CEBORA S.p.A. 2

3.302.107 12/11/02

CONTENTS

1- GENERAL INFORMATION.......................................................................................................................... 3

1.1 - Introduction. ................................................................................................................................................. 3

1.2 - General service policy. ................................................................................................................................. 3

1.3 - Safety information. ....................................................................................................................................... 3

1.4 - Electromagnetic compatibility...................................................................................................................... 3

2- SYSTEM DESCRIPTION .............................................................................................................................. 4

2.1 - Introduction. ................................................................................................................................................. 4

2.2 - Technical specifications................................................................................................................................ 4

2.3 - Description of power source art. 253............................................................................................................ 4

3- MAINTENANCE............................................................................................................................................ 5

3.1 - Periodic inspection, cleaning. ....................................................................................................................... 5

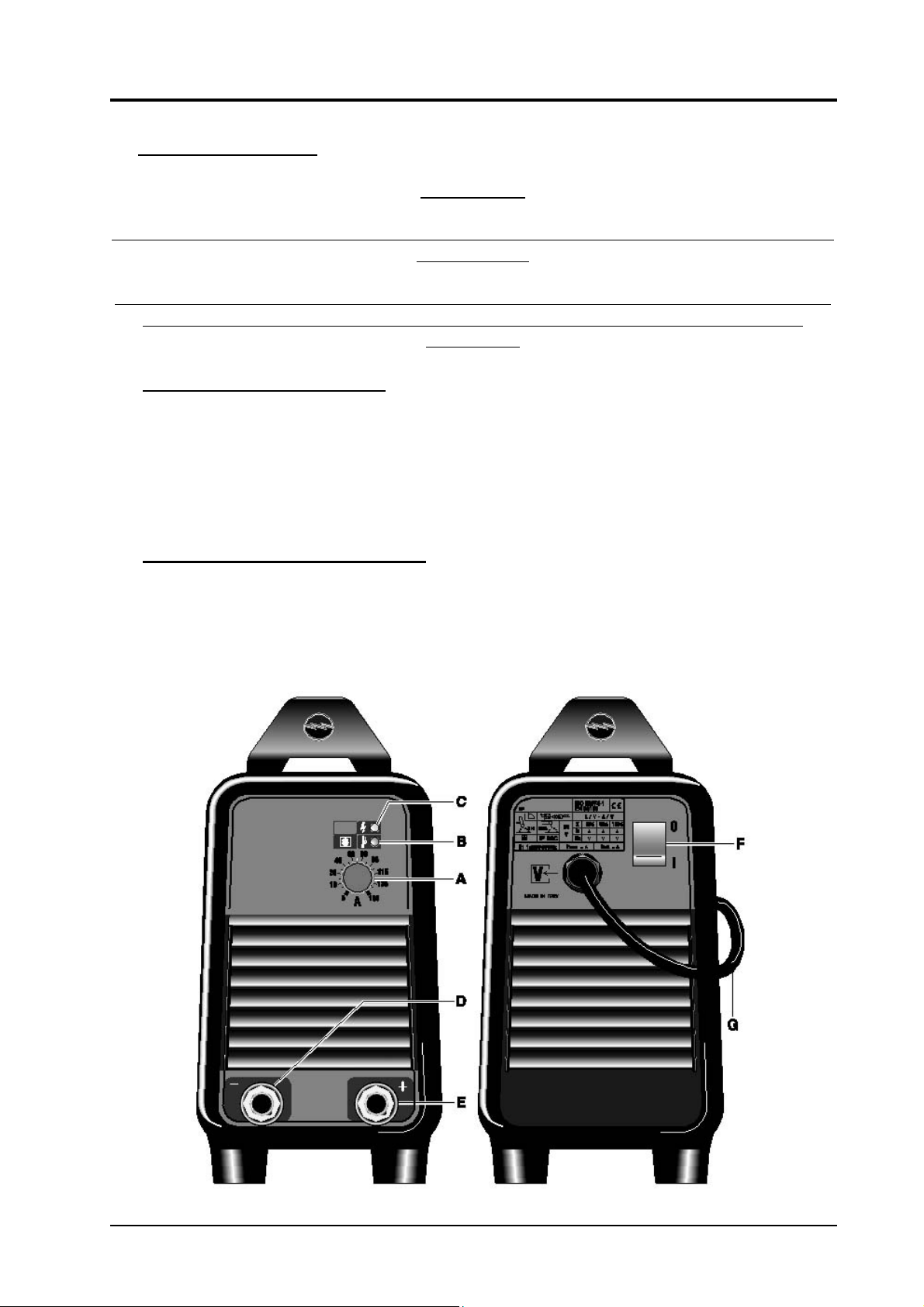

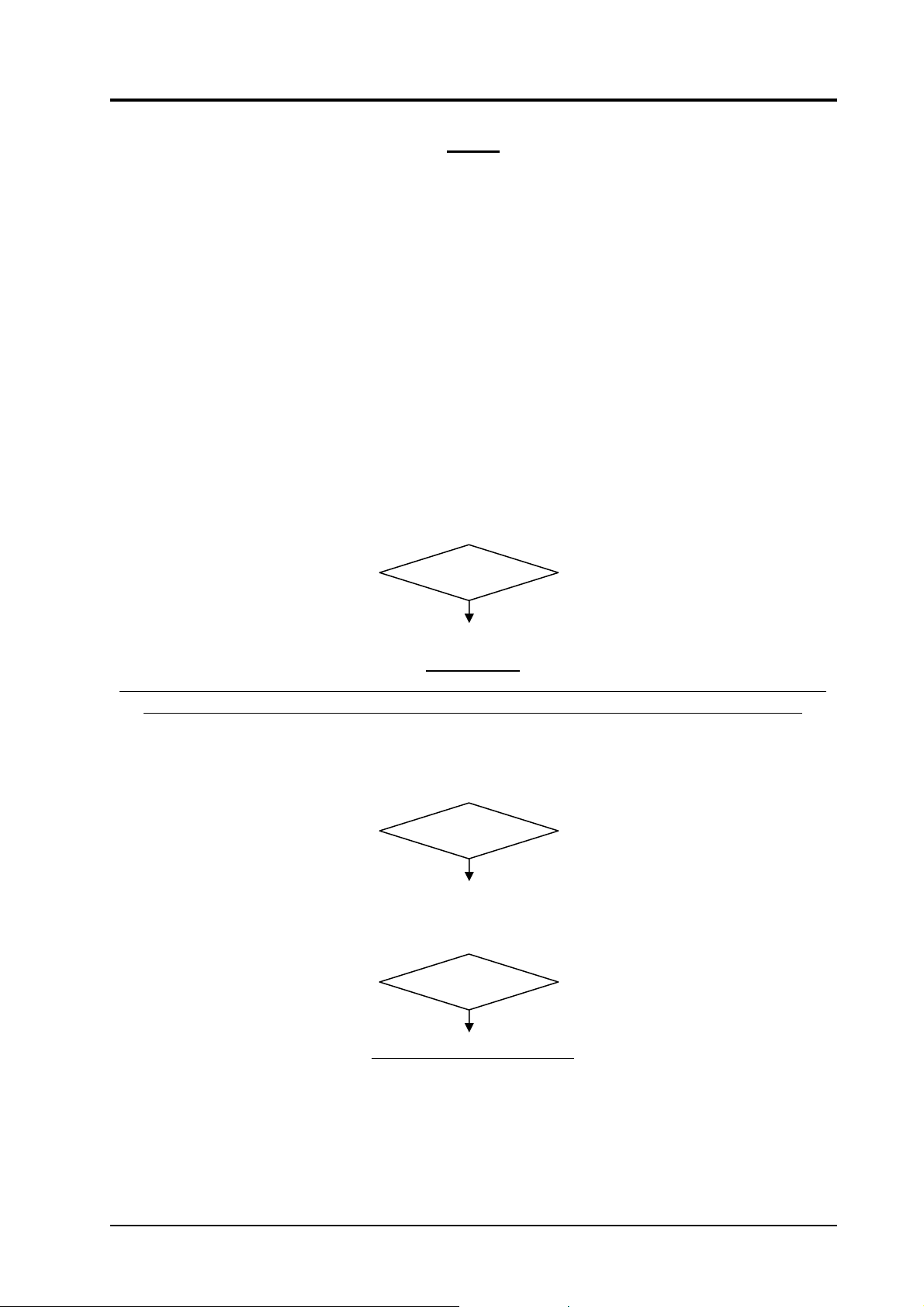

3.2 - Sequence of operations (fig. 3.2.1). .............................................................................................................. 5

3.2.1 - Power source commands and signals......................................................................................................... 5

3.2.2 - Starting the power source........................................................................................................................... 6

3.3 - Troubleshooting............................................................................................................................................ 7

3.3.1 - The power source does not start, control panel off. ................................................................................... 7

