Sloan OPTIMA Series Instructions for use

Installation of the Sloan OPTIMA Series Electronic Hand Dryer makes

drying of hands totally “hands-free” providing the ultimate in sanitary

protection and automatic operation. There are no buttons to push. The

OPTIMA series electronic hand dryer uses fiber optic and adaptive

sensingtechnologytosensetheuser’spresenceandactivate.Whenthe

user’s presence is no longer detected, the hand dryer automatically

stops.

The OPTIMA series electronic hand dryer is designed for easy

installation and maintenance, quiet and efficient operation, and years of

dependable, trouble-free service.

The following instructions will serve as a guide when installing the

OPTIMA Series electronic hand dryer. As always, good safety practices

and care are recommended when installing your new hand dryer. If

further assistance is required, contact your nearest Sloan

Representative office.

Made in the U.S.A.

EHD l.l. — Rev. 2 (01/01)

Code No. 0816167

INSTALLATION INSTRUCTIONS AND MAINTENANCE GUIDE

OPTIMA™ SYSTEMS

SENSOR OPERATED SURFACE MOUNTED ELECTRONIC HAND DRYER

Model EHD 120

Sensor Operated Hand Dryer

120 VAC

Model EHD 208/240

Sensor Operated Hand Dryer

208 VAC or 240 VAC

LIMITED WARRANTY

Sloan Valve Company warrants its Electronic Hand Dryers to be made of first class materials, free from defects of material or workmanship under normal use and to

perform the service for whichthey are intended in a thoroughly reliable andefficient manner whenproperly installed and serviced, for a periodof five yearsfrom date

of purchase. During this period, Sloan Valve Company will, atits option, repair orreplaceanypart or parts whichprove tobe thus defective if returned to Sloan Valve

Company, at customer’s cost, and this shall be the sole remedy available under this warranty. No claims will be allowed for labor, transportation or other incidental

costs. This warranty extends only to persons or organizations who purchase Sloan Valve Company’s products directly from Sloan Valve Company for purpose of

resale.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. IN NO EVENT IS SLOAN VALVE

COMPANY RESPONSIBLE FOR ANY CONSEQUENTIAL DAMAGES OF ANY MEASURE WHATSOEVER.

