Smartswitch RA-800 User manual

SMARTSWITCH

RA-800

Slave Alarm Monitor

Installation Manual

Model RA-800

Installation Manual

Wiring Block Diagram 4

Installation Steps 5

Wiring Diagram (AL-100) 5

Mounting Instructions 6

Programming Instructions 7 -12

Operating Instructions 13

Electrical Specifications 13

Table of Contents

4

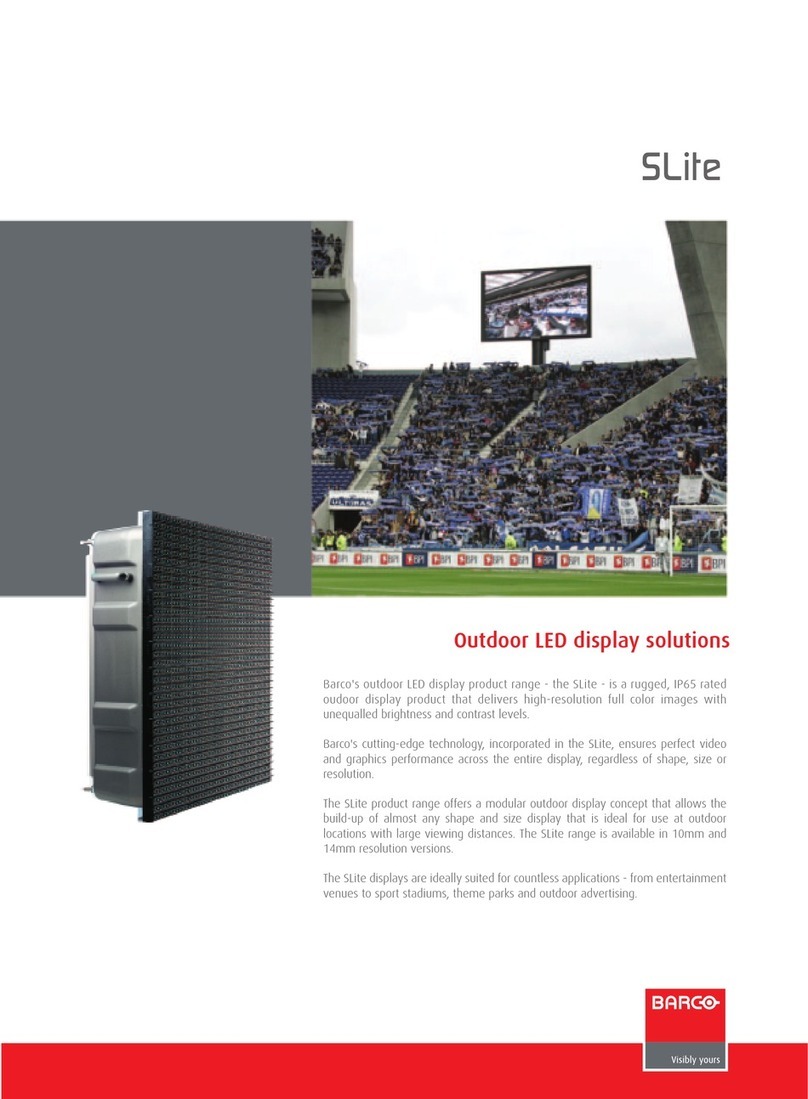

To next device

Wiring Block Diagram

Black

battery

negative

Red

battery

positive

Output relay

Inputs

1 to 4

White=Coms neg

Blue=Coms pos

Red=Battery +

Black=Battery -

AL-100

(IOU)

RA-800

Remote Display Unit (RDU)

AL 8000

Master Display Unit (MDU)

Inputs

5 to 8

Output relay

Inputs

1 to 4

White=Coms neg

Blue=Coms pos

Red=Battery +

Black=Battery -

AL-100

(IOU)

Inputs

5 to 8

5

Smartswitch Technologies Ltd recommends a Qualified Marine or Auto-

Electrician installsthis product.

Step 1:

Install and connect the Master Display Head Unit (AL-8000)

Step 2:

Install and connect the Input Units (AL-100) page 6 of the AL-8000 manual.

Step 3:

Setup Rotary Switches page 7 of the AL-8000 manual.

