SMAC VLC-ETC User manual

VLC-ETC

USER MANUAL

Version 1.3

2

Disclaimer

The contents of this user manual are intended to be as accurate as possible, but may be subject to

change without prior notification. SMAC shall not be liable for any damages that may arise as a

consequence of the use of information presented in this user manual.

Document Version

Note

By

Date

1.0

First released version

RZ

7/17/2020

1.1

Upgraded the hardware with the associated

pictures, I/O specifications and pinout

information.

RZ

11/6/2020

1.2

Updated the firmware version from 1.0.1 to 1.1.0,

with the following changes:

- new cyclic variables: digital inputs and outputs

- new acyclic variables: I2T parameters

- fault indication bits in statusword

- fault reset through controlword

- modified the system macros

RZ

7/1/2021

1.3

Fixed the velocity mode system macro, updated

VLC-ETC housing drawing, added a program

example for a 2-axis actuator

RZ

10/28/2021

Copyright SMAC Moving Coil Actuators, 2021.

3

Contents

Introduction .................................................................................................................................... 4

Hardware and Software Setup........................................................................................................ 6

2.1 Hardware................................................................................................................................. 6

2.1.1 Power/signal/communication connectors...................................................................... 6

2.1.2 I/O electrical schematics ............................................................................................... 10

2.1.3 Optional: disabling the STO........................................................................................... 12

2.2 Software Setup...................................................................................................................... 13

2.2.1 VLC configuration .......................................................................................................... 13

2.2.2 Connecting VLC-ETC to an EtherCAT network (with a TwinCAT example).................... 13

Programming the VLC-ETC ............................................................................................................ 16

3.1 Servo objects......................................................................................................................... 16

3.1.1 Acyclic servo objects...................................................................................................... 16

3.1.2 Cyclic servo objects ....................................................................................................... 18

3.2 Executing motion through servo objects .............................................................................. 22

3.3 Example: executing homing with TwinCAT under Config mode........................................... 22

3.4 Example: programming a sequence of motions with TwinCAT PLC under Run mode.......... 25

3.5 Example: programming a 2-axis linear-rotary actuator ........................................................ 35

A Appendix A: VLC System Macros................................................................................................... 49

4

Introduction

The VLC-ETC is an EtherCAT servo drive that is based on SMAC’s VLC 1-axis integrated controller/driver

and an additional layer that provides the EtherCAT connectivity. The VLC part is pre-programmed with

system macros to accommodate control and monitoring functionalities of the servo drive. Additional

macros can be programmed in the VLC to perform subroutines/functions that can be called from the

EtherCAT master. Background knowledge on the VLC is required to configure the servo parameters of

the VLC-ETC. Please refer to the latest VLCI-X1 manual for more information about the servo drive

parameters and programming. Table 1.1 presents the VLC-ETC specifications.

Table 1.1. VLC-ETC specifications (based on Hardware version 1.0).

Description

EtherCAT servo drive

Operating Modes

Position, Velocity, Torque

Filter Algorithm

PID

Max. Servo Loop Rate

100 µS

Trajectory Generator

Trapezoidal

Servo Position Feedback

Incremental Encoder with Index

Output (Standard)

PWM (space-vector-modulated), 3.5 Amps Cont. and 6.5

Amps Peak (with proper heat mitigation) at 50 VDC Max.

Motor Type

3-Phase Brushless, DC brushed, Linear voice coil

PWM Frequency

20.0 KHz

Current resolution

5.66 mA (approximate)

Encoder and Index Input

Differential

Encoder Supply Voltage

5 VDC

Encoder Input Voltage

5.5 VDC Max., -0.1 VDC Min.

Encoder Count Rate

40 million encoder counts per Second

Position Range

31 Bits

Velocity Range

31 Bits

Acceleration Range

31 Bits

Digital I/O

4x Opto-isolated Digital Inputs w/ common:

•24 V Level Input

4x Solid-state Relay Outputs w/ common:

•200 mA Current

•Tolerant to 60 V

Analog I/O

Input: 1 Channel (differential), 0 to +/-10V With 12-Bit

Resolution.

Output: 1 Channel, 0-10V With 12-Bit Resolution.

