SMC Sierra Monitor IT Series User manual

Manual # T12005

Document Revision: B1

Model 5100-99-IT

IT Series

4-20 mA Transmitter

Version 3.0

APPLICABILITY & EFFECTIVITY

Effective for all 5100-99-IT-XX Transmitters manufactured after August 2016.

Model 5100-99-IT 4-20 mA Transmitter

Contact Information

©2016 Sierra Monitor. All rights reserved.

Manual Number: T12005

This manual contains intellectual property that was developed by Sierra Monitor Corporation Inc. and is

protected by the copyright laws of the United States, international copyright treaties, and all other

applicable national laws. This manual contains information regarding technology that is protected under

one or more issued or pending United States and foreign patents.

Sierra Monitor and Sentry IT are trademarks of Sierra Monitor Corporation. All other trademarks are the

property of their respective owners.

This manual is licensed to users of Sierra Monitor products and may be copied, in whole or in part.

The offices of Sierra Monitor are located at:

Sierra Monitor Corporation

1991 Tarob Court

Milpitas, CA 95035

USA

Customer Service:

Telephone: (408) 262-6611

Fax: (408) 262-9042

Toll-Free: (800) 727-4377

Email: support@sierramonitor.com

Website: www.sierramonitor.com

Model 5100-99-IT 4-20 mA Transmitter

Table of Contents

TABLE OF CONTENTS

Product Description..........................................................................................................................................511.1 General.........................................................................................................................................................5

1.2 Product Configuration ..................................................................................................................................5

1.3 Modes of Operation......................................................................................................................................5

1.3.1 Sentry Interface.....................................................................................................................................5

1.3.2 Modbus Operation ................................................................................................................................6

1.3.3 Analog Operation..................................................................................................................................6

1.3.4 Remote Alarm Reset (Digital Input)......................................................................................................6

1.3.5 Optional Integral Relays........................................................................................................................6

1.4 Mechanical...................................................................................................................................................7

1.4.1 Enclosure..............................................................................................................................................7

1.4.2 Transmitter Electronics .........................................................................................................................8

1.5 Interconnect Wiring......................................................................................................................................8

1.6 Power Requirements....................................................................................................................................8

Cautions & warnings.........................................................................................................................................922.1 Introduction...................................................................................................................................................9

2.2 It Transmitters - General..............................................................................................................................9

2.3 Wiring...........................................................................................................................................................9

Installation........................................................................................................................................................1033.1 Transmitter Locations.................................................................................................................................10

3.2Wiring.........................................................................................................................................................10

3.2.1 ANALOG 4-20 Ma OPERATION ........................................................................................................10

3.2.2 Modbus Operation Using Rs-485 Connection....................................................................................10

3.2.3 Sentry Operation Using SMC Sentry Connection...............................................................................10

3.2.4 General ...............................................................................................................................................10

3.3 Enclosure Installation.................................................................................................................................11

3.4 Transmitter Address Switch.......................................................................................................................12

Operation..........................................................................................................................................................1844.1 Introduction.................................................................................................................................................18

4.2 Data Entry Keypad.....................................................................................................................................18

4.3 Main Menu..................................................................................................................................................19

4.4 Configure Set-Points..................................................................................................................................20

4.5 Maintenance Sub-Menu.............................................................................................................................22

Calibration........................................................................................................................................................2355.1 Calibration Preparation ..............................................................................................................................23

5.2 Calibration Gas Delivery Methods and Procedure.....................................................................................23

Appendix A. Service...............................................................................................................................................24

Appendix A.1. Transmitter Configuration..............................................................................................................24

Appendix A.2. Enclosure Replacement ................................................................................................................24

Appendix A.3. Transmitter Replacement..............................................................................................................25

Appendix A.4. Installation Inspection....................................................................................................................25

Appendix A.4.1. Controller Installation...........................................................................................................25

Appendix A.4.2. Moisture Traps and Rainshields..........................................................................................25

Appendix A.4.3. Standard Voltages ...............................................................................................................25

Appendix B. SPECIFICATIONS*............................................................................................................................26

Appendix C. MODEL NUMBERS & PARTS LIST..................................................................................................27

Appendix D. LIMITED 2 Year WARRANTY ...........................................................................................................28

Appendix E. MODBUS MEMORY MAP..................................................................................................................29

Model 5100-99-IT 4-20 mA Transmitter

Table of Contents

LIST OF FIGURES

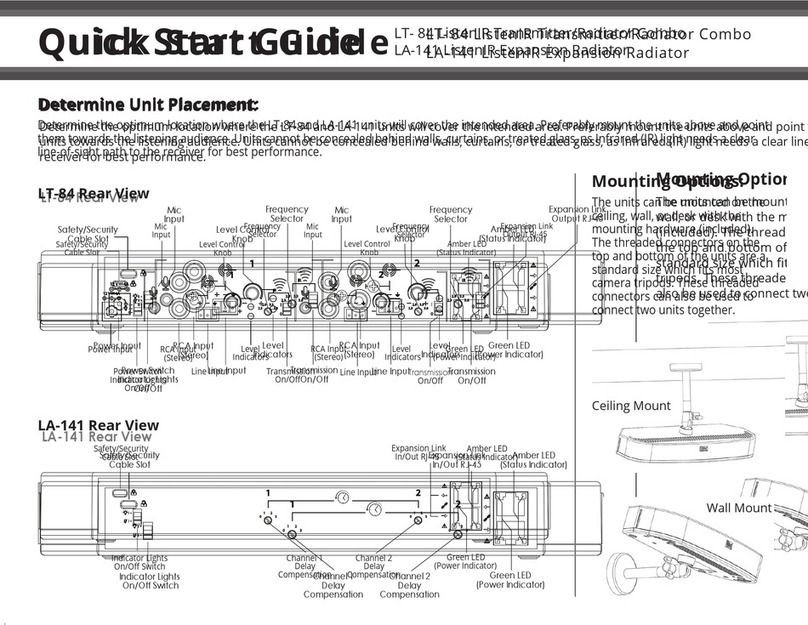

Figure 1: Model 5100-99-IT-A1 Transmitter –Cast Aluminum Enclosure Dimensions .............................................7

Figure 2: Model 5100-99-IT-S1 Transmitter –Stainless Steel Enclosure Dimensions..............................................7

Figure 3: Model 5100-99-IT Transmitter –Mounting Options ....................................................................................8

Figure 4: Sensor Module Address Switch Positions................................................................................................ 12

Figure 5: Transmitter Face Plate............................................................................................................................. 12

Figure 6: Interface Board Connectors ..................................................................................................................... 13

Figure 7: RS-485 –Termination, BIAS Jumper....................................................................................................... 13

Figure 8: 4-20mA Circuit Types............................................................................................................................... 14

Figure 9: 4-20 mA Circuit Type Connections for 5100-99-IT .................................................................................. 15

Figure 10: Wiring Connections for Modbus and Sentry Interface ........................................................................... 16

Figure 11: Wiring Connections for Remote Alarm Reset ........................................................................................ 17

Figure 12: Face Plate with Operator Key Pad......................................................................................................... 18

Figure 13: Master Menu .......................................................................................................................................... 19

Figure 14: Operation Display Values....................................................................................................................... 19

Figure 15: Set-Up Configuration Part 1................................................................................................................... 21

Figure 16: Set-Up Configuration Part 2................................................................................................................... 22

Figure 17: Maintenance Menu................................................................................................................................. 22

Figure 18: Transmitter Enclosure ............................................................................................................................ 24

Model 5100-99-IT 4-20 mA Transmitter

Page 5 of 29

PRODUCT DESCRIPTION1

1.1 General

The Model 5100-99-IT Transmitter is a member of the Information Technology “IT” family of gas sensor

transmitters.

IT Transmitters offer a broad array of features, including:

Integral alphanumeric LED display

4-20 mA output

Modbus®RTU interface

SMC Sentry interface

316 Stainless steel enclosure option

Auxiliary integral relay option

Remote display option

Low maintenance and operation costs

The 5100-99-IT is designed and approved for installation and operation in hazardous locations.

1.2 Product Configuration

Various transmitter configuration options are available. Where applicable, these options are factory configured

prior to shipment. Options which can be re-configured by the installer or field technician are fully described in this

manual.

1.3 Modes of Operation

1.3.1 Sentry Interface

IT gas sensor transmitter can be connected to on Sierra Monitor Sentry Model 5000 Controllers. When it is

connected to a Sentry system the IT transmitter must have a unique address which can be established by setting

an address between 1 and 8 on the Transmitter Address Switch accessible from the cover plate as illustrated in

Figure 5. Figure 10 in this manual provides the wiring terminations for connections to the Sentry Controller.

When the transmitter is operated in conjunction with a Sentry Controller, the alarms outputs in the transmitter can

both be set to “Sentry”, allowing the Sentry Controller to manage alarm acknowledge and reset rather than the

transmitter. The alarm relay outputs are triggered by the alarm values established in the transmitter and can be

independent of the settings in the Sentry Controller.

The Sentry configuration allows daisy chain installation using the Sentry multiplex capability, thus reducing costs

by avoiding the requirement for wiring junction boxes. The connector card has two sets of connections, allowing

for a continuous run to the next transmitter.

®Registered trademark of Schneider Electric

Model 5100-99-IT 4-20 mA Transmitter

Page 6 of 29

1.3.2 Modbus Operation

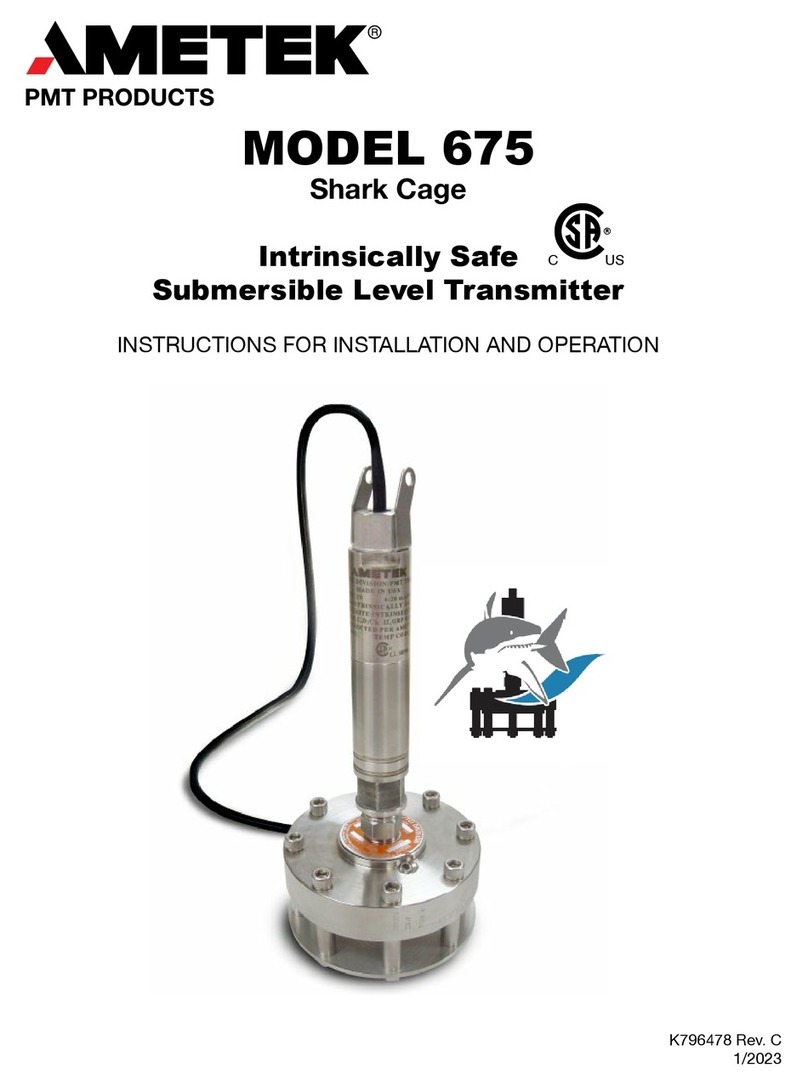

An RS-485 Modbus RTU serial interface allows direct connection to standard PLCs and DCSs. The Transmitter

Address Switch (section 3.5) allows the user to select up to 16 different Modbus addresses. Also, an additional

238 Modbus addresses (for a total of 254 different Modbus Addresses) are available via menu selection. Figure

10 in this manual provides the wiring terminations for Modbus connections. The 5100-XX-IT provides the

additional terminal connectors to enable the user to connect In/Out terminations of a RS-485 connection.

1.3.3 Analog Operation

The 4-20 mA interface allows direct connection to standard analogue controllers or PLCs. The 5100-XX-IT 4-20

mA connection can be wired as a Type 3 (3-wire) or Type 4 (4-wire) circuit as described by ANSI/ISA-50.00.01-

1975 Standard. (Figure 9)

1.3.4 Remote Alarm Reset (Digital Input)

An input is available for connection of remote alarm reset/acknowledge. Figure 11 provides the wiring termination

for connecting the remote alarm reset. This only resets local alarms, not Sentry alarms. This input can be wired as

supervised or non-supervised.

NOTE: When the Remote Alarm Reset is operated in a supervised mode that both the switch and resistor

must be present as outlined in Figure 11.

1.3.5 Optional Integral Relays

The optional relays are integral to the transmitter and are rated as SPDT, 250VAC, 8 Amps for the High Alarm

and Low Alarm relays and SPDT, 250 VAC, 2 Amp for the Trouble relay.

If the transmitter is provided with the optional relays, it will include Terminal P4 on the interface board (Figure 6

and Figure 7). Relay output connections are on P4.

Model 5100-99-IT 4-20 mA Transmitter

Page 7 of 29

1.4 Mechanical

The transmitter of comprised of the following two primary components.

1.4.1 Enclosure

Standard on the 5100-99-IT-A1 is an explosion-proof, rain-tight cast aluminum electrical housing (Figure 1) with

three ¾” FNPT conduit hubs. The 5100-99-IT-S1 (Figure 2) has a 316 Stainless Steel enclosure. Both enclosure

covers have a viewing window. The design of the enclosures allows 3-way mounting choices as shown in Figure

3.

Figure 1: Model 5100-99-IT-A1 Transmitter –Cast Aluminum Enclosure Dimensions

Figure 2: Model 5100-99-IT-S1 Transmitter –Stainless Steel Enclosure Dimensions

Model 5100-99-IT 4-20 mA Transmitter

Page 8 of 29

1.4.2 Transmitter Electronics

The Electronic Assembly consists of one top transmitter board (connected to the cover plate) and a lower

interface board. Connectors for wiring for power, signal interface and alarm relays are located on the interface

board assembly.

1.5 Interconnect Wiring

Not supplied with the transmitter, but necessary to the installation and operation is the multi conductor wiring

which connects the transmitter to its power source and controller. Before this wiring is installed it is important to

read and understand the control system installation instructions to determine wiring requirements and

alternatives.

1.6 Power Requirements

5100-99-IT operates on DC power between 10 VDC and 30 VDC. Regulated DC power must be supplied from a

separate source, or from an approved Sentry or IT controller.

Figure 3: Model 5100-99-IT Transmitter –Mounting Options

Model 5100-99-IT 4-20 mA Transmitter

Page 9 of 29

CAUTIONS & WARNINGS2

2.1 Introduction

Although IT Transmitter is designed and constructed for installation and operation in industrial applications

including "hostile" environments, caution should be taken to insure that the installation is made in compliance with

this instruction manual and that certain procedures and conditions are avoided. This chapter discusses the

necessary cautions. Read the entire chapter prior to installation of the equipment.

2.2 It Transmitters - General

Avoid installing Transmitter where they will be unnecessarily exposed to wind, dust, water (esp. direct hose

down), shock, or vibration. Observe temperature range limitations.

2.3 Wiring

The manufacturer recommends that extra caution be taken where the installation is near any sources of

electromagnetic or radio frequency interference. Precautions include:

Avoid running transmitter cable close to high power cables, radio transmission lines, or cables subject to

pulses of high current.

Avoid running cables near large electric motors or generators.

When the transmitter is to be operated in analog (4-20mA output) mode shielded cable is required.

All splices must be via either a termination hardware system or soldered. Improperly spliced cable can

result in corrosion, resistance changes and system errors.

Use low capacitance cable for RS-485 Modbus RTU Operation.

NOTE: Installation and wiring must be in accordance with the National Electrical Code. AC Voltage

conductors are not to be run in the same conduit as DC voltage conductors.

Model 5100-99-IT 4-20 mA Transmitter

Page 10 of 29

INSTALLATION3

NOTE: All transmitters are factory are pre-configured and calibrated. Identify all components during

unpacking and install using the factory configuration.

3.1 Transmitter Locations

Select locations for each transmitter so that they are placed in areas accessible for calibration.

3.2 Wiring

3.2.1 ANALOG 4-20 Ma OPERATION

The 4-20 mA output for the 5100-99-IT can be either 3-wire or 4-wire operation. If using 3-wire operation, use a

minimum of 18 AWG, shielded, 3-conductor cable up to 2000’. For 4-wire operation, use a minimum of 2 each, 18

AWG, twisted, shielded, pair up to 2000’.

3.2.2 Modbus Operation Using Rs-485 Connection

Use a minimum of 18 AWG, 2 conductor for DC power connection. No shield required. In addition, use a minimum

of 24 AWG, low capacitance, shielded data cable for RS-485 half duplex communication. The installation may be

planned in a manner which provides up to 32 sensor modules on a single home run.

Refer to Figure 7. Units ship with BIAS jumpers connected. For all installations, except very long cable runs,

leave these jumpers connected. The TERM jumpers should be installed in the last (furthest) module of every loop.

3.2.3 Sentry Operation Using SMC Sentry Connection

Wire shall be rated as 600 volt tray cable, such as Belden (or equivalent) 27331 or 27331 AS (shielded). If high

RFI or EMI levels exist wiring should be protected by conduit or shield. The installation may be planned in a

manner which provides up to 4 sensor modules on a single home run to a Sentry Controller.

NOTE: Be sure to follow all local electric code and safety requirements when installing the 5100-99-IT

Transmitter.

3.2.4 General

Install conduit as required by local code or construction specifications. When transmitters are to be multiplexed for

Sentry or RS-485 communication, two alternatives may be planned:

Use multi-position positive contact terminals to connect daisy chain wiring and provide a pigtail to connect

to the transmitter board.

NOTE: The drain wire of shielded cable must NOT be used as one of the conductors.

NOTE: Installation and wiring must be in accordance with the National Electrical Code. Temperature

rating of cable wire must be at least 75oC. If cable runs through higher temperature environments,

it must be specified for that environment.

Model 5100-99-IT 4-20 mA Transmitter

Page 11 of 29

3.3 Enclosure Installation

To protect the transmitter they should be removed from the enclosure and preserved until final installation and

wiring termination.

Prior to installation and wiring:

1. Remove the transmitter from the module housing by:

oUnscrew the two captive panel screws in the face plate

oLift the transmitter out of the housing

2. Install the module housing onto the end of the supply conduit and/or bolt into position as required.

NOTE: When housing earth grounding is required for the installation a grounding lug is located in the

base of the enclosure. Install the earth ground wire under the green lug.

3. Establish the module address according to Section 3.5.

NOTE: The starting delay period normally takes approximately 3 minutes but it depends on the sensor

connected.

P1

PCB Label

Function

1

Switch

IN +

Digital Input SW +

2

IN -

Digital Input SW -

3

4-20

IN +

4-20 mA Input +

4

IN -

4-20 mA Input -

5

GND

Ground

6

4-20

OUT +

4-20 mA Output +

7

OUT -

4-20 mA Output -

P2

1

RS 485

+

RS 485 (+) (A)

2

-

RS 485 (-) (B)

3

S

RS 485 shield (Isolated GND)

4

+

RS 485 (+) (A)

5

-

RS 485 (-) (B)

6

S

RS 485 shield (Isolated GND)

P3B

1

P

VDC Power

2

S

Sentry Signal or

Communication

3

G

VDC Ground

P3A

4

P

VDC Power

5

S

Sentry Signal or

Communication

6

G

VDC Ground

P4*

PCB Label

Function

1

WARNING

N/C

Low Alarm Relay NC

2

COM

Low Alarm Relay COM

3

N/O

Low Alarm Relay NO

4

ALARM

N/C

High Alarm Relay NC

5

COM

High Alarm Relay COM

6

N/O

High Alarm Relay NO

7

TRBL**

N/C

Trouble Alarm Relay NC

8

COM

Trouble Alarm Relay COM

9

N/O

Trouble Alarm Relay NO

*P4 Connections are installed only when the optional

Relays are included

** Trouble relay is a fail-safe so it is energized for normal

operation, functions are labeled for normal operation.

Model 5100-99-IT 4-20 mA Transmitter

Page 12 of 29

3.4 Transmitter Address Switch

For digital interface applications the module address switch (or Modbus node) Figure 5 must be set per the table

below.

