Smartgen HRC200 User manual

SMARTGEN (ZHENGZHOU) TECHNOLOGY CO., LTD.

HRC200

INDUSTRIAL REMOTE CONTROL

USER MANUAL

HRC200 Industrial Remote Control User Manual Page 2 of 16

Chinese trademark

English trademark

SmartGen —make your generator

smart

SmartGen Technology Co., Ltd.

No.28 Jinsuo Road

Zhengzhou

Henan Province

P. R. China

Tel: +86-371-67988888/67981888/67992951

+86-371-67981000(overseas)

Fax: +86-371-67992952

Email: sales@smartgen.cn

Web: www.smartgen.com.cn /www.smartgen.cn

All rights reserved. No part of this publication may be reproduced in any material form (including

photocopying or storing in any medium by electronic means or other) without the written permission of

the copyright holder.

Applications for the copyright holder’s written permission to reproduce any part of this publication

should be addressed to Smartgen Technology at the address above.

Any reference to trademarked product names used within this publication is owned by their respective

companies.

SmartGen Technology reserves the right to change the contents of this document without prior notice.

Table 1 Software Version

Date

Version

Note

2021-07-02

1.0

Original release.

HRC200 Industrial Remote Control User Manual Page 3 of 16

CONTENT

1 OVERVIEW....................................................................................................................................................4

2 PERFORMANCE AND CHARACTERISTICS ................................................................................................4

3 SPECIFICATION ...........................................................................................................................................5

4 PANEL AND WIRING TERMINAL DESCRIPTION........................................................................................6

4.1 HRC200R REMOTE CONTROL PANEL INDICATORS AND KEYS........................................................6

4.2 HRC200M RECEIVER PANEL INDICATORS AND INTERNAL KEYS....................................................8

4.3 COMMUNICATION CHANNEL CONFIGURATION ...............................................................................8

4.4 PAIRING.................................................................................................................................................9

4.5 RS485 INTERFACE............................................................................................................................. 10

4.6 RECEIVER WIRING TERMINAL.......................................................................................................... 11

5 PROGRAMMABLE PARAMETERS............................................................................................................ 12

5.1 PC PARAMETER SETTING ................................................................................................................ 12

5.2 PARAMETER RANGE AND DEFINITION ........................................................................................... 12

6 SYSTEM APPLICATION DIAGRAM .......................................................................................................... 13

7 OVERALL AND INSTALLATION DIMENSIONS ........................................................................................ 15

7.1 REMOTE CONTROL OVERALL DIMENSION..................................................................................... 15

7.2 RECEIVER OVERALL DIMENSION..................................................................................................... 15

8 TROUBLESHOOTING................................................................................................................................ 16

HRC200 Industrial Remote Control User Manual Page 4 of 16

1OVERVIEW

HRC200 is a long-distance wireless remote control with LoRa wireless chip transmission and

remote control distance of more than 200m. Used with engine controller, it can realize remote start,

stop, load, unload, emergency stop and other functions. HRC200 adopts fully sealed structure, IP65

protection level, which can effectively prevent dust, water or others from entering the controller, making

the controller operate stably and reliably, suitable for field, mining, urban construction and other

application sites with complex working conditions.

2PERFORMANCE AND CHARACTERISTICS

HRC200 industrial remote control is composed of remote control HRC200R and receiver HRC200M,

applying LoRa wireless transmission chip.

Remote Control:

——Can realize remote start, stop, load, unload, emergency stop and other functions, indicate

engine running/alarm, remote control battery, command send/receive status;

——Powered by 4 AA batteries;

——With remote control distance of more than 200m, 15 optional communication channels;

——Whole protection level can reach IP65.

Receiver:

——With RS485 interface, 5 output ports and 2 input ports, can control engine controller via RS485

interface or relay output port;

——With power, RS485, LoRa communication status indicator; 15 optional communication

channels;

——Supply range DC (8~35)V;

——Can set its parameters via PC;

——Modular structure design, anti-flaming ABS plastic shell, light weight, compact structure and

easy installation;

——Standard Πtype 35mm guide rail installation or screw installation is applied.

HRC200 Industrial Remote Control User Manual Page 5 of 16

3SPECIFICATION

Table 2 Technical Parameters

Item

Contents

Remote Control HRC200R

Working Voltage

Powered by 4 AA alkaline batteries.

