulic

fittings or electric connectors.

19

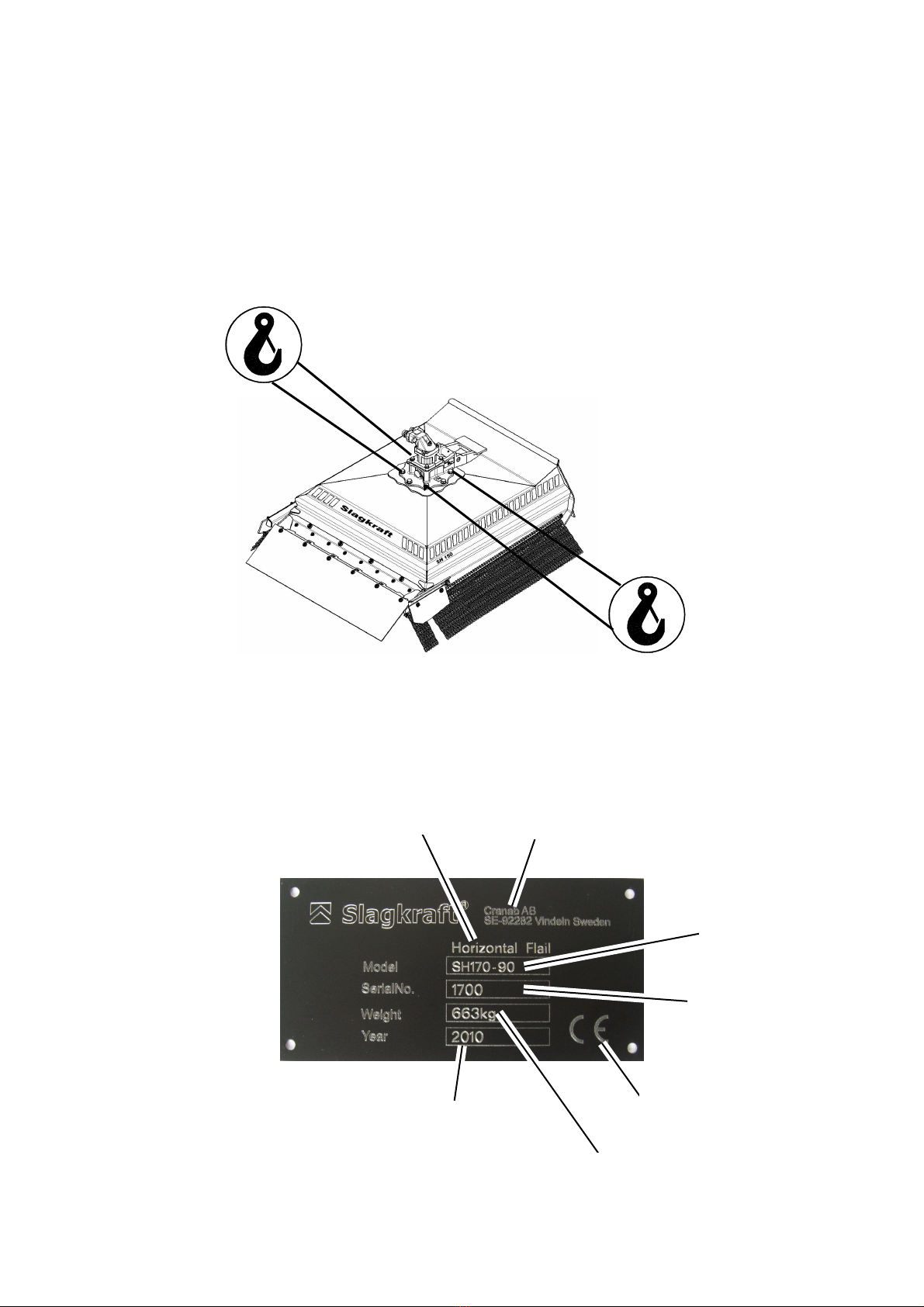

Lifting points

The horizontal flail has four points that are to be used when lifting. These lifting

points are marked with decals as illustrated below.

Type plate

The type plate on the machine is as illustrated below.

Year of

manufacture

Address to

Cranab AB

Machine weight

Machine serial

number

Machine type

designation

Product name

CE-Marking

Declaration of conformity

on last page

20

6

C

ONNECTING TO CARRIER

Slagkraft’s horizontal flail can be mounted on other carriers than Slagkraft

cranes. Slagkraft’s tilting mounts are therefore available in a variety of designs.

It is essential that an inspection is made after fitting to ensure satisfactory

stability. To inspect, extend the crane boom and flail to maximum reach, at right

angles to the direction of travel of the base machine, just above the ground. If

the machine is unstable it is to be balanced with counterweights and/or

stabilising cylinder before being used.

The tilt mount or the marked lifting points must be used to lift the horizontal flail.

Hoses

In cases where the horizontal flail is delivered without hoses the

recommendations below are to be followed when choosing hydraulic hose.

Hose dimensionFunction

inches mm

Working

pressure

bar

Bursting

pressure

bar

Draining ½ 6.4 288 1100

Pressure 1 25.4 380 1520

Return 1½ 38 50 200

Connecting

•Ensure that fastening of the horizontal flail to the crane is secure, check

pivots and bolted joints.

•Ensure that locking lugs / bolted joints on the base machine are fitted

correctly.

•Ensure that pressure and rate of flow are correct (see technical data).

•Recommended hose dimensions are minimum 1" for pressure, minimum 1½"

for return and minimum ½" for draining. The drain hose must be connected

direct to the reservoir so that pressure cannot be higher than 3 bar. The

draining pressure can be checked at the vacant drain port on the hydraulic

motor.

•A check valve (or similar) shall be connected between the hydraulic motor

pressure- and return ports to avoid cavitation. Check valve kit is available as

option.

•The carrier must be disconnected when connecting electric and hydraulic

leads.

This manual suits for next models

6

Table of contents