SMART-SCAN T2A Series User manual

T2A SERIES

SAFETY LIGHT CURTAINS

INSTALLATION GUIDE

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 2 Date: 27 November, 2017

SMARTSCAN TW Ltd

2F, No. 5, 10th Road, Taichung Industrial park,

Taichung City, Taiwan, R.O.C.

TEL: 886 - 4 - 23598885

FAX: 886 - 4 - 23599423

Important!

Failure to read and follow the instructions provided on the Installation Sheet and

Installation Guide can lead to the incorrect application or use of the T2A series safety light

curtain. This could lead to personal injury and damage to equipment. All applicable

machine safety standards and regulations should be taken into account when installing

the T2A series safety light curtain or any machine safety product.

The Installation Sheet and Installation Guide can be downloaded from our web site at

www.smartscan.com.tw

The T2A series Safety Light Curtain Installation Guide (CD1008A) is subject to change

without notice. SMARTSCAN TW Ltd shall not be held responsible for technical errors,

editorial errors or omissions contained herein, nor for incidental or consequential

damages resulting from the use of this material.

© 2016 SMARTSCAN TW Ltd. All Rights Reserved. Unless explicitly stated

otherwise, all rights including those in copyright in the content of this document are owned

by or controlled for these purposes by SMARTSCAN TW Ltd.

Except as otherwise expressly permitted under copyright law or SMARTSCAN TW Ltd,

reproduction of the document or alteration of this document may not be carried out in any

way without first obtaining SMARTSCAN TW Ltd's written permission.

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 3 Date: 27 November, 2017

Contents:

Figure A – Unpacking .....................................................................................................................................4

Figure B – Mounting Information ..................................................................................................................5

Figure C – Dimensional Information ..............................................................................................................6

Figure D – Operating Requirements ..............................................................................................................9

Figure E – Important Installation Considerations ........................................................................................11

Figure F - Electrical Connections..................................................................................................................13

Power Supply .......................................................................................................................................14

Only Automatic Reset mode................................................................................................................14

Safety Outputs OSSD1 and OSSD2.......................................................................................................15

Communication Link ........................................................................................ 錯誤! 尚未定義書籤。

Figure G,I – Status and Diagnostic Indication ..............................................................................................16

Receiver (RX) Status Indicators ............................................................................................................17

Emitter (TX) Status Indicators ..............................................................................................................18

Receiver (RX) Diagnostic Indicators (S1, S2 LED) .................................................................................18

Figure H – Identification Labels ...................................................................................................................20

Figure J – Test and Maintenance .................................................................................................................22

Testing the safety light curtain with the test piece..............................................................................22

Maintenance........................................................................................................................................24

Figure K – Operation Cycle...........................................................................................................................25

Figure L – Product Return Procedure...........................................................................................................26

Figure M – Model List ..................................................................................................................................27

Figure N – Declaration of Conformity..........................................................................................................35

Figure O – Glossary of Words and Language Translation ............................................................................38

Appendix 1 – Important Safety Information................................................................................................39

Appendix 2 - Certifications ..........................................................................................................................40

Appendix 3 - Mirrors ....................................................................................................................................41

Appendix 4 – Specification Table .................................................................................................................45

Notes............................................................................................................................................................47

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 4 Date: 27 November, 2017

T2A Series (Model No. T2A-xxx) Safety Light Curtain

Installation Sheet (CD1008A/211117)

Figure A – Unpacking

Remove all packaging material and retain it

Locate and keep the delivery note

Inspect all items for transit damage

Match goods supplied to those specified on the delivery note

Keep the Installation Sheet in a safe place

Each T2A series supplied would normally include:

Safety Light curtain

Test piece

Installation sheet

Service questionnaire form

Storage requirements:

Humidity - <95%

Temperature range between –20°C and +70°C

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 5 Date: 27 November, 2017

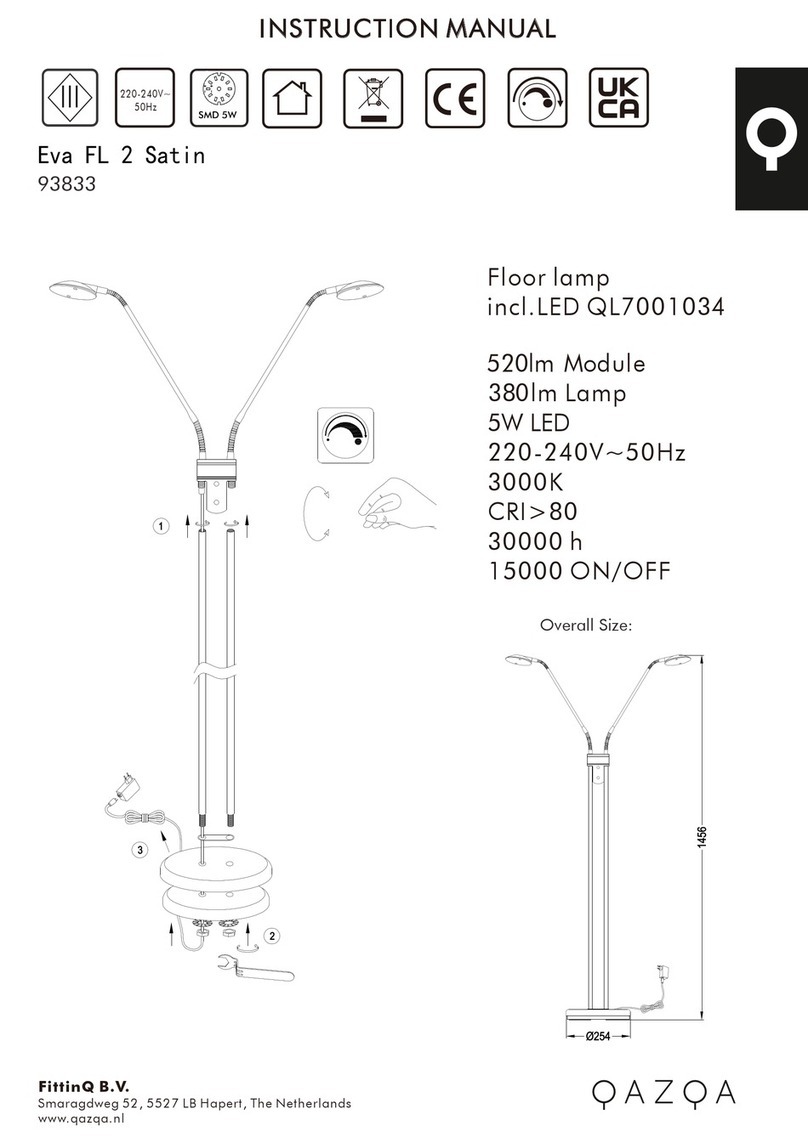

Figure B – Mounting Information

The T2A series comes with mounting brackets as standard. The mounting brackets are located

at the ends of the safety light curtain as shown above. The mounting bracket may be fixed at 90

degrees, with a +/-5˚ adjustment.

Use 4mm bolts for mounting and ensure they are fixed so as to prevent any movement or

loosening of the safety light curtain.

The T2A series used M12 cable connectors. Both the transmitter (Tx) and receiver (Rx) units

come complete with 3m cables attached. (Note: Option for 5m, 10m, 15m, 20m cables.)

Transmitter = 4 core cable.

Receiver = 5 core cable.

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 6 Date: 27 November, 2017

Figure C – Dimensional Information

Figure C describes important parameters associated with the safety light curtain such as

detection zone width (DZ).

T2A series

T2B series

T2C series

Measurements are shown for the safety light curtain’s overall length (including mounting

brackets), fixing centres and detection zone width.

The detection zone width (DZ) or protected height is needed to select the appropriate length to

cover the access area.

The light curtain’s dimensions including the mounting bracket are overall length (L) x 30mm width

x 30mm depth.

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 7 Date: 27 November, 2017

The overall length (L), mounting centres (CTR) and detection zone width (DZ) in millimeters for

each individual model is listed in Figure M.

T2A series T2B series

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 8 Date: 27 November, 2017

T2C series

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 9 Date: 27 November, 2017

Figure D – Operating Requirements

Humidity <95%

Temperature range between 0°C and +50°C

Vibration: Frequency <55Hz Max. Movement <0.35mm

Do not use equipment in explosive atmospheres (contact the manufacturer for further

advice).

Detection Zone width (DZ)

The detection zone width or protected height must be of a suitable size for each application to

prevent personnel access to the danger area. This can be over, under or around the light

curtains detection zone.

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 10 Date: 27 November, 2017

Object Detection Capability (ODC)

The minimum size of object guaranteed to be detected when placed in the light curtain’s infrared

sensing field. A test piece of appropriate size is provided to test that the light curtain object

detection capability is within the parameter specified for the particular model number.