Listed

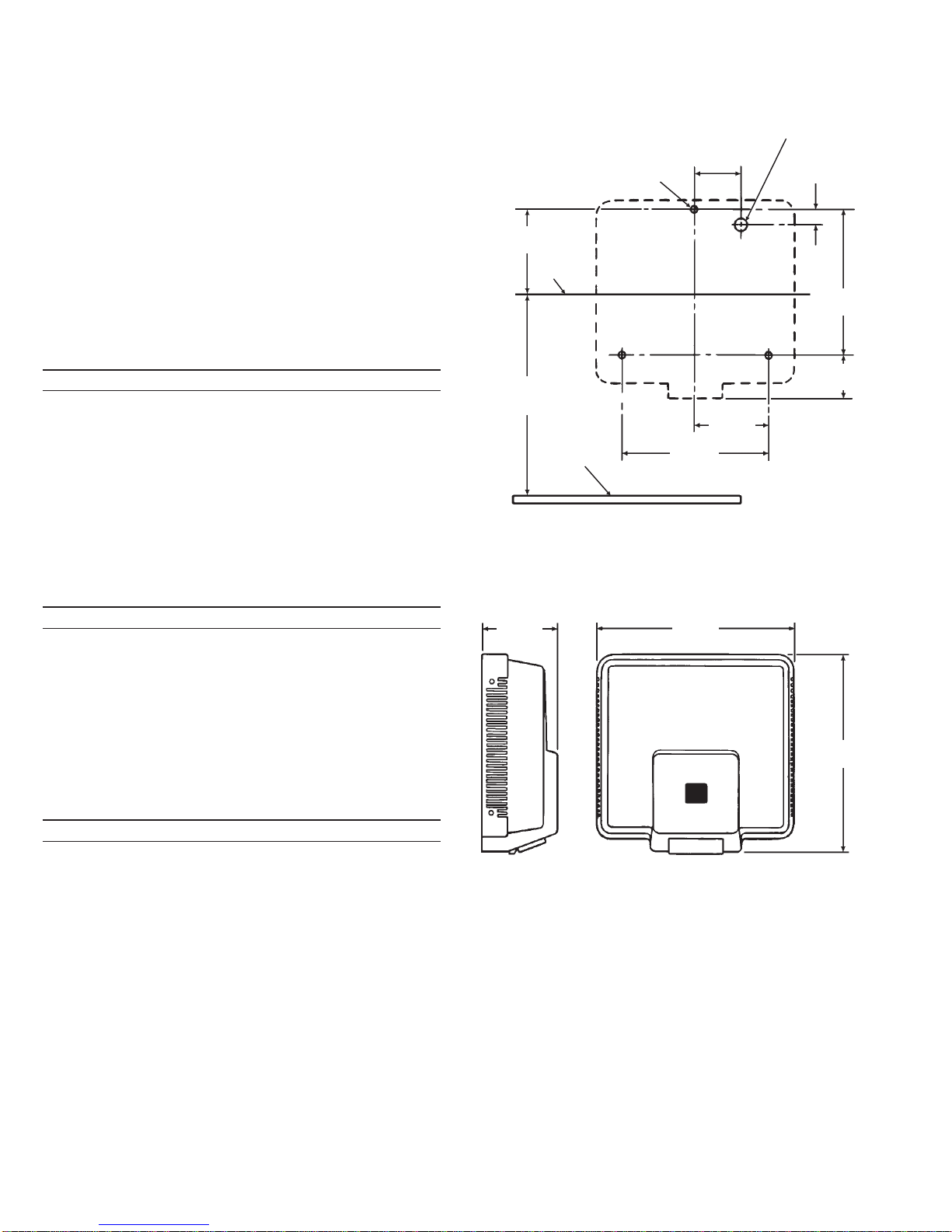

PRIOR TO INSTALLATION

Prior to installing the Sloan OPTIMA Series Electronic Hand Dryer,

determine the location where the dryer will be installed. Read the

following paragraph entitled “Installation Precautions” and then refer to

Table 1 and Figure 1 for recommended mounting heights.

Installation Precautions

•Mounting surface should be smooth and flat.

•Mount dryer at least 24 inches (610 mm) away from basins.

•Mount dryer at least 20 inches (508 mm) away from corners.

•Mount multiple hand dryers a minimum of 20 inches (508 mm) apart,

center to center.

•Avoid installing hand dryers in narrow hallways and behind swinging

doors.

Table 1 — Recommended Mounting Height

Users Height

Men 50 Inches (1270 mm)

Women 48 Inches (1219 mm)

Children 44 Inches (1118 mm)

Handicapped 42 Inches (1067 mm)

Prepare wall to receive mounting fasteners as shown in Figure 1. Refer

to Table 2 for recommended fasteners.

Note: A mounting template is provided to locate fastener positions.

Table 2 — Recommended Fasteners

Wall Type Fastener Type Qty.

Wall board, metal, hollow tile 1/4" Toggle Bolts 3

Stud wall, wood #14 Screws 3 †

Cement, brick, tile #12-14 Anchors 3 †

†Installation hardware provided by Sloan.

Drill a 7/8" (22 mm) minimum diameter hole in wall for electrical

connection. Install electrical line in the location shown in Figure 1.

Table 3 — Electrical Requirements

Model Voltage Amps Hz Watts

EHD 120 120 VAC 20 50/60 2400

EHD 208/240 ‡208 VAC 9 50/60 1870

EHD 208/240 ‡240 VAC 10 50/60 2400

‡Type EHD 208/240 can operate on either 208 VAC or 240 VAC per the

requirements listed.

