Slayer Single Group User manual

User Manual

Version 3

Revision 3!

1

Table of Contents

Section Page

Contacting Slayer 3

Warranty Information 4

Important Safety Advisory 5

Water Treatment Requirements 6

Recommended Tools & Accessories 8

Installing Your Machine 9

Factory Settings 16

Using Slayer 17

Cleaning & Preventative Maintenance 26

Troubleshooting 37

Video Guides 39!

2

Contacting Slayer

Phone

+1 (206) 284-7171

Address

Seattle Espresso Machine Corporation

5628 Airport Way South Studio 238

Seattle, Washington 98108

United States of America

___

CEO & Creator

Jason Prefontaine

jason@slayerespresso.com

COO

Fred Baruch

fred@slayerespresso.com

Technical Support

support@slayerespresso.com

Parts & Inventory

Melinda Davis

melinda@slayerespresso.com

Sales

Brandon King

brandon@slayerespresso.com

Customer Service & Office Admin

Elyse Stever

elyse@slayerespresso.com

Engineering

Spencer Branting

spencer@slayerespresso.com

Marketing & Content

Chris Elliott

chris.elliott@slayerespresso.com!

3

Warranty Information

Slayer offers a 15-month limited warranty on all electrical and mechanical parts.

Wearable parts (including but not limited to rubber seals, gaskets, and o-rings) are

not covered under warranty, nor are labor or shipping charges.

Due to the nature and characteristics of wood(s) used on Slayer machines,

cracking, shrinking, and/or warping of this wood is not covered under warranty.

Damage to or failure of your Slayer machine due to inadequately treated water is

not covered under warranty. Read “Water Treatment Requirements” on page 6 for

information about water-related issues.!

4

Important Safety Advisory

This guide includes important instructions about safe espresso machine installation,

operation, and maintenance. Read this manual completely before installing and

operating your Slayer espresso machine. Incorrect installation and operation may

result in damage to the equipment, personal injury, or even death. Disregarding the

instructions contained herein indemnifies Slayer from all resulting damages and

may void the machine’s warranty.

Shipping is coordinated by the customer and performed by a third party. Slayer is

not responsible for damage incurred during transport. Upon receiving your machine,

carefully inspect all packaging, equipment, and accessories for visible damage.

Photograph any visible damage and immediately contact your shipping company

representative. Comply with shipping company regulations. Do not connect your

machine to power, water, or drainage until all issues have been resolved or your

Slayer representative or reseller instructs you to do so. Failure to resolve issues

before using equipment may result in further damage or injury.

Installation should be performed by qualified personnel only and must comply with

all regulations and requirements of the authorities in your area. If guidance is

needed to safely install your machine, contact your Slayer representative or

reseller.

It is critical that an appropriately-rated and grounded electrical plug is used to

supply your machine with power. This is essential for the safe operation and use of

the equipment. Contact your Slayer representative or reseller with questions about

this requirement. If you are unsure about the safety of the electrical configuration,

do not attempt to install your machine.

Your Slayer espresso machine should only be used for the functions it was designed

to perform. Using your machine outside of its defined functionality – as it is

described in the "Using Slayer" section on page 23 of this guide – may be a safety

hazard, resulting in property damage, physical injury, or even death, and will

immediately void the warranty.

Slayer espresso machines are electrical appliances that should be used in a safe

manner appropriate to devices of their kind:

•Do not connect your Slayer espresso machine to electrical power through an

extension cord. The machine must be directly connected to an appropriately-

rated and grounded power source.

•Do not position the power cord in walkways or other areas with high foot

traffic.

•Slayer espresso machines are designed to be used indoors. When using your

machine outdoors, take precautionary measures to protect it from moisture,

humidity, and other natural elements.

•Before performing service on your machine, disconnect power source.!

5

Water Treatment Requirements

Improper water treatment is the most frequent cause of espresso machine damage.

Water is complex and varies significantly between regions, so take great care to

test the water quality at your location and adjust as necessary. Employ the help of a

reliable company (Slayer recommends OptiPure and BWT) to evaluate your water

and recommend and administer treatments.

When evaluating water quality, the two most important factors to consider are

calcium carbonate and chloride:

Calcium Carbonate: dissolved mineral that determines the "hardness" or

"softness" of water.

The desirable range of hardness is 4-6 grains. Over time, calcium carbonate

accumulates as a hard substance, called “scale”, and will inhibit the flow of

water. Machines subjected to “harder” water (greater than 6 grains) will

accumulate scale faster and require maintenance sooner.

