Sloan OPTIMA AIR EHD-700 Series Installation instructions

1

Dryer Model

Serial Number

Date Of Purchase

IMPORTANT SAFETY INSTRUCTIONS

OPTIMA AIR™HAND DRYER

EHD-700 SERIES

Sloan Valve Company warrants its Optima Air™Hand Dryer to be made of first class materials, free from defects of material or workmanship under normal use

and to perform the service for which it is intended in a thoroughly reliable and efficient manner when properly installed and serviced, for a period of five years (1

year for special finishes) from date of purchase. During this period, Sloan Valve Company will, at its option, repair or replace any part or parts which prove to be

thus defective if returned to Sloan Valve Company, at customer’s cost, and this shall be the sole remedy available under this warranty. No claims will be allowed

for labor, transportation or other incidental costs. This warranty extends only to persons or organizations who purchase Sloan Valve Company’s products directly

from Sloan Valve Company for purpose of resale.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. IN NO EVENT IS SLOAN VALVE COMPANY RESPONSIBLE FOR

ANY CONSEQUENTIAL DAMAGES OF ANY MEASURE WHATSOEVER.

WARNING: For proper electrical connections, check your local building codes.

Your unit must be installed by a qualied, licensed electrician.

INSTALLATION AND OWNERS MANUAL

CONTENTS OF BOX

LIMITED WARRANTY

Tamper-Proof 5/32” Hex

security bit wrench

Knockout Gasket (Included for

use with White Model only)

Hand Dryer Installation and Owners Manual

MODEL INFORMATION

Code No. 0816863

Rev.1 (11/18)