Note: ConnectHandDryer toa separate 20amp branchcircuitfromthe

nearestelectricaldistributionpanel.UseNo.14gaugeorlargerwirefrom

electrical distribution panel to Dryer.

Important: ALL ELECTRICAL WIRING SHOULD BE INSTALLED IN

ACCORDANCE WITH NATIONAL/LOCAL CODES AND

REGULATIONS.

ROUGH-IN —Figure 1

MOUNTING

HEIGHT

(SEETABLE 1)

3/8" (9.5 mm) DIA.

HOLE (3) PLACES

3/4"

(19 mm)

10"

(254 mm)

LEVELLINE

4-3/8"

(111 mm)

FINISHED

FLOOR

3-1/8"

(79 mm)

7/8" (22 mm) DIA. HOLE

FOR ELECTRICAL

CONNECTION

2-3/4"

(70 mm)

C/L

5-5/16"

(135 mm) 13-3/4"

(349 mm)

13-3/8"

(340 mm)

8-3/4"

(222 mm)

5-1/2"

(140 mm)

USE MOUNTING TEMPLATE PROVIDED

2

INSTALLATION

Step 1 — Mount Chassis to Wall (Figure 1)

String electrical wires through Chassis Assembly and secure Chassis

Assembly to wall using the recommended Fasteners listed in Table 2.

Step 2 — Electrical Hook-Up (Figures 2, 3 and 4)

Becertainthatpowerisdisconnectedatthemainpowersource.Connect

electrical wiring to the Hand Dryer as shown in the appropriate wiring

diagram in Figure 2.

WIRING DIAGRAM —Figure 2

Step 3 — Test Self-Calibration and Operation

Turn on electrical power. The red LED should illuminate for

approximatelythirty(30)seconds.ThegreenLEDshouldthenilluminate,

indicating that the self-calibration procedure has completed and the

Dryer is ready for use. Place hands in the sensor’s detection zone

(beneath the exhaustport oftheDryer). TheDryer shouldstartand emit

apowerful flowofwarmair.RemovehandsfrombeneaththeDryer.The

Dryer should stop.

Step 4 — Install Cover Assembly

Install Cover over Chassis Assembly.Use a 5/32" hex wrench tosecure

using four (4) Tamper-Resistant Cover Screws and Lock Washers.

Note: Do not overtighten fasteners.

POWER

BOARD

ASSEMBLY

TAMPER-RESISTANT COVER

SCREW AND LOCKWASHER —

FOUR (4) REQUIRED

BLOWER

ASSEMBLY

GRILLE

Figure 4

HEATER

ASSEMBLY

WIRING DIAGRAM

LABEL

FIBER OPTIC CABLE

SUBASSEMBLY

FIBER OPTIC

CONNECTOR

CHASSIS

ASSEMBLY

LED INDICATOR

LIGHTS

Figure 3

HEATER

CONNECTION BLOWER

CONNECTION

POWER BOARD

120 VAC

POWER SOURCE

L1 GND

WHT

RED

L2

BLK

WHT

HOT NEU.

THERMOSTAT

HEATER

ASSEMBLY

POWER

BOARD

RED

FIBEROPTIC

CONNECTOR

BLOWER

MOTOR

FIBER OPTIC WIRES

GRILLE

NEU.

CAUTION

1. DISCONNECT POWER

SOURCE BEFORE SERVICING.

2. POWER SOURCE SHOULD BE

PROTECTED WITH FUSE OR

CIRCUITBREAKER.

G

R

N

W

H

T

B

L

K

B

L

K

W

H

T

L2

L1

L1

L2

BLOWER

MOTOR

208/240 VAC

POWER SOURCE

L1

WHT

RED

L2

BLK

WHT

HOT NEU.