Chloride: chlorine combined with an electron from a negatively charged ion.

There are many types of chlorides, including calcium chloride, magnesium

chloride, sodium chloride, etc. Chlorides produce salts that impart a strong

taste, which alters the flavor of the espresso. Chlorides also encourage pitting

corrosion, which causes damage to the machine.

Your water filtration company will create a treatment plan based on your water

needs. Choose a filtration company that has solutions for addressing issues related

to both calcium carbonate and chloride.

Common treatment options include carbon filtration, ion exchange and reverse

osmosis:

Carbon Filtration: process by which water passes through the granular activated

carbon, which attracts and retains many chemicals in the water that have an

unpleasant taste or odor.

Carbon filtration is necessary for all Slayers. For water with 4-6 grains of

hardness, carbon filtration is likely the only necessary water treatment.

Ion Exchange: process by which water passes through an ion exchange system,

where where undesirable mineral components are retained and more desirable

substances such as sodium are released.

An ion exchange system should be used in combination with a carbon

filtration system and is especially beneficial for water in the range of 6-9

grains of hardness. This system is relatively inexpensive and effective in

6

removing inorganic substances. It does not, however, remove organic

substances, such as bacteria.

Reverse Osmosis with Blend-Back Valve (or Remineralized RO): process by

which water is forced through a semi-permeable membrane with selective pore

sizes at high pressure, then blended with the appropriate amount of desired

minerals.

Reverse osmosis may be a good solution for water in the range of 6-9 grains

of hardness, but is mandatory for water above 9 grains. When blending

minerals with the filtered water, target a TDS (total dissolved solids) value of

of 75-125 ppm. Experiment with various TDS levels to determine what is

ideal.

IMPORTANT: All Slayer espresso machines need to be connected to a carbon water

filter to remove chlorine, sediments, odor, and undesirable tastes from the water.

This requirement is in addition to any other necessary water filtration systems.

Filtration requirements may vary seasonally. Water should be tested during each

season to determine the best filtration plan. Once a filtration method has been

selected, take note of the filter’s peak capabilities. Contact the equipment vendor to

inquire about the life expectancy of the filters, then schedule replacement and re-

installation accordingly.

Every time a new water filter is installed, thoroughly rinse the filter before attaching

it to your machine or pump. Run water from the supply line through the filter and

down a drain for at least 2 minutes. Skipping this step will damage your machine.

Damage to or failure of your machine due to inadequately treated water is not

covered under warranty.!

7

Recommended Tools & Accessories

To properly use and maintain your espresso machine, Slayer recommends owning

an assortment of tools and accessories. These can each be organized in two

categories: Beverage Preparation and Equipment Care & Maintenance. Specific

requirements accompany each recommendation.

Beverage Preparation

•Espresso grinder

‣Adjustable grind setting

‣Capability for grinding very fine: espresso-to-Turkish

•Gram scale

‣Low resolution: 0.1-gram (1/10-gram) increments

•Shot glass

•Soft towel

•Steaming pitcher

‣Narrow spout

•Tamper

‣58mm base diameter

•Thermometer

Equipment Care & Maintenance

Tools

•Allen key

•Crescent wrench

•Flat-head screwdriver

•Grouphead brush

•Needle-nose pliers

•Phillips-head screwdriver

•Pick or awl

•Pliers

•Socket wrench (9/16”)

•Wrench

Supplies

•Approved espresso machine cleaner

•Approved espresso machine steam wand cleaner

•Non-abrasive surface cleaner

•Slayer lubricant

•Teflon tape

•Tung oil

Parts

See list of recommended spare parts on page!

8

Installing Your Machine

Only qualified service personnel should install Slayer espresso machines. Incorrect

installation may result in injury and/or damage to the equipment. Please read the

"Important Safety Information" section on page 5 before beginning installation.

Install your Slayer espresso machine with the following ordered steps:

1. Prepare Site

2. Unpack Equipment

3. Connect Drain Hose

4A-C. Connect Water Line

5. Connect Pump

6. Connect Machine to Power

7. Fill Tanks

8. Turn On Heating Elements

Step 1: Prepare Site

Your installation site will need direct access to power, water, and drainage. Building

regulations vary by region, so confirm local requirements prior to connecting your

machine.

Using quality, treated water is essential to achieving the best possible results when

preparing coffee and may also extend the life of your machine. Read the Water

Treatment Advisory on pages 6-7 for information about avoiding and addressing

water-related issues.