2

READ AND SAVE THESE INSTRUCTIONS

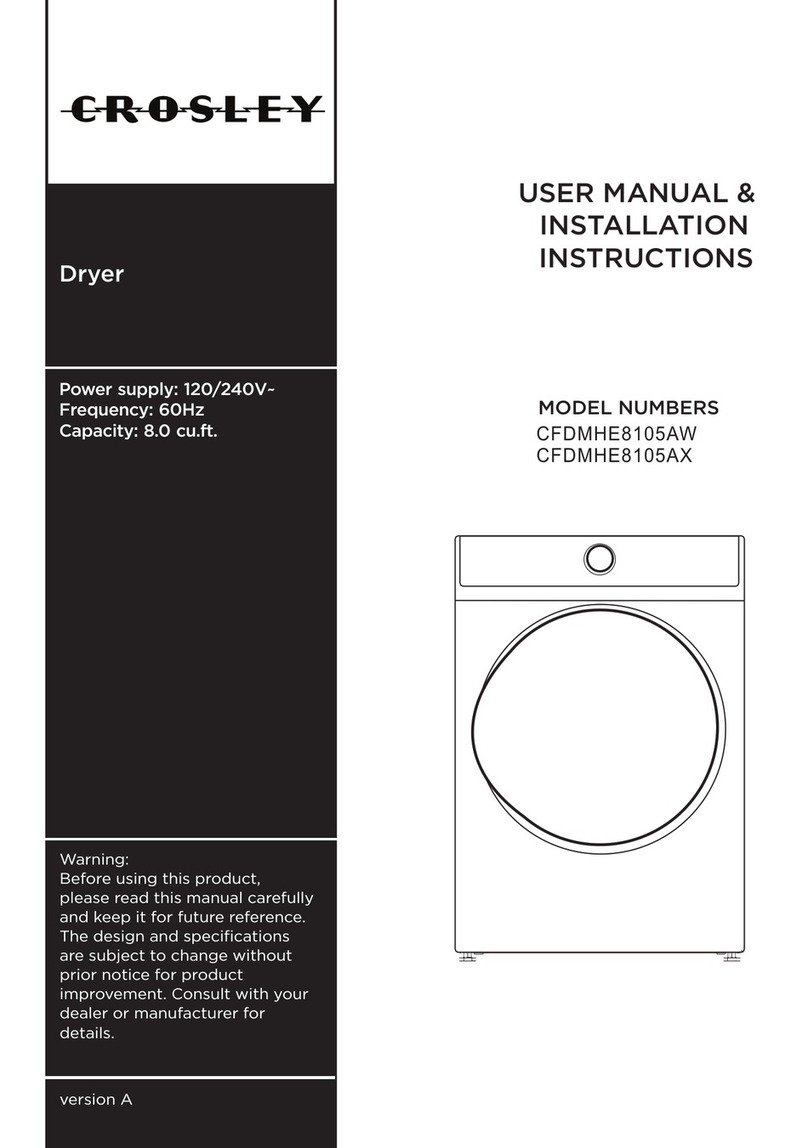

1.Disconnect the power source previously brought to the

hand dryer location (see pre installation wiring above).

2.Use the Tamper-Proof Wrench supplied and remove the

Tamper-Proof Bolt on bottom of cover lifting upwards to

remove cover from base plate.

3.If electrical wiring entry is to be made from the rear,

remove the appropriate pre-formed knockout on the base

plate. FOR WHITE Only - If entry is to be made from the

side, knock out the pre- formed area on the right side

of cover for your supply connection using knockout gasket

provided. A rigid conduit must be used.

4.Select the appropriate mounting height for dryer (Table 1)

and fastener, as recommended (Table 2).

There should be no obstruction between the hand dryer

and the oor. If mounting over a countertop, distance from

counter to dryer must be 15” (381 mm) minimum.

CAUTION: Do not use Base Plate as a guide when

drilling. Make sure no pipe work (gas, water, air) or

any electrical cables or wires are located directly

behind the area to be drilled.

5.Attach Base Plate at the four corners to smooth wall. Use

one of 2 knockouts provided for service entry on back of

Base Plate. If using surface wiring use knockout in right

side of cover. Use Knockout Gasket supplied around

conduit for water seal. See Mounting Details.

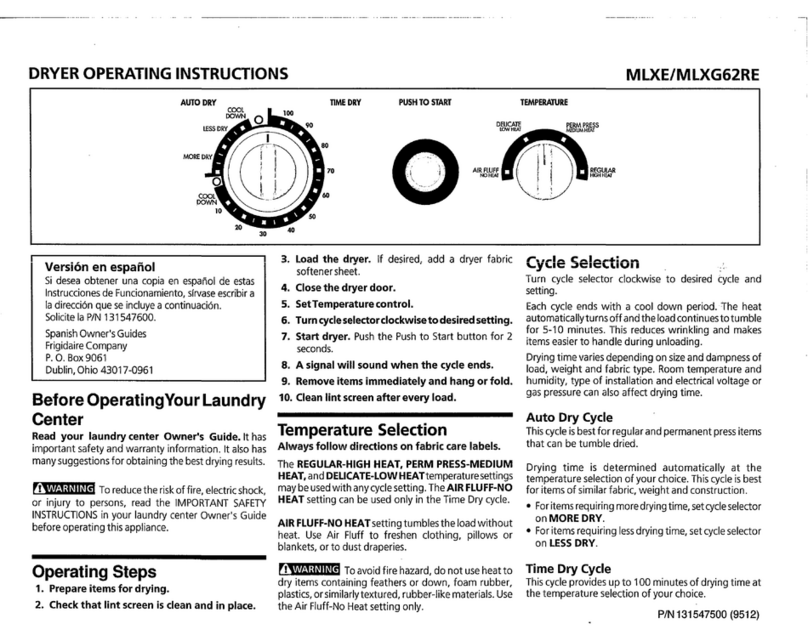

TABLE 1 TABLE 2

SUGGESTED MOUNTING HEIGHT

from oor to bottom of dryer:

Men 45” (114 cm)

Women 43” (109 cm)

Teenagers 41” (104 cm)

Small Children 35” (89 cm)

Handicapped 37” (94 cm)

1MOUNTING HARDWARE

Recommended Fastener (not supplied):

Masonry Wall ½” Expansion Sleeve with ¼” Lag Bolt

Hollow Wall ¼” Wing Type Toggle Bolt

Wooden Wall ¼” Lag Screw With Washer

2

Check that the electrical supply corresponds to that shown-

on the rating sticker of unit. If the dryer is connected to any

electrical supply other than that stated on the rating sticker

ofthe unit, permanent damage or improper, unsafe operation

ofthe unit may result.

