14

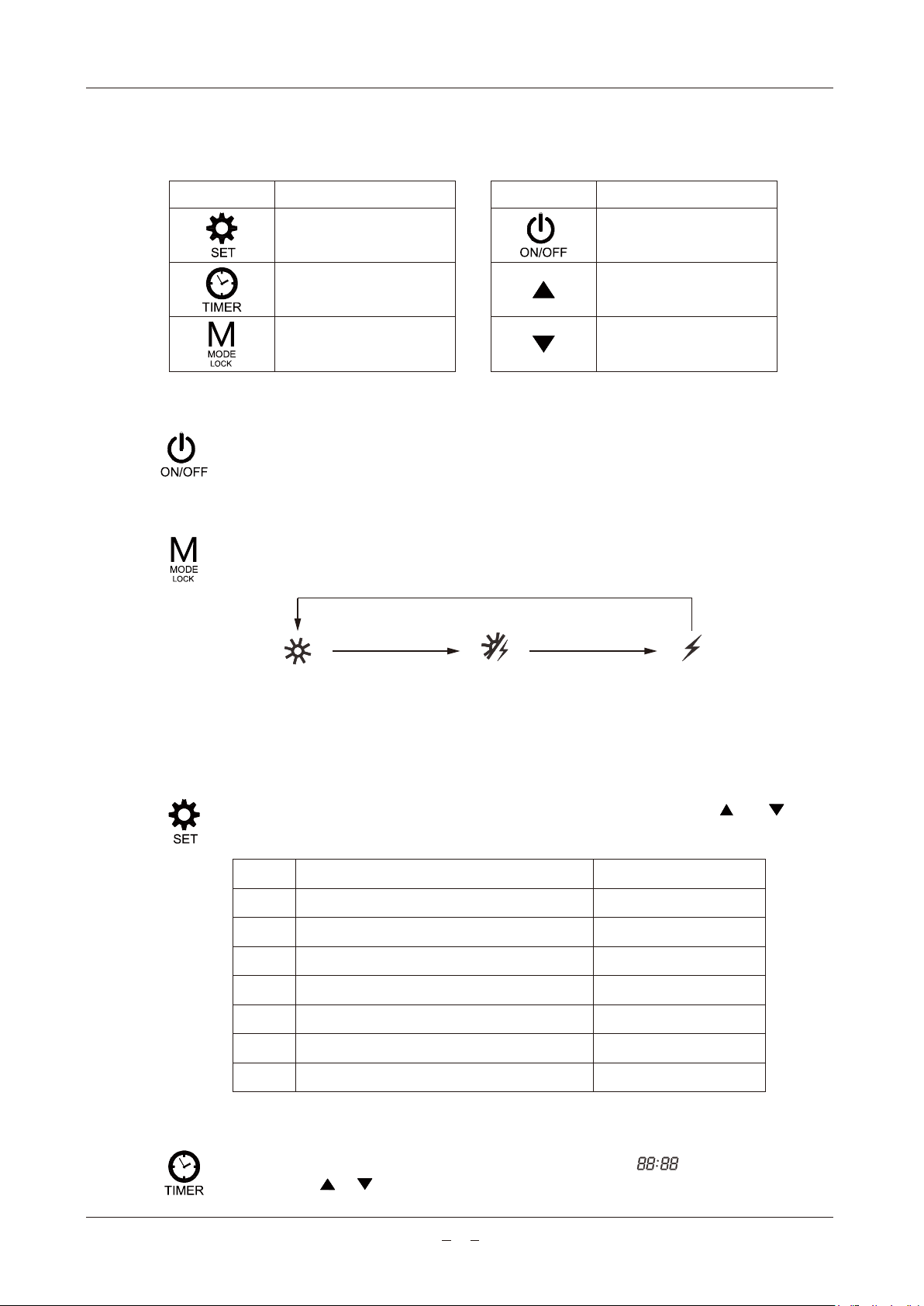

Press the timer button for 5 seconds, the timer setting state will be entered. After press it for 5 seconds, the timer

on icon and the hour of the clock will be flashed, and press or buttons to set the hour as you needed. Press

the timer button again, the minutes will be flashed. With the same steps, set the minute.

After the clock setting of the Timer on, press the timer button to confirm the setting of the timer on. After pressing

the timer button, the timer off icon will be flashed. Repeat the same steps, set the clock of the timer off. After the

timer off setting, please press the timer button again to save the timer on and off setting, and exit the setting.