STO (Safe Torque Off)

2x Opto-isolated STO Inputs:

•24 V Level Input

1x Opto-isolated STO Feedback Output:

•200 mA Current

•Tolerant to 60 V

5

LEDs

2 x 2 LEDs:

•EtherCAT LED: Run (green), Error (red)

•Servo Drive LED: Power ON (green), Fault (red)

Communication Interface

•1x serial/UART (micro USB port): 9600 baud default,

selectable between 2400 –460800

•2x EtherCAT RJ-45 ports

Supply Voltage

+24 to +48 VDC

Protections

•Driver overtemperature at 150 degrees C

•Overcurrent

•Overload

•Reverse polarity connection

•I2T

•(excessive) servo position error

VLC program space

•Macro storage: 53728 bytes

•Maximum number of macros: 512

•Maximum number of program registers: 2048

6

Hardware and Software Setup

2.1 Hardware

2.1.1 Power/signal/communication connectors

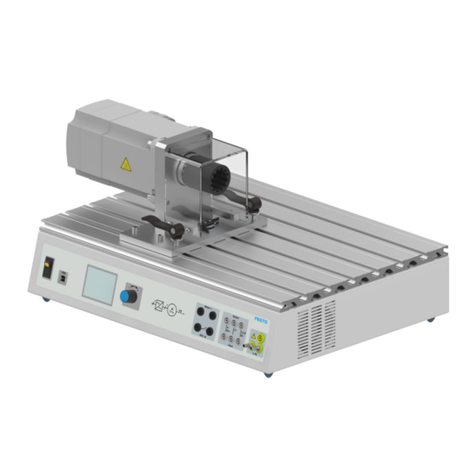

Figure 2.1 shows the VLC-ETC in its housing. The front and rear sides’ connectors as well as LED

status indicators are depicted in Figures 2.2 and 2.3. Pinout details of the connectors are

presented in the following pages of this manual.

Figure 2.1. VLC-ETC.

7

Figure 2.2. VLC-ETC front side connectors and LED status indicators.

Figure 2.3. VLC-ETC rear side connectors and LED status indicators.

EtherCAT RUN

J1

J2

J3

EtherCAT ERROR

J4

J5

J6

Servo drive fault

Servo drive power

8

J1 (EtherCAT input) / J2 (EtherCAT output)

RJ-45 Jack.

Pin

Signal

Description

1

TD+

Transmit data +

2

TD-

Transmit data -

3

RD+

Receive data +

6

RD-

Receive data -

J3 –I/O and STO interface

DSUB26 High Density Female Connector.

Pin number

Signal

Description

1

GPI_COM

Common terminal for general purpose digital inputs

2

GPO_COM

Common terminal for general purpose digital outputs

3

GPI2

General purpose digital input 2

4

GPI0

General purpose digital input 0

5

GND

Ground

6

STO_FB

STO feedback output

7

AN_OUT0

Analog output 0

8

GPO2

General purpose digital output 3

9

GPO0

General purpose digital output 1

10

STO2

STO input 2

11

STO1

STO input 1

12

GPI3

General purpose digital input 2

13

GPI1

General purpose digital input 1

14

GND

Ground

15

NC

Not connected

16

AN_OUT1

Analog output 1

17

GPO3

General purpose digital output 2

18

GPO1

General purpose digital output 0

19 - 22

+5V

+5V power for external circuitry

23

GND

Ground

24

AN_IN0+

Analog input 0 (differential) +

25

AN_IN0-

Analog input 0 (differential) -

26

STO_COM

Common terminal for STO inputs and output

1

8

1

19

9

18

26

9

J4 - Power interface

6 pin terminal block header, 5 mm pitch.

Pin number

Signal

Description

1

RTN

Power supply return / ground

2

V+

Power supply positive

3

U

Actuator phase U (positive for single-phase actuators)

4

V

Actuator phase V (negative for single-phase actuators)

5

W

Actuator phase W

6

GND

Ground

J5 –Encoder interface

DSUB15 Female Connector.

