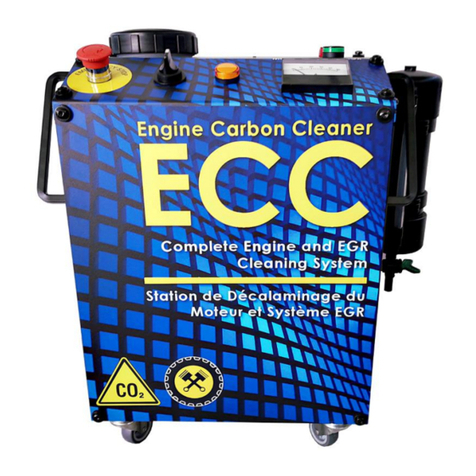

Smart Cover ECC320 User manual

ECC320 – User Manual

HHO Hydrogen on Demand Dual Fuel Generator Systems

ECC320 – User Manual2

Smart-Cover , 1km Lagada-Thessaloniki , P.C.57200,Tel. +302394020077 Email: info@smart-cover.gr , Website: www.smart-cover.gr

CONTENTS

1. Safety Precautions 3

2. Components of the machine 4

3. Setting up the machine 5

3.1 Filling the main tank for the first time 5

3.2 Refilling the main tank 5

3.3 Security Bubbler 6

4. Working with the machine 7

4.1 General use 7

4.3 Cleaning the air filter box 7

4.3 Working amperage 8

5. Diesel Cars and DPF Filter Cleaning 9

6. Maintenance 10

Regular Maintenance 10

Winter Maintenance 10

Bi-annual Maintenance 10

Technical Information 11

EC Declaration of Conformity 12

ECC320 – User Manual3

Smart-Cover , 1km Lagada-Thessaloniki , P.C.57200,Tel. +302394020077 Email: info@smart-cover.gr , Website: www.smart-cover.gr

1.Safety Precautions

Read and follow these safety precautions to avoid hazards. Your ECC320machine do not store hydrogen,

subsequently there is no fire hazard when used properly. However water electrolysis generates Hydrogen, a

explosive gas, which means that you should never light a match or smoke near or in front of the end of the

hose - the protection bubbler inside the machine could blow up!

Be sure to wear goggles and rubber gloves and only use professional tools; use common sense and general

safety procedures used for any work carried out on automotive operations and maintenance.

The electrolyte – Potassium hydroxide KOH - should be handled with extreme care because it´s a corrosive

product. Be sure to wear goggles and rubber gloves when adding or removing electrolyte solution from the

machine.

ECC320 – User Manual4

Smart-Cover , 1km Lagada-Thessaloniki , P.C.57200,Tel. +302394020077 Email: info@smart-cover.gr , Website: www.smart-cover.gr

2. Components of the machine

Security

Bubbler

Ventilation

Control Panel

Wheels

Bubbler Cap

Hydrogen Hose

Power Cable

Frontal Panel

Water Tank Lid Ammeter

Emergenc

y Switch

Water level

lights

Maintenance Panel

ON/OFF

Main Switch

Power Controls

Control Panel

ECC320 – User Manual5

Smart-Cover , 1km Lagada-Thessaloniki , P.C.57200,Tel. +302394020077 Email: info@smart-cover.gr , Website: www.smart-cover.gr

3. Setting up the machine

3.1 Filling the main tank for the first time

Please follow these simple steps:

1. Use a plastic container to prepare the electrolyte solution first outside the machine. Be sure to wear goggles

and rubber gloves for security reasons;

2. The electrolyte concentration to use is around 23 grs/liter of water. Add the full package (700 grs) provided

with the machine to 30 liters of water. You can use any type of water but try to avoid water with bad quality

or too many salts (iron or calcium). Tap water will work fine;

3. Turn the machine ON. The green light above the switch, lateral fans and a red light near the water tank,

buzzing and blinking, (Minimum Level) will be turned ON;