Overall Consumption

Can last about 72 hours.

Case Dimension (LxWxH)

156.9mmx63mmx53mm (without antenna)

Working Conditions

Temperature: (-25~+70)°C Humidity: (20~95)%RH

Actual working temperature is limited by battery characteristics.

Storage Condition

Temperature: (-30~+80)°C

Weight

0.2kg (without battery)

Receiver HRC200M

Working Voltage

DC (8~35)V

Overall Consumption

≤1.2W

Aux. Input Port

B- connected is active.

Aux. Output Port

Relay normally open volt-free output, specification DC30V/2A

RS485 Interface

Isolated, half-duplex, 2400/4800/9600/19200 baud rate can be set,

Modbus-RTU communication protocol, longest communication

distance 1,000m.

LINK

SmartGen special interface for program upgrade.

Case Dimension (LxWxH)

105mmx72.5mmx34mm

Working Conditions

Temperature: (-25~+70)°C Humidity: (20~95)%RH

Storage Condition

Temperature: (-30~+80)°C

Weight

0.2kg

HRC200 Industrial Remote Control User Manual Page 6 of 16

4PANEL AND WIRING TERMINAL DESCRIPTION

4.1 HRC200R REMOTE CONTROL PANEL INDICATORS AND KEYS

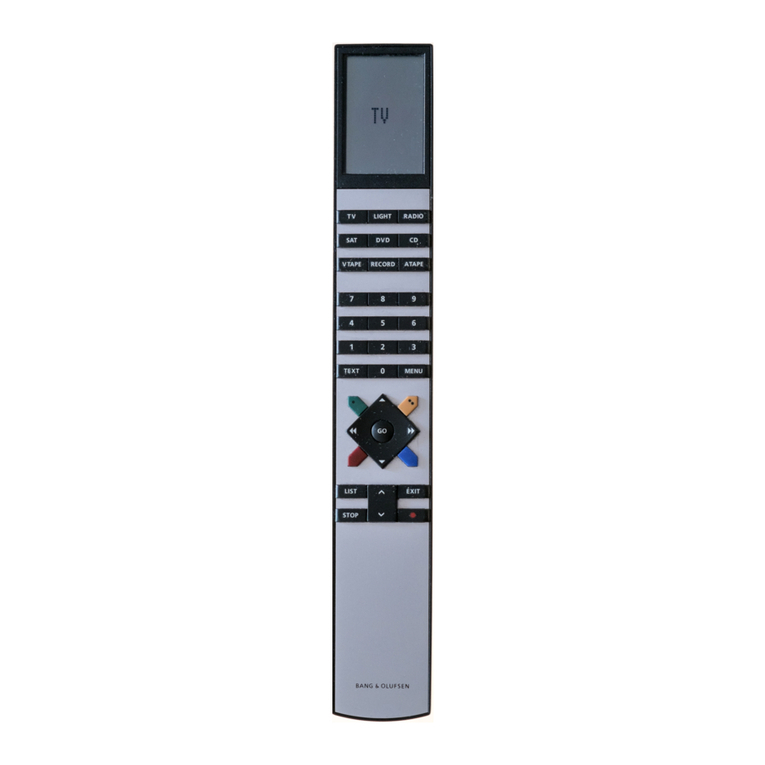

Fig.1 Remote Control Panel Description

Table 3 Indicators Description

Indicators

Description

Power Status

Indicator flashes yellow during pairing process;

Indicator keeps red on when battery voltage is low; it keeps green on when

battery voltage is normal.

Connection Status

Indicator flashes yellow during pairing process;

Press the key, indicator flashes red once when sending, indicator flashes

green once when receiving success;

Indicator displays yellow when communication abnormal situation lasts

over 5s; indicator flashes yellow once after pressing the key.

Common

Alarm/Running Status

Indicator flashes yellow during pairing process;

Indicator keeps green on during normal running;

Indicator flashes red when common alarm occurs;

It will extinguish when communication abnormal situation lasts over 5s.

HRC200 Industrial Remote Control User Manual Page 7 of 16

Table 4 Keys Description

Icon

Key

Description

Power

Long press this key 2s to power on the remote control, then long press this

key 2s again to power off the remote control.

Start

Press this key to send start command.

Stop

Press this key to send stop command.

F1

Press this key to send F1 command. (see the following description.)