Position

Address

Position

Address

1

Sensor 1

9

Sensor 09

2

Sensor 2

A

Sensor 10

3

Sensor 3

B

Sensor 11

4

Sensor 4

C

Sensor 12

5

Sensor 5

D

Sensor 13

6

Sensor 6

E

Sensor 14

7

Sensor 7

F

Sensor 15

8

Sensor 8

0

Software Menu

Figure 4: Sensor Module Address Switch Positions

NOTE: For Sentry (PSG) applications only sensor addresses 1-8 are allowed. If using Modbus output

sensor addresses 1-15 are available. Position 0 allows the Modbus Address to be set by software

menu, in the range 16-254.

Figure 5: Transmitter Face Plate

Model 5100-99-IT 4-20 mA Transmitter

Page 13 of 29

Figure 6: Interface Board Connectors

Figure 7: RS-485 –Termination, BIAS Jumper

Model 5100-99-IT 4-20 mA Transmitter

Page 14 of 29

Figure 8: 4-20mA Circuit Types

Model 5100-99-IT 4-20 mA Transmitter

Page 15 of 29

Figure 9: 4-20 mA Circuit Type Connections for 5100-99-IT

Model 5100-99-IT 4-20 mA Transmitter

Page 16 of 29

5100-99-IT TO MODBUS DEVICE

5100-99-IT TO SENTRY

Figure 10: Wiring Connections for Modbus and Sentry Interface

Model 5100-99-IT 4-20 mA Transmitter

Page 17 of 29

Figure 11: Wiring Connections for Remote Alarm Reset

5100-99-IT Remote Alarm Reset (Unsupervised)

(Dry contact only unpowered)

5100-05-IT REMOTE ALARM RESET (SUPERVISED)

SWITCH IN

SWITCH IN

+

-

+

-

+

GND

+

- -

IN IN OUT

SWITCH 4-20 4-20

P1

4.7K OHM (CUSTOMER SUPPLIED)

5100-XX-IT Remote Alarm Reset (Supervised)

Model 5100-99-IT 4-20 mA Transmitter

Page 18 of 29

OPERATION4

4.1 Introduction

The transmitter utilizes a visual menu system operated by means of a magnet. A magnetic tool (5358-50) is

supplied for this purpose. The menu system is used to configure alarm set-points, calibrate the transmitter and for

maintenance procedures and alarms acknowledge.

4.2 Data Entry Keypad

The module menu system is operated by means of directing the magnet stick toward each of four independent

hall-effect magnetic switches. Each switch functions as if it is a manually activated panel key. The keys are

located under the faceplate above and below the LED display and are labeled M , E , and as shown in

Figure 12.

Figure 12: Face Plate with Operator Key Pad

Model 5100-99-IT 4-20 mA Transmitter

Page 19 of 29

4.3 Main Menu

Key

Function

Display

Description

Reference

M

E

Mode

Switch [M]

▲

▼

M

E

Enter

Switch [E]

▲

▼

M

E

Up

Switch [▲] Previous Menu

▲

▼

M

E

Down

Switch [▼] Next Menu

▲

5100-XX

First screen at power up: Model No.

VXX-XX--

Second screen at power up: Version No.

STARTING

Third screen at start up: Starting Delay

XXX PPM

Normal condition - default display

M

E

Mode

ALMRSET:

Mode Function - Alarm Reset

▲

▼

Banner: "Press [E] to reset alarm"

M

E

RESET

Alarm Reset

▲

▼

XXX PPM

Default Display

M

E

Mode

ALMRSET:

Mode Function - Alarm Reset

▲

▼

M

E

Mode

CALIB:--

Mode Function - Calibrate

▲

▼

M

E

Mode

SETUP:--

Mode Function - Set up alarms, relays, etc

Figure 15 & Figure 16

▲

▼

M

E

Mode

MAINT:--

Mode Function - Maintenance

Figure 17

▲

▼

M

E

Mode

EXIT-?--

Exit Menu

▲

▼

M

E

Enter

XXX PPM

Apply Selected Mode (Exit)

▲

▼

XXX PPM

Default Display (Once a minute the sensor displays module address)

Figure 13: Master Menu

Figure 14 defines the key operational displays on the operator interface.

Display

Description

STARTING

Delay from loss of power at start-up

XXX PPM

Concentration

LXXX PPM

Low Alarm (Warning)

HXXX PPM

High Alarm (Alarm)

HIGH

Measures gas, concentration exceeds 100% of Full

Scale

CXXX PPM

Calibration Mode

ACK

Acknowledged Function

Figure 14: Operation Display Values

NOTE: If display shows “Start” instead of “Starting”, the module must be calibrated before using it.

Model 5100-99-IT 4-20 mA Transmitter

Page 20 of 29

4.4 Configure Set-Points

The transmitter set-points menu is used to initially set-up the alarm set points, relay actions, range, 4-20 mA

action and RS-485/Sentry address and baud rates.

Alarm Set-points: Once the Set-up menu is selected, press [E] to activate the Alarm Set-point screen.

Use the [▲] or [▼] keys to select Low Alarm or High Alarm menu. Key [▲] will adjust the setpoint

upwards and Key [▼] will adjust the value downwards. Once it reaches the desired setpoint, Key [E] will

accept it and ACK will appear.