•Make sure electricity is switched off at the main panel

before installing, maintaining or cleaning this hand dryer.

Dryer must be installed in accordance with current local

wiring andbuilding regulations.

•Do not wire this hand dryer into the lighting circuit. It must

be protected by an independent circuit.

INSTALLATION INSTRUCTIONS

•Dryer is intended to be permanently connected to power-

supply, and must be properly grounded.

SAFETY

•Troubleshooting and internal maintenance must be

performed by qualied service personnel.

•Do not use any power wash equipment for cleaning on

or near this unit.

•Do not use the dryer for drying hair.

•Do not obstruct air inlets or outlets.

PRE INSTALLATION WIRING

INSTALLATION INSTRUCTIONS

6.Identify the voltage of your dryer from the rating sticker of

the unit. Then connect to a dedicated branch circuit not

exceeding 20 Amp. per your local wiring and building

regulations.

7.Secure electrical wiring to terminals as indicated by

the schematic afxed to blower housing. An identied

ground connection point is supplied on the Base Plate for

your equipment ground wire. Dryers should be installed per

local code requirements.

8.In multiple installations, make sure the serial number

marked on the inside matches the cover number. Then

carefully replace Cover by inserting top of cover over

bracket and tilting downward. Use Tamper-Proof Bolt

previously removed in step 2.

9.Restore power and test for proper operation.

10. Return Tamper-Proof Wrench to owner.

READ AND SAVE THESE INSTRUCTIONS

MOUNTING DETAILS

TROUBLESHOOTING

Dryer does not turn on Dryer blows only cold air

1. Check power to the unit and connections. Verify dryer is

receiving voltage at Terminal Block.

2. Check RED service LED light for the following:

Light is ON – Place hands under Sensor. If light stays on,

then replace Sensor. If light goes off, check to make sure

wiring is correct. If OK, check wire connecting to Motor. If

both are OK, replace Motor.

Light is OFF – Check for loose, disconnected or improper

wiring (See wiring schematic on blower housing) or replace

Control Assembly.

Light is FLASHING – See error codes in CODE chart

Dryer does not Shut Off

1. May be mounted too close to a counter or object (adjust

Sensor range).

2. Check for loose, disconnected or improper wiring at

Control Assembly (refer to wiring schematic afxed to

blower housing.

3. Replace Control Assembly

1. Check heat setting on control.

2. Check for loose connections to Heating Element.

3. Replace Heating Element.

Dryer does not Always turn on, or turns on by itself

1. May be mounted too close to counter or object (adjust

Sensor range).

2. Check for foreign material on Optical Sensor next to Air

Outlet.

3. Check for loose wires on Control Assembly.

4. Replace Control Assembly.

Dryer heats up but no air comes out

1.Check wire connection to Motor.

2.Replace Motor.

Dryer has loss of air volume

1. Check motor speed setting (Labeled “M”) on control. Turn

clockwise to increase.

2. Check for slow running Motor or burning smell. If so,

replace Motor.

3. Check Pre-Filter for lint buildup. Clean by removing

Pre-Filter and rinse in warm water then dry Pre-Filter

before reinstalling.

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

A. Use this unit only in the manner intended by the manufacturer.

B. Before servicing or cleaning unit, switch power off at service panel and lock the service

disconnecting means to prevent power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a prominent warning device, such as a

tag, to the service panel.

OUTSIDE: Gently wash Cover (including air inlet holes)

using a soft cloth or sponge and a mild soap or detergent

with lukewarm water to loosen dirt and grime.

INSIDE: Sloan recommends inspecting the inside of the

dryer and cleaning as required at least once per year, or if

performance diminishes. Heavier usage, or an environment

that contains excessive lint, dust or other particles, requires

more frequent cleaning. Lint on the air inlet, the Pre-Filter,

or other internal parts of dryer will reduce efciency and

shorten the life of the working parts.