THERMOSTAT

HEATER

ASSEMBLY

POWER

BOARD

RED

FIBER OPTIC

CONNECTOR

FIBER OPTIC WIRES

GRILLE

B

L

K

W

H

T

L2

L1

L1

L2

3

SELF-ADAPTIVE SENSING

When thisHand Dryerpowers up,itautomaticallysetsitssensing range

depending on the environment in which it is installed. No mechanical

range adjustment is required.

The OPTIMA Series electronic hand dryer is factory set to operate at a

range of 4 to 11 inches (102 to 279 mm). This range should be

satisfactory for most installations.

OPERATION

The Sloan Electronic Hand Dryer operates by means of an optical

sensorydevice. Thesensorautomaticallyactivatestheunit whenhands

are placed in front of the sensor located at the exhaust port. A powerful

flowof warmairwilldryhandsinapproximately 30secondsand willshut

off automatically when hands are withdrawn, or after 60 seconds of

continuous operation.

1. The OPTIMA/EHD functions by means

of an electronic fiber optic photo-sensor

located at the exhaust port beneath the

Hand Dryer.

2. When hands are placed beneath the

exhaust port, the fiber optic

photo-sensor activates the Hand Dryer

which emits a powerful flow of warm air

to dry hands within 30 seconds.

3. When hands are withdrawn, the Hand

Dryer shuts off automatically. It is then

ready for the next user.

TROUBLESHOOTING GUIDE

FOR NEW EHD HAND DRYER MODELS MANUFACTURED SINCE

JUNE 1999 (MODELS WITH FIBER OPTIC ADAPTIVE SENSOR)

Note:Eachpowerboard hastwo(2)LED’s:agreenpowerindicatorand

a red sensor indicator. Electrical power must be supplied to Hand Dryer

for indicator lights to function.

If none of the solutions shown below works, the power board may

need to be reset; disconnect then reconnect electrical power and

retest.

I. NoairissuppliedwhenhandsareplacedinSensor’sdetection

zone.

RemoveCoverandcheckLEDindicatorlightsonthePowerBoard.

A. If green LED does NOT illuminate:

1. Power is not being supplied to dryer; check all electrical

connections and main power supply.

2. Power Board has failed; replace Power Board.

B. If a green LED illuminates first and then red LED illuminates

when hands are placed in the Sensor’s beam:

1. Blower Motor is not connected properly; check Blower

Motor leads for secure connection.

2. Power Board has failed; replace Power Board.

3. Blower Motor has failed; replace Blower Motor.

C. IfgreenLEDilluminatesfirst,butredLEDdoesNOTilluminate

when hands are placed in the Sensor’s beam:

1. Power Board or PowerBoard detection circuit hasfailed;

replace Power Board.

D. IfonlytheredLEDilluminates(greenLEDdoesNOTilluminate

when hands are removed from the Sensor’s beam):

1. Power Board or Power Board self-calibration circuit has

failed; replace Power Board.

2. OPTIMAFiberOpticCablehasfailed;replaceFiberOptic

Cable.

II. Only unheated air is supplied when hands are placed in the

Sensor’s beam.

A. Heater is not properly connected; check Heater leads for

secure connection.

B. Heater Assembly is defective; replace Heater Assembly.

III. Air cycles intermittently on and off.

A. OPTIMA Sensor blocked or out of position; clear obstruction

and make sure that it is positioned properly in Exhaust Grille.

B. The Power Board’s range feature is not functioning properly;

replace Power Board.

IV. Dryer runs continuously (will not stop).

A. Disconnect OPTIMA Fiber Optic Cable from Fiber Optic

Connector on the Power Board.

1. Ifdryercontinuestooperate, thePowerBoardhasfailed;

replace Power Board.

2. If dryer stops operating, the OPTIMA Fiber Optic Cable

has failed; replace Fiber Optic Cable.

4

TROUBLESHOOTING GUIDE (Continued)

FOROLDEREHDHANDDRYERMODELSMANUFACTUREDPRIOR

TO JUNE 1999

I. NoairissuppliedwhenhandsareplacedinSensor’sdetection

zone.