Alarm Relay Set-up: Once the Set-up menu is selected, press key [▼] once and press [E] to activate the

Relay Set-up menu. Use the [▲] or [▼] keys to select High Alarm or Low Alarm relay menu and press [E].

Use the [▲] or [▼] keys to select the correct alarm relay action for the application, Latch, Sentry or Non-

Latch. Selecting “Sentry” enables the Sentry Controller to make all alarm action decisions. * indicates the

current selection.

Range: Once the Set-up menu is selected, press key [▼] twice and press [E] to activate the Range Set-

up menu. Use the [▲] or [▼] keys to select Range menu and press [E]. When “Range” is selected menu

provides any choices of ranges available for the gas type selected. Use the [▲] or [▼] keys to select the

desired range. If the “User” range is selected, use the [▲] or [▼] keys to adjust the high end of the range

desired. See specifications (page 25) for optional ranges.

4-20mA: Once the Set-up menu is selected, press key [▼] three times and press [E] to activate the 4-

20mA Set-up menu. Use the [▲] or [▼] keys to select Calib or CalibOut menu and press [E]. The “Calib”

section of the menu allows the user to calibrate the 4 mA and 20 mA outputs. To calibrate the 4 mA and

20 mA outputs it is necessary to have an amp meter connected to the 5100-XX-IT and upon selecting the

4 mA output calibration then the [▲] or [▼] keys can be used to adjust the 4 mA reading on the amp

meter until it reads 4 mA. Similar steps can then be performed for the 20 mA output. The CalibOut section

allows the user to select the 4-20 mA output action desired during calibration. * indicates the current

selected value. Available selections include:

oTrack –the 4-20mA value tracks the calibration gas exposed to the transmitter

oZero –the 4-20mA value is held at 0mA during calibration

oC1.50mA –the 4-20mA value is held at 1.50mA during calibration

oC4.00mA –the 4-20mA value is held at 4.0mA during calibration

oTblOut –the TblOut menu allos user to select 2.5 mA or A user selected value for Trouble mA

signal

oDigInput –the DigInput menu allows user to select supervised or non-supervised input

oWarmMin –the WarmMin menu allows user to select warm up time in minutes

RS-485: Once the Set-up menu is selected, press key [▼] four times and press [E] to activate the RS-

485/Sentry Set-up menu. Use the [▲] or [▼] keys to select “Mode” or “Calib” menu and press [E]. The

“Mode” menu allows the user to select units including %LEL, % Vol, PPM % Full Scale, or NA. The “Calib”

section of the menu allows the user to calibrate the 4 mA and 20 mA outputs and inputs. Note that the

5100-99-IT has a rotary switch on the faceplate and it is used to select addresses 1-15. When connected

to Sentry the user can select 1-8 and when using Modbus RS-485 the user can select addresses 1-15.

For Modbus addresses above 15, set the rotary switch to 0 and then use the “Address” menu to select

any address between 16 and 254. The Baud rate menu allows the user to select a baud rate of 38400,

19200, 9600, 4800 or 2400. * indicates current selection. Sentry default is 9600.