TO CLEAN: Shut off power to dryer at service connection.

Uses the Tamper-Proof Wrench supplied and remove the

Tamper-Proof Bolt on bottom of cover lifting upwards to

remove cover from base plate. Gently clean all parts using a

small, soft brush. Unclip the Pre-Filter, rinse with water and

dry. Re-install.

CLEANING / MAINTENANCEMOUNTING DETAILS

3

4

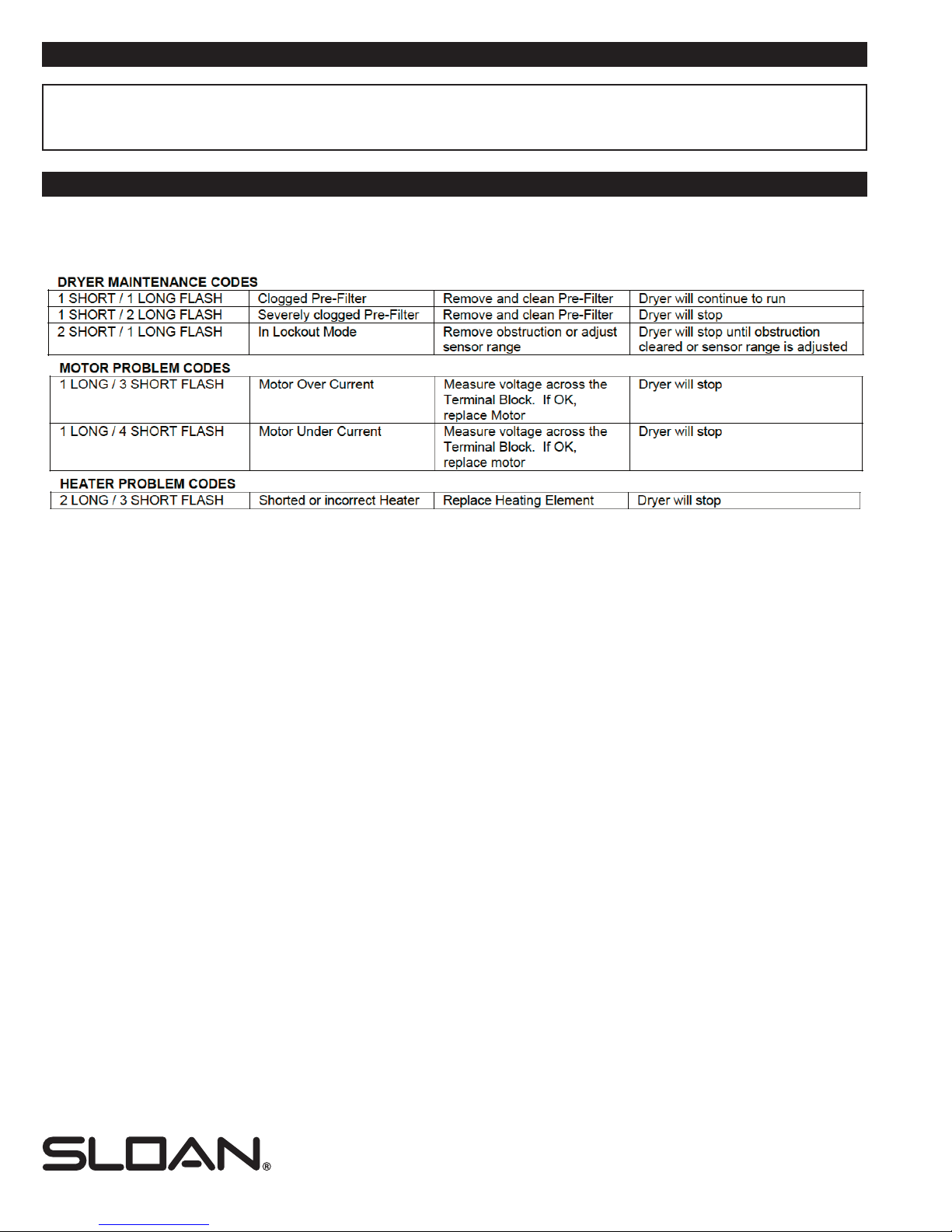

CODE CHART

Codes are displayed by the ashing of the red LED light in the sensor behind air outlet.

