Slee ERGOTEC User manual

DESIGN &

MANUFACTURING

MADE IN GERMANY

ERGOTEC

WORKTABLE

O P E R A T I N G

M A N U A L

2/16 Manual_Ergotec_2022-10-001.00_EN.docx

Manual_Ergotec_2022-10-001.00_EN.docx 3/16

Content

1Purpose of the device 4

2Symbols 4

3Safety notes 4

4Parts 5

5Specifications 6

6Installation and initial commissioning 7

6.1 Installation 7

6.2 First use7

7Use of the Ergotec workplaces 8

8Errors 11

9Cleaning and maintenance 14

9.1 Cleaning 14

9.2 Recommended maintenance and service schedule 14

10 Service 15

11 Warranty 15

12 DisposaL 15

4/16 Manual_Ergotec_2022-10-001.00_EN.docx

1Purpose of the device

Workplaces must increasingly meet good ergonomics. The Slee ergonomic worktables comply with good ergo-

nomics using electrically height-adjustable parts. The height adjustment can be stored electronically and can eas-

ily be recalled, allowing the user to easily adjust the desired working height.

2Symbols

Hazards and situations, where caution is required, are marked by this symbol.

Special instructions regarding the operation of the device are indicated with this

symbol.

Mechanical components that can lead to injury during use are marked with this

symbol.

3Safety notes

The institution that owns the device and the people who work with it are responsible for safe use.

Manual_Ergotec_2022-10-001.00_EN.docx 5/16

4Parts

Ergotec

Basic table (optional ergonomic cutout)

•

Cooling plate

(optional)

Water bath

(optional)

6/16 Manual_Ergotec_2022-10-001.00_EN.docx

5Specifications

General

Nominal supply voltage 230 V AC +/- 10 %

Nominal frequency 50/ 60 Hz

Power consumption 120 VA

Protection class (1) I

Fuses 1 x T 1 A

Mains cable 1 x 0,75 mm2/ 10 A (C13 / C14)

Pollution degree (1) I

Installation category for over voltage 2

(1) according to IEC 1010, EN 61010

Working temperature +10 up to +35 °C

Relative humidity max. 80 % rel., non-condensing

Storage temperature +5 up to +55 °C

Humidity during storage max. 80 % rel., non-condensing

Maximum weight capacity 400 kg

Dimensions cooling plate 320 x 300 mm

Temperature cooling plate down to -15 °C max.

Power cooling plate 120 VA

Dimensions of the aggregate container

(under the table)

320 x 225 x 180 mm

Dimensions water bath (plate) 250 x 290 mm

Dimensions water bath (bath) 195 x 195 x 60 mm

Temperature range water bath room temperature up to 85 °C

Dimensions of the water bath

(under the table)

242 x 280 x 95 mm

Length drain pipe 85 mm

Manual_Ergotec_2022-10-001.00_EN.docx 7/16

6Installation and initial commissioning

6.1 Installation

The device must be placed on a flat, vibration-free surface.

Connect the mains cable.

6.2 First use

Initialize the control box by pressing and holding simultaneously. The columns move down-

wards until they have reached the mechanical stop and then switch off. Now release the buttons. The control

box beeps three times to indicate that the initialization has been completed. The table is now ready for use.

There is a risk of crushing when changing the table height.

8/16 Manual_Ergotec_2022-10-001.00_EN.docx

7Use of the Ergotec workplaces

Turn the table on.

Set the table height manually:

Press , to raise the table.

Press , to move the table down.

The columns move as long as the button is pressed.

Save table heights:

Set the table with the / buttons.

The table height is shown in the display.

Press 3 x M to enter memory mode.

Then press M1, M2 or M3 within ± 5 seconds to save the setting.

The control box beeps to indicate that the setting has been completed.

Recalling stored height settings:

Press M1, M2 or M3 until the set position is reached.

There is a risk of crushing when changing the table height.

Manual_Ergotec_2022-10-001.00_EN.docx 9/16

Use of the cooling plate:

Turn the cooling plate on.

The display will now flash for a few seconds and then show the current room temperature.

The cooling plate will now be cooled down to the set temperature.

Setting of the desired temperature:

To set the desired temperature press the SET button two times in quick succession.

The set temperature will be displayed and can be adjusted within 5 seconds.

Adjust the temperature by pressing or .

Confirm the new setting by pressing SET twice.

As the cooling plate cools down, a blue “❆“ is shown on the right upper corner of the display.

10/16 Manual_Ergotec_2022-10-001.00_EN.docx

Use of the water bath:

Turn the water bath on.

