Smartswitch TD-1000 User manual

TD-1000

Tank Monitor

Installation Manual

2

TD-1000 Master Display Unit

Provides the following functions:

•visual indication of tank level (bar graph & percentage)

•turn pump on or off

•two-point or five-point calibration for irregular tank geometries

•disable toilet when black tank full

•all tanks are name selectable e.g. (Aft-Grey) (Port Fuel) (Water)

•audible alarm

Electrical Specifications TD-1000

Operate voltage = 9 - 30vdc

Quiescent Current = 30mA @12vdc

Alarm/Buzzer output = 300Ma @ 12vdc

Pump output = 4 Amps @ 12vdc

Size = 65mm x 65mm x 80mm Deep

Data Retention = 50 years (without power)

Outputs

Pump Output (4 Amps @ 12vdc)

The TD-1000 has one output, which can be used to control an interposing relay for a

pump such as a waste tank discharge pump. An auto-off feature is standard and is

particularly helpful in preventing damage caused by a pump running dry. The auto-off

point is programmable.

Alarm Output (300Ma @ 12vdc)

The alarm output can be programmed to activate a relay when the waste tank reaches

the set alarm point, or can be used to disable the toilet, or used to activate a buzzer

(buzzer supplied)

3

TD-1000 Wiring

Red = Battery +

Black = Sensor -

Black = Buzzer -

Blue = Buzzer +

White = Output +

Green = Sensor In

Black = Battery -

Purple = Sensor +

Connector

Mounting

50mm

Size= 75mm x 75mm

Drill a hole using a 50mm hole saw

4

Pump Circuit Connection

TO PUMP

BATTERY

White

Relay

Toilet Disable Connection

Toilet Pump

Toilet Pump

Blue wire

Relay

Toilet Disable Connected to SmartSwitch Toilet controller

(connect blue output wire to SmartSwitch STS-220 toilet controller as shown)

Blue wire

OR

STS-220

Tank Full Switch

5

Programming Instructions

Step 1: Placing the unit in Program Mode

Press and hold down the Scroll key now press and hold the Mute key. Hold together for 3 seconds.

Push the Enter/Pump button to select the tank Name or scroll to another function

Step 2: Selecting Tank Name

The display will now show:

Push the Enter button to select the tank Name or scroll to another name

PLEASE SEE PAGE 8 FOR SENSOR CALIBRATION

Step 3: Setting the Alarm point

The display will now show:

The alarm point is the point where the tank will alarm you. E.g. almost or empty, almost or full

Use the Scroll or Mute key to move the alarm point to the desired level. Press the Enter key to set this as

your alarm point.

Set Alarm

0%

SET-UP MENU

Program Tank

Calibrate

Set Alarm

More

SET-UP MENU

Black Tank

Aft Black

Fwd Black

More

6

Step 4: Audible Alarm On /Off (default is On)

The display will now show:

Press the Enter Key, if the Alarm is On this will turn it Off if its Off this will turn it On

Step 5: Pump Off

The display will now show:

The Pump Off point is the point where the Pump will turn Off. E.g. almost or empty, almost or full

Use the Scroll or Mute key to move the Pump Off point to the desired level. Press the Enter key to set this as

your Pump Off point.

If the Pump key is pressed the pump output will turn on and automatically turn Off

when the Pump Off point is reached.

If the tank name is either Black or Grey the pump will stop when the tank is equal to

or less than the programmed stop point.

If the tank name is either Fresh or Fuel the pump will stop when the tank is equal to

or greater than the programmed stop point.

Disable Toilet:

If you want to use the Alarm Output as a Toilet Disable control instead of an Alarm then from the Set-Up

Menu scroll down to “Toilet En/Dis” then press the Enter key. Repeat if you want to turn back into an Alarm

output.

Exit Menu

Scroll to Exit and push the Enter key

Alarm On/Off

Set Pump Off

10%

7

PLEASE NOTE: For sensor Model SEN-100 The Maximum Tank Height is 1 Meter

PLEASE NOTE: For sensor Model SEN-250 The Maximum Tank Height is 2.5 Meter

The maximum surge and safe pressure is 28psi.

For more information see “Calibration Tips & Tricks” on our web site www.smartswitch.co.nz

Mounting Adaptors Available:

A range of mounting adaptors are available which includes flat sidewall, top mount, 1.5” pipe, 2” pipe, 3” pipe

and drain valve. Ask your dealer for details.

