smart home 2386W User manual

LIMITED WARRANTY

Seller warrants to the original consumer purchaser of this product that,for a period of two years from the date of

purchase, this product will be free from defects in material and workmanship and will perform in substantial confor-

mity to the description of the product in this Owner’s Manual. This warranty shall not apply to defects or errors

caused by misuse or neglect.

If the product is found to be defective in material or workmanship, or if the product does not perform as warranted

above during the warranty period, Seller will either repair it, replace it or refund the purchase price, at its option,

upon receipt of the product at the address below, postage prepaid, with proof of the date of purchase and an explana-

tion of the defect or error. The repair, replacement,or refund that is provided for above shall be the full extent of

Seller's liability with respect to this product.

For repair or replacement during the warranty period, call Smarthome customer service to receive an RA# (return

authorization number), properly package the product (with the RA# clearly printed on the outside of the package)

and send the product, along with all other required materials, to:

Smarthome, Inc.

ATTN: Receiving Department

17171 Daimler Street

Irvine, CA 92614-5508

LIMITATIONS

THE ABOVE WARRANTY IS IN LIEU OF AND SELLER DISCLAIMS ALL OTHER WARRANTIES,WHETHER ORAL

OR WRITTEN, EXPRESS OR IMPLIED, INCLUDING AND WARRANTY OR MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE. ANY IMPLIED WARRANTY, INCLUDING ANY WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE, WHICH MAY NOT BE DISCLAIMED OR SUPPLANTED AS PROVID-

ED ABOVE SHALL BE LIMITED TO THE ONE YEAR PERIOD OF THE EXPRESS WARRANTY ABOVE. NO OTHER

REPRESENTATION OR CLAIM OF ANY NATURE BY ANY PERSON SHALL, BE BINDING UPON SELLER OR MODI-

FY THE TERMS OF THE ABOVE WARRANTY AND DISCLAIMER.

IN NO EVENT SHALL SELLER BE LIABLE FOR SPECIAL, INCIDENTAL, CONSEQUENTIAL, OR OTHER DAMAGES

RESULTING FROM THE POSSESSION OR USE OF THIS PRODUCT, INCLUDING WITHOUT LIMITATION DAMAGE

TO PROPERTY AND, TO THE EXTENT PERMITTED BY LAW, PERSONAL INJURY, EVEN IF SELLER KNEW OR

SHOULD HAVE KNOWN OF THE POSSIBILITY OF SUCH DAMAGES.

Some states do not allow limitations on how long an implied warranty lasts and/or the exclusion or limitation of

damages, in which case the above limitations and/or exclusions may not apply to you. You may also have other legal

rights that may vary from state to state.

© Copyright 2002 Smarthome

17171 Daimler St.

Irvine, CA 92614-5508

(800) SMARTHOME

(949) 221-9200

http://www.smarthome.com

SSwwiittcchhLLiinncc

Remote Control Dimmer Switch

OOwwnneerr’’ssMMaannuuaall

For Models #2386W and 2386I

(and Remote Control Dimmer Model #2382W/I)

LLSS

CONGRATULATIONS!

You’ve just purchased the highest quality powerline-controllable wall switch available. SwitchLinc LS is a specially

designed version of the world’s first two-way powerline remote control dimmer switch, the SwitchLinc 2-Way Dimmer.

It gives you remote control of lighting and inductive loads. It only differs from the SwitchLinc 2-Way in that it does not

have a transmitter to control other home automation products. Since it does not have a transmitter circuit, it will not

have a significant impact on the X10 signal levels. See page 9 to learn more about signal loading.

SwitchLinc LS can also be controlled remotely from a powerline transmitter for powerful grouped lighting control.

Each SwitchLinc LS can be a member of up to 64 lighting scenes,allowing one powerline signal to set elegant“mood

lighting.”

The SwitchLinc’s X10 address is electronically set; there are no code wheels on the unit to adjust. SwitchLinc LS is eas-

ily installed and programmed. It installs (connects to home wiring) just like a regular light switch. This makes it ideal

for retrofits in existing homes and it easily installs in new homes, with no special training required to install it.

KEY FEATURES

• Wires in just like a standard wall switch*

• All settings are held in non-volatile memory (no code wheels to set)

• Very easy to program

• High quality micro switches give the user tactile feedback when pressed (no mushy feel)

• True rocker action (top = on/bright, bottom = off/dim)

• 8-level LED“Bar”shows brightness of circuit

• Status LED/ Set Button shows powerline activity and facilitates programming

* Requires a neutral connection

OTHER SWITCHLINC MODELS

SwitchLinc 2-Way 600-Watt #2380W/I - (White or Ivory)

SwitchLinc 2-Way 1000-Watt #2381W/I - (White or Ivory)

SwitchLinc 2-Way 600-Watt Fluorescent #2383W/I - (White or Ivory)

SwitchLinc Lite 600-Watt Dimmer #2384W/I - (White or Ivory)

SwitchLinc Lite Fluorescent 600-Watts #2385W/I - (White or Ivory)

SwitchLinc Slave Switch for 3-Way, 4-Way, & Up circuits #2382W/I - (White or Ivory)

(Note: 2382 does not have LED brightness bar.)

OTHER SMARTHOME PRODUCTS FOR YOUR NEW

SWITCHLINC WALL SWITCH

Control your entire home with these elegant

KeypadLinc Wall Mount X10 keypads that will

blend perfectly into even the most upscale

décor! When your home is outfitted with multi-

ple SwitchLinc 2-Ways and SwitchLincs LS, the

KeypadLinc Wall Controllers are perfect for acti-

vating the scenes feature. The KeypadLincs are

programmable to communicate the special

scene setup and lock-in sequences, making set-

ting up scene lighting a snap.

