Sloan EHD-511 SPOUT User manual

LIMITED WARRANTY

Unless otherwise noted, Sloan Valve Company warrants this product, manufactured and sold for commercial or industrial uses, to be free from defects

in material and workmanship for a period of three (3) years (one (1) year for special finishes, SF faucets, PWT electronics and 30 days for PWT software)

from date of first purchase. During this period, Sloan Valve Company will, at its option, repair, replace, or refund the purchase price of any product

which fails to conform with this warranty under normal use and service. This shall be the sole and exclusive remedy under this warranty. Products must

be returned to Sloan Valve Company, at customer’s cost. No claims will be allowed for labor, transportation or other costs. This warranty extends only

to persons or organizations who purchase Sloan Valve Company’s products directly from Sloan Valve Company for purpose of resale. This warranty

does not cover the life of the batteries.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. IN NO EVENT IS SLOAN VALVE

COMPANY RESPONSIBLE FOR ANY CONSEQUENTIAL DAMAGES OF ANY MEASURE WHATSOEVER.

INSTALLATION INSTRUCTIONS

FOR COMPLETE SLOAN HAND

DRYER SPOUT

Code No. 0816673

Rev. 2 (07/15)

EHD-511 SPOUT

Read this entire installation manual to ensure proper

installation. When nished with the installation, le this

manual with the owner or maintenance department.

Compliance and conformity to local codes and ordinances is

the responsibility of the installers.

Separate parts from packaging and make sure all parts are

accounted for before discarding any packaging material.

If any parts are missing, do not begin installation until you

obtain the missing parts.

Turn OFF electrical power to the electrical outlets, then

unplug all electrical units prior to installation. Electrical

power MUST remain off until installation is complete.

Wear all proper safety equipment prior to installation.

IMPORTANT

TOOLS REQUIRED FOR INSTALLATION

• Slotted screwdriver • Wire stripper/crimping tool

PRIOR TO INSTALLATION

Prior to installing the Hand Dryer spout install the items listed below.

IMPORTANT:

• INSTALL ALL ELECTRICAL WIRING IN ACCORDANCE

WITH NATIONAL/LOCAL CODES AND REGULATIONS.

• INSTALL ALL PLUMBING IN ACCORDANCE WITH

APPLICABLE CODES AND REGULATIONS.

• A 24 VAC STEP-DOWN TRANSFORMER MUST BE USED.

• USE APPROPRIATE PRECAUTIONS WHILE CONNECTING

THE POWER SOURCE.

THIS PRODUCT CONTAINS MECHANICAL AND/OR

ELECTRICAL COMPONENTS THAT ARE SUBJECT TO NORMAL

WEAR. THESE COMPONENTS SHOULD BE CHECKED ON A

REGULAR BASIS AND REPLACED AS NEEDED TO MAINTAIN

THE VALVES PERFORMANCE.

!!! IMPORTANT !!!

If you have questions about how to install your hand dryer, consult

your local Sloan Representative

or call Sloan Technical Support at:

1-888-SLOAN-14 (1-888-756-2614)