Your Slayer espresso machine weighs approximately 160 kg (350 lb.) when filled

with water and needs to be installed on a structure that is capable of supporting its

weight.

Use the following diagram to locate and drill holes in the counter for the water and

drain lines. Note that electrical plugs vary in size and a larger hole may be required

to accommodate the main power cord.!

9

10

2 Group

3 Group

Step 2: Unpack Equipment

Your Slayer espresso machine will arrive in a lidded wooden crate, bolted to a pallet

at the base. Unpack with the following steps.

Parts and tools:

•Phillips-head screwdriver

•Two (2) Rubber feet (included)

•Steam handles (included)

•Drip tray mirror (included)

•Three (3) nuts for drip tray mirror (included)

Procedure:

1. Use a phillips-head screwdriver to loosen and remove the screws

(approximately eight [8] screws) located along the lower edge of the crate.

2. Carefully lift the lid from the pallet.

3. Remove all banding and packing material from the machine.

4. Use a phillips-head screwdriver to loosen and remove the screws

(approximately two [2] screws) from the base of the pump, then detach it

from the pallet.

5. The machine is attached to the pallet with two (2) bolts that are screwed into

two (2) of its four (4) legs, one on each side of the machine. Use a socket

wrench to loosen and remove the two (2) bolts from the underside of the

pallet.

6. Attach the included rubber

feet to the bottom of the two

(2) legs that were bolted to

the pallet.

7. Prepare surface by laying out

one or more towels, which

will rest under the machine’s

feet and allow for easy sliding

into desired position.

8. Holding the machine by the

lower part of the Xs, as

shown, employ two (2) or

more people to lift the

machine up and onto the

towels on the prepared

surface.

9. Slide machine into desired

position, then left legs, one or two at a time, to remove towel(s).

10.Attach the steam handles by threading into place.

11.Attach the drip tray mirror using the three (3) included nuts.

12. Pull both steam actuators forward, into the “on” positions. Leave steam

actuators in the “on” positions until “Step 8: Turn on Heating Elements”.

11

Lift Here

Step 3: Connect Drain Hose

Parts and tools:

•Drain hose (included)

•Hose clamp (included)

•Flat-head screwdriver

Procedure:

1. Use the hose clamp to fasten

the drain hose to the drain

outlet, as shown.

‣The drain hose has an inside

diameter of 5/8" (1.6cm).

2. Prevent clogging by ensuring

that the drain line always goes

downwards.

‣Leave steam actuators in the “on” positions for “Step 8: Turn on Heating

Elements”.

Step 4A: Connect Water Line

For machines without hot water

IMPORTANT: Before connecting a water treatment system to your espresso

machine, rinse the system by running water through it for at least two (2) minutes.

Failure to follow this step will result in equipment damage. Read the Water

Treatment Requirements on pages 6-7 for information about avoiding and

addressing water-related issues.

Parts and tools:

•40”x3/8” braided stainless steel hose

•60”x3/8” braided stainless steel hose (with 90-degree fitting)

•Wrench

Procedure:

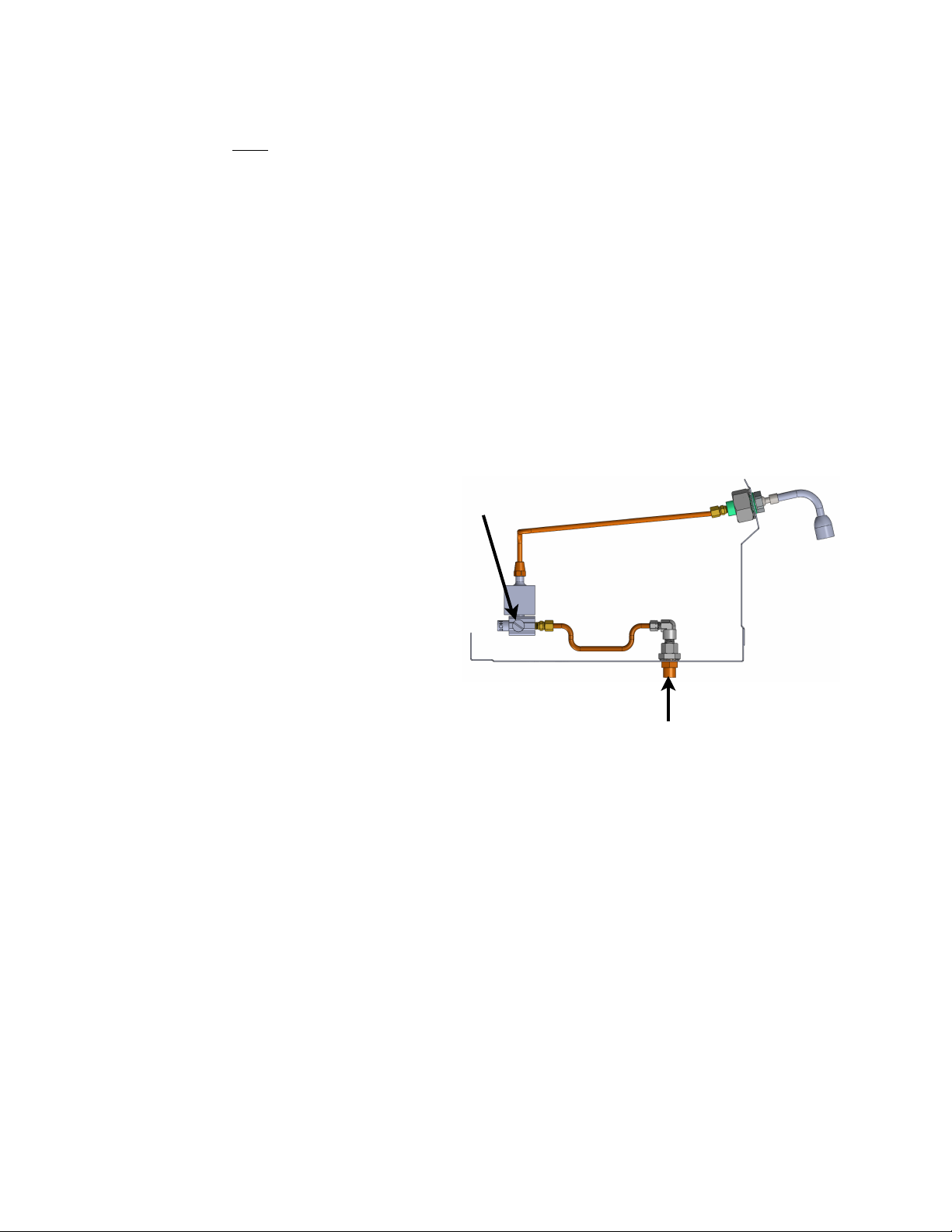

1. Use the shorter, 40”x3/8” braided hose to connect the water treatment

system outlet to the pump inlet.

2. Use the longer, 60”x3/8” hose to

connect the pump outlet to the

espresso machine water inlet

(located at the bottom-rear of

the machine).

‣The end with the 90-

degree fitting should

connect to the espresso

machine.

‣Leave steam actuators in the

“on” positions for “Step 8: Turn

on Heating Elements”.!

12

Outlet to

Inlet from

Step 4B: Connect Water Line

For machines with hot water

IMPORTANT: Before connecting a water treatment system to your espresso

machine, rinse the system by running water through it for at least two (2) minutes.

Failure to follow this step will result in equipment damage. Read the Water

Treatment Requirements on pages 6-7 for information about avoiding and

addressing water-related issues.

Parts and tools:

•40”x3/8” braided stainless steel hose

•Two (2) 60”x3/8” braided stainless steel hoses (with 90-degree fittings)

•Wrench

Procedure:

1. Use the shorter, 40”x3/8” braided hose to connect the water treatment

system outlet to the pump inlet.

2. Use one of the longer, 60”x3/8” hoses to connect the pump outlet to the

espresso machine water inlet (located at the bottom-rear of the machine).

‣The end with the 90-degree fitting should connect to the espresso

machine.

3. Use another of the longer, 60”x3/8” braided hoses to connect the T-fitting on

the pump to the hot water mix-valve inlet on the espresso machine (located

near the drip tray).

‣The end with the 90-degree fitting should connect to the espresso

machine.

‣Leave steam actuators in the “on”

positions for “Step 8: Turn on Heating

Elements”.

13

Inlet from

Outlet to

Outlet to

Hot Water

Step 4C: Adjust Hot Water Temperature

For machines with hot water

Parts and tools:

•Flat-head screwdriver

Procedure:

1. Remove the cup tray.

2. Use a large, flathead screwdriver to remove the two top and one lower rear

screws from the x-leg, then lift to remove the left rear side panel.