F2

Long press this key 6s to enter pairing, press it again during the pairing

process to cancel pair;

Press this key to send F2 command. (see the following description.)

Load

Press this key to send load command.

Unload

Press this key to send unload command.

Emergency

Stop

Press this key to send emergency stop command, turn it clockwise to

reset. (When this key is pressed, load/unload/start/F1/F2 keys are all

inactive, communication status indicator keeps flashing red.)

No Key

Operation

If can’t receive the data and no key operation within 10 minutes, remote

control power will automatically shut off.

HRC200 Industrial Remote Control User Manual Page 8 of 16

4.2 HRC200M RECEIVER PANEL INDICATORS AND INTERNAL KEYS

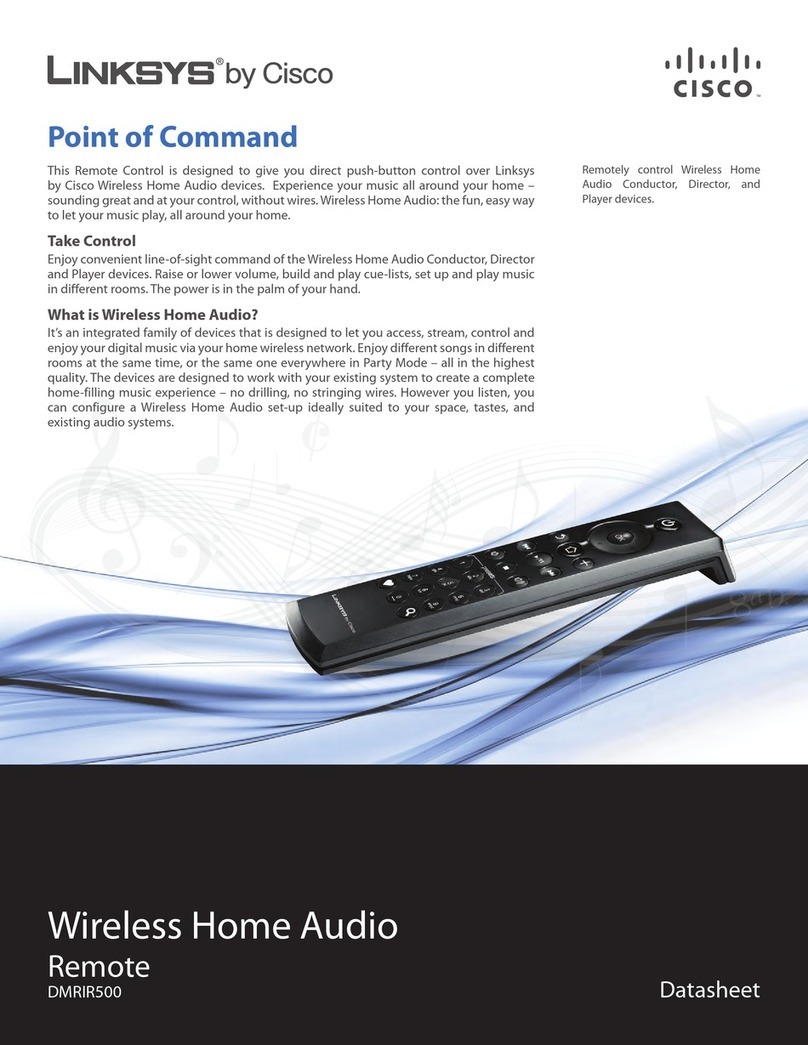

Fig.2 Receiver Panel Description

Table 5 Indicators and Keys Description

Indicator

Description

POWER

(Indicator: green)

Always illuminating: power is normal;

Always extinguishing: power is abnormal.

RS485

(Indicator: green)

Flashing: RS485 communication is normal;

Always extinguishing: RS485 communication fails.

LoRa (Indicator: green)

Flashing: communication with remote control is normal;

Always extinguishing: communication with remote control fails.

PAIR (key)

Long press it 6s to enter pairing mode;

Press it again after entering pairing mode can cancel pair.

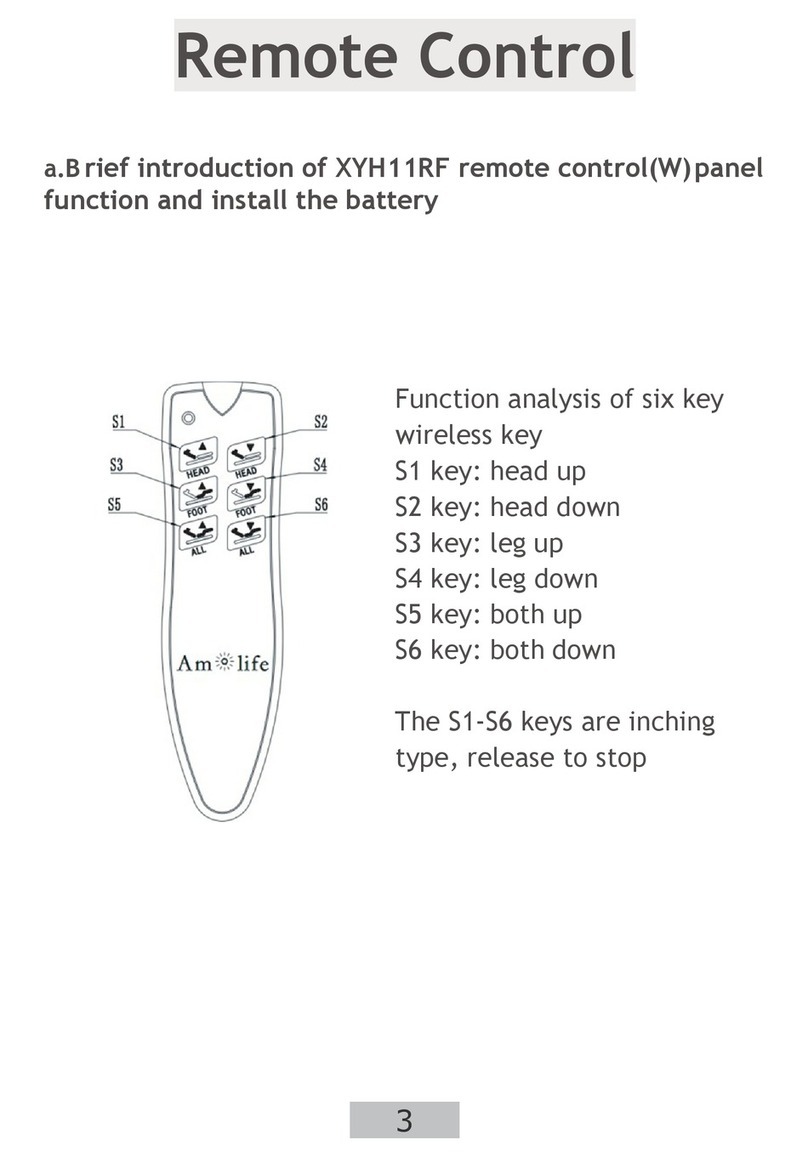

4.3 COMMUNICATION CHANNEL CONFIGURATION

The remote control configures the communication channel via jumper cap. Jumper cap leftmost

and rightmost positions are inactive, it is 1 when the middle four positions are connected to the jumper

cap, otherwise it is 0. The default jumper cap position is 1111 (515MHz).

Fig.3 Communication Channel Configuration

HRC200 Industrial Remote Control User Manual Page 9 of 16

Table 6 Communication Channel Configuration Steps

Step

Description

1

Turn the bottom screw cover anticlockwise to open the base.

2

Change the middle four jumper cap positions to configure the

communication channel and replace the battery at the same time.

3

Turn the bottom screw cover clockwise to close the base.

The receiver configures the communication channel via dial switch. It is 1 when the dial switch is

set to ON position, otherwise it is 0. The default dial switch position is 1111 (515MHz).

Table 7 Communication Channels

No.

Channel Frequency (MHz)

1

0001

445

2

0010

450

3

0011

455

4

0100

460

5

0101

465

6

0110

470

7

0111

475

8

1000

480

9

1001

475

10

1010

485

11

1011

490

12

1100

495

13

1101

500

14

1110

505

15

1111

515

It is 1 when the dial switch is set to ON position, otherwise it is 0.

NOTE: When the dial switch is configured as 0000, it is configuration mode (refer to 4.1).

4.4 PAIRING

Table 8 Pairing Description

Method

Process

Method 1:

Remote control waits

for receiver pairing.

1. Turn the remote control and receiver to the same channel. (see the

communication channel configuration, default channel is 515MHz.)

2. Turn on the remote control power, its power indicator keeps on. Long

press F2 key 6s, all indicators are flashing yellow, which means entering

pairing mode. Press F2 key again during LoRa pairing can cancel pair.

3. Turn on the receiver power, POWER indicator keeps on. Insert a slender

needle less than 3.5mm in diameter into the PAIR hole vertically, then long

press PAIR key 6s.

HRC200 Industrial Remote Control User Manual Page 10 of 16

Method

Process

4. If pairing successfully within 60s, remote control COMM indicator

extinguishes after illuminating green 2s, receiver LoRa and RS485 indicators

extinguish, POWER indicator keeps green for a long time. Otherwise, COMM

indicator keeps red for a long time when the pairing fails.

Method 2:

Receiver waits for

remote control

pairing.

1. Turn the remote control and receiver to the same channel. (see the

communication channel configuration, default channel is 515MHz.)

2. Turn on the receiver power, POWER indicator keeps on. Insert a slender

needle less than 3.5mm in diameter into the PAIR hole vertically, then long

press PAIR key 6s, LoRa, RS485 and POWER indicator flash green. Press

PAIR key again during LoRa pairing can cancel pair.

3. Turn on the remote control power, its power indicator keeps on. Long

press F2 key 6s.

4. If pairing successfully within 60s, remote control COMM indicator

extinguishes after illuminating green 2s, receiver LoRa and RS485 indicators

extinguish, POWER indicator keeps green for a long time. Otherwise, COMM

indicator keeps red for a long time when the pairing fails.

4.5 RS485 INTERFACE

Receiver connects to engine controller via RS485 interface, 120Ω terminal matching resistor is

recommended to use (when RS485 A(+) and TR terminal is short connected), RS485 communication

line must use twisted shielded pair line.

Fig.4 RS485 Connection Diagram

HRC200 Industrial Remote Control User Manual Page 11 of 16

4.6 RECEIVER WIRING TERMINAL

Fig.5 Mask Diagram

Table 9 Wiring Terminal Description

No.

Function

Cable Size

Remark

1

COM

0.75mm2

Relay common port.

2

AUX. OUTPUT5

0.75mm2

Normally open volt-free output, capacity

DC30V/2A.

3

AUX. OUTPUT4

0.75mm2

Normally open volt-free output, capacity

DC30V/2A.

4

AUX. OUTPUT3

0.75mm2

Normally open volt-free output, capacity

DC30V/2A.

5

AUX. OUTPUT2

0.75mm2

Normally open volt-free output, capacity

DC30V/2A.

6

AUX. OUTPUT1

0.75mm2

Normally open volt-free output, capacity

DC30V/2A.

7

TR

/

RS485 communication line uses twisted

shielded pair line. When 120Ω terminal

matching resistor is required, A(+) and TR

terminal should be short connected.

8

RS485 A(+)

0.5mm2

9

RS485 B(-)

0.5mm2

10

AUX. INPUT2

0.75mm2

B- connected is active.

11

AUX. INPUT1

0.75mm2

B- connected is active.

12

B+

0.75mm2

Externally connects power positive.

13

B-

0.75mm2

Externally connects power negative.

HRC200 Industrial Remote Control User Manual Page 12 of 16

5PROGRAMMABLE PARAMETERS

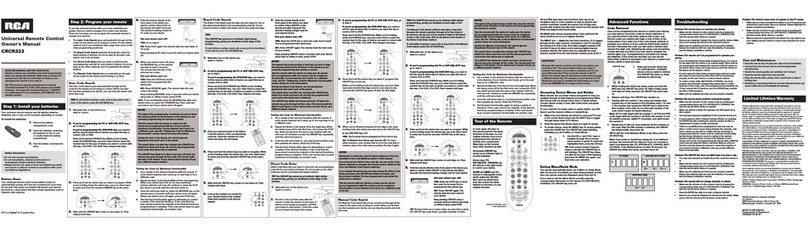

5.1 PC PARAMETER SETTING

Before operation, please remember the dial switch position of HRC200M, then set switch to

configuration mode (namely 0000 position). PC connects to receiver via RS485 communication

conversion module, then the related parameter configuration of receiver can be done via PC software.

After the configuration is completed, dial switch must recover to previous position.