This manual suits for next models

1

Table of contents

Popular Transmitter manuals by other brands

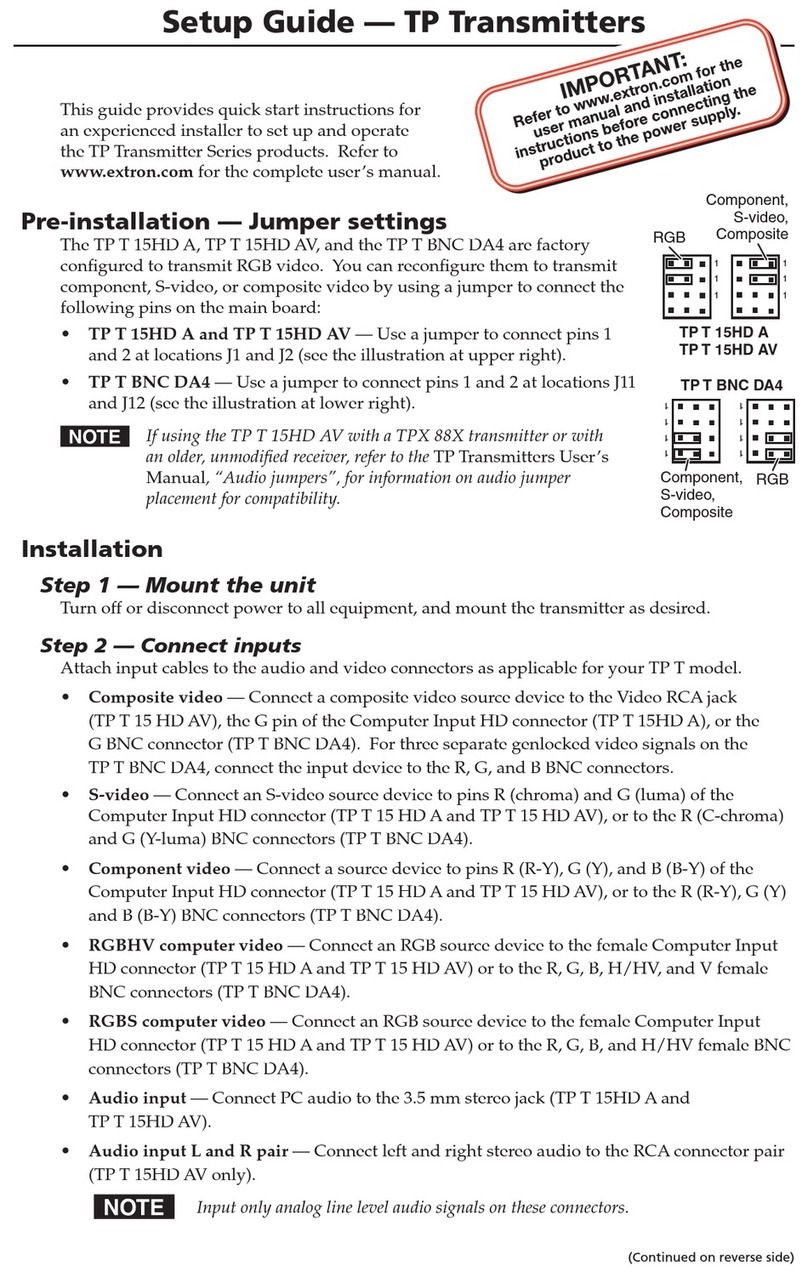

Extron electronics

Extron electronics TP Series Setup guide

Hollyland

Hollyland SYSCOM 421 User Note

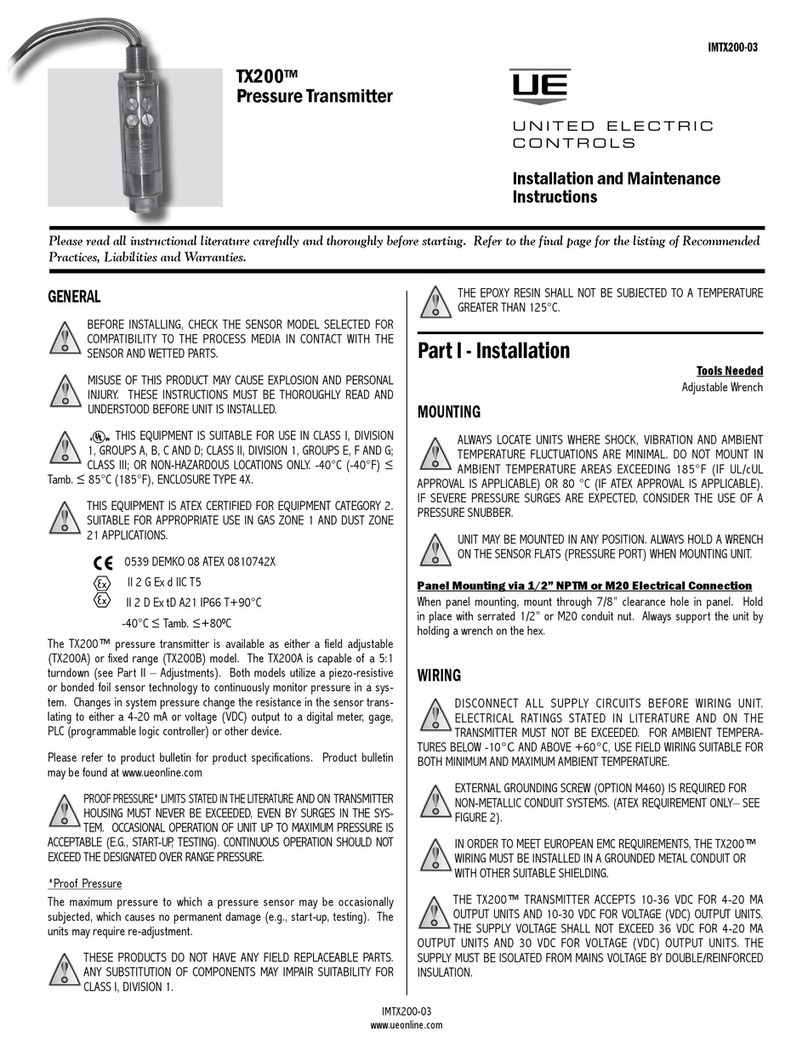

Ametek