Remove Cover and check LED indicator light on thePower Board.

A.If LED does not illuminate:

1.Power is not being supplied to dryer; check all electrical

connections and main power supply.

2.Power Board has failed; replace with Sensor/Power Board

Replacement Kit.

B.If green LED illuminates and then turns red when hands are

placed in the Sensor’s beam:

1.Blower Motor is not connected properly; check Blower Motor

leads for secure connection.

2.Power Board has failed; replace with Sensor/Power Board

Replacement Kit.

3.Blower Motor has failed; replace Blower Motor.

C.If green LED illuminates but does NOT turn red when hands are

placed in the Sensor’s beam:

1.OPTIMA Sensor blocked or out of position; clear obstruction

and make sure that it is positioned properly in Exhaust Grille.

2.OPTIMA Sensorhasfailed; replacewithSensor/Power Board

Replacement Kit.

3.Power Board has failed; replace with Sensor/Power Board

Replacement Kit.

D.IfredLED isilluminated butdoesnotturngreenwhenhandsare

removed from the Sensor’s beam:

1.OPTIMASensorislockedonandunithasexceeded60second

time out; reduce range.

2.OPTIMA Sensor blocked or out of position; clear obstruction

and make sure that it is positioned properly in Exhaust Grille.

3.OPTIMA Sensorhasfailed; replacewithSensor/Power Board

Replacement Kit.

4.Power Board has failed; replace with Sensor/Power Board

Replacement Kit.

II. Only unheated air is supplied when hands are placed in the

Sensor’s beam.

A.Heater is not properly connected; check Heater leads forsecure

connection.

B.Heater Assembly is defective; replace Heater Assembly.

III. Air cycles intermittently on and off.

A.OPTIMASensorblockedoroutofposition; clearobstructionand

make sure that it is positioned properly in Exhaust Grille.

B.Range may be too long; reduce range.

C.OPTIMA Sensor has failed; replace with Sensor/Power Board

Replacement Kit.

IV. Unit is difficult to activate.

A.OPTIMASensorblockedoroutofposition; clearobstructionand

make sure that it is positioned properly in Exhaust Grille.

B.Range may be too short; increase range.

C.OPTIMA Sensor has failed; replace with Sensor/Power Board

Replacement Kit.

V. Dryer runs continuously (will not stop).

A.Disconnect OPTIMA Sensor from Power Board. If Dryer

continues to operate, the Power Board has failed. If Dryer stops

operating,OPTIMASensorhasfailed.Ineithercase,replacewith

new Sensor/Power Board Replacement Kit.

If further assistance is required, please contact the Sloan Valve

Company Installation Engineering Department at 1-888-SLOAN-14.

5

4

6

VIEW WITHOUT COVER

8

BOTTOM VIEW OF COVER

9

7

5

2

3

1

Copyright © 2001 SloanValve Company

Parts List —EHD Hand Dryer

Item Part Code Description

No. No. No.

1 EHD-93 0305427 Mounting Hardware (Not Shown)

2 EHD-127 0305438 Lock Washer (4 Required)

3 EHD-17 0305437 Cover Screw (4 Required)

4 EHD-214-A 0305574 Chassis Assembly, 120 VAC

EHD-215-A 0305540 Chassis Assembly, 208 VAC/240 VAC

5 EHD-182-A 0366002 Power Board Assembly, 120 VAC

EHD-183-A 0366003 Power BoardAssembly, 208 VAC/240 VAC

6 EHD-216-A 0305577 Blower Assembly, 120 VAC

EHD-217-A 0305541 Blower Assembly, 208 VAC/240 VAC

7 EHD-11-A 0305401 Heater Assembly, 120 VAC

EHD-14-A 0305543 Heater Assembly, 208 VAC/240 VAC

8 EHD-184-A 0366004 Exhaust Grille/Fiber Optic Cable Sub-Assembly

9 EHD-204-A1 0305709 Cover Assembly, White

EHD-204-A2 Cover Assembly, Black

EHD-204-A3 0305711 Cover Assembly, Almond

EHD-204-A4 0305712 Cover Assembly, Gray

NOTICE:The information contained in this document is subject to

change without notice.