4. Open the water tank lid and pure gently the mixture inside the water tank avoiding any spell. As the water

level raises in the tank the red buzzing light will be turned OFF;

5. Continue adding the electrolyte solution until the green steady light is turned ON. When this light appears

please stop adding electrolyte solution;

6. Close the water tank lid making sure it is well tight;

7. Turn the machine OFF.

3.2 Refilling the main tank

As you use the machine the water level inside the tank will start to descend. First the green will turn OFF. After

around 100 hours of work the red light will start to buzz and blink. It´s time to refill the machine again with

electrolyte solution

For refilling please follow these simple steps:

1. Use a plastic container to prepare the electrolyte solution first outside the machine. Be sure to wear goggles

and rubber gloves for security reasons;

2. The electrolyte concentration to use is around 5 grs/liter of water. Add around 150 grs of Potassium

Hidroxide 90% pure to 30 liters of good quality water.

4. Open the water tank lid and pour gently the mixture inside the water tank avoiding any spell. As the water

level raises in the tank the red buzzing light will be turned OFF once again;

ECC320 – User Manual6

Smart-Cover , 1km Lagada-Thessaloniki , P.C.57200,Tel. +302394020077 Email: info@smart-cover.gr , Website: www.smart-cover.gr

5. Continue adding the electrolyte solution until the green steady light is turned ON. When this light appears

please stop adding electrolyte solution;

6. Close the water tank lid making sure it is well tight.

3.3Security Bubbler

The bubbler is located laterally in the machine and serves two purposes: cleaning the Hydrogen gas and act as

a safety barrier against a flame. If a flame reaches the bubbler and ignites the reduced hydrogen accumulated

at the top of the bubbler but the water column will prevent the flame to reach the main tank where there is

much more hydrogen accumulated.

The bubbler comes already filled with a light acid solution from

factory. The level of this solution should be kept between the 2

marks in the metallic protection. If the level drops below the inferior

mark then you should refill the bubbler.

For refilling the bubbler, please follow these simple steps:

1. The solution to use is a light acid, like vinegar (Ph 3);

2. Open the threaded cap positioned on the top of the bubbler;

3. With a small funnel, pure gently the solution and check at the

same time the level rising inside the lateral hose of the bubbler;

4. Stop pouring when the level reaches the maximum level mark;

5. Close the threaded cap. If necessary add a little bit of Teflon tape

to tight it better.

ECC320 – User Manual7

Smart-Cover , 1km Lagada-Thessaloniki , P.C.57200,Tel. +302394020077 Email: info@smart-cover.gr , Website: www.smart-cover.gr

4.Working with the machine

4.1General use

Please follow thesesimple steps for the general use of the Engine Carbon Cleaner:

1. Open the air filter box, remove filter element and clean the area inside in order to avoid dust particles from

entering the engine;

2. Insert the hose of the machine in the air intake manifold inside the air filter box;

3. Turn engine ON and let it work for some time until it reaches normal working temperature (80-90º);

4. At this point turn the machine ON;

5. Press the first red power control switchand check the amperage in the ammeter;

6. Let the engine work idling for the first 20 minutes with only one button working;

7. Every 10 minutes press hard acceleration pedal in order to improve removal of the carbon deposits;

8. After the first 20 minutes of treatment increase the rotations of your engine to 1000 rpm and turn ON

second and third power control Swicth. Check again amperage in the ammeter.