When the timer on/off is already set, press the SET button, and the timer on/off will be cancelled.

5.3.5 Increase/up button and Decrease/down button

5.3.6 Disinfect function

These two buttons is used when the temperature setting, the clock setting and parameters query.

When the unit is running, press these two buttons together, and all the buttons will be locked. At the same time,

the lock icon will be displayed. Press the two buttons together, the lock function will be canceled.

Under the running state of the unit, the water setting temperature can be raised by pressing the increase/up

button, while the water setting temperature can be lowered by pressing the Decrease/down button.

45% tank volume boosted to 60°C daily.

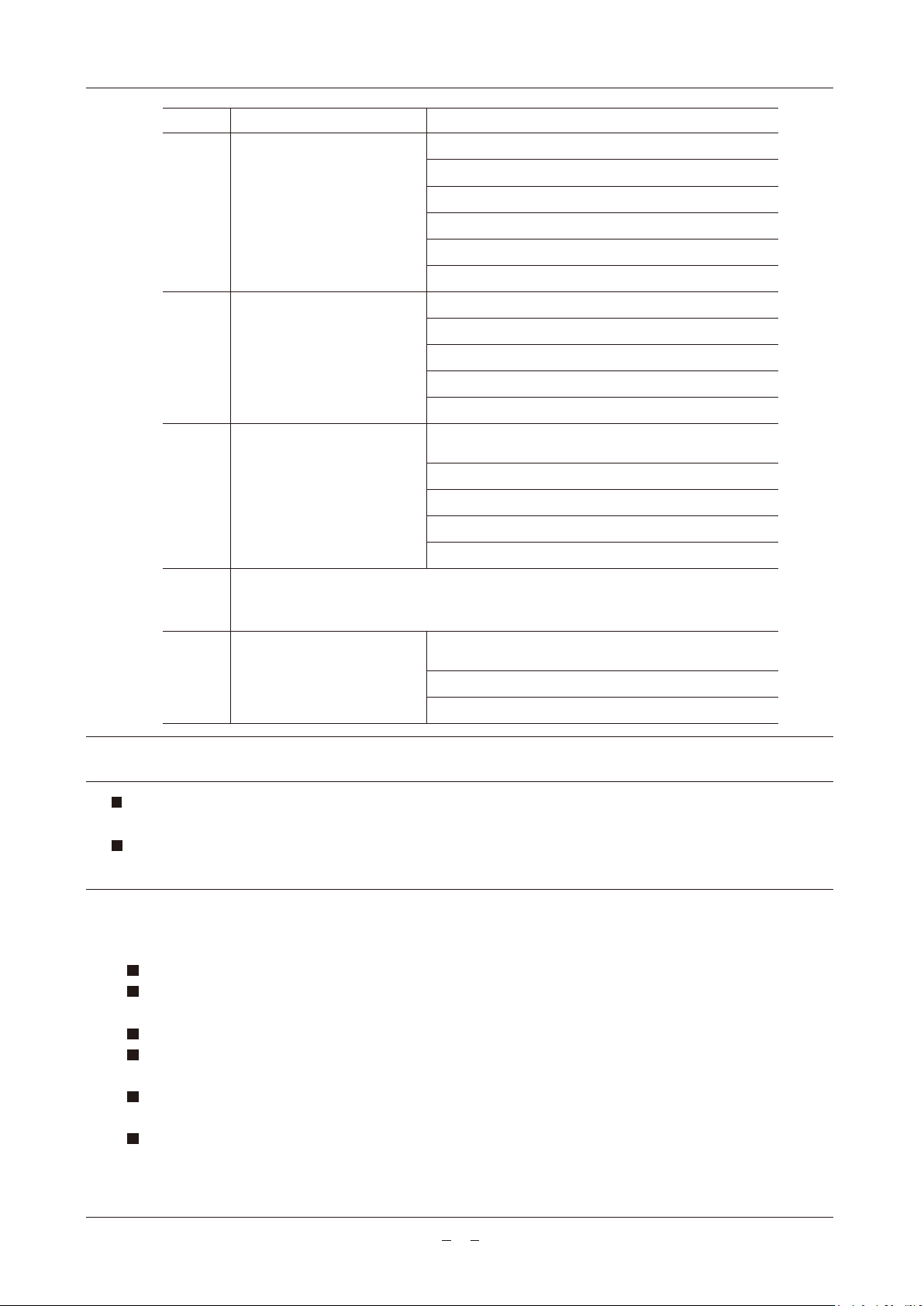

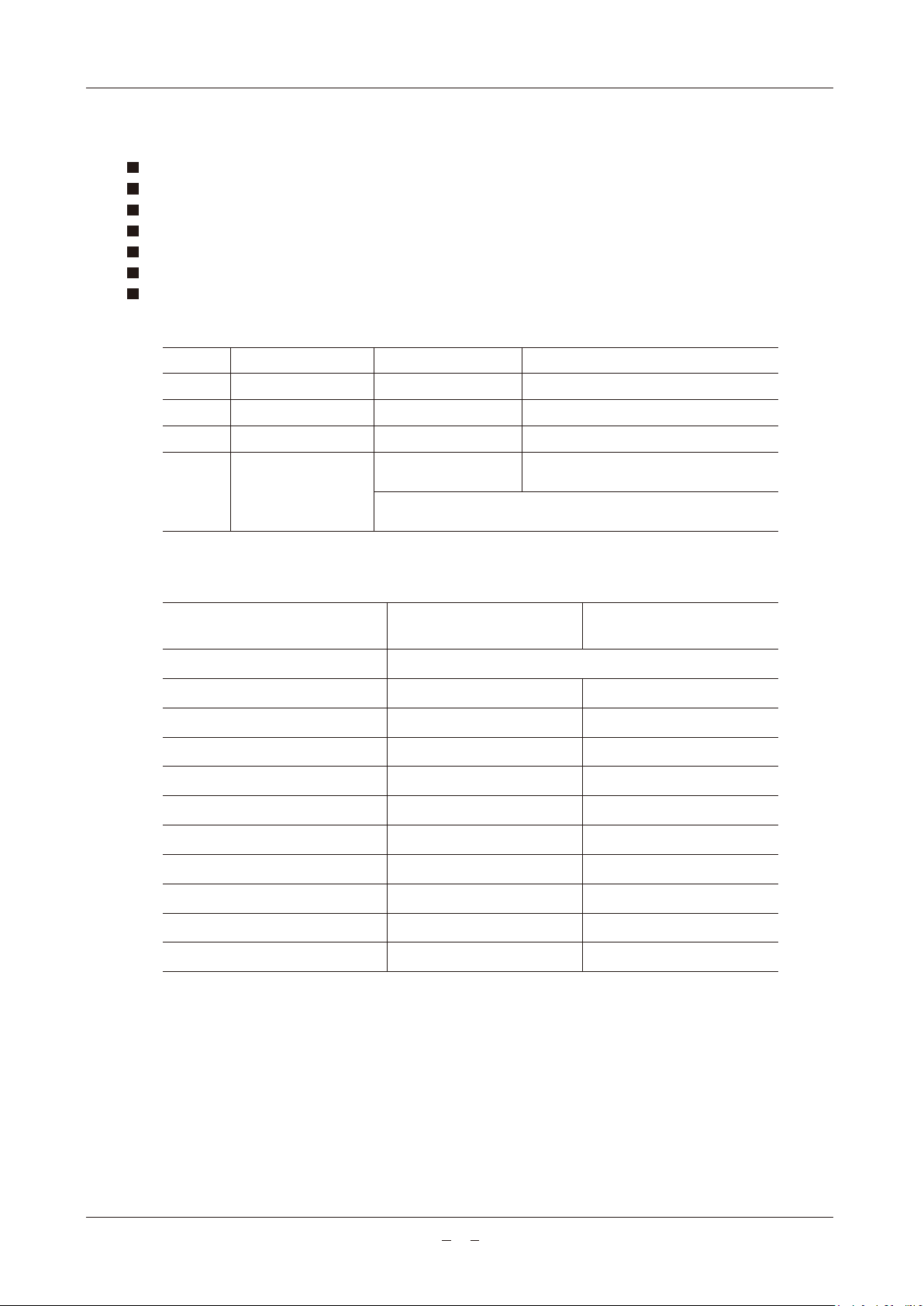

6. Troubleshooting

6.1 Non-error tips

6.2 Something about self-protection of unit

Why compressor cannot start immediatedly after setting?

Unit will wait for 3 minutes to balance the pressure of the refrigerant system before starting compressor agian. It is

a self protection logic of the unit.

Q:

A:

Why sometimes the temperature shown on the display decreased but the unit still keep off?

To avoid the unit turning on/off frequently, the unit will activate heat pump only when the water temperature in the

bottom of the tank is lower than the setting temperature.

Q:

A:

Why sometimes the unit shows ‘PA’ on the display?