2

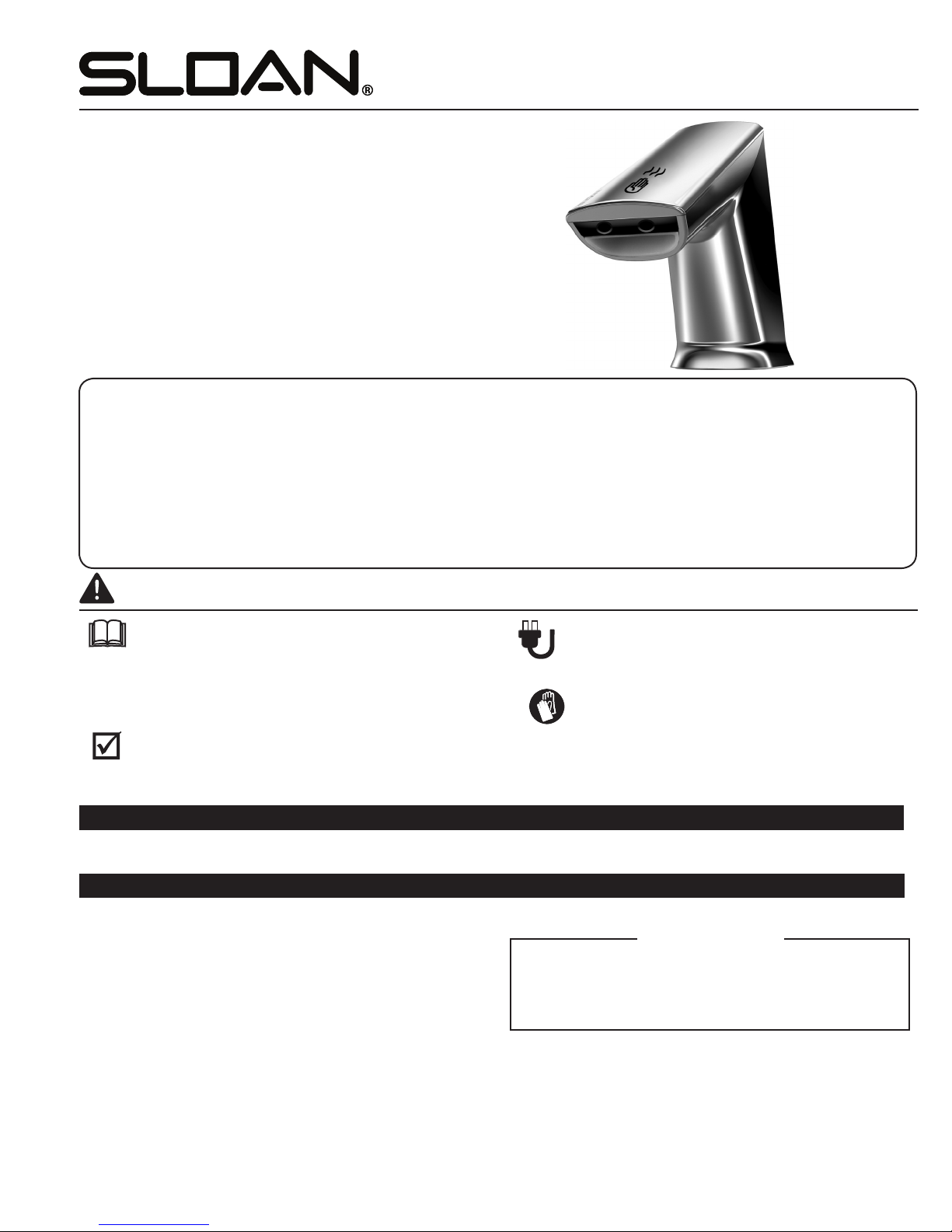

1 - INSTALL SPOUT

HOLDING NUT

A

SSEMBLY

A

B

C

D

A

B

C

D

BASYS DRYER

SPOUT

LOCKING NUT

WASHER

A

B

C

D

BASYS DRYER

SPOUT

LOCKING NUT

WASHER

A

B

C

D

A

B

C

D

A

B

C

D

A

B

C

D

A

B

C

D

Remove holding nut assembly from the spout shank.

Unscrew counterclockwise.

Ensure the wires are located inside corresponding

slots on the sides of the spout shank. Insert spout

shank into the deck hole.

Holding the spout down on the sink deck, Spread wires

away from spout shank, align wires into grooves on

locking nut washer (1). Turn the locking nut until it

makes contact with the wires. Align spread wires in

corresponding relief grooves on top of the locking nut

washer.

(2) Spread the wires horizontally. Turn the locking nut

until snug making sure the wires are in the

corresponding wire relief grooves on the locking nut

washer. Align the spout as desired and tighten the

locking nut until the spout is rmly locked into place.

HOLDING NUT

ASSEMBLY

SPOUT

SHANK

1. 2.

