SMAC VLC-2-EIP User manual

VLC-2-EIP

USER MANUAL

Version 1.0

2

Disclaimer

The contents of this user manual are intended to be as accurate as possible, but may be subject to

change without prior notification. SMAC shall not be liable for any damages that may arise as a

consequence of the use of information presented in this user manual.

Document Version

Note

By

Date

1.0

First released version

RZ

5/13/2022

1.1

Updated the VLC-2-EIP picture and connector

numbering. Added a new section on programming

guidelines.

RZ

7/29/2022

Copyright SMAC Moving Coil Actuators, 2022.

3

Contents

Introduction .................................................................................................................................... 5

Hardware and Software Setup........................................................................................................ 7

2.1 Hardware................................................................................................................................. 7

2.1.1 Power/signal/communication connectors...................................................................... 7

2.1.2 I/O electrical schematics ............................................................................................... 13

2.1.3 LEDs ............................................................................................................................... 15

2.1.4 Optional: disabling the STO........................................................................................... 16

2.2 Software ................................................................................................................................ 17

2.2.1 VLC configuration .......................................................................................................... 17

2.2.2 Modification of IP settings ............................................................................................ 17

2.2.3 Connecting VLC-2-EIP to an Ethernet/IP network (with a Studio 5000 example) ........ 18

Programming the VLC-2-EIP.......................................................................................................... 22

3.1 Servo objects......................................................................................................................... 22

3.1.1 Acyclic servo objects...................................................................................................... 22

3.1.2 Cyclic servo objects ....................................................................................................... 25

3.2 Executing motion through servo objects .............................................................................. 28

3.3 VLC-2-EIP Programming Guidelines ...................................................................................... 29

3.3.1 General guidelines......................................................................................................... 29

3.3.2 Phasing/Homing management...................................................................................... 29

3.3.3 Fault management ........................................................................................................ 30

3.4 Controlling the VLC-2-EIP with a PLC using Studio 5000 software utilizing Add-On-

Instructions........................................................................................................................................ 31

3.4.1 Basic servo configuration .............................................................................................. 31

3.4.2 Input and status display ................................................................................................ 34

3.4.3 Digital I/O....................................................................................................................... 35

3.4.4 Fault management ........................................................................................................ 36

3.4.5 Phasing .......................................................................................................................... 37

3.4.6 Homing .......................................................................................................................... 39

3.4.7 Position Move................................................................................................................ 41

3.4.8 Velocity Move................................................................................................................ 44

3.4.9 Torque Move................................................................................................................. 46

3.4.10 Current Move ................................................................................................................ 48

3.4.11 Softland ......................................................................................................................... 49

4

3.4.12 Stop Motion................................................................................................................... 51

3.4.13 Motor OFF and ON ........................................................................................................ 52

A Appendix A: VLC System Macros................................................................................................... 53

5

Introduction

The VLC-2-EIP is an ODVA-conformant Ethernet/IP servo drive that is based on SMAC’s VLC-25-07 2-

axis integrated controller/driver and an additional layer that provides the Ethernet/IP connectivity. As

opposed to the traditional daisy-chaining of two separate Ethernet/IP servo drives for the control of

2-axis system such as SMAC’s LCR/LAR series actuators, a single VLC-2-EIP is able to achieve the same

task at a lower cost and a lower installation complexity.

The VLC part of the servo drive is pre-programmed with system macros to accommodate control and

monitoring functionalities of the servo drive. Additional macros can be programmed in the VLC to

perform subroutines/functions that can be called from the Ethernet/IP master. Background knowledge

on the VLC is required to configure the servo parameters of the VLC-2-EIP. Please refer to the latest

VLC-25-07 manual for more information on the servo drive parameters and programming.

Table 1.1. VLC-EIP-25 specifications (based on Hardware version 1.0).

Description

Ethernet/IP 2-axis servo motor controller/driver

Operating Modes

Position, Velocity, Torque

Filter Algorithm

PID

Max. Servo Loop Rate

100 µS

Trajectory Generator

Trapezoidal, electronic gearing

Servo Position Feedback

Incremental Encoder with Index

Output

PWM (space-vector-modulated), 6.0 A Continuous and 7.8 A

Peak.