The heat pump available running ambient temperature is from -7°C to 40°C. If the ambient temperature is out of

this range, the unit will show the PA to let user notice it.

Q:

A:

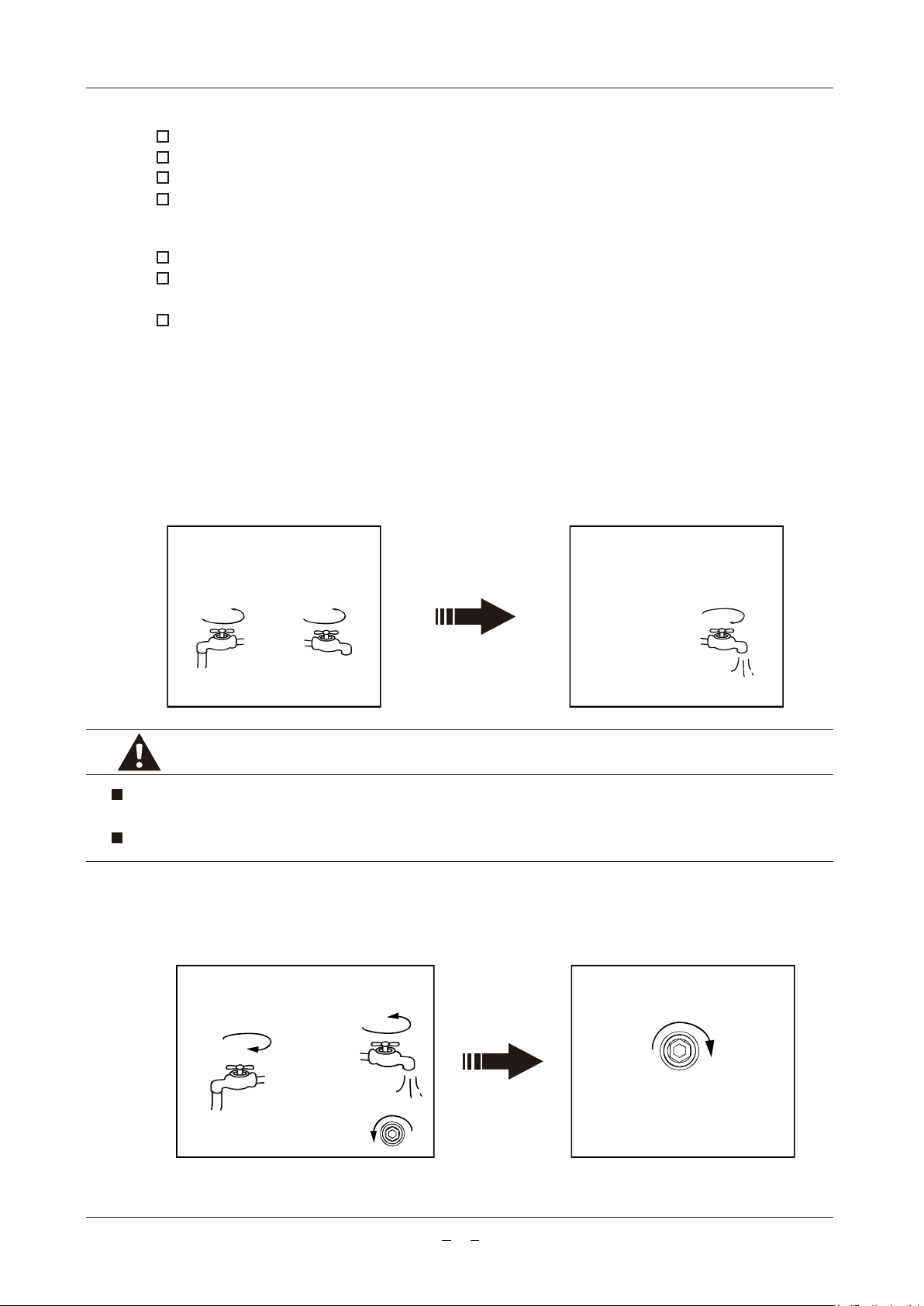

Why sometimes there is some water flowed from drainage pipe of PTR valve? (When the unit with PTR valve)

Because the water tank is pressure-bearable one, when water is heated inside the tank, water will expand, so the

pressure inside the tank will increase. If the pressure goes up more than 1.0MPa, PTR valve will activate to relief

the pressure and hot water drop will be discharged correspondingly. If water drop is continually discharged from

PTR valve drainage pipe, it is abnormal, please contact qualified staff to repair.