3. Use the adjustment needle-valve to regulate the amount of cold water that

mixes with the hot water.

‣Turn counter-clockwise to increase the amount of cold water and decrease

the water temperature.

‣Turn clockwise to decrease the amount of cold water and increase the

water temperature.

‣Leave steam actuators in the “on” positions for “Step 8: Turn on Heating

Elements”.

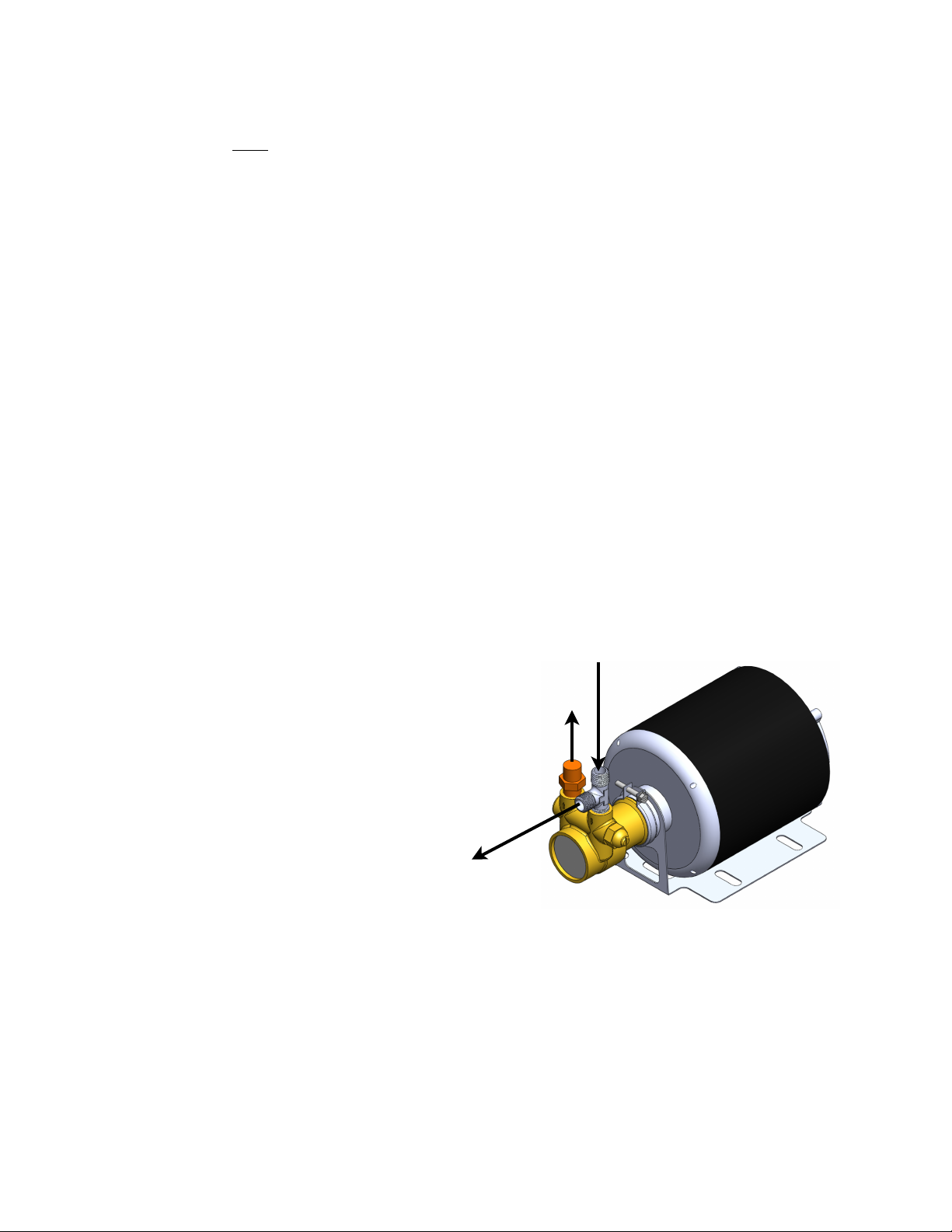

Step 5: Connect Pump

Two (2) electrical cords extend from

outside of your Slayer espresso

machine. The thinner of these cords

has a small, white quick-connect plug.

Insert the quick connect plug into the

matching plug unit on the pump

motor.

Step 6: Connect Machine to Power

IMPORTANT: Before beginning any electrical work on your machine, ensure that

both the red power switch and white heating element switch are in the "off"

position.