Step 4:

Program the Remote Display Unit (RA-800) page 7 to 12.

The RA unit needs to be programmed similarly (but not exactly the same

as the AL-8000) to identify the alarms that you want to monitor from that

unit.

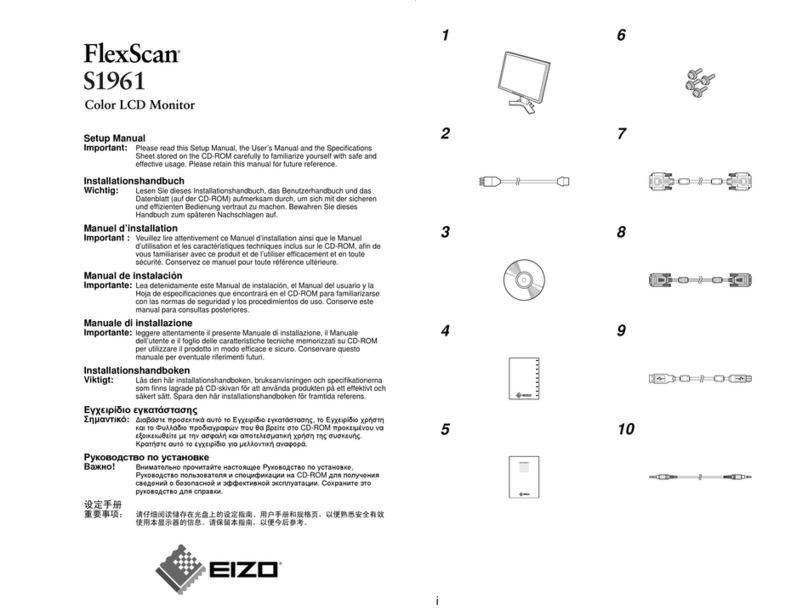

Wiring Diagram for RA-800 (MDU)

Installation Steps

Model :

Serial No :

Voltage :

D.O.M :

Back View

Batt +

Batt -

Net +

Net -

6

The AL-8000 manual will also be required when programming this unit.

Explanation of override groups:

There are four Override groups 1, 2, 3, and 4

If this option is selected then any input (alarm) that is joined to the override group will ONLY

be active when that override input is active (typically used for engine override).

Example: If input 5, 6 & 7 are joined to the override one group and the override one signal is

connected to the Port engine running signal then the system will only look at these inputs

when the Port engine is running.

Override groups are attached to I/O rotary switch 2 inputs 1, 2, 3 and 4

(Refer to the AL-8000 manual page 7 for switch positions)

Explanation of inputs with timers:

There are 8 timers available and may be programmed from 5 seconds to 10 minutes. Once

an input attached to a timer has been activated the programmed timer will start but the

system will not look at the input until the timer has expired. These timers are attached to I/O

Box switch position 2 Input 5, 6, 7, 8 and I/O Box switch position 3 Input 1, 2, 3, and 4. See

step 9. (Refer to the AL-8000 manual page 7 for switch positions)

Step 1: Placing the unit in Program Mode

Press and hold down the Backlight & Scroll keys together for 3 seconds. This will bring you to

the Set-Up Menu and place the unit in program mode.

Note: Press the Scroll key to scroll through the Set-Up Menu

Program:

Step 2: Selecting Which AL-100 to program

The display will now show

Use the “SCROLL” or “BACKLIGHT” keys to change the switch number, which corresponds

to the I/O unit being programmed (refer to the AL-8000 manual page 7) for switch numbers.

Programming Instructions:

Select Switch 2

< Down Up >

SET-UP MENU

PROGRAM (see step 2)

ERASE (see step 11)

SET ADDRESS (see step 12)

EXIT MENU

Use the Scroll key to

scroll down to these.

7

Once the switch number has been selected push the “MUTE” key to accept.

Step 3: Select Input

Use the “SCROLL” or “BACKLIGHT” keys to change the input number, which corresponds to

the input being programmed.

Once the switch number has been selected push the “MUTE” key to accept.

Step 4: Override Feature

The overrides are only attached to I/O Box switch position 2, Input 1, 2, 3 and 4

The following will be displayed when the above I/O Box is being programmed.

If no is selected the system will NOT ask about override 2, 3 or 4 if yes is selected then the

question will be asked about override two when you are programming input 2 and the same

for input three and input four. If No is selected go to step 5.