Motor Type

3-Phase Brushless, DC Brushed, DC Linear Actuator

PWM Frequency

20.0 KHz

Current resolution

2.93 mA (approximate)

Encoder and Index Input

Differential

Encoder Supply Voltage

5 VDC

Encoder Input Voltage

5.5 VDC Max., -0.1 VDC Min.

Encoder Count Rate

40 million encoder counts per second

Position Range

31 Bits

Velocity Range

31 Bits

Acceleration Range

31 Bits

General Purpose Digital I/O

4x opto-isolated digital inputs, 5V to 24 V max

4x opto-isolated digital outputs, 60V, 200 mA max

Dedicated Digital I/O

2x opto-isolated coarse home inputs

STO (Safe Torque Off)

2x STO opto-isolated digital inputs, 5V to 24 V max

1x STO opto-isolated feedback output, 60V, 200 mA max

Analog Inputs

2x 12-bit pseudo-differential analog inputs, 0 to +/- 10V range

3x 12-bit analog inputs, 0V to 10V range (0V to <10V optional)

Analog Outputs

2x 12-bit analog outputs, 0V to 10V range (0V to 5V optional)

6

LEDs

1x Power on LED

1x Status LED

2x Fault LEDs

Serial Interface

RS-232 non-isolated, 9600 baud default, selectable between

2400 - 921600

Supply Voltage

+8 To +48 VDC

Protections

> Reversed power supply polarity connection

> Driver overtemperature

> I2T

> (excessive) servo position error

Program space (VLC part)

> Macro storage: 56286 bytes

> Maximum number of macros: 512

> Maximum number of program registers: 2048

7

Hardware and Software Setup

2.1 Hardware

2.1.1 Power/signal/communication connectors

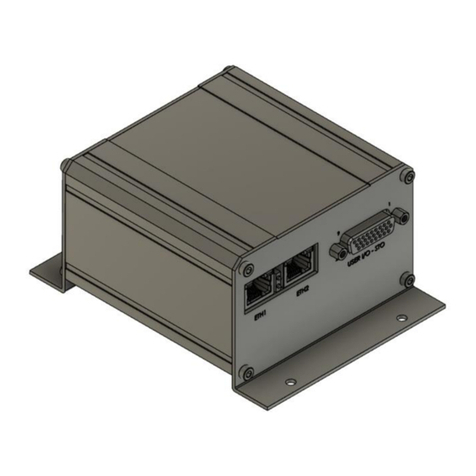

Figure 2.1 shows the VLC-2-EIP, consisting of a mother- and daughter- boards. The motherboard is

essentially a VLC-25-07 (2-axis integrated controller/servo drive), whereas the daughterboard

contains all the Ethernet/IP-related components. Pinout details of the connectors J1-J8, ETH1-2 and

status LEDs in Fig. 2.1 are presented in the following pages.

Figure 2.1. VLC-2-EIP

J1

J2

J4

J6

J8

Status LEDs

J7

J5

J3

ETH1

ETH2

8

J1 - Power interface

2 pin terminal block header, 5.08 mm pitch.

Pin number

Signal

Description

1

V+

Power supply positive

2

V-

Power supply return / ground

J2 –General purpose + dedicated digital opto-isolated I/O

D-SUB 15 connector, high-density, male.

Pin number

Signal

Description

1

GPI0

General purpose digital input 0

2

GPI1

General purpose digital input 1

3

GPI2

General purpose digital input 2

4

GPI3

General purpose digital input 3

5

GPI_COM

Common terminal for general purpose digital inputs

6

GPO0

General purpose digital output 0

7

GPO1

General purpose digital output 1

8

GPO2

General purpose digital output 2

9

GPO3

General purpose digital output 3

10

GPO_COM

Common terminal for general purpose digital outputs

11

+5V

+5V power for external circuitry

12

STO2

STO input 2

13

STO1

STO input 1

14

STO_FB

STO feedback output

15

STO_COM

Common terminal for STO’s

1

2

9

J3 –Axis 2 Motor Output

4 pin terminal block header, 5.08 mm pitch.