#12061 - SoftTouch IR KeypadLinc

#12062 - SoftTouch 8-Button KeypadLinc

#12063 - Custom 6-Button KeypadLinc

#12064 - Custom 8-Button KeypadLinc

#12065 - Credit Card Remote for SoftTouch IR KeypadLinc (#12061)

2

Brightness LED “Bar”

Status LED/Nightlight

and Set Button

15

Custom 6 -

trim plate not incl

SoftTouch IR -

trim plate not incl

SoftTouch 8 -

trim plate not incl

SPECIFICATIONS

• Load types: permanently installed incandescent and general inductive loads

• Single pole or multi-location (with Remote Dimmer Switches)

• Operation: Dimming Triac

• Maximum load: 600 watts

• Input power: 125 VAC, 60 Hz, 5 amps

• Connections (16 AWG): Black (to line),Red (to load) White (to neutral, required)

Yellow (to optional Remote Dimmer Switches(2382))

• Addresses: 1 PLC (X-10) Base (Primary) Address of 256 possible

Up to 64 PLC (X-10) Scene Addresses of 255 possible

• On-Level: (Primary Address) 1 of 31 possible (3.2%-100%) or resume dim

(Scene Address) 1 of 32 possible (0%-100%)

• Ramp Rate: 0.125 to 9 seconds if programmed locally

0.125 seconds to 9 minutes if programmed remotely

• Maximum number of

SwitchLincs per multiple gang box: 4

• Maximum number of

SwitchLincs per circuit: 10 (with more than 6, a PLC amplified

coupler-repeater is highly recommended)

• Minimum load: No minimum load required

• Operating temperature range: 40OF to 104OF

• Minimum PLC receive level: 10mV

• Maximum PLC signal rejection: 200mV

• Mounts in single or multiple-ganged J-box

(200W of load control is lost on 600W SwitchLinc for each immediately adjacent

switch installation; e.g., 600W load control becomes 400W with a switch to the

immediate right or left. To avoid downgrading load control, use a triple-gang box.)

• Status indicator: Green LED

• Brightness indicator: 8 Green LEDs

• Dimensions: Front Bracket Main Body

(width) 1.73” 1.74”

(height) 4.14” 2.71”

(depth) 1.73” 1.40”

• Weight: 4.0 oz.

• ETL Listed for use in the U.S. and Canada

ABOUT THE SWITCHLINC’S CERTIFICATION

SwitchLinc has been thoroughly tested by ITS ETL SEMKO, a nationally recognized inde-

pendent third-party testing laboratory. Products bearing North American ETL Listed

mark signifies that the product has been tested to and has met the requirements of a

widely recognized (consensus) U.S and Canadian product safety standard,that the manu-

facturing site has been audited, and that the manufacture has agreed to a program of

quarterly factory follow-up inspections to verify continued conformance.

PREPARATION

Before installing SwitchLinc, please familiarize yourself with the following and take the necessary precautions listed

here:

• Be sure that power to the load being controlled has been disconnected by removing the fuse or turning

the circuit breaker off. Installing SwitchLinc with the power on may expose you to dangerous voltages

and may damage the product.

• Refer to the SwitchLinc Wiring Diagrams on page 4 to determine the wire colors of the connections to

SwitchLinc. Note: All SwitchLincs require a neutral connection.

• Wiring for 3-way, 4-way, & up switch circuits follow conventional (standard, non-remote) wiring practice

(plus the requirement for a neutral). Wiring “slave” switches requires the Line (Black) wire be accessible and be

the same 110V leg of the house wiring. The Grey wire on the “slave” switch is to be connected to NEUTRAL

ONLY. If neutral is not available, cap the Grey wire (which simply causes the LED not to function).

• SwitchLinc may feel warm during operation. The amount of heat generated is within U.L. approved

limits and poses no hazards. To minimize heat build-up, ensure that the area surrounding the rear of the

SwitchLinc has adequate ventilation (i.e., clear away excess insulation).

• Installation should be performed only by a qualified electrician, or by a homeowner who is familiar and com-

fortable with electrical circuitry.

• Follow all routine safety precautions.

OPERATIONS

Double tapping a SwitchLinc will cause the light to ramp at a two-second rate. Only programmed ramp rates greater

than two seconds are effected.

3

14

Input at Switch Output at Bulb

Tap top of rocker

(when light is off)

Light ramps up to

preset ON-level

Tap top of rocker

(when light is on)

Light ramps up to

full brightness

Press & hold

top of rocker

Light brightens until

rocker is released

Tap bottom

of rocker

Light ramps down

to OFF

Press & Hold

bottom of rocker

Light dims until

rocker is released

Basic Operations

Input at Switch Output at Bulb

Double-tap

top of rocker

Light ramps fast to

full brightness

Double-tap

bottom of rocker

Light dims fast

to OFF

Advanced Operations

CAUTION!!

Read and understand these instructions before installing. This device is intended for installation in accordance with the

National Electric Code and local regulations in the United States, or the Canadian Electrical Code and local regulations in

Canada. To reduce the risk of overheating and possible damage to other equipment, do not install a SwitchLinc to control

a receptacle or fluorescent lighting fixture. For indoor use only. Connect only cop-per or copper-clad wire to this device.

Before installing, disconnect power at circuit breaker or remove fuse to avoid shock or damage to the control. It is rec-

ommended that a qualified electrician perform this installation. Retain these instructions for future reference.

Dimming an inductive load (such as a ceiling fan) below the minimum voltage set by the manufacturer of the load device

could cause damage to the load device from overheating. If the manufacturer of the load device does not recommend

dimming, DO NOT use SwitchLinc 2-Way with that device (use SwitchLinc 2-Way Fluorescent #2383W/I or Fluorescent

Lite #2383W/I). USER ASSUMES ALL RISKS ASSOCIATED WITH DIMMING AN INDUCTIVE LOAD.