3.3.2 - Power source powered, fan (9) stopped. .................................................................................................... 8

3.3.3 - Power source powered, display and signals does not indicate the correct values. ..................................... 8

3.3.4 - In open circuit operation, the output voltage is not regular. ...................................................................... 9

3.3.5 - In resistive load operation, the output voltage is not regular. .................................................................... 9

3.3.6 - In TIG, arc unstable, welding irregular.................................................................................................... 10

3.4 - Error codes.................................................................................................................................................. 11

3.4.1 - Yellow led (B) lit, with fix light. ............................................................................................................. 11

3.4.2 - Yellow led (B) flashes (four fast flash with interval of 4 seconds fix light). ........................................... 11

3.4.3 - Yellow led (B) off, during first 3 seconds after start-up (no lamp-test)................................................... 11

3.4.4 - Yellow led (B) flashes (two fast flash with 1,5 seconds pause)............................................................... 11

3.4.5 - Yellow led (B) flashes (three fast flash with 1,5 seconds pause)............................................................. 11

4- COMPONENTS LIST................................................................................................................................... 12

4.1 - Power source art. 253: see file ESP253.pdf enclosed at the end of the manual.......................................... 12

4.2 - Components table: see file ESP253.pdf enclosed at the end of the manual................................................ 12

4.3 - Spare parts list. ........................................................................................................................................... 12

5- ELECTRICAL DIAGRAMS ........................................................................................................................ 12

5.1 - Power source art. 253: see file SCHE253.pdf enclosed at the end of the manual. ..................................... 12

5.2 - Power board (13) code 5.602.091/C. .......................................................................................................... 12