The display will flash for a few seconds and then show the current room temperature.

The water bath will now heat up to the set temperature.

Setting the desired temperature:

To set the desired temperature press the SET button two times in quick succession.

The set temperature will be displayed and can be adjusted within 5 seconds.

Adjust the temperature pressing or .

Confirm the new setting by pressing twice.

As the heating element heats up the water bath, a “1” is shown on the left bottom of the display.

Manual_Ergotec_2022-10-001.00_EN.docx 11/16

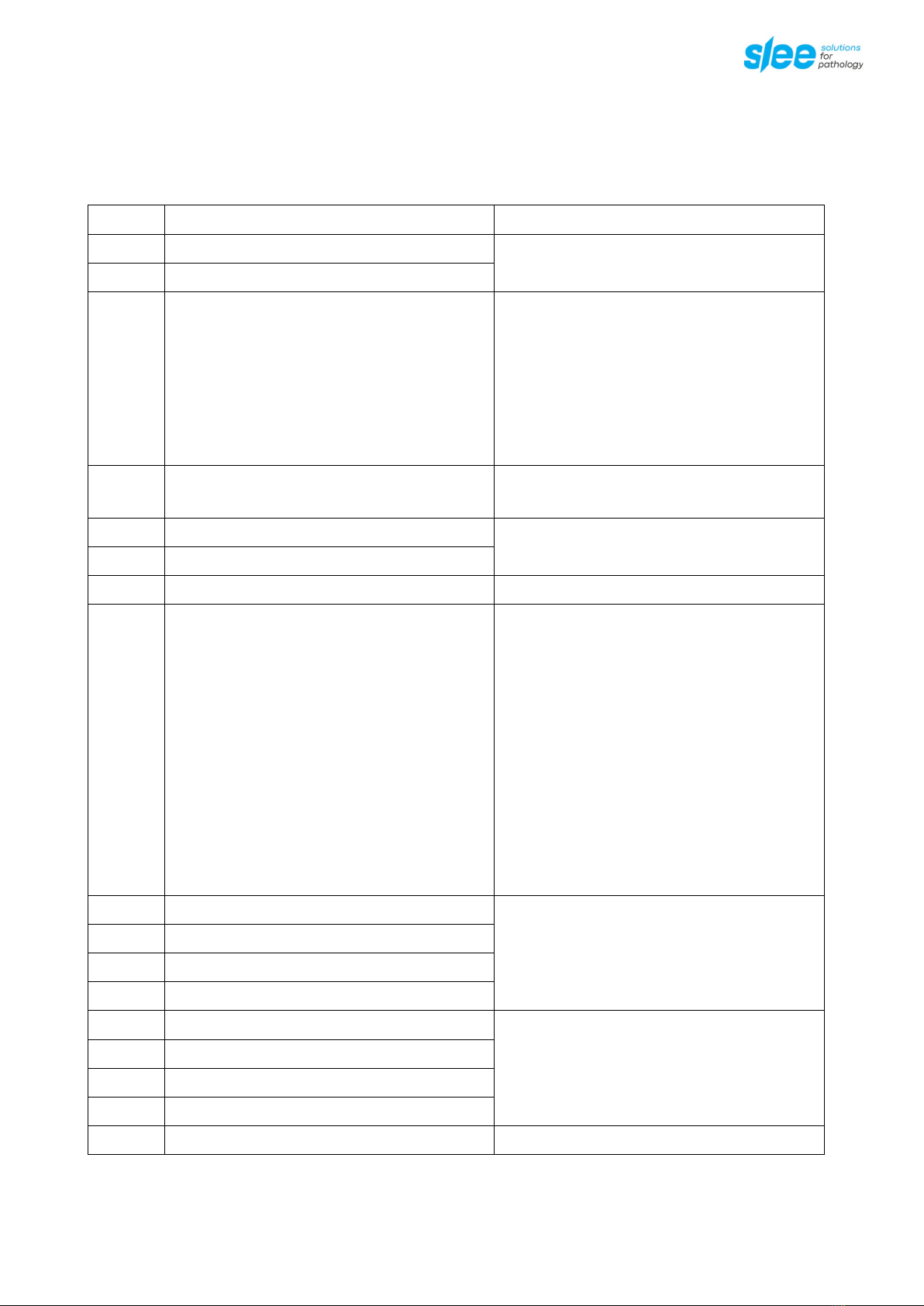

8Errors

Error codes in the display of the height-adjustable table:

Code Description Solution

A0 SC-Reset OK

A63 THD-Display overflow

A64 Forced reset The control box must be reset. Keep the “up”

and “down” keys pressed simultaneously until

the control box gives an acoustic signal. The

table will move to the lowest end position.