Your espresso machine will ship with the power configuration requested at the time

of purchase. Only an electrician or approved technician should wire the power cord

into an appropriately-rated plug end. Once the plug end is attached, insert the main

power cord into an appropriately-rated and grounded receptacle.

Step 7: Fill Tanks

Procedure:

1. Pull one steam actuator forward, into the “on” position, until it stops.

2. Turn on the main water line and red power switch; tanks will begin to fill.

‣Wait to turn on the white heating element switch.

14

Mix-Valve

Inlet for Hot

‣Filling will take approximately and is complete when the pump motor

ceases to work and a “click” is heard.

3. When Slayer has filled completely, move the brew actuators left, into the

“on” positions.

4. When water begins to run from the groupheads, return the brew actuator to

the "off" position.

‣Leave steam actuators in the “on” positions for “Step 8: Turn on Heating

Elements”.

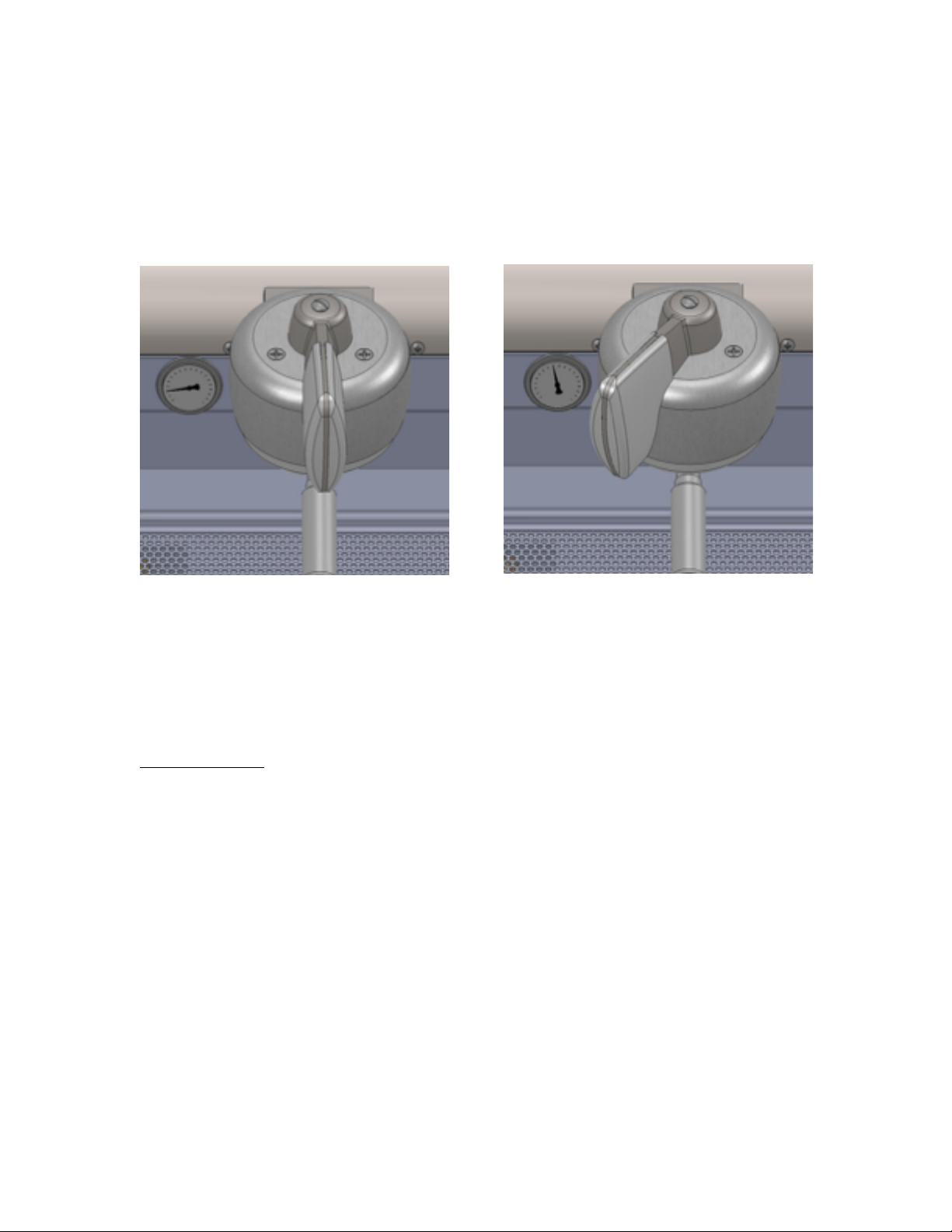

Step 8: Turn On Heating Elements

1. Per step 7, ensure that both steam actuators are pulled forward, into the

“on” positions.