Pin number

Signal

Description

1

2MA

Axis 2 motor phase A/U (positive for single-phase actuators)

2

2MB

Axis 2 motor phase B/V (negative for single-phase actuators)

3

2MC

Axis 2 motor phase C/W

4

GND

Ground

J4 –Analog I/O

D-SUB 15 connector, high-density, female.

Pin number

Signal

Description

1

AN_IN2

Analog input 2, single-ended

2

AN_OUT0

Analog output 0

3

AN_OUT1

Analog output 1

4

AN_IN0+

Analog input 0, differential input +

5

AN_IN1+

Analog input 1, differential input +

6

AN_IN3

Analog input 3, single-ended

7

GND

Ground

8

GND

Ground

9

AN_IN0-

Analog input 0, differential input -

10

AN_IN1-

Analog input 1, differential input -

11

AN_IN4

Analog input 4, single-ended

12

+5V

+5V power for external circuitry

13

+5V

+5V power for external circuitry

14

GND

Ground

15

GND

Ground

1

2

3

4

1

6

5

10

11

15

10

J5 –Axis 1 Motor Output

4 pin terminal block header, 5.08 mm pitch.

Pin number

Signal

Description

1

1MA

Axis 1 motor phase A/U (positive for single-phase actuators)

2

1MB

Axis 1 motor phase B/V (negative for single-phase actuators)

3

1MC

Axis 1 motor phase C/W

4

GND

Ground

J6 –Communication (RS232)

D-SUB 9 connector, female.

Pin number

Signal

Description

1

+5V

+5V power for external circuitry

2

TX

RS232 Transmit

3

RX

RS232 Receive

4

N/C

Not connected

5

GND

Ground

6

N/A

Reserved, do not connect

7

N/A

Reserved, do not connect

8

N/A

Reserved, do not connect

9

N/A

Reserved, do not connect

1

2

3

4

1

6

5

9

11

J7 –Incremental encoder interface

D-SUB 26 connector, high-density, female.

Pin number

Signal

Description

1

N/C

Not connected

2

N/C

Not connected

3

N/C

Not connected

4

+5V

+5V power for external circuitry

5

+5V

+5V power for external circuitry

6

2A-

Axis 2 encoder phase A-

7

2A+

Axis 2 encoder phase A+

8

1A-

Axis 1 encoder phase A-

9

1A+

Axis 1 encoder phase A+

10

N/C

Not connected

11

N/C

Not connected

12

1HOM

Axis 1 home input

13

GND

Ground

14

GND

Ground

15

2B-

Axis 2 encoder phase B-

16

2B+

Axis 2 encoder phase B+

17

1B-

Axis 1 encoder phase B-

18

1B+

Axis 1 encoder phase B+

19

2HOM

Axis 2 home input

20

N/C

Not connected

21

GND

Ground

22

GND

Ground

23

2Z-

Axis 2 encoder phase index-

24

2Z+

Axis 2 encoder phase index+

25

1Z-

Axis 1 encoder phase index-

26

1Z+

Axis 1 encoder phase indx+

1

6

5

9

12

J8 –Expansion I/O

RJ-25 socket connector.

Pin number

Signal

Description

1

RX-

Receive data- input

2

TX-

Transmit data- input

3

RX+

Receive data+ input

4

TX+

Transmit data+ input

5

CLK+

Clock+ input

6

CLK-

Clock- input

ETH1 & ETH2 (Ethernet/IP ports)

RJ-45 Jack.

Pin

Signal

Description

1

TD+

Transmit data +

2

TD-

Transmit data -

3

RD+

Receive data +

6

RD-

Receive data -

1

6

1

8

13

2.1.2 I/O electrical schematics

Digital inputs

Digital outputs

+5 V

GPI_COM

GPI1

To μC

To μC

To μC

10KΩ

10KΩ

10KΩ

(5 –24 VDC)

(5 –24 VDC)

(5–24 VDC)

(5 –24 VDC)

To μC

10KΩ

GPI2

GPI4

GPI3

Internal to VLC-2-EIP

Optocouplers

GPO1

GPO_COM

(200 mA, 60 VDC tolerant)

Sinking output from

μC output circuitry

620Ω

GPO2

GPO3

GPO4

620Ω

620Ω

620Ω

Sinking output from

μC output circuitry

Sinking output from

μC output circuitry

Sinking output from

μC output circuitry

+5 V

(200 mA, 60 VDC tolerant)