Gradateurs commandant une lampe a filament de tungstene - afin de reduire le risque of surchauffee et la possibilite d'en-

dommagement a d'autres materiels, ne pas installer pour commander une prise, un appareil a monteur, une lampe fluores-

cente ou un appareil alimente par un transformateur.

TROUBLESHOOTING & TECHNICAL SUPPORT

Possible Cause

SwitchLinc was triggered by

a scene

Primary address ramp rate may

be set too slow

SwitchLinc may be in Program

Disable mode

SwitchLinc may not be “activated”

(has not been manipulated within

the last 4 minutes)

Surge in power line

SwitchLinc is in system off position

Incomplete (open) wire

connection in wall box

Incomplete (open) wire

connection at fixture

SwitchLinc needs a neutral wire

in order to operate

The CLEAR or SET commands

were not sent in the correct order

Check the Status LED/Set Button

Move the transmitter to another

outlet

The triac dims the load by

‘chopping’ up the sine wave

The load is producing electrical

noise and it’s interfering with

SwitchLinc’s reception of

X10 signals

It is normal for wall dimmers to

get warm

Solution

Check scene membership and remove unwanted

scene from SwitchLinc, or perform a Factory Reset

to reset SwitchLinc to factory defaults

Install an X10 Signal Blocker for the home

Increase ramp rate if desired

(see page 5)

Re-enable Program mode or perform a Factory

Reset to reset SwitchLinc to factory defaults

Manually turn SwitchLinc ON or OFF or send its

X10 address during Step 2 of programming

Reset SwitchLinc by pulling out the Set Button for

a minute and then pressing it in

Press in the Set Button/Status LED

Check wall box wires to ensure all connections are

tight and no bare wire is exposed

Check fixture to ensure all connections are tight

and no bare wire is exposed

Look in the rear of the junction box for a group of

white wires all tied together with a wire nut. Those

are the neutral wires, connect the SwitchLinc’s

white wire there

Don’t hold down the buttons too long, it may send

duplicate codes (i.e. two O16 codes)

It will blink when there is any X10 activity on the line

SwitchLinc needs at least 50mV of signal strength

for reliable operation, a coupler-repeater or a signal

bridge may be needed (see pg.9)

The bulbs filaments are vibrating. Using rough

service, 130-volt, or appliance grade bulbs will

reduce the noise

Run the SwitchLinc in the Full-on mode, or

consider getting SwitchLinc Fluorescent models

that have no-dimming abilities

Install a noise filter like Smarthome #4835 between

the load and the SwitchLinc or increase the signal

strength with a coupler-repeater to overcome the

line noise

SwitchLinc will dissipate 1-watt per 100 watts

controlled. Using metal junction boxes, removing

insulation around the outside of the box, or using

a small load can help lessen the heat

Problem

Light controlled by

SwitchLinc turned itself

ON

Light does not appear

to come ON or go OFF

when SwitchLinc is

tapped (manually)

SwitchLinc will not take

programming of scene,

ramp rate, etc.

SwitchLinc is locked up

LED is not visible and

or SwitchLinc is not

controlling the light

Existing switch only has

two wires

Difficulty setting scenes

with a maxi-controller

SwitchLinc is not

Receiving signals

The load is buzzing

when on or dimmed

Switchlinc turns on, but

not off by X10 control

The switch is getting

too warm to the touch

If these solutions have been tried and the manual has been reviewed and you still cannot resolve an issue you’re having

with the SwitchLinc, please call our Technical Support Dept. at 949-221-9200 or e-mail tech@smarthome.com.

INSTALLATION

1. Remove the power from the existing switch/device.

2. Remove the faceplate from the existing switch/device.

3. Unscrew and pull the device out of the wallbox.

4. Disconnect the wires from the device.

5. Using a wire tester or voltmeter, identify and mark “Hot,” “Neutral,” “Ground,”and“Traveler”(if applicable)

wires that were connected to the device.

6. Before making any connections to SwitchLinc,gently pull the Status LED/ Set Button on the SwitchLinc

until a click is heard. This will open the “air gap” and isolate the SwitchLinc from the electricity when the circuit

breaker is turned back on.

7. Orient SwitchLinc so the LED is at the top, and make connections according to the “SwitchLinc Wiring Diagram”

below. Wire remote dimmer switches according to the “SwitchLinc Multi-Way Wiring Diagram” below.

For additional help installing SwitchLincs in a 3-way circuit, see page 12.

8. After all connections have been made, ensure that all wire connectors are firmly attached and that there is no

exposed copper except for the Ground wire.

9. Gently place the wires and switch into the wallbox (with LED at top of device) and screw into place.

10. Before installing the faceplate, restore power to the circuit, and press in the SwitchLinc Status LED/ Set Button

top until it is even with the front plastic trim ring. Once the Set Button is pressed in, power will be supplied to

the SwitchLinc and the green LED will come on.

11. After testing SwitchLinc for proper operation (see Operations table on page 3), install the faceplate

(sold separately).

413

Note: When installing multiple SwitchLincs in a J-box, or many on the same circuit breaker, please see specifications at

the end of this manual for limitations and recommendations.

SwitchLinc Wiring Diagram

Optional Remote Dimmer

Switch Model #2382

SwitchLinc LS

Model #2386

SwitchLinc LS

Model #2386

Step 5: Connect the bare copper ground wire to the other ground wires in the wall box.

If you have a four-way or greater switching circuit, see Special treatment for Four-way circuits at the end of this section.

Step 6: Install the Master SwitchLinc in the remaining wall box

There will be the two traveler wires from the first box and the wire that carries power from the switch to the lights; we

call this the LOAD. The travelers can sometimes be easily recognized because those two wires are covered by the same

cable sheath or covering around the wires. The wires can also be identified by the same method described earlier; turn

on the power, (taking the same precautions), and using a voltmeter to find the wire with electricity. The wire with elec-

tricity is the LINE wire.