Should a 4 to 20-milliamp loop sensor supplied by another manufacturer be used, then the adaptor (part

number SM-420) will need to be installed.

Sensor Installation:

The sensor should be mounted as low in the sidewall as possible using a ¾” spin-in or the flat sensor

adaptor. If the sensor adaptor is used it will require drilling a 5/8” hole in the sidewall. Apply silicon glue

liberally to the bottom of the adaptor. Using #10 x ½” stainless steel self-tapping screws attach the adaptor

to the sidewall. Once the adaptor is attached make sure that the hole in the adaptor is clear of any excess

glue. Allow drying as per the instructions for the glue. Wrap the threads of the sensor using Teflon plumbers

tape and install the sensor. Tighten by hand. It is not recommended to install the sensor in the bottom of

the tank. Although the sensor will operate correctly it will provide an area for debris to collect which would be

difficult to flush out.

Sensor Installation

! WARNING !

Tank

Top mount adaptor

(tube not supplied)

Tank

Sidewall adaptor

Tank

The top-mounting adaptor requires 3/4" ABS or

PVC pipe cut to the proper length so that the

pipe is about 1/2" from the bottom of the tank.

This pipe glues into the adaptor and the sensor

screws into the top of the adaptor. It is held on

with 2 self-tapping screws. Care must be taken

that the sensor threads are sealed with Teflon

tape and screwed in tight to ensure no air

leaks, as the tube must remain pressurized.

The sensor will be damaged if subject to over

pressure during installation, caused by

Compressing the small air gap between the

sensor and the ball valve.

DO NOT PRESSURIZE TANK WITH SENSOR FITTED

Pipe adaptor

Valve

8

Press and hold down the Scroll key now press and hold the Mute key. Hold together for 3 seconds. This will

bring you to the Set-Up Menu.

Use the Scroll or Backlight key to scroll to “Calibrate” and press the ENTER Key.

This will bring you to the Calibrate Menu.

The display will now show:

Use the Scroll key to scroll to switch between them, then press the Enter key.

Two different methods of tank programming are available if using the pressure sensor:

2 Point Calibration: sets tank low and high points which can only be used if the tank is a regular shape.

5 Point Calibration: sets tank low, tank quarter, tank half, tank three quarters and tank full points, offering

more accuracy if the tank is an irregular shape.

Sensor Programming Instructions

SET-UP MENU

Program Tank

Calibrate

Set Alarm

More

Calibration

2 Point

5 Point

9

2 Point Calibration: (Bottom & Top)

The display will now show:

Fill the tank to the required TANK LOW LEVEL, minimum suggested is liquid just covering the sensor. Wait

for approx. 60 seconds for the fluid to settle and press the Enter key. The display will show “Setting Level

Please Wait”.

The display will now show:

Fill the tank to the TANK HIGH LEVEL. Wait for approx. 60 seconds for the fluid to settle and press the Enter

key. The display will show “Setting Level Please Wait”.

If no fluid is added the display will show:

For more information see “Calibration Tips & Tricks” on our web site www.smartswitch.co.nz

Tank

High Point

Low Point

The High Level

is not greater

than the Low level

Set

Low Level

Input = ??????? V

Set

High Level

Input = ??????? V

10

5 Point Calibration: (Bottom, ¼, ½, ¾ & Top)

The display will show:

Fill the tank to the required TANK LOW LEVEL, minimum suggested is liquid just covering the sensor. Wait

for approx. 60 seconds for the fluid to settle and press the Pump key. The display will show “Setting Level

Please Wait”.

The display will now show:

Fill the tank to the 1/4 LEVEL. Wait for approx. 60 seconds for the fluid to settle and press the Enter key. The

display will show “Setting 1/4 Please Wait”.

The display will now show:

Fill the tank to the 1/2 LEVEL. Wait for approx. 60 seconds for the fluid to settle and press the Enter key. The

display will show “Setting 1/2 Please Wait”.

Tank

High Point

Low Point

3/4 Point

Half Point

1/4 Point

Voltage from Sensor (see table 1 page 19)

Set

Low Level

Input = ??????? V

Set

1/4 Level

Input = ??????? V

Set

1/2 Level

Input = ??????? V

11

The display will now show:

Fill the tank to the 3/4 LEVEL. Wait for approx. 60 seconds for the fluid to settle and press the Enter key. The

display will show “Setting 3/4 Please Wait”.

The display will now show:

Fill the tank to the FULL LEVEL. Wait for approx. 60 seconds for the fluid to settle and press the Enter key.