BLOWER MOTOR

4 PIN CABLE

GROUND

PROGRAMMING

CABLE

3

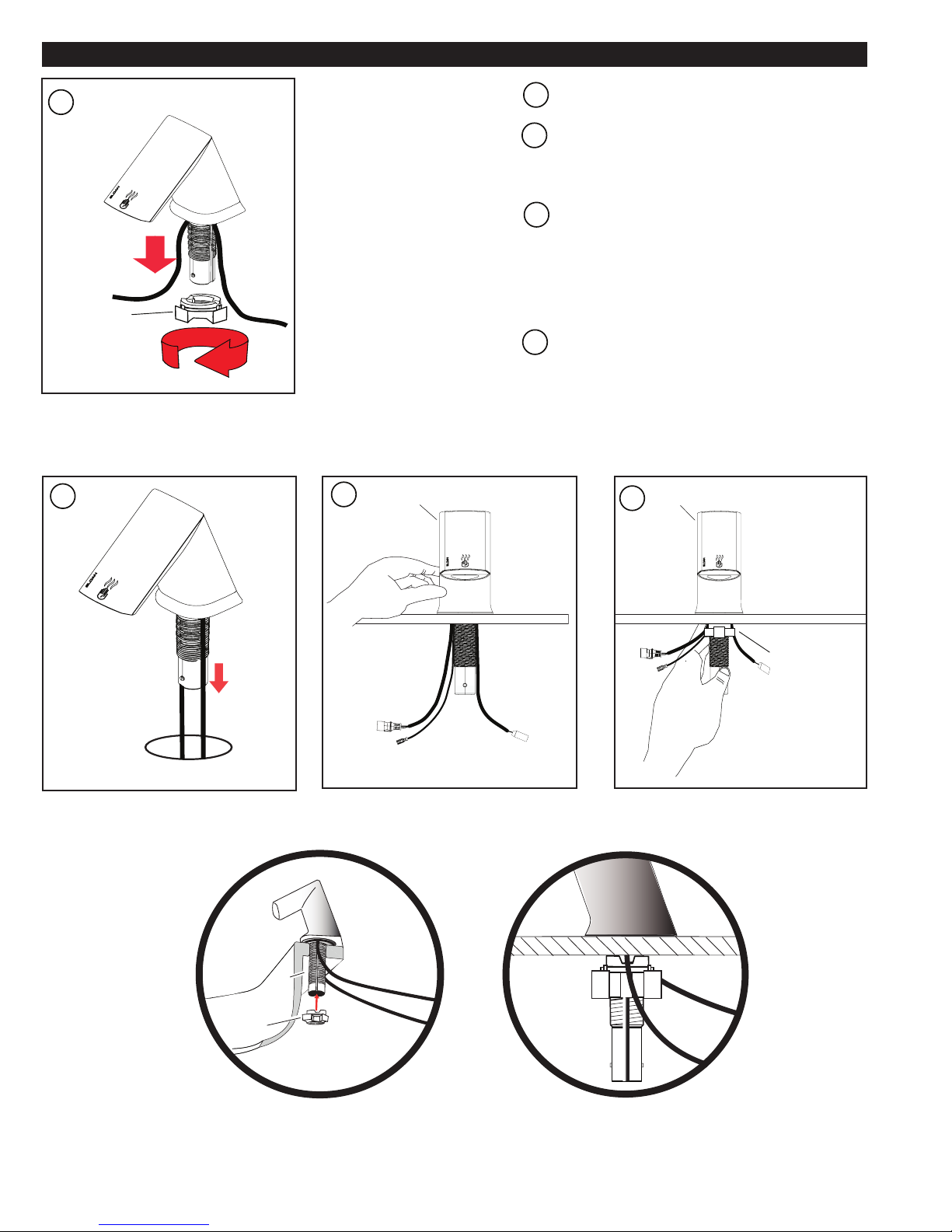

2 - CONNECT HOSE

BASYS DRYER

SPOUT

LOCKING NUT

WASHER

HOSE

SPOUT

SHANK

BLOWER MOTOR

A

B

C

D

A

B

C

D

Align slots in ared connector end of hose with shank guides.

Slide over the spout shank until it stops. Rotate the ared con-

nector clockwise until it locks into place (will feel it snap into

place).

A

B

C

D

A

B

C

D

3- CONNECT WIRES

BLOWER MOTOR

GROUND

4 PIN CABLE

PROGRAMMING

CABLE

A

B

C

D

A

B

C

D

Plug the four (4) pin cable from the spout into

the Four (4) pin socket on the Hand Dryer

Motor. Plug the ground cable into the ground

tab on the Blower Motor.

A

B

C

D

A

B

C

D

Leave the Programming Cable unattached. Do not

remove or cut-off cable. Cord can be bundled.