SLOAN VALVE COMPANY •10500 Seymour Avenue• Franklin Park, IL 60131

Phone: 1-800-9-VALVE-9or 1-847-671-4300 •Fax:1-800-447-8329 or 1-847-671-4380

http://www.sloanvalve.com

Printed in U.S.A. 01/01

Table 4 — Power Board and Sensor Replacement Kits †

Production

Dates Voltage

Power

Board

Part No.

(Obsolete)

Sensor

Part No.

(Obsolete)

Sensor/Power

Board Replacement

Kit Part No.

(Code No.) ‡

1986 - 1991 120 VAC EHD-12-A EHD-13-A EHD-1006-A (3366007)

208/240 VAC EHD-65-A EHD-13-A EHD-1007-A (3366008)

1991 - 1995 120 VAC EHD-12-A EHD-234-A EHD-1006-A (3366007)

208/240 VAC EHD-65-A EHD-234-A EHD-1007-A (3366008)

1995 - 1999 120 VAC EHD-1004-A EHD-1003-A EHD-1006-A (3366007)

208/240 VAC EHD-1005-A EHD-1003-A EHD-1007-A (3366008)

†Power Boards and Sensors are no longer available for EHD Hand Dryers

manufactured prior to June 1999. When servicing this older product, both the

Power Board and Sensor must be replaced using the Sensor/Power Board

Replacement Kits listed in Table 4 above.

‡The Sensor/PowerBoard Replacement Kitsinclude Sloan’slatest technology

Power Board Assembly (Item No. 5), Exhaust Grille/Fiber Optic Cable

Sub-Assembly (Item No. 8), Wiringand Installation Instructions.

WHEN SERVICING OLDER SLOAN EHD HANDDRYERS

Sloan Valve Company is dedicated to providing sensor operated

productsthat incorporatetoday’slatestelectronictechnologies.Tokeep

pacewith thesenewtechnologiesitisoftennecessarytomake changes

to our products. Current EHD Hand Dryer Power Boards and OPTIMA

Fiber Optic Sensors will operate in older Sloan EHDHand Dryersif the

following conditions are met:

•Hand dryers built between September 1995 and June 1999 used

Power Board Assemblies EHD-1004-A (120 VAC) and EHD-1005-A

(208/240 VAC) and OPTIMA Sensor Assembly EHD-1003-A. These

unitscanbeidentifiedbyaRangePotentiometerlocatedonthePower

Board.

•Hand dryers built before September 1995 used Power Boards

EHD-12-A (120 VAC) and EHD-65-A (208/240 VAC) and OPTIMA

Sensor EHD-234-A (EHD-13-A if built before 1991). These units can

be identified by a Range Potentiometer located on the OPTIMA

Sensor (NOT on the Power Board).

IF EITHER THE POWER BOARD OR THE OPTIMA SENSOR HAS

FAILED IN AN OLDER UNIT, BOTH COMPONENTS MUST BE

REPLACED.

Note: Hand Dryers built before 1991 included a flashing indicator light

visiblethroughawindowontheHandDryerCover.ReplacementCovers

no longer furnish the indicator light; therefore, disconnect and remove

the light if replacing the Cover or OPTIMA Sensor.

6

This manual suits for next models

3

Table of contents

Other Sloan Dryer manuals

Popular Dryer manuals by other brands

Hotpoint

Hotpoint TVFS 83C instruction manual

Huebsch

Huebsch Alliance Laundry Systems DR7102WE user guide

Frigidaire

Frigidaire FEQ1442CE Factory parts catalog

Electrolux

Electrolux T5675 Service manual

Grundig

Grundig GTN 38250 HGCW User instructions

Bosch

Bosch WTW85480CS Installation and operating instructions