The display will show “Setting Level Please Wait”.

If no fluid is added between each step the display will show:

For more information see “Calibration Tips & Tricks” on our web site www.smartswitch.co.nz

Table 1:

SmartSwitch strongly recommends that Table 1 be used to record voltages for each tank level at time of tank

calibration. These voltages will be displayed during the calibration setup.

Reason: Should the TD-1000 ever need to be replaced the tank will need to be re-calibrated, but if table 1

has been filled out then creating these input voltages using a potentiometer can be done without the tank

sender connected, making the process very simple.

Input

Tank Name

Empty

1/4

1/2

3/4

Full

Level

Sensor

Set Full Point

Input = ?.?? v

Table 1

Set

3/4 Level

Input = ??????? V

The ??? Level

is not greater

than the Low level

Table of contents

Other Smartswitch Monitor manuals

Popular Monitor manuals by other brands

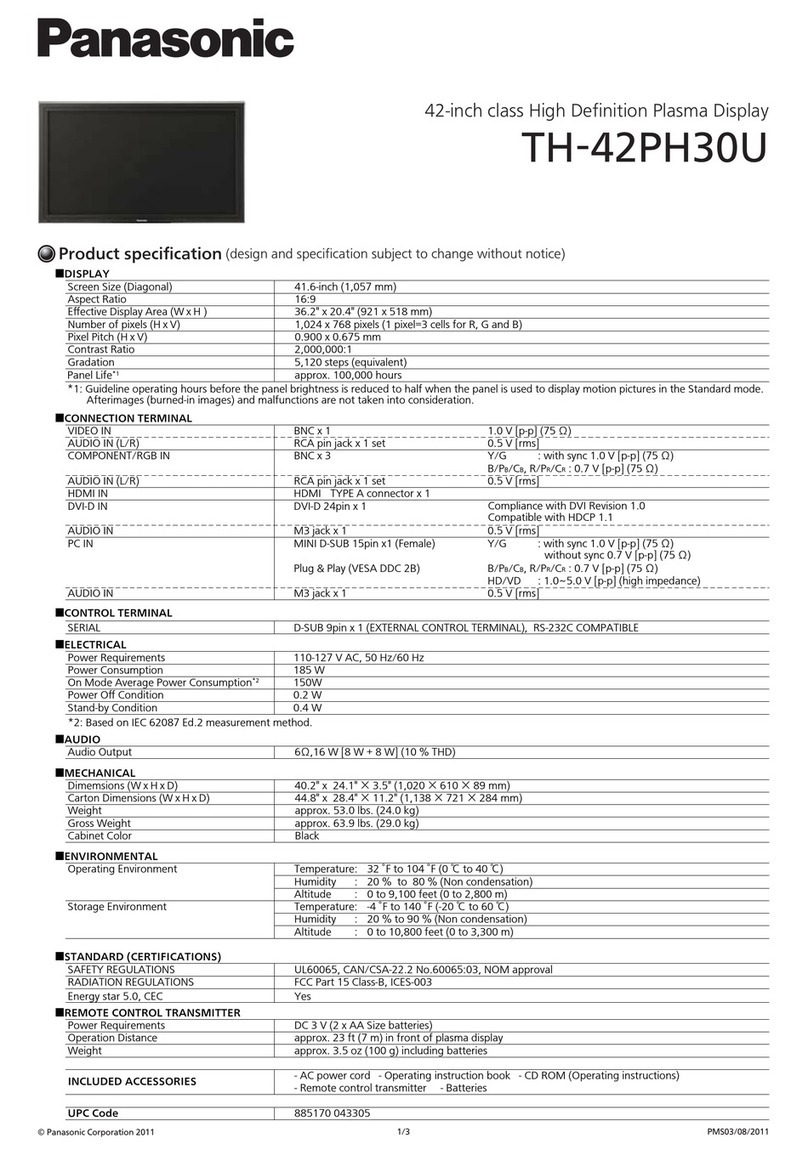

Panasonic

Panasonic TH-42PH30U Specifications

Shenzhen Mindray Bio-Medical Electronics

Shenzhen Mindray Bio-Medical Electronics MEC-1000 Service manual

Plura

Plura PBM-3G Series operating instructions

Velleman

Velleman MONCOLHA5PN6 user manual

Elo TouchSystems

Elo TouchSystems 15D1 user guide

AOC

AOC E943FWS - Service manual