2. Move the white heating element switch to the "on" position by flipping it to

the left.

3. The machine is heated when steam begins to flow from the steam wand; at

this point, move the steam actuators into the “off” positions.

4. Lift to remove cup tray and check the inside of the machine for leaks or

collected water.

5. Allow Slayer to fully heat before use.

15

Factory Settings

Brew Tank Temperature: 93°C (200°F)

Pre-Heat Tank Temperature: 85°C (185°F)

Steam Tank Temperature: 118°C (245°F)

Steam Pressure: 1.5 bar

Flow Rate: 40 grams per 30 seconds

Pump Pressure: 9 bar!

16

Using Slayer

Introductory Brewing Information

Slayer is a unique method for preparing espresso. Familiar processes and variables

may need to be altered when using this machine. Consider the following

generalizations and guidelines when preparing espresso with Slayer.

Roast Profile

Slayer utilizes flow restriction and multiple extraction sequences to permit

“flavor profiling” for individual coffees. Because dark-roasted beans may not

exhibit the full potential of your Slayer, nor the flavorful complexity of your

coffee, Slayer recommends light and medium roasts.

Ground Particle Size

Due to its slower introduction of water, permitted by a precision needle valve,

Slayer is able to brew espresso with coffee that has been ground at extremely

fine settings. Smaller particles reveal more of the coffee’s surface area to water,

thereby allowing the extraction of more flavor-carrying oils. These oils create a

rich, silky mouthfeel, mask bitterness, and increase perceived sweetness. When

setting up your grinder, target a setting that achieves the recommended

beverage yield with the recommended dose weight in the recommended brew

time. Continue reading for recommendations regarding these brewing

parameters.

Dose Weight & Basket Size

During its extended “pre-brew” phase, Slayer saturates the ground coffee puck

to an extent of thoroughness that no other espresso machine can match. As a

result, the coffee puck’s resistance to high pressure and maximum flow is

minimal. In order to achieve adequate extraction time, Slayer recommends

using 19-21 grams of ground coffee in the included portafilter basket. Lighter

doses and/or larger baskets will lead to prohibitively short extraction times and

may cause channeling.

Bed Depth & Tamp Pressure

With most espresso machines, firmly tamping ground coffee is essential to

forming a puck through which water will evenly flow. Due to its slower

introduction of water, Slayer changes the importance of tamping: instead of

tamping to a specific pressure (e.g. 30 lb.), Slayer recommends tamping to a

specific depth in order to achieve the adequate headspace between the coffee

puck and the shower screen. This space allows the coffee to release gas and

bloom before brewing. To ensure consistent results, target a tamp depth that

levels the top of the tamper piston with the top of the portafilter basket

(approximately 10 mm).

Brew Time

With most espresso machines, extraction should last 25-30 seconds. Due to its

slower introduction of water, Slayer may brew espresso in 40 seconds or more.

Begin by targeting a 45-second (20s pre-brew + 25s brew) extraction time.

17

Preparing Espresso

Slayer’s brew actuator allows for three positions: "off", “pre-brew", and "full brew".

The grouphead is in the "off" position when the brew actuator is moved all the way

right. The "pre-brew" setting is activated when the actuator is moved to the middle

of the group. "Full brew" is achieved when the actuator is moved all the way left.

The following guidelines represent a good starting point when first using Slayer.

Coffee is a complex food item that differs from variety to variety, farm to farm, and

even seed to seed. Changes in brewing variables – including grind, dose,

temperature, flow rate, time, etc. – affect all coffees uniquely.

Standard Shot

The procedure for brewing a standard shot is similar to that for other espresso

machines:

1. Remove the portafilter from the grouphead and wipe the basket with a

clean, dry towel.

2. Set the grind to the same degree of coarseness as you would for another

espresso machine.

3. Grind and dose 19-21 grams of coffee into the portafilter.

4. Tamp coffee to approximately 30 pounds of pressure, briefly flush group,

then lock the portafilter into the grouphead.