Continue with the connections below….make sure the power is turned off!!!

Connect the neutral and ground wires using the same instructions given above for the remote switch.

Return to the installation instructions on page 4 and continue on with step 9.

SPECIAL TREATMENT FOR FOUR-WAY CIRCUIT

If your lighting circuit includes more than two switches controlling a set of

lights, some wall boxes will have four wires. Two of the wires are coming from

the wall box where the power enters the circuit (step one above) and the

remaining wires connect through to the master SwitchLinc's location (step six

above). In this center position, install another SwitchLinc Remote Dimmer

Switch.

Connect the Black wire on the SwitchLinc Remote Dimmer to the two Black

travelers with a single wire nut.

Connect the Ye l l o w wire to the remaining two Red travelers with a single wire

nut.

Connect the neutral and ground wires using the same instructions given above for the remote switch.

Visit www.smarthome.com/SL_3-way.html to see these instructions with larger color photos.

Step 7: Connect the master

SwitchLinc's Black LINE wire to the

identified Line wire, usually Black, out

of the wall.

Step 8: Connect the other traveler,

usually Red,to the Yellow Control wire

on the SwitchLinc Master.

Step 9: Connect the remaining wire

out of the wall, usually Black, to the

SwitchLinc Master's Red wire.

5

PRIMARY ADDRESS PROGRAMMING

Setting the Primary Address

Each SwitchLinc requires a primary X10 address to operate. It ships from the factory with “A1” as the default address;

it will also have this address after a performing a factory reset. Any of the 256 X10 addresses can be programmed.

The SwitchLinc does not use code wheels or dials to set its primary address. Instead, it will accept the first X10 address

it finds on the powerline once the programming mode is started. Any X10 transmitter can be used to set the primary

address.

1. Using a fingernail or the tip of a very small screwdriver, press and hold the Status LED/ Set Button above the

main paddle on (see diagram on page 2) for approximately 5 seconds, until the brightness

Status LED flashes and the load controlled by the SwitchLinc goes to 100% brightness. When the Status LED/ Set

Button is released, the green nightlight LED and the top LED on the light bar will alternately blink.

2. Within 30 seconds, transmit the desired primary address (housecode and unit code) from any transmitter.

The light(s) controlled by the SwitchLinc will blink and the Status LED/ Set Button will stop flashing.

Setting the Ramp Rate (Optional)

The “Ramp Rate”is the rate at which SwitchLinc brings the brightness of the light up or down when the switch is

turned on locally or receives a powerline carrier (PLC) ON-command to its primary address. The Ramp Rate is

adjustable. The factory default is about 3 seconds. If you wish to change the ramp rate, follow the instructions below.

1. Press and hold the rocker to adjust the Brightness LED level to correspond to the the desired ramp rate

(brighter = faster) according to the following table. (See ADVANCED PRIMARY ADDRESS PROGRAMMING

following this section for instructions on REMOTELY setting the primary address ramp rate for ramp rates in

smaller increments or slower than 9 seconds.)

2. Tap the Status LED/Set Button TWICE. The light will blink.

Setting the ON-Level (Optional)

The Default ON-Level is the default brightness level to which SwitchLinc will adjust the light when the switch is turned

on locally or receives a powerline carrier (PLC) ON-command to its primary address.You can set the ON-Level to a

fixed brightness level or to resume its previous brightness level. (See ADVANCED PRIMARY ADDRESS PROGRAM-

MING following this section for instructions on REMOTELY setting the ON-level.)

Setting a fixed brightness level:

1. Adjust the brightness of the light to the desired level by pressing and holding SwitchLinc’s rocker.

2. Tap the Status LED/Set Button ONCE.The light will blink.

Setting resume dim:

1. Turn the light off.

2. Tap the Status LED/Set Button ONCE.

12

Brightness LED Level Ramp Rate in Seconds

8 0.1

7 0.2

6 0.3

5 0.5

4 2.0

3 4.5

2 6.5

1 8.5

NO LED 9.0

HELP FOR USERS WITH THREE-WAY

(OR GREATER) LIGHTING CIRCUITS

SwitchLincs can be installed in place of an existing three-way lighting circuit. Most of the questions we receive from

folks installing SwitchLinc involve three-way or greater circuits. A three-way circuit is one where there are two switch-

es controlling the same set of lights. A four-way circuit has three switches controlling the same set of lights. When

updating an existing mechanical 3-way switch to SwitchLincs, you will need at least:

One 2386 SwitchLinc (called this the master switch)

One 2382 SwitchLinc Remote Dimmer (commonly called the 'slave' switch)

When replacing a three-way mechanical switch with an X10 unit, each switch will have three wires connected to it from

the wall box. Four-way or greater circuits will have four wires connected to the switches in the center of the circuit.

For this tutorial, we will follow the most commonly used wire colors for homes in North America.

Step 1: Find the Hot Wire

The SwitchLinc Master and remote switch need to go

in certain locations. The first task is to find the wall

box where the electricity comes into the circuit. Turn

off the electricity at the breaker box and remove all

the switches from the wall so that the bare copper

ends of the wire are left exposed. Each wall box

should have three wires sticking out of it. If the cir-

cuit is a four-way or greater, some of the boxes will

have four wires. Making sure that none of the wires

are touching anything and that no one is around the

wall boxes, turn the electricity back on. Using a volt-

meter or voltage sensor, individually test each wire

for voltage. When 120 volts is measured,note that

wire as LINE, (this wire is usually black). The other

two wires, commonly black and red, are the travelers

and go to the next wall box. Turn off the electricity

to resume installing the new switches.

In the wall box where the electricity comes into the circuit, install a SwitchLinc Remote Dimmer switch. It is very

important that a remote dimmer be installed in this position. The system will not work correctly if a master

SwitchLinc is installed.

Step 2: Connect the Black Line, the

Black traveler,and the Black wire on

the SwitchLinc Remote Dimmer all

together with a single wire nut.

Step 3: Connect the Yellow wire on the

SwitchLinc Remote Dimmer to the

remaining wire out of the wall, usually

a Red wire.

Step 4: Locate the group of White

wires in the rear of the box that were

not connected to the old switch.

These are the neutral wires and the

Gray wire connects in there.

611

ADVANCED PRIMARY ADDRESS PROGRAMMING

The SwitchLinc’s Ramp-Rate and Default On-Level can be remotely set using an X10 Maxi-Controller

(Smarthome #4020 or X10 # SC503 OR PHC02) or an equivalent transmitter capable of sending

Housecode and Unit Code without ON or OFF. These procedures and all the following ones will not

work with a transmitter that sends the X10 address with a command. Transmitters in which one

button is pressed to turn on or off a load WILL NOT WORK.

Remotely Setting the Ramp Rate (Optional)

1. Either manually or remotely adjust the brightness of SwitchLinc to the level corresponding to

the desired ramp rate according to the table below (e.g., B5 Preset Dim Level 48% for a 38.5 second rate).

2. Transmit the “clear”sequence: O16, P16, N16 M16, O16

3. Transmit the primary address of the SwitchLinc being programmed (e.g., B5). The light will blink.

Remotely Setting the Default On-Level (Optional)

1. Either manually or remotely adjust the brightness of SwitchLinc to the desired Default ON-Level (e.g.,

B5 Preset Level 25%).

2. Transmit the following PLC sequence: P16, N16, M16, O16, O16

3. Transmit the primary address of the SwitchLinc being programmed (e.g., B5). The light will blink.

SCENE ADDRESS PROGRAMMING

Setting the Scene Addresses

Each SwitchLinc LS can be a member of up to 64 scenes. A scene address is simply an X10 address (just like a primary

address),and is set at the time scene membership is programmed.

When you transmit an ON to a scene address, all switches programmed to be members of that scene will turn on to

their independent ON-levels at their independent ramp rates for that scene.

The scenes can be set with a Maxi-Controller or any transmitter that is capable of sending Housecode and Unit Code

without ON or OFF. Transmitters in which one button is pressed to turn a load on or off WILL NOT WORK. When

using a Maxi-Controller or an equivalent transmitter, be careful when pressing the buttons, SwitchLinc will ignore

some commands if they are not in the right sequence. “Fat-Fingering”or accidentally pressing the same button twice

may prevent the programming from being accepted.

If KeypadLinc controllers are installed in the house and one of their buttons is programmed to transmit to SwitchLinc

2-Ways, it can be used to quickly set up scenes (see the KeypadLinc manual for more information). If a TouchLinc 4.0

Touchscreen is available,use the SmartLinc Lighting Control drop-in app to help automate the scene setting process. It

can be downloaded from the Smarthome web site at this address: http://www.smarthome.com/files/1270_control.zip

Brightness Preset Ramp Rate Brightness Preset Ramp Rate

LED Level Dim Level in Seconds LED Level Dim Level in Seconds

8 100% 0.1 4 52% 34.0

97% 0.2 48% 38.5

94% 0.3 45% 43.0

7 90% 0.5 42% 47.0

87% 2.0 3 39% 60.0 (1 min)

84% 4.5 35% 90.0 (1.5 min)

81% 6.5 32% 120.0 (2 min)

6 77% 8.5 29% 150.0 (2.5 min)

74% 19.0 2 26% 180.0 (3 min)

71% 21.5 23% 210.0 (3.5 min)

68% 23.5 19% 240.0 (4 min)

5 65% 26.0 16% 270.0 (4.5 min)

61% 28.0 1 13% 300.0 (5 min)

58% 30.0 10% 360.0 (6 min)

55% 32.0 6% 420.0 (7 min)

3% 480.0 (8 min)

NO LED 0% 540.00 (9 min)

5. Install an X10 phase coupler (signal bridge) or coupler-repeater (amplifier) at the incoming electrical service.A

common problem with X10 signals is getting the signals between the two legs of electricity that service the home. A

coupler-repeater is recommend for homes of 3,000 square feet or greater. Smaller homes will work well with a passive

phase coupler.

6. Work with the electrician to isolate non-automation loads.Ask the electrician to place the non-X10 carrying lines on

one of the two incoming lines. Having the kitchens and laundry appliances plus the heating systems on one phase will

help keep potential noise off the X10 carrying lines. He probably won't be able to accommodate 100% of the loads on

one phase or another, but an attempt should be made.

GLOSSARY OF TERMS

X10 Address- The Address part of an X10 signal contains the House and Unit code. An Address can be Unit codes 1 to

16 and House codes A - P. There are 256 total X10 addresses. Examples of X10 Addresses are A-1, B-5, P-15, O-9.

X10 Command- The Command is action part of an X10 signal. It tells the module what to do when it sees its address.

Examples of a command are ON, OFF, Bright, DIM, PREdim, All Light ON, and All Units OFF. There are other rarely

used commands, but these are the most common ones.

Status & Status Request- Some X10 receivers like SwitchLinc2-way have the ability to report their status when asked.

These modules contain transmitters that can send X10 signals. When a transmitter sends a Status Request com-

mand, the module will reply with its status (On, Off, Predim at some %).

Resume Dim Level- If set, the SwitchLinc can come on to the level it was at before it was turned off.

PreDimLevel- One of 32 brightness levels the SwitchLinc supplies to lights. When a scene address is received, the

SwitchLinc can instantly (or slowly) change the lights brightness to a predefined brightness level.

Scenes in SwitchLincs- SwitchLincs Wall Switches can be set up to respond to multiple X10 signals and when received

come onto a predefined brightness level all with one signal. One scene signal from a KeypadLinc can instantly

(within seconds) change the lighting mood in your home.

Maxi Controller- An X10 transmitter that has separate buttons for the unit codes and the commands. In some of the

advanced set up functions for the SwitchLinc, it is necessary for only a unit code to be sent. The X10 SC-503,

Leviton 6320, Stanley 370-2549 are examples of Maxi-Controllers. We recommend having a Maxi Controller to set

up the SwitchLinc.

X10 Keypress- This is an X10 signal that only contains the house and unit code WITHOUT a command. The Maxi-

Controller, some TouchLinc LCD controllers and home automation interfaces can produce a keypress command.

Appliance Module- An X10 receiver device that can be used with any type of load, including lighting. It will never

contain dimming control as it always has a hard contact relay. An Appliance Module will ignore the All Lights ON

command.

Lamp Module- An X10 receiver device that is designed to be used with lighting devices. It may contain dimming con-

trol or it may have a hard contact relay. A Lamp Module will respond to the All Lights ON command.

Hot or Line- The wire in the junction box that contains the incoming electricity from the electrical panel. It is usually

black and may be tied with a wire nut to other black wires in the rear of the box.

Load- The wire in the junction box that goes to the light(s). Usually, there is just one load wire in a junction box and it

is black. It has no voltage when the switch is off.

Neutral- While not used on a mechanical switch to control a load, SwitchLinc will need a neutral wire to operate.

Generally, the neutral wires are white and located in the rear of the junction box. There may be two or more wires

tied together by a wire nut.

#4020 Maxi-

Controller

10 7

Programming Scene Membership and On-Levels

(Note: After you activate a scene, you can adjust all the lighting circuits in the scene by sending dim or brighten com-

mands to the scene address.)

Removing a SwitchLinc LS from a Scene

Programming Scene Ramp Rates (optional)

You can adjust the rate at which each SwitchLinc LS in a scene ramps up and down. If you do not adjust this option for

a switch, its scene ramp rate will be the same as its primary address ramp rate.

Helpful Tools

If you’re investing in home automation,there are a few tools that will make your projects run smoother:

Invest in a Maxi-Controller

This plug-in transmitter has the ability to send individual X10 commands. The buttons are sepa-

rated into Addresses and Command functions. To use this controller,you have to press the address

(for example,“5”), then the command (ON, OFF, BRIGHT, etc.). Some of the KeypadLinc and

SwitchLinc advanced programming features need to be programmed with individual button press-

es in order to set certain features.For more info visit: http://www.smarthome.com/4020.html

X10 Signal Meter

This is an invaluable tool when it comes to installing and diagnosing problems.By knowing the signal strength at a

specific location, you can make sure that the signal will always trigger that X10 module.Generally, it’s ideal to have at

least 100mV at each location. Conservative installers will want even more; perhaps 250mV just in case the homeowner

installs a new big-screen TV after final installation. The extra margin will still give

the X10 receivers enough signal to be reliably triggered. These units can also be used

to measure the effects of signal absorption mentioned earlier. Plug in the transmitter

and measure the signal, then unplug the device that’s plugged into that outlet. If you

see a 10% or greater change, it’s time for a filter on that device. Smarthome has three

units to choose from:

http://www.smarthome.com/4814.html

http://www.smarthome.com/4811.html

http://www.smarthome.com/4813.html

Voltmeter or Voltage Tester

During the installation of SwitchLincs, it may be necessary to identify the wires inside the wall box. Knowing for sure

which wire is the HOT or LINE wires can reduce the guesswork when installing a single switch and it absolutely neces-

sary when working with 3-way lighting circuits. A voltmeter is ideal for this application. Many of the digital models

can also read current so you'll know how much power is being drawn by the SwitchLinc's load.

A simpler measurement tool, available at most home improvement centers, is a voltage sensor. This device, often cost-

ing less than $20, can sense voltage when its tip is placed near a wire. The tip of the voltage sensor can tell if voltage is

inside the wire without touching the bare copper conductor or breaking the insulation.

When using these tools, be certain to read and understand the safety instructions. Often when these tools are

used, the power to the circuit will need to be turned on. When working around live electrical wires, take your

time and concentrate on the task.

Helpful Hints for New Construction

By design, X10 equipment does not need much in the way of special wiring. The following are six items we recom-

mend for all homes with X10 installations:

1. Ask the builder or electrician to run the neutral wire to each wall switch location. This wiring may be a code

requirement or a regular practice in your area, but unless explicitly specified, it may get omitted. The SwitchLinc and

KeypadLinc controllers require the neutral connection.

2. Specify the installation of deep J-boxes in all locations where X10 switches, receptacles, or transmitters will be used.

While all X10 products fit in the spacing offered by all North American electrical boxes, the deep models have extra

working space and make the installation go a little easier. Deep boxes only costs a few cents more than normal depth

models. Look for single gang boxes that are 22cu or higher (cubic inches) and double gang boxes that are 36cu or

higher.

3. If the SwitchLinc is going to be controlling 400 watts or more,do not place insulation around the wall box and con-

sider using metal junction boxes. Dimmers that control high loads will dissipate heat that may be felt through the

switch faceplate. Metal boxes will more efficiently draw out the heat and spread it over all the surfaces of the box. By

keeping wall insulation four inches from the box, free air will help move the heat away from the switch and box.

4. Install a whole-house surge suppressor. Adding one whole-house surge protector at the beaker will help protect

against costly damage to the X10 components and other delicate electrical equipment.

Using a Maxi-Controller or

Similar Device

1. Transmit O16, N16, M16, P16, M16

(“clear” sequence)

2. Adjust all SwitchLincs (manually or

remotely) involved in this scene to the

desired brightness for the scene.

3. Transmit M16,N16,O16,P16 within 4

minutes of adjusting the first SwitchLinc

4. Transmit the desired scene address

(e.g., L1). The lights will blink.

Using TouchLinc

Control Setup Application

1. Press “CLR”

2. Adjust all SwitchLincs (manually or

remotely) to the brightness at which you

desire them to come on when the scene

is triggered

3. Press the desired scene address

(e.g., L1)

4. Press “Set”. The lights will blink.

Using TouchLinc

Control Setup Application

1. Press “CLR”

2. For each SwitchLinc to be removed from

the scene, activate the switch (either

manually or remotely) by turning it on/off,

brightening/dimming it, or sending its

Housecode and Unit Code and ON

3. Press the scene address from which

you want the SwitchLinc(s)

removed (e.g., L1)

4. Press “Del”. The lights will blink.

Using a Maxi-Controller or

Similar Device

1. Transmit O16, N16, M16, P16, M16

(“clear” sequence)

2. For each SwitchLinc to be removed from

the scene, activate the switch (either

manually or remotely) by turning it on/off,

brightening/dimming it, or sending its

Housecode and Unit Code and ON

3. Transmit O16,P16,M16,N16 within 4

minutes of activating the first SwitchLinc

to be removed

4. Transmit the scene address from which

you want the SwitchLinc(s) removed

removed (e.g., L1). The light(s) con

trolled by the SwitchLinc(s) removed from

the scene will blink (if they are still on.)

Using TouchLinc Control

Setup Application

1. Press “CLR”

2. For each SwitchLinc in the scene whose

ramp rate you want to change, adjust

the Brightness level (either manually

or remotely) to correspond to the

desired ramp rate (brighter=faster)

3. Press the scene address (e.g., L1)

4. Press “RR”. The lights will blink.

Using a Maxi-Controller or

Similar Device

1. Transmit O16, N16, M16, P16, M16

(“clear” sequence)

2. For each SwitchLinc in the scene whose

ramp rate you want to change, adjust

the Brightness level (either manually

or remotely) to correspond to the

desired ramp rate (brighter=faster)

3. Transmit N16,O16,P16,M16 within 4

minutes of adjusting the first SwitchLinc

4. Transmit the scene address (e.g., L1).

The lights will blink.

#4020 Maxi-

Controller

#4814 Power Line Signal Analyzer

89

SETTING OPTIONS

Factory Reset (to default settings)

If the SwitchLinc begins to operate strangely, the factory reset procedure can be used to clear the EEPROM's memory

and restore it factory default settings. Doing this procedure will clear the unit of all scene addresses and ramp rates.

1. Gently pull out the Status LED/ Set Button on the SwitchLinc until a click is heard. This completely removes

the power from the lighting circuit being controlled by the SwitchLinc.

2. Wait five seconds, push in and hold in the Status LED/ Set Button.

3. Release the Status LED/ Set Button after five seconds.

4. WAIT approximately 25 seconds until the Status LED/ Set Button illuminates before using the switch.

During this time, the Status LED/ Set Button will remain off and the load controlled by the SwitchLinc will

be off. When the reset procedure is complete, the load will come on to 100% and the SwitchLinc is ready for

initial programming or use.

SETTING GLOBAL (HOUSE-WIDE) OPTIONS

Disable Program

(Prevents accidental programming of SwitchLinc settings for all SwitchLincs in the home)

Transmit the following PLC sequence: M16, O16, P16, N16, P16

(Re-) Enable Program (default)

Transmit the following PLC sequence: N16, M16, O16, P16, P16

OTHER FEATURES

Power Restore

In the event of a power loss,the SwitchLinc will automatically return the lighting circuit being controlled to its last

brightness level when the power was interrupted.

HOW POWER LINE SIGNALS TRAVEL AROUND A HOME AND HOW

TO IMPROVE RELIABILITY

From time to time our tech support staff receives calls and e-mails from folks who have installed a large number of

X10 transmitters and receivers. Generally, the installer is experiencing problems communicating to some receivers.

Most of the time when a few modules and a transmitter are first installed, they all work together. Some folks may find

that after installing many modules, some of them don't respond to the transmitter or sometimes they do respond and

other times they don’t. However, odds are slim that after installing a dozen modules they will always work perfectly

without some help. The bottom line is that there is a reliability issue with the entire home automation system.

Most homes in North America have two lines of 120 volts coming into the home from the utility company. This split-

single phase electricity is divided out at the home’s breaker box into the circuits that feed light switches, plug in outlets,

and appliances.Half of the electricity outlets and wall switches are fed by one of the 120-volt lines and the second 120-

volt line feeds the other half. The intermittent operation of X10 modules usually happens when the transmitter is send-

ing signals on Line A and the receiver module is plugged into an outlet on Line B. For the signals to get between the

two, it must leave the home, travel to the utility company transformer then come back in on the other AC line. By the

time the signal gets back to the home, travels through the electrical meter and circuit breaker box, there may not be

enough signal left to trigger the module.

The first order of business will be to install a X10 coupler-repeater also known as

amplifier. A coupler-repeater will see the incoming signal, re-generate it, and blast it

out over the both legs of the 120 volts. We recommend that any home larger than

3000 square feet install a coupler-repeater. In smaller homes, a passive signal bridge

also known as a phase coupler may give satisfactory results.

Once the signal has been amplified, it’s time to preserve it. Since the X10 signals go

everywhere in the home, some electrical devices will have more of an effect on the

signal strength than other devices. X10 signals are like water pressure in pipes, it

actually goes everywhere it can. In the last 20 years, an explosion of electrical

devices has invaded our homes. Computers, video gear, and fancy electronics are more present than years past. The

more complicated the electrical power supply is in a device, the more likely it is to absorb signals. Engineers who

design power supplies build in traps to filter out and kill electrical noise. Unfortunately, the X10 signal looks like elec-

trical noise to these devices. The result is that a large percent of the transmitted signal is lost to these devices leaving

less for X10 receivers. The most common source of signal loss are:

Televisions Computer systems

Audio/Video gear Computer UPS's and power strips

Power supplies for laptops and cell phones

Testing for the problem is pretty simple. If a device is suspected of causing sig-

nal absorption,unplug the device and then re-transmit the signal. It’s very

important that the device is unplugged and not just turned off! If the X10 con-

trolled product begins working after the appliance is unplugged, then a filter will

be needed on that device to keep X10 signals from being absorbed and raise the

signal strength of the entire home. Smarthome has two filters on our website

and catalog (4845 and 4845ACF). An average home will need between three and five filters. If you are in the business

of installing automation systems and not in the‘call-back’ business, include some of these in your bid as part of the

standard package.

The number of X10 transmitters installed in a home will have an effect on the signal strength. Each X10 transmitter

contains a tuned circuit that when it’s not sending X10 signals it’s absorbing them! Generally, the closer the absorbing

transmitter is electrically to the sending transmitter, the more effect it will have on the other’s signal strength.

SwitchLincs 2-ways,KeypadLincs, and modules with Status Request are examples of transmitters. Installing a great

number of these will necessitate the use of amplifiers and filters.

Problems are typically seen in homes where there are over 20 SwitchLinc 2-ways or KeypadLincs installed and steps

have not been taken to increase or preserve the signal strength. With so many transmitters installed, the X10 signal is

loaded down. Even the SwitchLinc 2-Ways that are not programmed to transmit will still electrically absorb the signal.

If you like the idea of scene controlled lighting, but don’t need 2-way communications (the ability of the SwitchLinc to

transmit), look at the SwitchLinc LS dimmer. It has been designed so that it does not load down or absorb X10 signals.

#4821AC Coupler - Repeater

#4845 Plug-In Filters

This manual suits for next models

3

Table of contents

Other smart home Switch manuals

Popular Switch manuals by other brands

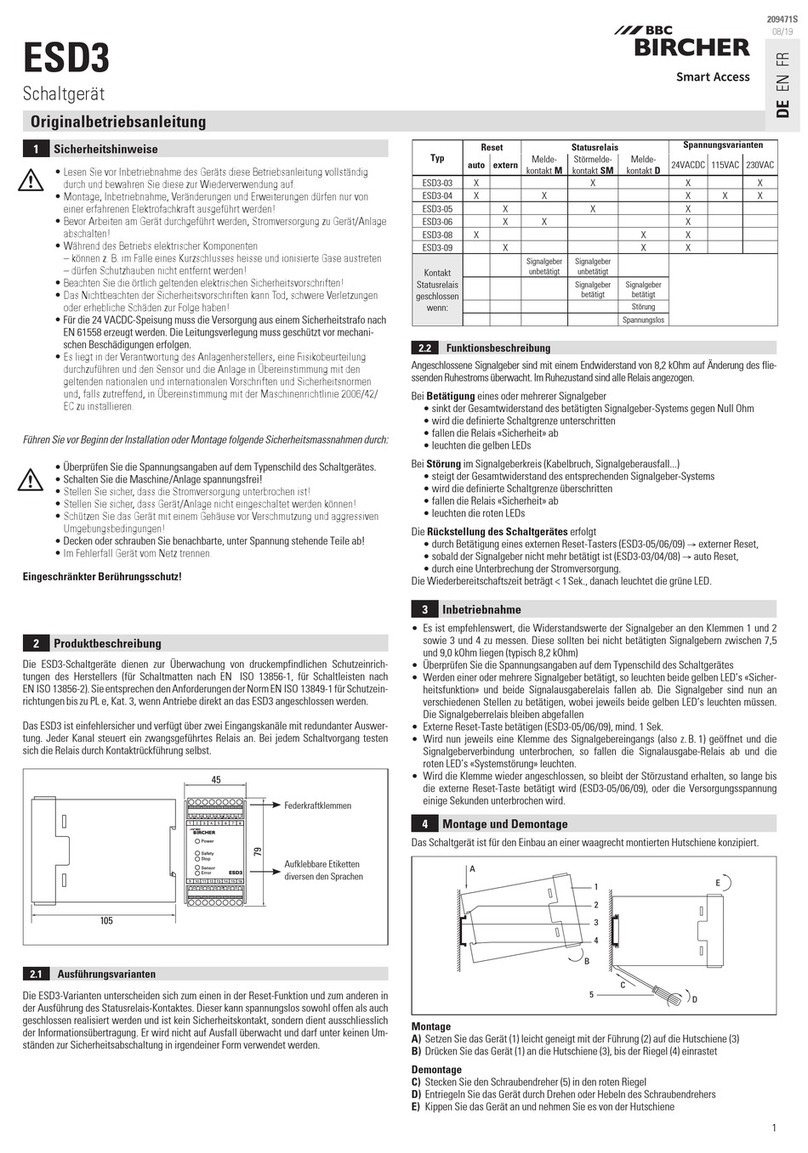

Bircher

Bircher ESD3 Translation of the original instructions

LevelOne

LevelOne FGP-1072 user manual

ZyXEL Communications

ZyXEL Communications ES1100-8HP-240W user manual

HPE

HPE FlexNetwork 5130 EI Series Configuration guide

PESA

PESA Cougar Series Open Me First

United Electric Controls

United Electric Controls 117 Series Installation and maintenance instructions