Transparent objects are not detected.

Range

This is the maximum scanning range of the light curtain between the Transmitter (TX) head and

Receiver (RX) head. Ensure the light curtain is capable of satisfying the range requirement for

the particular application it is being used for.

Reset Location

Reset devices must be located such that the danger area can be seen to be clear of persons

before the system is activated. The reset device should not be accessible from inside the

danger area.

Environmental factors can affect the operation of a safety light curtain and proper consideration

should be taken into account for mounting a system where fog, rain, smoke, dust, large

temperature fluctuations etc is a consideration.

Safety light curtains do not protect personnel from chemicals, heat, gases, radiation, flying parts

etc. They are not a physical barrier.

The machine operators must be instructed in the use of the safety light curtain by the

owner/provider of the machinery.

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 11 Date: 27 November, 2017

Figure E – Important Installation Considerations

1. Consider reflective surfaces that

may give rise to an optical ‘short

circuit’ from the direct path of the

safety light curtain’s infrared

beams as shown in the first

illustration of Fig. E. To ensure

the safety light curtain is mounted

far enough away from reflective

surfaces use the formula provided

to calculate the minimum distance

(X) between the light curtain and

reflective surface.

2. To prevent intermittent tripping of

the safety light curtain ensure that

extraneous infrared energy

between 800 and 1000

nanometers is not directed towards

the Perspex window of the receiver

unit (RX). Extraneous sources

would include infrared sensors,

infrared remote controls, scanning

systems or sunlight.

3. To prevent personnel from reaching

the danger point of the machine

additional mechanical guarding

may be required so that any access

has to be through the sensing field of the safety light curtain. The safety light curtain must be

positioned so as to prevent any overreach or under reach to the danger point. It must not be

possible to stand between the safety light curtain and the danger point.

The protection afforded by the safety light curtain should correspond to the machine Risk

Assessment under ISO 12100 for the machine being guarded.

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 12 Date: 27 November, 2017

4. Ensure the light curtain transmitter (TX) and receiver (RX) units are mounted accurately

in-line with each other and are both perpendicular and parallel to each other within the

parameters shown for each axis.

5. If utilising mirrors to deflect the light curtain ensure the mirror length is 50mm longer at either

end of the light curtain detection zone width and mounted centrally to the zone. To ensure

reliable operation the light curtain deflection angle (A) from the mirror must not be less than

40 degrees or greater than 100 degrees. (SeeAppendix 3)

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 13 Date: 27 November, 2017

Figure F - Electrical Connections

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 14 Date: 27 November, 2017

Power Supply

Use a regulated power supply +24V DC ±10% fused at 1.5A. The T2A light curtain current

consumption is rated at 0.5A + load current of the OSSDs. The Brown wire on both the

Transmitter (TX) and Receiver (RX) head cables must be connected to 24V DC (L+). The Blue

wire on both the Transmitter (TX) and Receiver (RX) head cables must be connected to 0V DC

(L-).

Before the power supply is applied to the light curtain ensure both TX and RX heads are aligned

correctly.

Only Automatic Reset mode

The automatic reset mode allows the safety light curtain to be reset automatically, that is, on a

blockage of the safety light curtain’s sensing field it will turn off the safety outputs (OSSDs).

Removing the blockage from the sensing field of the light curtain will re-activate and turn on the

safety outputs (OSSDs). The configuration of the safety light curtain in the auto reset mode will

depend on the customer’s risk assessment for the machine.

Warning The shield on both the Transmitter (TX) and Receiver (RX) head

cables must be connected to Earth (PE).

Warning Do not disconnect the cables from the Transmitter (TX) or Receiver

(RX) head with the power still connected to the T2A series light curtain.

Any wiring or re-wiring of the light curtain must be done with the power supply

disconnected.

Any input or output signals that are not being used must be terminated safe.

The machine must be disconnected during electrical installation to ensure no

inadvertent start up of the machine occurs.

The connection cables must be not be routed with high-voltage cables, e.g.

inverter cables or motor power supplies.

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 15 Date: 27 November, 2017

Safety Outputs OSSD1 and OSSD2

Two independent (PNP) electronic switching failsafe signal outputs (OSSDs) are provided for the

machine safety circuit. Interruption of the safety light curtains infrared sensing field will cause

the OSSDs to go to an OFF state and initiate a machine stop condition.