When the table reached the lowest position, it

will stop for a second and then move up again

a few cm, to its final stop position.

A65 Child lock activated Deactivate the child lock by pressing the "M"

button for 10 seconds.

A66 (Additional) Manual safety control A second (release) control must be connected.

A67 (Additional) Manual safety control

A69 Contact strip not connected Connect the contact strip.

A6F Motion monitoring The control box has detected an error while

moving the table. The table could be locked.

Remove the obstacle and move the tabletop

up or down for a bit (move into the opposite

direction).

A motor is not connected properly. Check the

connections and perform a reset: Hold down

the “up” and “down” keys simultaneously un-

til the control box gives an acoustic signal. The

table moves to the lowest end position. It will

stop for a second and then move up again a

few cm, to its final stop position.

A70 Hall sensor; no signal Consult your supplier.

A71 Hall sensor; wrong direction or engine

A72 Motor is missing / no connection

A73 Motor is missing / no power

A79 Link error 2nd control box Consult your supplier.

A7A Link error 2nd control box

A7B Link error 2nd control box

A7C Link error 2nd control box

AC9 Duty cycle exceeded

12/16 Manual_Ergotec_2022-10-001.00_EN.docx

ACA Overheated The table has been in use longer than permit-

ted. Wait a few minutes.

Afterwards the system is operational again.

A07 Engine(s) overheated

Manual_Ergotec_2022-10-001.00_EN.docx 13/16

Error code concerning the cooling plate and water bath:

If an “E” code appears in the display, the display or the sensor are defective.

Contact your supplier.

Other possible problems with the cooling plate:

The cooling plate does not become

evenly cold.

The condenser can be

clogged.

Make it dust free.

The cooling system is leaking

or blocked.

Contact your supplier.

The cooling plate does not reach the

set temperature

Leak in cooling system

The cooling plate no longer cools at

all

Compressor defective

Other possible problems with the water bath:

The temperature in the water bath

becomes warmer than the set tem-

perature.

Problem with the thermal fuse Contact your supplier.

Defect in the display

14/16 Manual_Ergotec_2022-10-001.00_EN.docx

9Cleaning and maintenance

9.1 Cleaning

The table top should be cleaned regularly with lukewarm water.

The table legs must be cleaned of dust and dirt every six months. This can be done with a dust cloth.

Wear protective clothing and disposable gloves following GLP.

Do not use chemicals to clean the device.

Only use alcohol-based agents.

9.2 Recommended maintenance and service schedule

Daily Remove waste after use.

Weekly Clean the table top.

Semiannually Clean table legs.

Annually The condenser of the cooling plate must be made dust-free (this can be done with a

vacuum cleaner).

Manual_Ergotec_2022-10-001.00_EN.docx 15/16

10 Service

Internal components should only be serviced by technicians authorized by SLEE medical GmbH.

If technical service or spare parts are necessary, please contact your local SLEE medical GmbH distributor. Please

have the following information available:

•complete contact details,

•type of device and serial number,

•location of device and name of user,

•purpose of service call,

•delivery date of the unit.

If it is necessary to return the device, it must be cleaned and disinfected before delivery. It must be returned in its

original packing.

If the device or parts thereof are sent back in a dirty or non-disinfected condition, SLEE medical GmbH reserves

the right to return the parts to the debit of the customer.

11 Warranty

SLEE medical GmbH guarantees that the product delivered has been subjected to a comprehensive quality control

procedure, and that the product is faultless and complies with all technical specifications and / or agreed charac-

teristics warranted.

SLEE medical GmbH guarantees that the device is manufactured under an ISO 9001:2015 and ISO 13485:2016

quality management system.

Unauthorized modification or repair by third party persons will void the warranty.

Only original SLEE medical GmbH spare parts must be used.

Guarantee claims can be put forward only if the device is used according to this manual and for the purpose

described.

Mistakes and errors which occur because of improper use cannot be accepted.

12 DisposaL

The device or parts of the device must be disposed of according to existing local applicable regulations.

LEE medical GmbH • Am Neuberg 14

55268 Nieder-Olm • Germany

www.slee.de

T: +49 (0) 6136 76997-0

www.slee.de LinkedInYouTube Instagram

INS1300GB Manual_Ergotec_2022-10-001.00_EN

Table of contents

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual