SMART-SCAN 7000 Series User manual

This manual suits for next models

25

Table of contents

Other SMART-SCAN Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

ML Accessories

ML Accessories BT ACTS Series Installation & maintenance manual

Milwaukee

Milwaukee HOBL 7000 Original instructions

Beamz

Beamz 4-SOME instruction manual

Hoselink

Hoselink L245 user manual

BARRON

BARRON EXITRONIX 82 Series manual

hudson valley

hudson valley mitzi MAIA HL692401 installation instructions

Patriot Lighting

Patriot Lighting 343-1471 installation manual

Blizzard Lighting

Blizzard Lighting Mezmerizor 4FX user manual

Somogyi Elektronic

Somogyi Elektronic Home FLR10LED instruction manual

Ikan

Ikan lightstar LSW-003 quick start guide

Elation

Elation Rayzor Q7 user manual

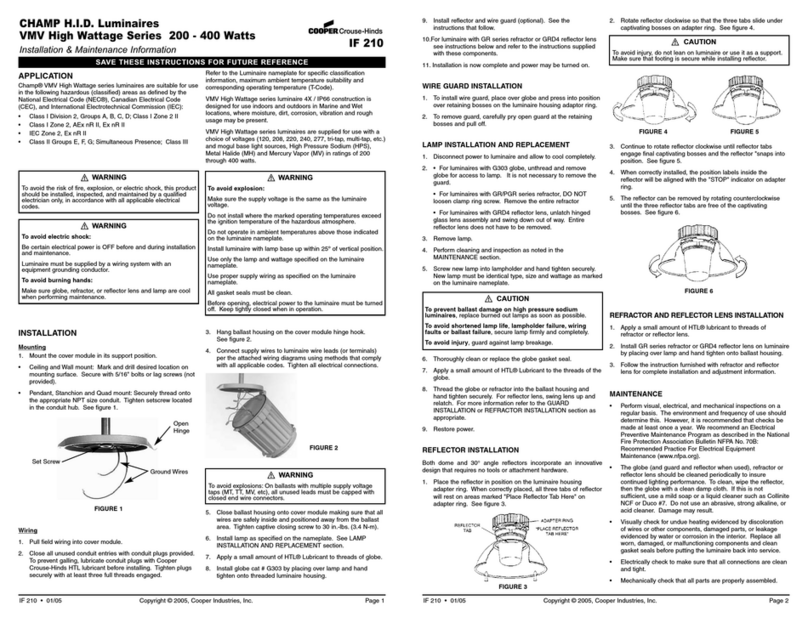

Cooper Crouse-Hinds

Cooper Crouse-Hinds Champ VMV High Wattage Series quick start guide

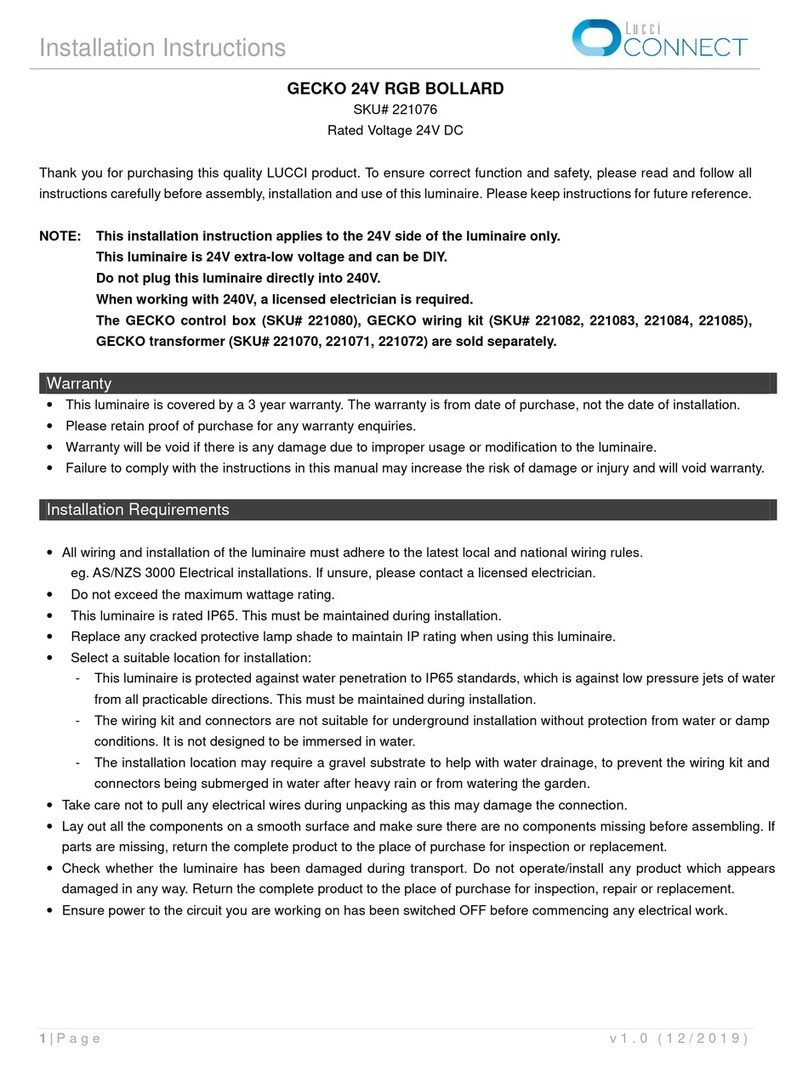

Lucci CONNECT

Lucci CONNECT GECKO 221076 installation instructions

Avlite

Avlite AV-OL-FL864-12-R Service manual

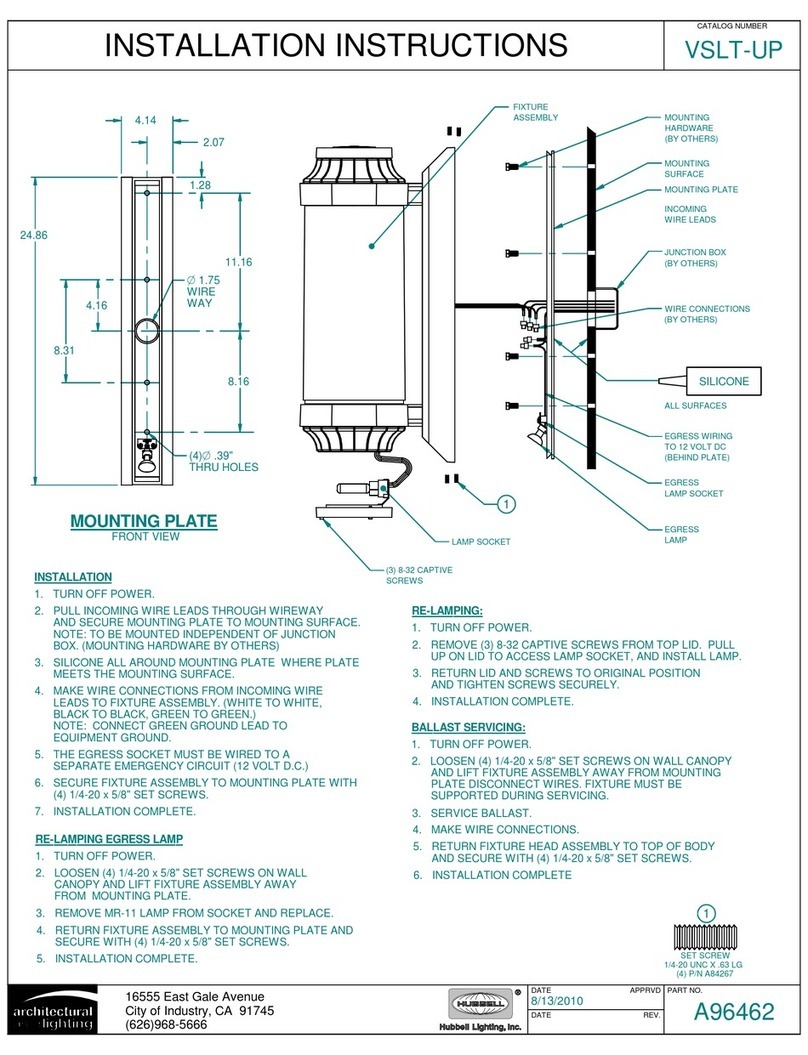

Hubbell

Hubbell VSLT-UP installation instructions

RANCEO

RANCEO See Snake CLH25 instruction manual

BARRON

BARRON EXITRONIX LL30 Series installation instructions

Avantes

Avantes AvaLight-LED Operation and installation manual