Q:

A:

Why sometimes the temperature shown on the dispay decreased while unit is running?

When the temperature of layer water inside the tank is much higher than the bottom part, upper hot water will be

mixed by the bottom cold water which is continually flow from the inlet tap water so that will decrease the water

temperature of upper part .

Q:

A:

When the self-protection happens, the unit will be stopped and start sef-check, and restart when the protection

resolved.

In the following circumstance, self-protection may happen:

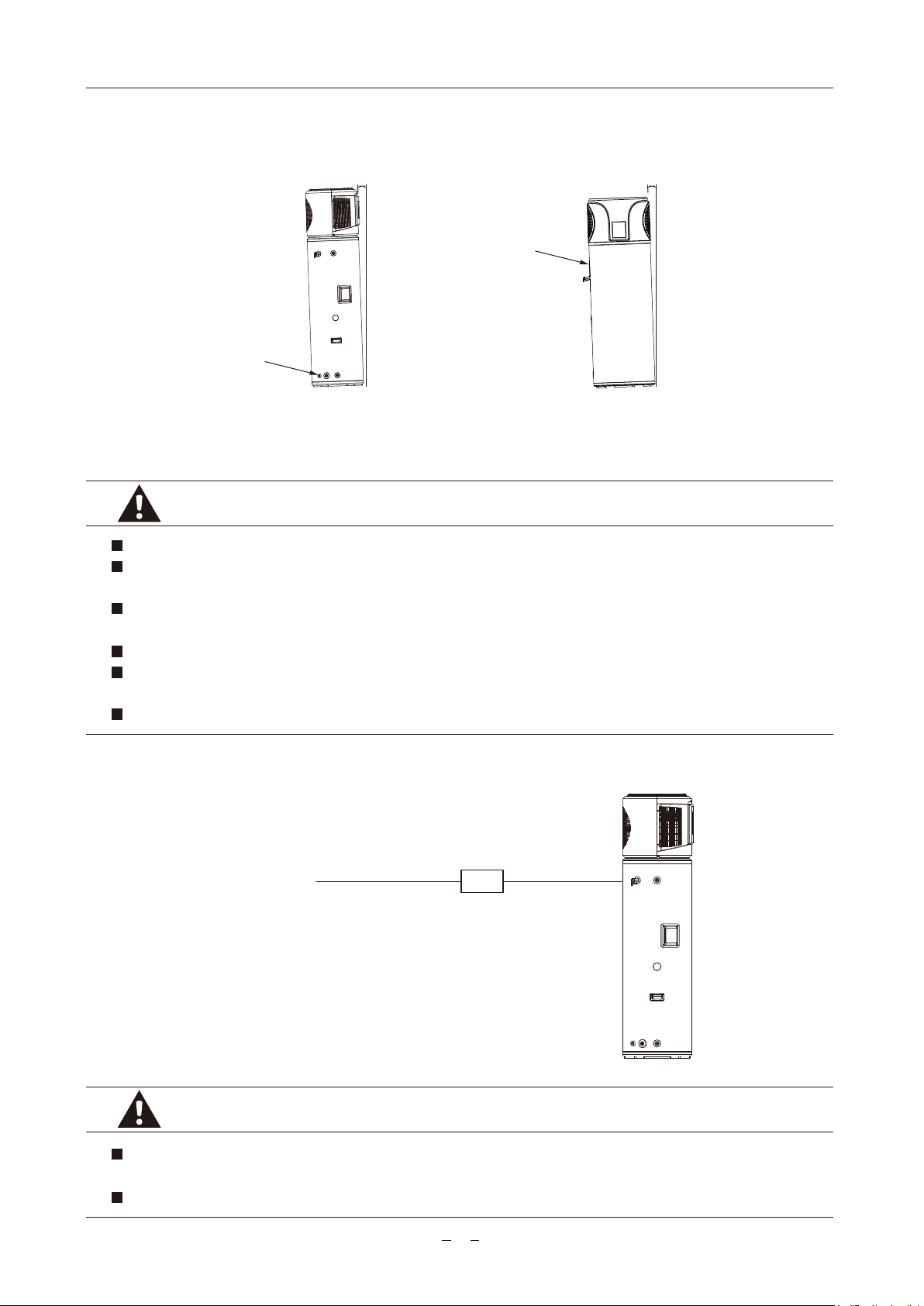

Air inlet or outlet is blocked;

The coil is covered with too much dust;

Incorrect power supply (Exceeding the range of 220-240V).