5. Move the brew actuator directly to the "full brew" position.

6. Allow the espresso to brew until the preferred extraction has been

achieved (when blonding occurs, when the desired beverage yield has

dispensed, or when the desired brew time has elapsed), then move the

actuator to the "off" position.

7. Remove the portafilter from the grouphead and knock out spent coffee.

Wipe the portafilter with a clean towel to remove grounds and oil.

18

Full-brew position

Pre-brew position

8. Briefly move the brew actuator to the "full brew" position to purge

grounds and oil from the dispersion screen. Move the grouphead to the

"off" position and return the portafilter.

"Slayer Shot"

To brew a "Slayer shot", ensure that the flow rate is at the desired setting and

the grinder is set finer than normal, then:

1. Remove the portafilter from the grouphead and wipe the basket with a

clean, dry towel.

2. Grind and dose 19-21 grams of coffee into the portafilter.

3. Tamp the ground coffee to a depth of approximately 10mm, briefly flush

group, then lock the portafilter into the grouphead.

4. Move the brew actuator into the center of the grouphead to activate pre-

brew.

5. Pre-brew times will vary based on the dose, grind, flow rate, brew

temperature, and characteristics of the coffee. The average Slayer pre-

brew takes approximately 20 seconds. Watch the bottom of the portafilter

basket shot mirror to see when the coffee puck becomes fully saturated.

6. The fully saturated portafilter basket will begin to drip. Immediately

before espresso starts to flow consistently, move the brew actuator to the

"full brew" position.

7. Allow the espresso to brew until the preferred extraction has been

achieved (when blonding occurs, when the desired beverage yield has

dispensed, or when the desired brew time has elapsed), then move the

actuator to the "off" position.

8. Remove the portafilter from the grouphead and knock out spent coffee.

Wipe the portafilter with a clean towel to remove grounds and oil.

9. Briefly move the brew actuator to the "full brew" position to purge

grounds and oil from the dispersion screen. Move the grouphead to the

"off" position and return the portafilter.

Extended Pre-Brew: Enhancing Sweetness

When espresso lacks sweetness, the pre-brew phase may be extended to extract

more of the naturally-sweet oils:

1. Follow "Slayer Shot" steps 1-5 above, but allow the espresso to continue

extracting in the “pre-brew” stage until it has dispensed up to 7 grams

(0.25 ounces).

2. Move the brew actuator to the "full brew" position, then resume "Slayer

Shot" steps 7-9.!

19

Reduced Flow: Muting Acidity

Undesirable acidity can be softened by moving the actuator back to the middle

position at the end of the extraction process:

1. Follow "Slayer Shot" steps 1-6.

2. When the machines dispenses approximately two-thirds of the desired

volume, return the brew actuator to the middle position, then resume

"Slayer Shot" steps 7-9.

”Bumped” Pressure: Increasing Acidity

If more acidity is desired, the full-brew stage can be briefly engaged before pre-

brew:

1. Follow "Slayer Shot" steps 1-3.

2. Move the brew actuator to the "full brew" position until the grouphead

pressurizes (less than 1 second), then quickly return the actuator to the

"pre-brew" position.

‣Engaging “full brew” for longer than 1 second may cause the puck to

choke, extending extraction and resulting in undesirable flavor.

3. Resume "Slayer Shot" steps 4-9, combining instructions for “Enhancing

Sweetness” and “Reducing Acidity”, if desired.

Steaming Milk

Slayer produces powerful steam by combining high pressure with restricted steam

tip holes. Various steam tip options (numbered 0-5) are available to allow the

barista to customize their steaming experience and milk texture.

Steam milk with the following steps.

1. Fill a cold pitcher with the desired volume of fresh milk.

2. Immediately before steaming milk, aim the steam wand toward the drip tray

or into a towel and pull the steam actuator forward to release steam and

purge condensation. Then, turn off the steam wand.

3. Submerge the steam tip in milk and turn on the steam wand.

4. Immediately move the pitcher down to expose the steam tip to the surface of

the milk, incorporating fine air bubbles.

5. When the milk reaches body temperature, submerge the steam tip again,

then tilt the pitcher to form a gentle whirlpool.

6. When the pitcher feels hot, turn off the steam wand.

‣The final milk temperature should be 65-68ºC (150-155ºF).

7. Wipe the steam wand with a damp cloth, removing all milk residue, then

briefly turn on the steam wand to purge milk from the wand.

20

Other manuals for Single Group

1

This manual suits for next models

2

Table of contents

Other Slayer Coffee Maker manuals