Slider Dynamic User manual

1

Click on the orange text for the particular

section you would like to see.

To get back to this page, select the Slider

logo at the bottom of each page.

If you have further questions or need to

order any spare parts, please contact us:

US:

+1 (401) 247-7745i

560 Metacom Ave.

Warren, RI 02910

UK:

0208 749 2292

info@crokeruk.com

19 Acton Park Estate

The Vale, London, W3 7QE

©2014-2015 WaterRower

TABLE OF CONTENTS

Replacing the Chain 02-03

Replacing the Flywheel 04

Replacing the Idler Sprocket 05-06

Cleaning the Flywheel 07

Cleaning the Rails 08

Oiling the Chain 09

Tightening the Bungee 10

Replacing the Bungee 11-12

Replacing the Drive Sprocket 13

Rail Troubleshooting 14

Replacing the Rail Bracket 15

Replacing the Rail Wheels 16

Replacing the Sensor 17

Replacing the Seat Wheels 18

Replacing the Handle 19

Replacing the Foot Strap 20-21

SERVICE MANUAL

2

REQUIRED TOOLS:

ALLEN WRENCH TOOL SET

SCREWDRIVER

1. Unplug Monitor. Remove the monitor cover bolts (4)

using a 3mm allen tool.

BE CAREFUL NOT TO STRIP THE BOLTS, it is

recommended on older machines to use Liquid Wrench

or WD-40, apply pressure and slowly turn as to not strip.

2. Remove the 3mm bolts (6) securing the front cover.

3. Remove top 3mm bolts (2) holding the rear cover.

SLIDER CHAIN REPLACEMENT

4. Pull the bungee chain block pulley up above the

footplate and secure using a screwdriver.

5. Undo the bolt holding the connector end of the chain.

6. Remove the original chain.

7. Remove the chain from the handle end by undoing the

two socket inserts on the rower side of the handle.

8. Pull the U Bolt from the handle.

9. Undo one insert nut and slide the chain swivel end of

the chain off.

10. Attach the new chain.

11. Thread the insert nut and turn until it is equal with the

other side on the U bolt.

12. Insert the U bolt into the handle.

13. Secure the U bolt with the socket insert nuts.

14. Once attached to the handle, place the handle on the

top rails and straighten the chain out.

3

15. Insert the open end of the chain through the plastic

chain faring opening.

16. Thread the chain over the top sprocket, then down to

the second drive sprocket on the flywheel drive shaft.

17. Thread the chain over the large plastic pulley, then down

towards the footplate.

18. Insert the chain around the small pulley on the bungee/

chain block.

19. Thread the chain back up and over the small idler pulley

then back down to the chain/bungee block pulley.

20. Holding the chain, insert one chain clip into the two

end links on the chain. Insert the other chain clip in the

opposite direction of the same two links the first chain

clip is attached to.

21. Thread the bolt through the connector plate and tighten

the nut.

22. Pull the handle to make the bungee/chain block plate

move up, and remove the screwdriver that was securing

the block in place.

23. Check that the chain is running smoothly and correctly

around all sprockets and pulleys. Use the threading

procedure picture as a guide.

24. Replace all covers and reattach monitor cable.

SLIDER CHAIN REPLACEMENT

4

REPLACING THE FLYWHEEL

REQUIRED TOOLS:

17 MM WRENCH (2)

PHILIPS HEAD SCREWDRIVER

MALLET

1. Take screws (4) out of the Flywheel Cover, Remove Cover

2. Using both 17 mm wrenches, loosen the flywheel bolt.

3. Loosen flywheel nut, take off spacer and nut. and remove

flywheel. If the flywheel won’t come off, put the nut back

on the end of the shaft and tap the nut with the mallet.

This will loosen the flywheel, and allow you to remove it.

4. Replace with new flywheel. You may need to tap on the

opposite side of the shaft for it to slide on all the way.

Take the spacer and nut and put back on the shaft.

5. Tighten bolts on both sides of the shaft. Take a few

strokes to check that is not too tight. If it is too tight,

the chain won’t recoil properly.

6. Put flywheel cover back on and put the screws back in.

5

REPLACING THE IDLER SPROCKET ASSEMBLY

REQUIRED TOOLS:

(2) 4MM ALLEN KEYS

3MM ALLEN KEY

VICE GRIPS OR PLIERS

CLOTH

1. To release bungee pressure, stand the machine up and

unclip bungees from the axle. Clip on the safety bungee

bracket (or tie off so they don’t slip into the machine).