Pin number

Signal

Description

1

A+

A positive

2

I+

Index positive

3

B+

B positive

4, 5, 6

+5V

+5V supply for encoder

7, 8

NC

Not connected

9

A-

A negative

10

I-

Index negative

11

B-

B negative

12, 13

GND

Ground

14, 15

NC

Not connected

1

6

1

8

9

15

5

10

J6 - Serial interface

Note: when this port is connected to a PC, the VLC becomes accessible through a serial

terminal software (such as Tera Term) for configuration and programming purposes, while

the EtherCAT communication is being interrupted. To operate the VLC-ETC in EtherCAT

mode, make sure to first power cycle the VLC-ETC after disconnecting the micro usb cable

from this port.

USB Type B (micro) Female Connector.

Pin number

Signal

Description

1

USB+

+5 VDC

2

USB D-

Data -

3

USB D+

Data +

4, 5

USB- (GND)

Ground

2.1.2 I/O electrical schematics

Digital inputs

1

5

+5 V

GPI_COM

GPI0

To μC

4.7KΩ

(5 –24 VDC)

(5–24 VDC)

To μC

4.7KΩ

GPIx

Internal to VLC-ETC

Optocouplers

11

Digital outputs

STO

GPO1

GPO_COM

(200 mA, 60 VDC tolerant)

Sinking output from

μC output circuitry

GPOx

620Ω

620Ω

Sinking output from

μC output circuitry

+5 V

Internal to VLC-ETC

Solid-state relays

(200 mA, 60 VDC tolerant)

STO1

STO2

STO_FB

2.5 kΩ

To μC

+5 V

(5 –30VDC)

(200 mA, 60 VDC tolerant)

Internal to VLC-ETC

Solid-state relay

(5 –30VDC)

Opto

-couplers

AND gate

STO_COM

To μC

2.5 kΩ

330 Ω

To driver

power supply

12

Analog input (differential)

Analog output

2.1.3 Optional: disabling the STO

The two STO inputs (STO1 and STO2, see section 2.1.2) have to be supplied with the specified

DC voltage in order to enable the VLCI’s driver power stage to operate the actuator. If the

external means of supplying the DC voltage is not considered, the VLCI’s on-board +5V supply

can be used to supply STO1 and STO2, and together with connecting the STO_COM with the

GND, the power stage is enabled. This is shown in Figure 2.4. When both STO1 and STO2 are

energized, the STO_FB output becomes active to indicate the drive is ready to be operated.

Figure 2.4. Disabling STO with the on-board +5V supply.

AN_INx+

0 –3.3VDC

To μ

C ADC

(12-bit)

Internal to VLC-ETC

Differential amplifier

AN_INx-

-10 VDC to 10 VDC

From μC DAC (12-bit)

Internal to VLC-ETC

0 - 10 VDC

Non-inverting amplifier

AN_OUTx

1

19

9

18

26

Jumper wires

13

2.2 Software Setup

2.2.1 VLC configuration

Remark: to perform VLC configuration, the user is expected to be familiar with programming

the VLC/LAC. Refer to the latest VLCI-X1 manual for more information on the programming.

Serial communication can be established between the VLC part and a PC through the micro

USB port (J6) of the VLC-ETC. A serial terminal software (with selectable baud rates of up to

460800, such as Tera Term) can be used to configure the VLC for the following purposes:

•Loading of system macros (see appendix A, unless these macros were pre-loaded in the

VLC).

•Setting/tuning of actuator servo parameters (Optional, as this can also be done through

EtherCAT). The servo parameters can later be stored in MD151-MD154 presented in

appendix A, which later will be loaded onto the EtherCAT side upon VLC-ETC power-up

(after a PS command).

•Programming of custom macros that are to be called via EtherCAT (Optional).

Appendix A presents the system macros. Due to these macros, there are restrictions in

programming the custom macros as follow:

•All macros can be used except: 0, 151-159, 200-241

•All registers can be used except: 200-229

For the VLC configuration, the baud rate setting of the terminal software has to be adjusted to

460800. Also note that if a serial echo is desired, this can be enabled through the EN command.

2.2.2 Connecting VLC-ETC to an EtherCAT network (with a TwinCAT example)

The VLC-ETC is ready to be connected to an EtherCAT network, provided the following

conditions are met:

•System macros have been loaded and saved in the VLC.

•The micro USB cable is disconnected from the USB port (J6) and after that, the VLC-

ETC is power-cycled.