The connections are provided via the Black wire (OSSD1) and the White wire (OSSD2) on the

Receiver (RX) head cable.

Outputs ON = +24V DC (Light curtain clear)

Outputs OFF = 0V DC (Light curtain blocked)

The electronic outputs are monitored and rated at a maximum switching rating of 24V DC,

500mA. LED indicators located on the Receiver (RX) head show the status of the OSSDs.

Green LED ON = OSSD1 and OSSD2 active ON

Red LED ON = OSSD1 and OSSD2 inactive OFF

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 16 Date: 27 November, 2017

Figure G,I – Status and Diagnostic Indication

The T2A series has status indication LEDs on the Receiver (RX) and LED S1, S2 used for error

mode indication, the LEDs was located at the bottom of the Receiver (RX) head.

They provide a range of functions to help in the set-up of the safety light curtain and in fault

diagnosis.

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 17 Date: 27 November, 2017

Figure G & I defines the features (F) associated with the Smartscan T2A light curtain system.

Receiver (RX) Status Indicators

F1 –CLEAR (Light curtain active or blocked) (Two color LED, Red & Green)

CLEAR GREEN LED ‘on’ and RX OSSD OFF LED ‘off’ = Light curtain has been initiated

and the OSSDs are in the on state, (only when the light curtain detection zone is clear of

any obstruction).

The CLEAR (Red LED) provides one functions,

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 18 Date: 27 November, 2017

RED LED ‘on’ = Light curtain safety off. OSSD1 and OSSD2 are ‘OFF’ e.g. when

the light curtain detection zone is ‘blocked’.

All CLEAR (Green LED) ‘on’ = Light curtain aligned.

F3 – OSSD (OSSD output status) (Red LED)

Red LED ‘on’ = OSSD output turn OFF.

Red LED ‘off’ = OSSD output turn ON.

Red LED ‘blinking’ = the light curtain system is in lockout.

If the Red LED indicator is flashing the system is in lockout. To recover from a lockout

condition, disconnect the transmitter and receiver from the power source and then

re-apply.

Emitter (TX) Status Indicators

F2 – CLEAR (Light curtain active or blocked) (Two color LED, Red & Green)

CLEAR GREEN LED ‘on’ and RX OSSD OFF LED ‘off’ = Light curtain has been initiated

and the OSSDs are in the on state, (only when the light curtain detection zone is clear of

any obstruction).

The CLEAR (Red LED) provides one functions,

RED LED ‘on’ = Light curtain safety off. OSSD1 and OSSD2 are ‘OFF’ e.g. when

the light curtain detection zone is ‘blocked’.

All CLEAR (Green LED) ‘on’ = Light curtain aligned.

Receiver (RX) Diagnostic Indicators (S1, S2, S3 LED)

Fault Diagnosis

The display panel also provides 6 different error codes, (E0, E1, E2, E3, E4, E5, E6) to aid

fault diagnosis.

E0 = Light curtain OSSDs output disparity

The E0 error code will be displayed if an electrical short-circuit occurs with the 2

independent (PNP) electronic switching failsafe signal outputs (OSSD1) of the

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 19 Date: 27 November, 2017

safety light curtain or they are being driven higher than the 500mAmaximum

specification.

E1 = Light curtain OSSDs output short

The E1 error code will be displayed if an electrical short-circuit occurs with the 2

independent (PNP) electronic switching failsafe signal outputs (OSSD2) of the

safety light curtain or they are being driven higher than the 500mAmaximum

specification.

E2 = RX internal system error, EMC CPU I/O port fault

The E2 error code will be displayed if an electrical short-circuit occurs with the 2

independent (PNP) electronic switching failsafe signal outputs (OSSDs) of the

safety light curtain or they are being driven higher than the 500mAmaximum

specification.

E3 = TX, RX Communication error

The E3 error code will be displayed, if failure in RX EMC CPU U1 Beam 1~4 I/O

port status is error (short circuit).

Safety Light Curtain – T2A Series

Installation Guide

File Number: CD1008A

page 20 Date: 27 November, 2017

Figure H – Identification Labels

Examples are shown below of the identification labels that are affixed to the bottom of the

transmitter (TX) and receiver (RX) columns.

T2A series T2B series

This manual suits for next models

82

Table of contents

Other SMART-SCAN Lighting Equipment manuals