2. Use 4mm Allen wrench to remove plastic cover (4 bolts).

3. Take 3mm Allen wrench (you may need to tap with a

mallet) and loosen the bolts on the monitor cover and

the front cover. Be careful not to strip - turn slowly with

pressure or apply WD-40/ Liquid Wrench.

6

REPLACING THE IDLER SPROCKET ASSEMBLY

4. Take bungees and chain and move to the sides of the

body. (use a tool or cloth to keep it off your paint)

5. Use two 4mm Allen wrenches on either side of idler

sprocket assembly to loosen. Once loose, take the

assembly out.

6. Put replacement assembly in. Tighten with 4mm wrench

on either side of the axle.

7. Move bungees and chain back to pulley system and put

covers back on.

8. Tighten all the covers and clip bungees back to the

Bungee/Chain Block axle.

9. Oil chain to smooth out and quiet the new sprocket

system.

7

CLEANING THE FLYWHEEL

TOOLS NEEDED:

PHILLIPS SCREWDRIVER

VACUUM

1. Take screws (4) out of the Flywheel Cover.

2. Remove Flywheel Cover

3. Use a vacuum to clean out any dust and dirt.

4. Replace the cover and screws.

8

CLEANING THE RAILS

TOOLS NEEDED:

CLOTH

MULTI-PURPOSE CLEANER

1. With a mild, multi-purpose cleaner, clean tracks and

wheels inside the rails.

2. Clean seat wheels.

3. If machines are receiving excessive use, clean daily.

9

OILING THE CHAIN

TOOLS NEEDED:

CLOTH

OIL

1. Pull chain out to the finish position and slowly retract

back while oiling with cloth. Do this from under the

chain so it does not drip on the machine or your floor.

2. Oil the full length of the chain.

3. Row 250 meters to spread the oil out to the rest

of the chain.

4. This should be done only a few times a year based on

use (otherwise the oil can build up in the gears).

10

TIGHTENING THE BUNGEE

NO TOOLS NEEDED

1. Lock the Slider and stand it up.

2. Take one bungee clip off of the axle.

3. Pull bungee towards the larger opening in the keyhole to

loosen (or ‘unlock’). Pull 2 inches through, then tighten

towards the narrow keyhole to lock into place. Clip back on

bottom pulley axle (flat side to machine body).

Repeat steps for opposite side.

Make sure both clips are back on the axle.

Slowly lower machine, unlock the plate and row.

If it still feels loose repeat above steps.

4. You may need to cut off any excess bungee. If the

bungee appears frayed or does not give ample tension

after tightening, it is time to replace your bungee.