9. Keep the machine working for one (1) hour to complete engine cleaning;

10. Every 10 minutes accelerate the engine in order to remove faster carbon deposits.

11. Repeat this operation every 10 000 km.

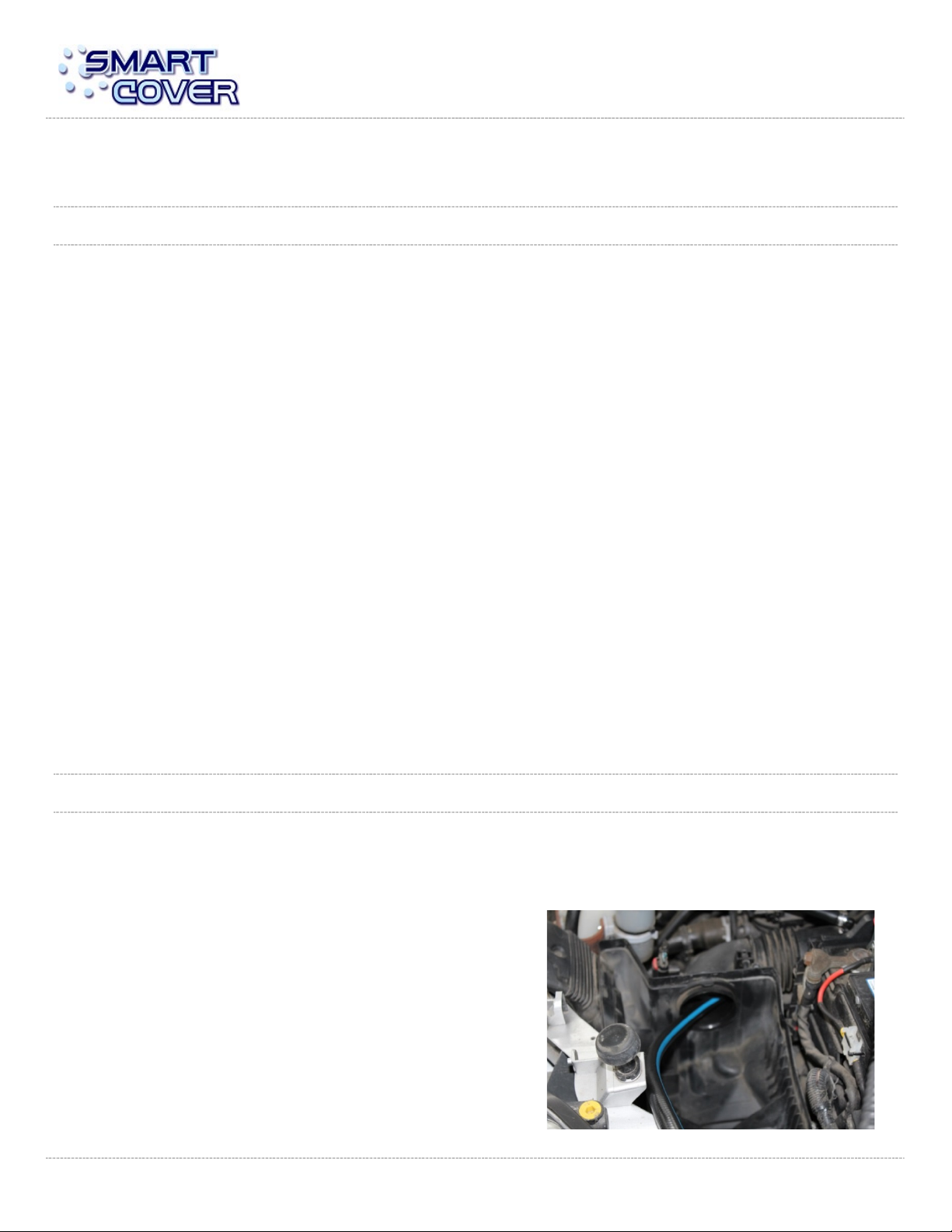

4.3Cleaning the air filter box

The system is operated by vacuum suction from your engine's air intake which takes the HHO directly to the

combustion chamber mixing it with the air/fuel. The injection point must be done rightafter the air filter box

and the MAF/MAP sensor enhancer. Please follow the next steps:

1. Open the air filter box and remove the air filter;

2. In the air filter box please cover the engine air intake

with a cloth to prevent dust particles from entering the

engine;

3. With an air compressor clean the air filter area so that

it stays completely free from dust particles;

4. Remove the cloth and insert the hose in the air intake

manifold.

ECC320 – User Manual8

Smart-Cover , 1km Lagada-Thessaloniki , P.C.57200,Tel. +302394020077 Email: info@smart-cover.gr , Website: www.smart-cover.gr

4.3Working amperage

Each one of the 3 black switches controls 1/3 of the total power of the machine. You must turn on or more

switches buttons to the right until you reach the desired amperage.

For one hour of work, the working amperage will depend on your engine size:

• Engine Size up to 1500 cc: 4A (1 hour);

• Engine Size up to 3000 cc: 6A (1 hour);;

• Engine Size up to 4500 cc: 8A (1 hour);

Above this engine sizes you must increase the number of hours of the machine working:

• Engine Size up to 9000 cc: 8A (2 hours)

• Engine Size up to 13500 cc: 8A (3 hours)

• Engine Size up to 18000 cc: 8A (4 hours)

ECC320 – User Manual9

Smart-Cover , 1km Lagada-Thessaloniki , P.C.57200,Tel. +302394020077 Email: info@smart-cover.gr , Website: www.smart-cover.gr

5. Diesel Cars and DPF Filter Cleaning

In modern diesel cars it´s always advisable to make the DPF filter diagnosis before the treatment,especially

when the car drives only in towns and it is not possible to make the normal regeneration of the DPF. If the

diesel car has already a problem with the diesel particulate filter (DPF), then it´s likely that the problem could

get more severe with our treatment due to soot coming out of the engine and exhaust system.

If the DPF is clogged then we should clean it using our

engine carbon cleaning machine. We the lines below we

will explain how do this operation.

The main function of the DPFfilter is to reduce the

emissions of fine particles (soot) contained in the exhaust

gases. The DPF works in two stages, first he collects the

particles and after it eliminates them:

First step: The filter traps the particles in suspension in the

exhaust gases. A layer of soot then starts forming on the walls of the filter. In long tern this layer of soot will

influence the performance of the engine being necessary to start the regeneration process on the second step.

Second step:When we have the right conditions, the filter force the temperature of the exhaust gases to rise

enough to burn the soot layers. The regeneration process will not work properly when temperatures are low

in winter (for example in Northern Europe) or when the cars only drive in towns or small distances.

When cleaning diesel cars we recommend also the useof the special DXA250 additive

produced for our machines. This additive allow the regeneration of diesel particulate

filters using our engine carbon cleaning machines without removing the DPF. This

additive lowers the ignition temperature of the soot collected in the DPF, optimizing

the regeneration process. The increase ofexhaust gases temperature provided by the

combustion of hydrogen during the treatment will allow the right conditions for the

regeneration of the FAP.

This additive can be used as a preventive treatment or as a repair treatment if the DPF

filter is very clogged. Preventive treatment should take place in countries where

temperatures are low in winter (for example in Northern Europe) or when the cars only

run in cities and small distances.

Dosage: We add a bottle (250 ml) of the additive in 20 liters of fuel just before starting

the treatment with our machine.

Duration: 1.5 hours

Engine revolutions during treatment: Engine at 1000 rpm for 30 minutes and after one hour at 2500 rpm.

ECC320 – User Manual10

Smart-Cover , 1km Lagada-Thessaloniki , P.C.57200,Tel. +302394020077 Email: info@smart-cover.gr , Website: www.smart-cover.gr

6. Maintenance

Regular Maintenance

Depending on the weekly working hours, you should check the water level inside the water tank. If the level is

too low, refill the tank with electrolyte solution to allow amperage to be at normal operational values.

Winter Maintenance

If temperatures drop below -4ºC then you should add 20-25% isopropyl alcohol to the water solution in order

to avoid water from freezing, even with the more severe temperatures. Don´t use another type of alcohol or

you risk damaging the stainless steel plates.

Bi-annual Maintenance

Depending on the working hours of the machine, you should clean the machine and remove all deposits every

six months. Please follow these simple steps:

1. Add 50% isopropyl alcohol to the water solution and leave it in the machine without working for 24 hours;

2. Next day start the machine and let it work for 20 minutes;

3. Stop the machine and open the back maintenance panel. Inside the machine you will find one valve to help

you flush the water;

4. Once all water is out, please close the valves a add fresh water until you reach the maximum water level in

the tank;

5. Open the valve again and let it flush all the liquid inside the machine;

6. Close the valves and put in place the frontal panel;

7. Repeat all steps mentioned in point 3.1.

ECC320 – User Manual11

Smart-Cover , 1km Lagada-Thessaloniki , P.C.57200,Tel. +302394020077 Email: info@smart-cover.gr , Website: www.smart-cover.gr

Technical Information

Voltage: 230V AC

Power: 2200 W

Energy consumption (kW/h): 1,44

HHO Gas Output Max: 1200 l/h

Max. Pressure (kg/cm2): 0,2

Max. Water Consumption (L/h): 0,30

Water refilling: manual

Water Tank Capacity: 32 liters

Autonomy: 100 hours

Dimensions - L x l x h (mm): 500 x 500 x 900 mm

Weight: 75 kg

Warranty: 24 months

ECC320 – User Manual12

Smart-Cover , 1km Lagada-Thessaloniki , P.C.57200,Tel. +302394020077 Email: info@smart-cover.gr , Website: www.smart-cover.gr

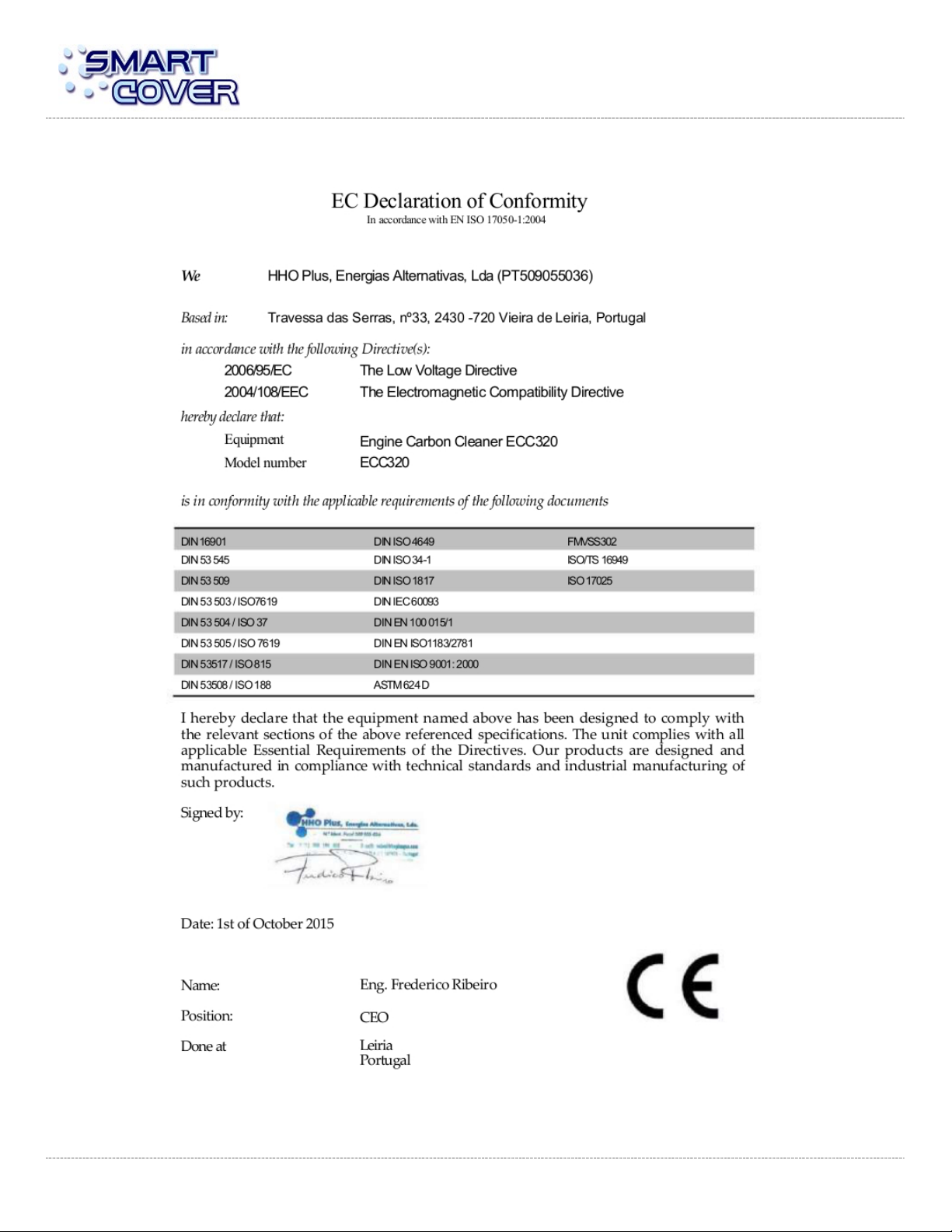

EC Declaration of Conformity

ECC320 – User Manual13

Smart-Cover , 1km Lagada-Thessaloniki , P.C.57200,Tel. +302394020077 Email: info@smart-cover.gr , Website: www.smart-cover.gr

HHO Plus

HHO Plus, Energias Alternativas, Lda

VAT Id. Number: PT509055036

Headquarters:

Travessa das Serras 33

2430 - 720 Vieira de Leiria

Portugal

Production Plant:

Zona Industrial de Vieira de Leiria

Rua Manuel Joaquim Afonso Lote 10

2430 - 837 Vieira de Leiria

Portugal

Email: [email protected]

Telephone: 00 351 244 697 116

Table of contents

Other Smart Cover Portable Generator manuals

Popular Portable Generator manuals by other brands

K&S BASIC

K&S BASIC KSB 40i S owner's manual

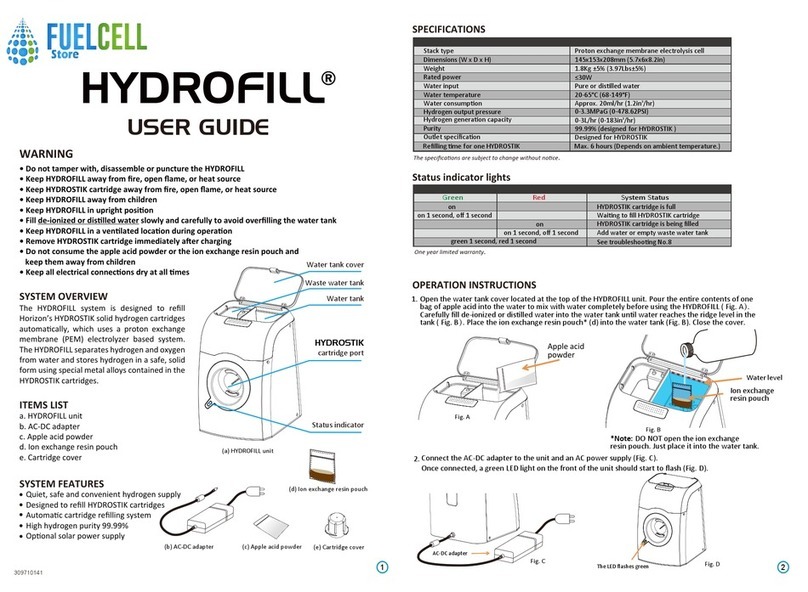

Horizon Fuel Cell Technologies

Horizon Fuel Cell Technologies HYDROFILL user guide

Tektronix

Tektronix AWVG1 user manual

Flextool

Flextool DP4 operating instructions

Generac Power Systems

Generac Power Systems Mobile Power MMG185 Specifications

Technaxx

Technaxx TX-199 user manual