(200 mA, 60 VDC tolerant)

(200 mA, 60 VDC tolerant)

(200 mA, 60 VDC tolerant)

Internal to VLC-2-EIP

Solid-state relays

14

Home inputs

STO

Analog input (differential)

+5 V

1HOM

To μC

4.7KΩ

To μC

2HOM

Internal to VLC-2-EIP

Optocouplers

4.7KΩ

+5 V

STO1

STO2

STO_FB

2.5 kΩ

To μC

+5 V

(5 –30VDC)

(200 mA, 60 VDC tolerant)

Internal to VLC-2-EIP

Solid-state relay

(5 –30VDC)

Opto

-couplers

AND gate

STO_COM

To μC

2.5 kΩ

330 Ω

To driver

power supply

AN_INx+

0 –3.0 VDC

To μ

C ADC

(12-bit)

Internal to VLC-2-EIP

Differential amplifier

AN_INx-

(-10 VDC to 10 VDC)

x = 1,2

15

Analog input (single-ended)

Analog output

2.1.3 LEDs

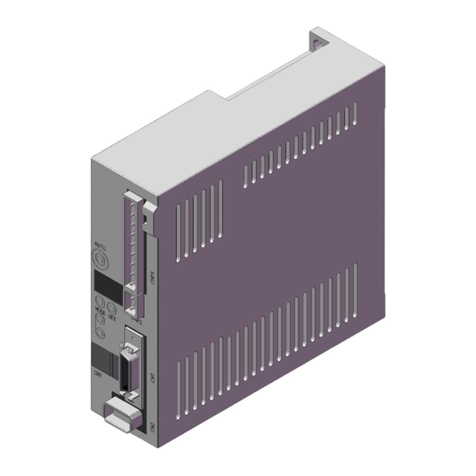

Figure 2.2. VLC-2-EIP status LED’s.

There are 4 LEDs in VLC-2-EIP, namely power, status, axis 1 fault and axis 2 fault. The location of

these LEDs can be seen in Figure 2.2.

•Power LED turns ON when the specified DC voltage is supplied into the controller

•Status LED blinks if an incorrect program command is executed

•Axis fault LED turns ON when the corresponding servo axis experiences fault such as driver

overtemperature, I2T trip and excessive servo position error (SE command).

(0 –10VDC)

AN_INx

40.612 kΩ

20 kΩ

To μC ADC

(12-bit)

1 nF

Internal to VLC-2-EIP

From μC DAC (12-bit)

Internal to VLC-2-EIP

(0 - 10 VDC)

Non-inverting amplifier

AN_OUTx

x = 1,2

POWER

STATUS

FAULT 1

FAULT 2

16

2.1.4 Optional: disabling the STO

The two STO inputs (STO1 and STO2, see section 2.1.2) have to be supplied with the specified DC

voltage in order to enable the VLC’s driver power stage to operate the actuator. If the external means

of supplying the DC voltage is not considered, the VLC’s on-board +5V supply can be used to supply

STO1 and STO2, and together with connecting the STO_COM with the GND, the power stage is enabled.

This is shown in Figure 2.3. When both STO1 and STO2 are energized, the STO_FB output becomes

active to indicate the drive is ready to be operated.

Figure 2.3. Disabling STO in VLC-2-EIP with the on-board +5V supply.

1

6

5

10

11

15

J2

J4

17

2.2 Software

2.2.1 VLC configuration

Remark: to perform VLC configuration, the user is expected to be familiar with programming

the VLC/LAC. Refer to the latest VLC-25-07 manual for more information on the programming.

Serial communication can be established between the VLC part and a PC through the RS232

port (J6) of the VLC-EIP-25. A serial terminal software (with selectable baud rates of up to

921600, such as Tera Term) can be used to configure the VLC for the following purposes:

•Loading of system macros (unless the macros were pre-loaded in the VLC)

•Setting/tuning of actuator servo parameters (Optional, this can also be done through

Ethernet/IP)

•Programming of custom macros to be called via Ethernet/IP (Optional)

Appendix A presents the system macros. Due to these macros, there are restrictions in

programming the custom macros as follow:

•All macros can be used except the reserved: 0 –3, 120 –162, 300 –326, 400 –439

•All registers can be used except: 200-413

For the VLC configuration, follow these steps:

•Set the serial baud rate of the serial terminal software to 921600.