Normal operation will be indicated by the red LED being on when not drying and off when hands are under the sensor.

SLOAN VALVE COMPANY • 10500 Seymour Avenue • Franklin Park, IL 60131

Phone: 1-800-9-VALVE-9 or 1-847-671-4300 • Fax: 1-800-447-8329 or 1-847-671-4380

sloan.com

0816863 Rev.1 (11/18)

Copyright © 2018 SLOAN VALVE COMPANY

The information contained in this document is subject to change without notice.

ADJUSTING THE HEAT OUTPUT, MOTOR SPEED AND SENSOR RANGE

The dryer is shipped with maximum heat and maximum motor speed. To adjust, turn the corresponding knob

COUNTERCLOCKWISE to reduce. H = HEAT M = MOTOR R = RANGE

TROUBLESHOOTING (CONT.)

If problems cannot be resolved with the above troubleshooting steps, please call Sloan

at 1.888.756.2614 and one of our trained technicians will be happy to assist you.

4

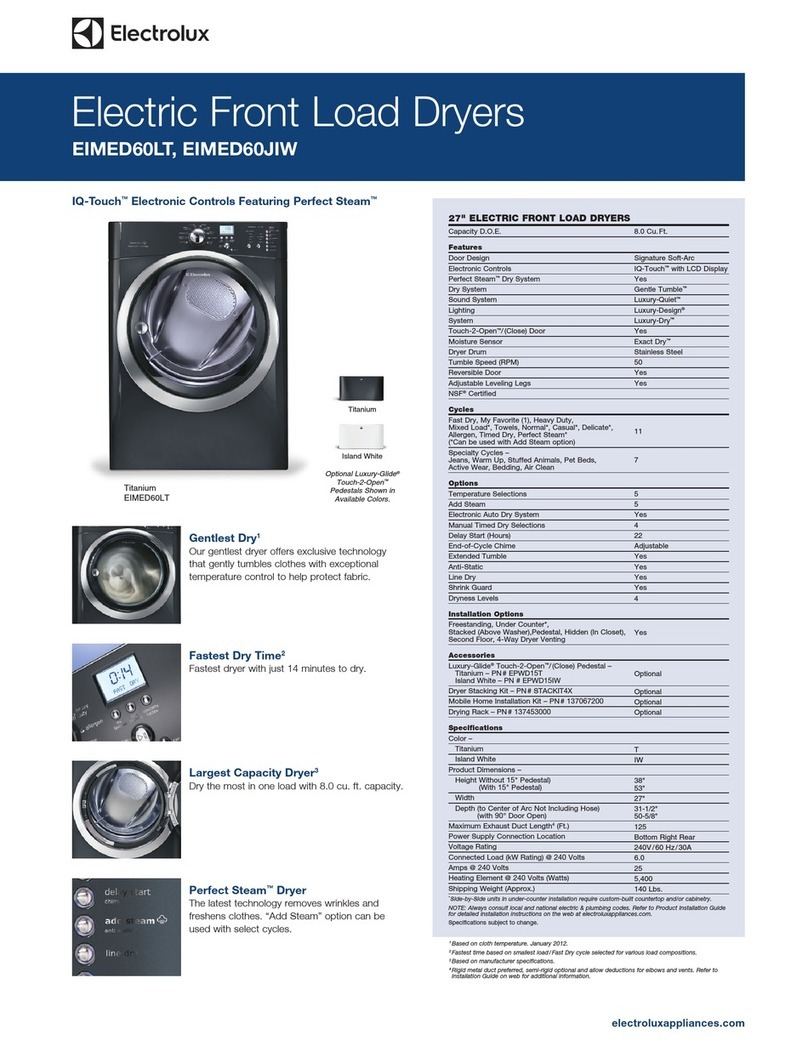

Other Sloan Dryer manuals