In case TwinCAT is used, the ESI (EtherCAT Slave Information) file of the VLC-ETC has to be

copied into the following typical directory in a PC with TwinCAT installed:

C:\TwinCAT\3.1\Config\Io\EtherCAT . The ESI file can be obtained from SMAC.

The following are the steps to establish a connection between VLC-ETC and TwinCAT:

➢Open TwinCAT and start a new TwinCAT project

➢Ethernet adapter installation: On the top part of the development environment (Fig.

5), select TwinCAT > Show Realtime Ethernet Compatible Devices. Make sure that the

Ethernet Adapter of the PC is installed.

14

➢On the left pane of the TwinCAT development environment, right-click on I/O>Devices,

select “Add new item”. A window “Insert Device” appears as shown in Figure 2.5.

Select EtherCAT Master and click OK.

➢A window “Device Found At” appears as in Figure 2.6, select the Ethernet adapter that

is already installed.

Figure 2.5. Adding an EtherCAT master.

Figure 2.6. Selection of an Ethernet adapter.

15

Figure 2.7. VLC-ETC connected to TwinCAT.

➢Right-click on the newly-added “Device 1 (EtherCAT)” and select scan. The VLC-ETC will

appear as shown in Figure 2.7.

➢To view the various data belonging to VLC_ETC, double-click on Box 1 (VLC_ETC). A list

of data will appear as shown in Figure 2.8. The data in the upper dashed rectangle are

configuration objects, which are acyclic (only updated upon request). Meanwhile, the

lower dashed rectangle contains cyclic objects (updated periodically) in the EtherCAT

OPERATIONAL state.

Figure 2.8. Various acyclic (upper rectangle) and cyclic (lower rectangle) objects of VLC_ETC.

16

Programming the VLC-ETC

3.1 Servo objects

Servo objects are parameters and variables that are used to perform control and monitoring of

the VLC-ETC. From its update behaviour perspective, there are two servo object types in VLC-

ETC:

•Acyclic: updated upon request, used for servo configuration purposes.

•Cyclic: updated periodically, manipulated and monitored by a motion program executed

by the EtherCAT master.

3.1.1 Acyclic servo objects

Table 3.1 presents the acyclic servo objects. Objects with indices 8000, 8001, 8002, 8004

(partially), 8005 and 8006 are standard ones that are also found in VLC, therefore, explanations

on their usage are available in the VLC user manual. Additionally, commutation electrical cycle

(index: 8004) corresponds to the EC command in VLC, which is used for phasing of 3-phase

actuators.

Table 3.1. List of acyclic servo objects.

Index

Sub-

index

Object

Data

Type

VLC equivalent

command/variable

8000

POSITION LOOP CONTROLLER PARAMETERS

1

Proportional constant

UINT16

SG

2

Integral constant

UINT16

SI

3

Derivative constant

UINT16

SD

4

Integral limit

UINT16

IL

5

Velocity feedforward constant

UINT16

FV

6

Acceleration feedforward constant

UINT16

FA

7

Derivative sampling frequency

UINT8

FR

8

Integral Sampling gain

UINT8

RI

8001

Current mode gain

UINT16

SC

8002

ADDITIONAL SERVO PARAMETERS

1

Servo speed

UINT8

SS

2

Phase and sense setting

UINT8

PH

3

Dead band

UINT16

DB

4

Output offset

INT16

OO

5

Maximum following error

UINT16

SE

8003

HOMING PARAMETERS

1

Homing method

UINT16

N/A

2

Homing speed

UINT32

N/A

3

Homing acceleration

UINT32

N/A

4

Home offset

INT32

N/A

5

Position error threshold

UINT32

N/A

6

Homing timeout

UINT16

N/A

17

Index

Sub-

index

Object

Data

Type

VLC equivalent

command/variable

8004

COMMUTATION PARAMETERS

1

Commutation phase

UINT16

SP

2

Commutation electrical cycle

UINT32

EC

3

Commutation voltage

UINT16

N/A

4

Absolute home

INT32

DA

8005

GENERAL PURPOSE REGISTERS

1

GPR11

INT32

AR11

2

GPR12

INT32

AR12

…

15

GPR25

INT32

AR25

8006

I2T PARAMETERS

1

I2T Nominal current

UINT16

i2t_NOM

2

I2T Trip level

UINT32

i2t_TRIP

8007

Save all parameters

UINT8

PS

Important notes (for more information, see the program examples in the VLCI-X1 manual):

oFor 1-phase actuators, set the object “Commutation phase” (8004;1) to 27307

oFor 3-phase actuators, set the object “Phase and sense setting” (8002;2) to 1

3.1.1.1 Homing parameters

Homing parameters (index: 8003) are specific to the VLC-ETC. To perform homing through the

manipulation of cyclic objects (further description in the following subsection of this manual),

phasing (in case a 3-phase actuator is used) has to be executed successfully beforehand.