Fig.6 PC Configuration Interface

5.2 PARAMETER RANGE AND DEFINITION

Table 10 Parameter Content and Range

No.

Item

Range

Default

Description

1

Comm. Address

1-254

1

2

Baud Rate

(0-3)

2

0: 2400bps

1: 4800bps

2: 9600bps

3: 19200bps

3

Parity Bit

(0-2)

0

0: No Parity

1: Odd Parity

HRC200 Industrial Remote Control User Manual Page 13 of 16

No.

Item

Range

Default

Description

2: Even Parity

4

Stop Bit

(0-1)

0

0: 1-bit

1: 2-bit

5

Aux. Input 1

(0-9)

1

0: Not Used

1: Remote Control Inhibit

2: Simulate Start Key

3: Simulate Stop Key

4: Simulate Unload Key

5: Simulate Load Key

6: Simulate F1 Key

7: Simulate F2 Key

8: Simulate Running Status

9: Simulate Alarm Status

6

Aux. Input 2

(0-9)

0

7

Aux. Output 1

(0-6)

5

0: Not Used

1: Start Control

2: Stop Control

3: Unload Control

4: Load Control

5: F1 Control

6: F2 Control

8

Aux. Output 2

(0-6)

6

9

Aux. Output 3

(0-6)

0

10

Aux. Output 4

(0-6)

0

11

Aux. Output 5

(0-6)

0

12

Aux. Output 1

Output Delay

(0-999.9)s

1.0s

When it is set as 0, relay

continuously outputs when the

remote control key is firstly

pressed, relay stops output when

the key is pressed again.

When it is set as other values,

relay disconnects output after

outputting set delay value.

13

Aux. Output 2

Output Delay

(0-999.9)s

1.0s

14

Aux. Output 3

Output Delay

(0-999.9)s

1.0s

15

Aux. Output 4

Output Delay

(0-999.9)s

1.0s

16

Aux. Output 5

Output Delay

(0-999.9)s

1.0s

6SYSTEM APPLICATION DIAGRAM

Remote control communicates with receiver via LoRa, engine controller and receiver can be

controlled by RS485 communication or digital input/output port.

Fig.7 HRC200 System Application Diagram

HRC200 Industrial Remote Control User Manual Page 14 of 16

Fig.8 HRC200M Digital Control Application Diagram

Table 11 Parameter Configuration

No.

Item

Parameter

HRC200

1

Aux. Input 1

8: Running Status

2

Aux. Input 2

9: Alarm Status

3

Aux. Output 1

2: Stop Control

4

Aux. Output 2

4: Load Control

5

Aux. Output 3

3: Unload Control

6

Aux. Output 4

1: Start Control

ACC7100A

1

Aux. Output 2

38: Start Success Output

2

Aux. Output 3

42: Common Alarm

3

Aux. Input 3

34: Simulate Stop Key

4

Aux. Input 4

35: Simulate Load Key

5

Aux. Input 5

36: Simulate Unload Key

6

Aux. Input 6

37: Simulate Start Key

HRC200 Industrial Remote Control User Manual Page 15 of 16

7OVERALL AND INSTALLATION DIMENSIONS

7.1 REMOTE CONTROL OVERALL DIMENSION

Unit: mm

Fig.9 HRC200R Overall Dimension

7.2 RECEIVER OVERALL DIMENSION

Installation method can be 35mm guide rail installation or screw (M4) installation. Overall

dimension is as follows:

Unit: mm

Fig.10 HRC200M Overall Dimension

HRC200 Industrial Remote Control User Manual Page 16 of 16

Fig.11 HRC200M Guide Rail Installation

Fig.12 HRC200M Screw Installation

8TROUBLESHOOTING

Table 12 Troubleshooting

Symptom

Possible Solutions

Receiver Inactive for Power

Check the power supply.

RS485 Comm. Abnormal

Check the connection line;

Check whether communication address, baud rate, parity bit, stop bit

set is correct;

Check whether A(+) and B(-) of RS485 are reversely connected;

Try to connect 120Ω terminal matching resistor.

Pairing Failure

Check whether the channel of remote control and receiver is same.

Receiver and PC Fails to

Connect

Check whether the receiver dial switch is set to 0000 position.

Remote Control Key Inactive

Check whether the emergency stop key is pressed, when it is

pressed, other function keys are inactive.

_________________________________

Table of contents

Other Smartgen Remote Control manuals