•Type in the command EN and press enter. Note that any commands will not show up

in the terminal window, unless this step has been performed.

•Set the VLC baud rate to a lower value, e.g. 9600, through the command BR9600 and

press enter.

•Set the serial baud rate of the terminal software to 9600.

•At this point, the VLC can be configured/programmed as it is typically done.

2.2.2 Modification of IP settings

Table 2.1 presents the default values of the IP settings of the VLC-2-EIP. These settings can be

modified through Ethernet/IP explicit message set attribute service of the standard TCP/IP

object (Class 0xF5), instance 1, attribute 5 (Interface Configuration). The VLC-2-EIP will take the

newly modified IP settings after a power cycle.

Table 2.1. IP-settings-related objects of VLC-2-EIP

Name

Type

Default Value

IP address

UINT32

0xC0A80069 (192.168.0.105)

Network Mask

UINT32

0xFFFFFF00 (255.255.255.0)

Gateway Address

UINT32

0.0.0.0

Name Server

UINT32

0

Name Server 2

UINT32

0

18

Users could use a free Ethernet/IP explicit messaging software such as Molex EIPTool to perform

the IP settings modification. The steps are as follow:

•Set the PC’s IP address to 192.168.0.1

•Open the Molex EIPTool software.

•Refer to the figure below and perform the following

oSet the station to: 192.168.0.105

oSet the Communications to either UCMM or Connected. Select the 0xF5 TCP/IP

tab.

oClick on Get_Attribute of the Interface Configuration (attr 5). This will show the

default IP settings of Table 2.1.

oChange the parameters of the Interface Configuration (attr 5) as required and

click on Set_Attribute.

oThe newly set parameters (IP settings) will be applied after power cycling the

VLC-1-EIP.

2.2.3 Connecting VLC-2-EIP to an Ethernet/IP network (with a Studio 5000 example)

The VLC-2-EIP is ready to be connected to an Ethernet/IP network, provided the following

conditions are met

•System macros have been loaded and saved in the VLC

•The RS232 cable is disconnected from the RS232 port (J6) and after that, the VLC-EIP-

25 is power-cycled.

19

2.2.3.1 Installation of EDS file

the EDS (Electronic Data Sheets) file of the VLC-2-EIP can be obtained from SMAC. In the Studio

5000 environment, create a new project. The EDS file installation steps are as follow (refer to

Fig. 2.4):

1. Go to Tools>EDS Hardware Installation Tool

2. Click Next

3. Select “Register an EDS file”

4. Select “Register a single file” and use “Browse” to find the EDS file

5. Click “Finish” to complete the setup

Figure 2.4. Installation of EDS file in Studio 5000.

1

2

3

4

5

20

2.2.3.2 Adding the VLC-2-EIP into the PLCs Ethernet/IP network

1. In the left-pane of Studio 5000 environment, right-click on ‘Ethernet’ and select ‘New Module..’

2. Search for the device’s name corresponding to the EDS file, as shown below, e.g. ‘VLC-EIP-25’.

Double-click on the one corresponding to the VLC-2-EIP. In the ‘New Module’ window, specify

a name for the VLC-EIP and the IP address based on the discussion in section 2.2.2 of this

manual, whether the default one or a newly-defined one is used.

Table of contents

Other SMAC Servo Drive manuals

Popular Servo Drive manuals by other brands

Allen-Bradley

Allen-Bradley MPL-A310, MPL-A320, MPL-A330, MPL-A420, MPL-A430, MPL-A4530,MPL-A4540, MPL-A4560, MPL-A520, MPL-A540, MPL-A560, MPL-B310,... installation instructions

VERVIEW

VERVIEW Atlas OVU00247 quick start guide

SSD Drives

SSD Drives 637 product manual

Sinee

Sinee EA180 Series manual

JUNG ANTRIEBSTECHNIK U. AUTOMATION GMBH

JUNG ANTRIEBSTECHNIK U. AUTOMATION GMBH HighDynamic HA01-23 installation guide

INVT

INVT SV-DA200 Series Operation manual