Align slots of round squared connector end of hose

to opening guides on hand dryer motor into the

opening until it stops, rotate the connector

counterclockwise until it locks into place.

CARE AND CLEANING

Important:

DISCONNECT ELECTRICAL SUPPLY TO DRYER PRIOR TO SERVICING.

Gently wash spout using a soft cloth or sponge and a mild soap or detergent with lukewarm water to loosen dirt and grime.

CLEANING SHOULD BE PERFORMED BY QUALIFIED SERVICE PERSONNEL

With normal use, dryer will require cleaning once a year. Heavier usage requires more frequent cleaning. Use a small, soft

brush to gently clean all parts.

4

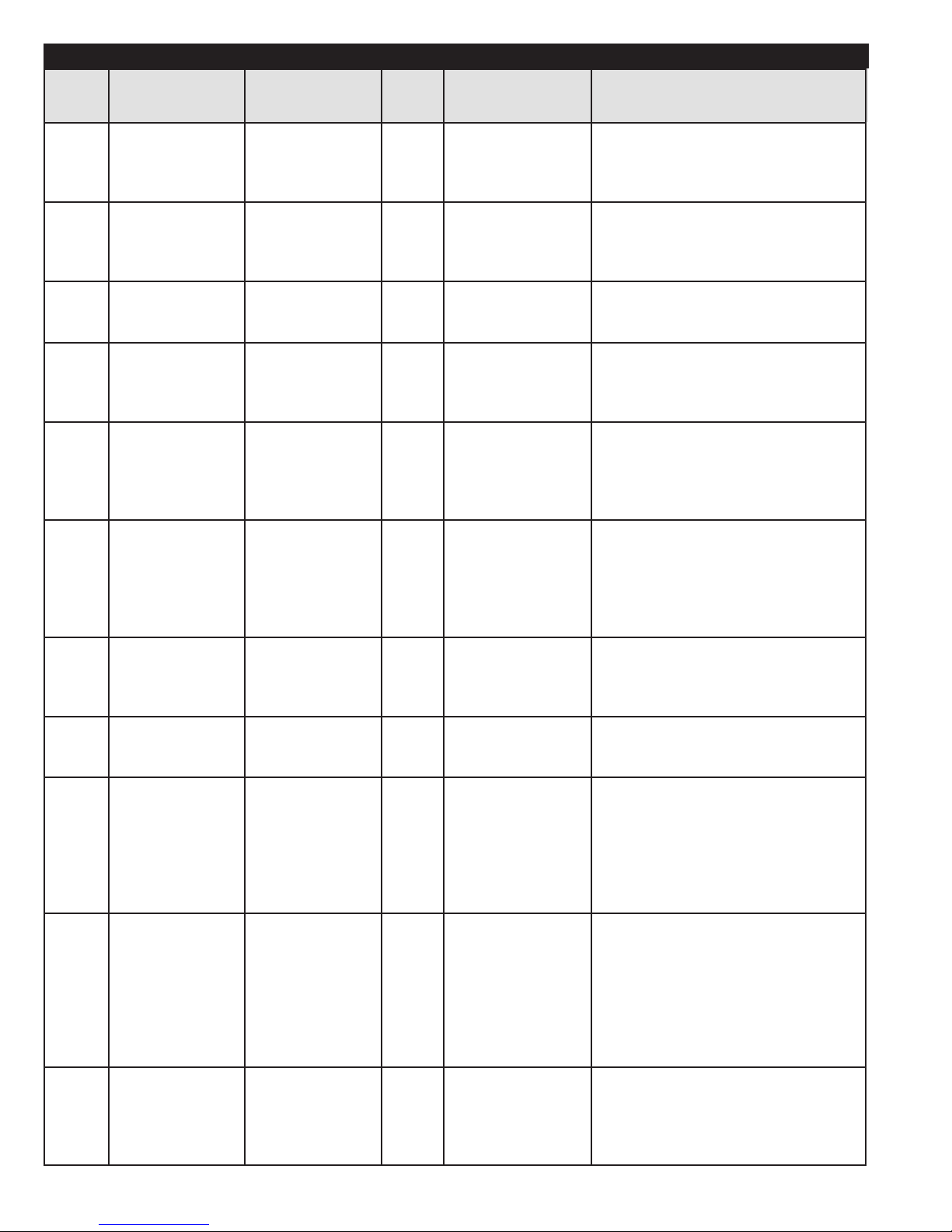

ERROR CODES AND SOLUTIONS

DRYER

STATE

ERROR

MESSAGE

1st FLASH 2nd

FLASH

DRYER

OPERATION

POSSIBLE

SOLUTION

OFF No error or

condition, user absent

No ash, steady OFF

(at dryer box) and No

ash, steady ON

(at spout)