Furthermore, position loop control parameters have to be set properly since homing involves

a controlled motion. Therefore, in principle all the relevant objects in Table 3.1 will have to be

set prior to homing. The following objects describe the homing parameters of Table 3.1 in

detail:

•Homing method (value depends on the chosen method below)

oCurrent position (0): no motion is involved. This sets the position value =

“Home offset” object.

oNegative mechanical limit (1): retracts the shaft until actuator the rear bumper

is detected, and sets the position value = “Home offset” object.

oPositive mechanical limit (2): extends the shaft until the actuator front bumper

is detected, and sets the position value = “Home offset” object.

oNegative index (3): retracts the shaft until the index is detected.

oPositive index (4): extends the shaft until the index is detected.

oNegative mechanical limit and index (5): retracts the shaft until actuator the

rear bumper is detected, extends until the index is detected and sets the

position value = “Home offset” object

oPositive mechanical limit and index (6): extends the shaft until actuator the

rear bumper is detected, retracts until the index is detected and sets the

position value = “Home offset” object

18

•Homing speed: speed of retracting and extending shaft movements during homing.

•Homing acceleration: acceleration of the shaft movement during homing.

•Home offset: the value sets to the actuator’s actual position after homing is completed.

•Position error threshold: the position error value to conclude the existence of the

mechanical limit.

•Homing timeout: the time period allowed to complete the homing. If homing has not

been completed within the time period, homing is considered to be failed.

3.1.1.2 Commutation parameters

Except for the commutation voltage, the rest of commutation parameters are available in the

standard VLC. The relevance of these parameters for the actuator operation are as follow:

•1-phase (brushed/voice coil) motor: Commutation phase has to be set to 27307. See

the VLC manual for more information on this object.

•3-phase (brushless) motor: Commutation voltage and electrical cycles are to be

configured to perform phasing. Additionally, the object Phase and sense setting

(8002;2) have to be set to 1. See the program example in VLC manual for more

information.

3.1.1.3 I2T parameters

These parameters are used to configure the actuator overloading characteristic in terms of

peak current and time period, which are intended to protect the actuator from possible

overheating. A further discussion on this topic is covered in the VLCI-X1 manual.

3.1.1.4 Save all parameters

By changing the value of the object Save all parameters (index: 8007) from 0 to 1 or vice-versa,

all acyclic servo objects from index 8000 –8006 will be saved to the non-volatile memory of

the VLC, which allow the object values to be retained after a VLC-ETC power cycle.

3.1.2 Cyclic servo objects

In Table 3.2, the INPUT and OUTPUT are seen from the EtherCAT master / TwinCAT perspective.

Some of the objects have their VLC equivalence and therefore, further information about them

are to be found from the VLC manual. The OUTPUT object value is applied to the VLC-ETC upon

a change of its value. Note that GPR’s 101 – 104 are only meaningful when they are used within

custom macros that can be called by the EtherCAT master.

19

Table 3.2. List of cyclic servo objects.

I/O

Object

Data type

VLC equivalence

INPUT

Statusword

UINT16

N/A

Modes of operation display

UINT16

N/A

Position actual value

INT32

TP command

Following error

INT32

TF command

Current value

INT16

IMON variable

Macro call indicator

UINT16

N/A

GPR 101

INT32

Register 101

GPR 102

INT32

Register 102

Digital inputs

UINT8

BI command

OUTPUT

Controlword

UINT16

N/A

Modes of operation

UINT16

N/A

Setpoint

INT32

N/A

Profile velocity

UINT32

SV command

Profile acceleration

UINT32

SA command

Maximum torque

INT16

SQ command

Macro call

UINT16

MS command

GPR 103

INT32

Register 103

GPR 104

INT32

Register 104

Digital outputs

UINT8

BO command

Meanwhile, for objects that do not have a direct VLC equivalence:

3.1.2.1 Statusword

The statusword contains bits with various servo status, as described in Table 3.3.