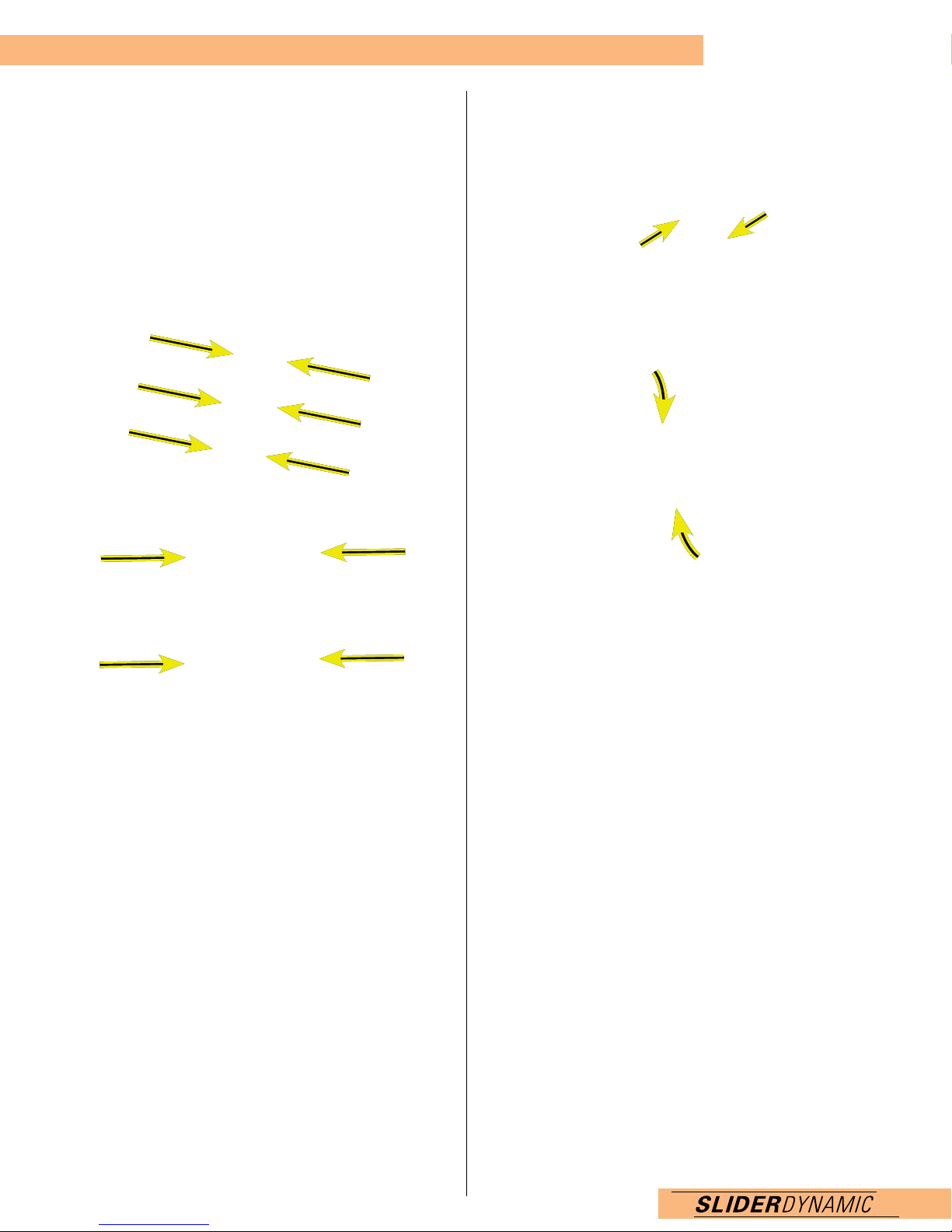

2. pull through

two inches

3. lock into place

1. pull down to unlock

11

REPLACING THE BUNGEE

TOOLS NEEDED:

3MM ALLEN WRENCH

4MM ALLEN WRENCH

1. Lock the machine.

2. Take the 6 bolts off the front cover off using 3mm

Allen wrench. Take the black cap off using a 4mm

Allen wrench.

3. Stand machine up.

4. Take note of how the bungees are wrapped and parallel

(not crossed) before taking out old bungee.

5. Unhook bungees, unlock and slide out of hooks.

6. Insert the new bungee in bungee block.

7. Pull tight and line up.

8. Take right bungee piece and tie off on foot straps.

(cont. on next page)

12

REPLACING THE BUNGEE

9. Take left bungee up and around. Feed into machine to

top pulley, then feed it up and around.

10. Place bungee in hook and lock to small side of keyhole

(flat side to the body).

11. Take the right side of the bungee and hook down and

around. Feed into machine to top pulley. Feed downward

and around.

12. Attach the bungee hook to the axle (flat side to body).

Make sure bungees are parallel - if they are crossed

recheck your steps.

13

REPLACING THE DRIVE SPROCKET

TOOLS NEEDED:

PHILLIPS SCREWDRIVER, 3MM ALLEN WRENCH, MALLET,

(2) 17MM WRENCHES, PLIERS

1. With the Slider Flywheel forward, unscrew the 4 Flywheel

screws using a Phillips screwdriver.

2. Loosen the drive axle bolts using 17mm wrenches, then

take bolts off and remove flywheel.

3. Take the back cover off using a 3mm Allen tool, making

sure not to strip bolts. Use WD40 if not easily loosened.

4. Use the screwdriver to hold the chain off of the

drive sprocket.

5. Take a mallet and tap out the drive axle.

6. Unscrew the drive sprocket. You may need, pliers or

vise grips.

7. Put the new drive sprocket on.

8. Tap drive axle back on (making sure the chain can attach

around it).

9. Put the chain on the drive sprocket.

10. Put the flywheel back on, using 17mm wrenches

to attach.

11. Put the flywheel cover back on, screw in the 4 screws

using a Phillips screwdriver.

14

RAIL TROUBLESHOOTING

TOOLS NEEDED:

PHILLIPS SCREWDRIVER

3MM ALLEN WRENCH

MALLET

(2) 17MM WRENCHES, PLYERS

If your rails are not traveling back and forth:

Check that the rail brackets are not bent or loose.

If they are bent, take off the bracket, try to straighten it out

and put it back on.

Row to see if the rails are corrected. If unable to straighten,

call customer support @ 800-455-9022 for a replacement.

If the brackets are not bent, clean the wheels and check that

they are spinning properly.

15

REPLACING THE RAIL BRACKET

TOOLS NEEDED:

5MM ALLEN WRENCH

PARTS NEEDED:

SKID BRACKET, L BRACKET, BOLTS

1. Remove the 5mm bolts from the bracket and skid strip.

2. Align the rectangular skid bracket on the top rail.

3. While holding the skid bracket, place the L bracket on

top and align holes. Place each bolt in, hand tighten

first, then tighten with a 5mm Allen wrench.