_ Dryer ready for

operation

Normal

ON No error or

condition, user

presenting hands

No ash, steady OFF

(at dryer box) and No

ash, steady ON

(at spout)

_ Dryer running Dryer running while hands are under unit.

Normal

ON Time to clean prelter

or change HEPA Filter

1 Short 1 long Dryer still runs Check and clean prelter. Code should reset

after repowering unit. If code reappears then

HEPA lter may need replacing.

OFF Motor over current

severe

1 long 3 short dryer stops running until

power is removed, fault

has been repaired and

power reapplied

Motor is drawing much more current than

normal. Motor coould be failing. Replace motor.

Call Sloan Tech Support 1-888-756-2614.

OFF Motor quick over

current

1 long 3 short dryer stops running until

power is removed, fault

has been repaired and

power reapplied

Motor drew a quick over current than normal.

Could have been caused by a quick over

voltage condition or something blocking motor.

Motor could be failing. Replace motor. Call

Sloan Tech Support 1-888-756-2614.

ON Heater open condition 2 long 4 short Dryer still runs. Code

clears when power is

removed and fault is

repaired.

Heating element had opened during operation

(thermostat tripped). check for clogged lter,

blocked or kinked hose and blocked mufer.

If problem persists heating element may be

broken or disconnected. Replace or reconnect.

Call Sloan Tech Support 1-888-756-2614.

ON Notication of recent

mains over voltage

3 long 1 short Dryer still runs Dryer had a spike of higher voltage than

normal. Code is for information purposes. Code

will clear if unit power is removed and

reapplied.

ON Notication of recent

mains under voltage

3 long 2 short Dryer still runs Dryer had a spike of lower voltage than normal.

Code is for information purposes. Code will

clear if unit power is removed and reapplied.

Off Mains over voltage in

progress

3 long 3 short Dryer stops running until

mains voltage returns

to a safe level. When

safe level returns, dryer

runs. The code changes

to notication of recent

mains over voltage.

Dryer has unsafe voltage applied. Check

voltage source. Code will reset when voltage is

back to normal.

OFF Mains under voltage

in progress

3 long 4 short Dryer stops running

untill mains voltage

returns to a safe level.

When safe level returns,

dryer runs. The code

changes to notication

of recent mains under

voltage.

Dryer has unsafe voltage applied.

Check voltage source. Code will reset when

voltage is back to normal.

OFF Control Temperature

over temp severe

4 long 3 short Dryer stops running until

power is removed, fault

has been repaired and

power reapplied.

Dryer control is running very hot. Filter clog

may have been disregarded. Check lter and

reapply power. If continues Call Sloan Tech

Support 1-888-756-2614.

SLOAN • 10500 SEYMOUR AVENUE • FRANKLIN PARK, IL 60131

Phone: 1-888-SLOAN-14 (1-888-756-2614) • Fax: 1-800-447-8329 • www.sloanvalve.com

© 2015 SLOAN VALVE COMPANY Code No. 0816673 – Rev. 2 (07/15)

Item Code No. Part No. Description

1. 0366050 EHD-511A BASYS Style Dryer Spout Repair Kit

2. 0366015 EHD-515A Holding Nut Assembly Repair Kit

3. 0366008 EHD-512A Hose and Muffler Repair Kit

4. 0366009 EHD-513A Motor Assembly 110/120V w/HEPA Filter

5. 0366014 EHD-514A HEPA Filter Repair Kit (filter with screen)

PARTS LIST

1

23

4

5

The information contained in this document is subject to change without notice.

If further assistance is required, please

contact Sloan Technical Support at:

1-888-SLOAN-14 or visit us online at:

www.sloanvalve.com

Table of contents

Other Sloan Dryer manuals