Table 3.3. Statusword bits.

Bit

Description

0

Initialization done. This will be set to 1 after VLC-ETC performs its initialization

process upon power-up, indicating that it is ready to be operated.

1

Servo enabled. This will be set to 1 when the servo is enabled by MN command.

The bit is set to 0 if servo is disabled through MF command.

2

Reserved.

3

Motion execution acknowledge bit. Set to 1 on a rising edge transition the

controlword “start motion” bit and set to 0 on falling edge transition of the

same controlword bit.

4

Trajectory complete. Set to 1 if the servo has completed a position move. Set

to 0 if the servo is busy executing a commanded move.

5

Reserved.

6

Homing Success. Set to 1 after homing has been completed successfully.

7

Homing failure. Set to 1 if homing fails (when the homing process takes longer

than the configured timeout value).

8

Phasing success. Set to 1 after phasing is successfully performed. Set to 0 upon

failed phasing or at power-up.

9

Phasing failure. Set to 1 after a failed phasing. Set to 0 upon successful phasing

or at power-up. A failed phasing could be caused by incorrect “commutation

electrical cycle”, incorrect “phase and sense setting” or insufficient phasing

setpoint value.

20

10

Macro call error. Set to 1 if an undefined macro is called. Set to 0 when a new

call to a defined macro is performed, or any of the mode of operation is

executed.

11

Macro execution. Set to 1 when a macro is being executed. Set to 0 when

macro execution is completed.

12

General fault. Set to 1 in the event of overtemperature, I2T being tripped, or

STO is activated. Set to 0 otherwise, or if the fault has been successfully reset.

13

Servo error. Set to 1 when the following error has exceeded the acyclic variable

“Maximum following error”. Set to 0 otherwise, or if the fault reset has been

executed.

14

Reserved.

15

STO status. Set to 1 when STO is active (or if any of the STO inputs is not

energized). Set to 0 when STO is inactive.

3.1.2.2 Controlword

The controlword contains bits that represent certain servo functions, as described in Table 3.4.

Important notes:

oOnly one of the bits between 0 –5 and 9 can have a value of 1 at the same time.

oBy setting all bit values to 0 (same as decimal value: 0), macro execution will be

stopped and servo is turned off.

Table 3.4. Controlword bits.

Bit

Description

0

Idle. This bit does not do anything, but can be used to allow an easy transition

of controlword decimal value. Example of use is given in the upcoming section.

1

Start motion/macro call. On a rising edge, starts the execution of motion based

on the selected mode of operation or executes a macro call.

2

Abort motion. On a rising edge, motion is terminated abruptly (for modes of

operation 1, 2, 3) and servo is held in its position.

3

Motor off. On a rising edge, servo is turned off.

4

Motor on. On a rising edge, servo is enabled.

5

Abort macro execution. On a rising edge, macro execution is aborted.

6 - 8

Reserved.

9

Fault reset.

10 - 15

Reserved.

Table of contents

Other SMAC Servo Drive manuals

Popular Servo Drive manuals by other brands

Kollmorgen

Kollmorgen AKD 2G Accessories guide

Danfoss

Danfoss VLT AutomationDrive FC 302 operating guide

Asco

Asco JOUCOMATIC 448 Series Installation and operation

Mitsubishi Electric

Mitsubishi Electric MELSERVO-J5 MR-J5-G Series user manual

Leadshine

Leadshine IES Series Hardware installation manual

Pilz

Pilz PMCtendo DD5 operating manual

Festo

Festo TP 1410 operating instructions

Siemens

Siemens SIMOTICS S-1FK2 Configuration manual

YASKAWA

YASKAWA E-III Series Safety precautions

Festo

Festo CMMT-AS-C2-3A-...-S1 Series Instructions & installation

Delta Electronics

Delta Electronics ASDA-B2 series user manual

Metronix

Metronix smartServo BL 4000-C Series Mounting instructions