One override only (Single engine vessel):

If this feature is required then the override one group must be on.

When programming I/O Box switch position 2 Input 1

Answer YES to “ DO YOU WANT TO USE OVERRIDE ONE”

When programming I/O Box switch position 2 Input 2

Answer NO to “ DO YOU WANT TO USE OVERRIDE TWO”

The engine running signal MUST be connected to I/O Unit Switch Position 2, Input 1

Two overrides (Twin-engine vessel):

If this feature is required for both Port and Starboard engines, then both override one and

override two groups must be on.

When programming I/O Box switch position 2 Input 1

Answer YES to “ DO YOU WANT TO USE OVERRIDE ONE”

When programming I/O Box switch position 2 Input 2

Answer YES to “ DO YOU WANT TO USE OVERRIDE TWO”

When programming I/O Box switch position 2 Input 3

Answer NO to “ DO YOU WANT TO USE OVERRIDE THREE”

When programming I/O Box switch position 2 Input 4

Answer NO to “ DO YOU WANT TO USE OVERRIDE FOUR”

The Port engine running signal MUST be connected to I/O Unit Switch Position 2, Input 1

The Stb engine running signal MUST be connected to I/O Unit Switch Position 2, Input 2

Use Override 1

< No Yes >

Select Input 1

< Down Up >

8

Three overrides (Two engine vessel & Aux):

When programming I/O Box switch position 2 Input 1

Answer YES to “ DO YOU WANT TO USE OVERRIDE ONE”

When programming I/O Box switch position 2 Input 2

Answer YES to “ DO YOU WANT TO USE OVERRIDE TWO”

When programming I/O Box switch position 2 Input 3

Answer YES to “ DO YOU WANT TO USE OVERRIDE THREE”

When programming I/O Box switch position 2 Input 4

Answer NO to “ DO YOU WANT TO USE OVERRIDE FOUR”

The engine one running signal MUST be connected to I/O Unit Switch Position 2, Input 1

The engine two running signal MUST be connected to I/O Unit Switch Position 2, Input 2

The engine three running signal MUST be connected to I/O Unit Switch Position 2, Input 3

Four overrides (Four engine vessel):

When programming I/O Box switch position 2 Input 1

Answer YES to “ DO YOU WANT TO USE OVERRIDE ONE”

When programming I/O Box switch position 2 Input 2

Answer YES to “ DO YOU WANT TO USE OVERRIDE TWO”

When programming I/O Box switch position 2 Input 3

Answer YES to “ DO YOU WANT TO USE OVERRIDE THREE”

When programming I/O Box switch position 2 Input 4

Answer YES to “ DO YOU WANT TO USE OVERRIDE FOUR”

The engine one running signal MUST be connected to I/O Unit Switch Position 2, Input 1

The engine two running signal MUST be connected to I/O Unit Switch Position 2, Input 2

The engine three running signal MUST be connected to I/O Unit Switch Position 2, Input 3

The engine four running signal MUST be connected to I/O Unit Switch Position 2, Input 4

Two overrides joined:

Override one and two can be interconnected by selecting option 5 in Step 8.

Both override one and two will need to be active before any input attached to them will be

looked at.

Setting Delay Time:

The delay time is the time it takes (approx) to start the engine (and is programmable from 1 to

20 seconds) during this time the inputs are looked at by the system but NOT latched as

genuine faults. If for example the delay time is set for 5 seconds and the engine is started, the

oil pressure alarm will display and the buzzer will sound, if after 5 seconds the oil pressure is

OK the buzzer will turn off and the display oil pressure fault will disappear. If however after 5

seconds (or any other time while the engine is running) the oil pressure is NOT OK the buzzer

will keep sounding and the display will flash the text “Oil Pressure” or whatever text has been

programmed.

Use the “SCROLL” or “BACKLIGHT” keys to scroll through the delay times. Push the “MUTE”

key to accept, this will take you back to Step 3.

Seconds = 00

< Down Up >

9

Step 5: Setting Alarm Tones

There are three alarm tones available

1/ Alarm & Tone. Gives an audible alarm tone on fault

2/ Alarm NO Tone. Does NOT give an audible alarm tone on fault

3/ Alarm & Repeat Tone. Gives an audible alarm tone on fault & after muting will return in 1 minute

Use the “SCROLL” or “BACKLIGHT” keys to scroll through the options and the “MUTE” key to

enter.

The display will now show:

Step 6: Selecting /Creating Alarm Name’s

The display will now show:

Use the “SCROLL” or “BACKLIGHT” keys to scroll through the pre-named Alarms. Once you

have found the one required push the “MUTE” key to enter.

If you would like to create your own name push the “MUTE” key. Use the “SCROLL“ key to

sequences thru Alpha set including 0 –9.

The “BACKLIGHT” key moves the cursor to the next position.

When finished push the “MUTE” key. If Ignition Override has been set as per Step 4 this will

take you to Step 7. If not and the input as a timer attached if not it will take you to Step 9, if no

timer is attached it will take you to Step10.

Step 7: Use Override

The display will now show:

If YES is selected and only ONE override group has been selected as per Step 4 (one

override only) it will take you to Step 9 if the input as a timer attached other wise it will take

you to Step 10.

If more than one override group has been selected it will take you to Step 8.

Use Override

< No Yes >

ENGINE OIL PRESSURE

< Alarm Text >

1=Alarm & Tone

< Select Alarm Type >

10

Step 8: Which Override Group

The display will now show:

Push the “SCROLL” or “BACKLIGHT” keys to scroll thought the override groups.

Upon pushing the “MUTE” key the input that you have just setup now belongs to whichever

group you selected and will only be active when the override input is active.

Step 9: Timers

There are 8 timers available and may be programmed from 5 seconds to 10 minutes. These

timers are attached to I/O Box switch position 2 Input 5, 6, 7, 8 and I/O Box switch position 3

Input 1, 2, 3, and 4.

If one of these inputs are being programmed the display will now show, if not it will take you to

Step 11.

If No is selected this will take you to Step10.

If Yes is selected the display will now show.

Use the “SCROLL” or “BACKLIGHT” keys to scroll through the times.

If zero seconds are required push the “MUTE” key, this will take you to the minute’s field

If zero minutes are required push the “MUTE” key, this will take you to Step 10.

Override group 1

< Down Up >

USE DELAY TIMER

< No Yes >

Note: This will only be asked if I/O Box switch

position 2 Input 5, 6, 7, 8 or I/O Box switch

position 3 Input 1, 2, 3, and 4 are being

programmed.

Seconds = 00

< Down Up >

Minutes = 00

< Down Up >

11

Step 10: Next or End

The display will now show:

Push the “BACKLIGHT” key to set-up the next input or the “SCROLL” key to exit set-up mode.

Step 11: Erase

Selecting Erase will erase all settings associated with the AL-100 (IOU).

If a mistake is made on any input a complete erase is not required just reprogram the

input.

Step 12: Set Address

Up to three RA-800 remote displays may be connected to the network. Each RA-800 on the

network MUST have a different “Address”.

Selecting “Set Address” will display the following and the current address set will be

displayed.

Push the “SCROLL” or “BACKLIGHT” keys to scroll thought the network address 7, 8 or 9.

When the network address has been selected push the Mute key to enter.

NOTE: When setting up a system with more than one remote display please ensure you set

each RA-800 to different address numbers.

If adding or replacing a RA-800 on an existing system please check the address of the unit or

units already on the system and set the new / replaced RA-800 to a different number.

< End Next >

Are U Sure

< Yes No >

Unit Address = ?

< Down Up >

12

Keyboard:

Scroll –Used for scrolling up or down a page if more than 8 alarms exist at once.

Mute - Mutes the alarm.

BackLight –Turns backlight on and off.

Alarms:

Should an alarm trigger the system will give an audible alarm and the alarm text will flash on

the display.

Pushing the mute button will mute all alarms. If the fault condition is still present the alarm text

will stop flashing and stay on, should another fault occur the alarm would start again. If the

fault condition has gone the fault text will disappear from the screen.

Normal Operation Screen:

Operating Instructions

Electrical Specifications RA-800

Supply Voltage 12 to 32 Volts DC (Auto-sensing)

Quiescent Current 0.03 Amps

Data Retention 50 years (without power)

SCANNING ALL ALARMS

*************************

Table of contents

Other Smartswitch Monitor manuals