16

REPLACING THE RAIL WHEELS

TOOLS NEEDED:

5MM ALLEN KEY

10MM WRENCH

1. Remove the rear base rail end caps.

2. Remove the bumpers.

3. Slide rail back until wheels are exposed.

4. Using a 5mm Allen Key and a 10mm wrench, remove

the wheels.

5. Assemble the wheel (spacers on the outside and punch

through the middle).

6. Insert the wheel from underneath the top rail.

7. Slide the bolt through the wheel, knocking the punch out.

8. Screw the nut onto the bolt. Tighten with wrenches.

Make sure the wheel can spin (the thread of the bolt

needs to come past the nut to lock).

9. Repeat the above steps on the other side. Return the

bumpers and covers.

10. Replace the front wheels. Remove the front base rail

covers and bumpers and slide the machine forward so the

wheels are accessible.

11. Repeat Steps 4-9

12. Your Slider’s wheels should now be replaced. Test row to

make sure rails are sliding properly.

wheel

spacer (both sides)

punch

17

REPLACING THE SENSOR

TOOLS NEEDED:

3MM ALLEN WRENCH

PHILLIPS SCREWDRIVER

SMALL PHILLIPS SCREWDRIVER

17MM WRENCH

1. Take a 3mm Allen wrench and loosen top back cover

bolts (2) and remove. Slide cover open.

2. Take flywheel cover off using a Phillips Screw Driver.

Using a 17mm wrench, loosen flywheel bolt. Remove bolt

and flywheel.

3. Take small Phillips screwdriver and unscrew the sensor

and peel off. Look inside the machine and open the tabs

that hold the cable. Remove the sensor and cable.

4. Replace with new sensor plug in the back of the monitor.

Run through the tabs inside the machine and out of the

hole by the flywheel. Peel off the cover so the sticky

adhesive is exposed, line up with screw hole and stick.

5. Tighten sensor screw.

6. Replace flywheel using 17mm wrench. Attach the

flywheel cover using a Philips screwdriver.

7. Attach rear cover. Insert bolts and tighten with a 3mm

Allen key.

18

REPLACING THE SEAT WHEELS

TOOLS NEEDED:

5MM ALLEN KEY

13MM WRENCH

PHILLIPS SCREWDRIVER

1. Remove screws from the rear top rail endcaps and

remove endcaps.

2. Slide the seat off. Using the 5mm Allen key and 13mm

wrench, remove the nut and bolt.

3. Take the old wheel off and put the new one on. Make

sure to put washer on one side of the bolt and the

spacer on the other.

The easiest way to do this is to:

-put the bolt partially through

-put on the washer

-put the wheel on

-partially slide bolt through the wheel (to hold wheel)

-insert the spacer

-push bolt through

4. Screw nut on and tighten until the bolt has passed

the lock nut thread. In order to ensure the wheel spins

freely, be sure not to overtighten.

5. Repeat above steps until all the wheels have been

replaced.

6. Put the seat back on the top rail. Make sure the indent

is towards the back of the machine.

7. Replace the end caps and screws.

19

REPLACING THE HANDLE

TOOLS NEEDED:

5MM ALLEN KEY

1. Use a 5mm allen key and remove handle bolts.

2. Take the U-Bolt out of the handle (be careful that it does

not retract into the machine).

3. Hook on the handle rest.

4. Take the new handle and slide it into U-Bolt,

5. Insert 5mm bolts and tighten.

20

3. Loop the new foot strap through with the buckle part

towards the middle of the footboard. Note the hole in

the foot strap, line up the hole in the strap with the

screw hole in the footboard.

4. Insert the screw through the footboard and hole in the

foot strap.

REQUIRED TOOLS:

7MM WRENCH

PHILIPS SCREWDRIVER

1. Using the 7mm wrench, locate the small nut on the back

of the footboard. Hold the nut with the wrench. Using

the screwdriver, unscrew the middle inside bolt.

2. Remove the screw, bolt and old strap. Place screw

nearby for reuse.

FOOT STRAP REPLACEMENT

Table of contents

Popular Home Gym manuals by other brands

Deltech Fitness

Deltech Fitness DF102 Assembly instructions

Rugged Computing

Rugged Computing Y230 Assembly instructions & owner's manual

Scandika

Scandika Styrke II SF-2472 user manual

CYBEX

CYBEX Jungle Gym 17000 Owner's and service manual

ParaBody

ParaBody 915101 Assembly instructions

Finnlo

Finnlo AQUON COMPETITION manual