Ametek 675 Instructions for installation and operation

Greystone Energy Systems

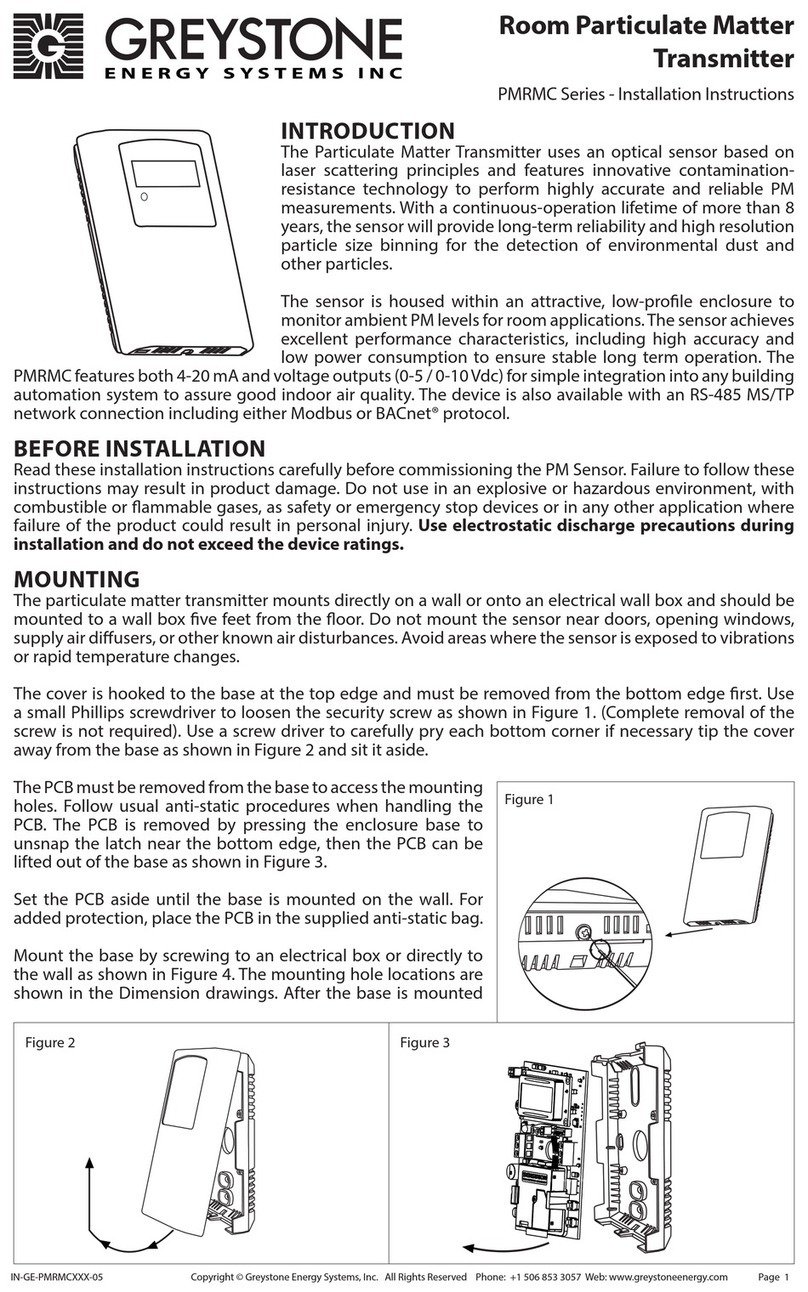

Greystone Energy Systems PMRMC Series installation instructions

ADI

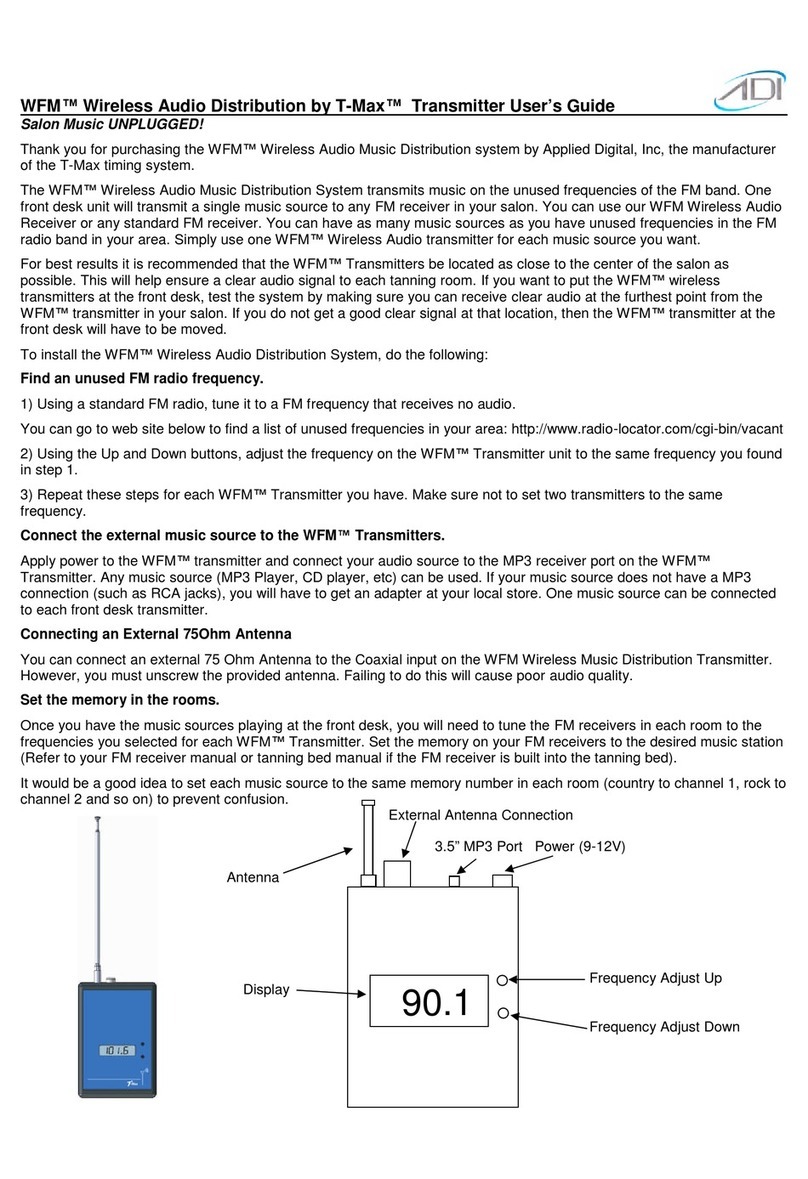

ADI WFM user guide

Minebea

Minebea CSA-591 instruction manual

Helipal

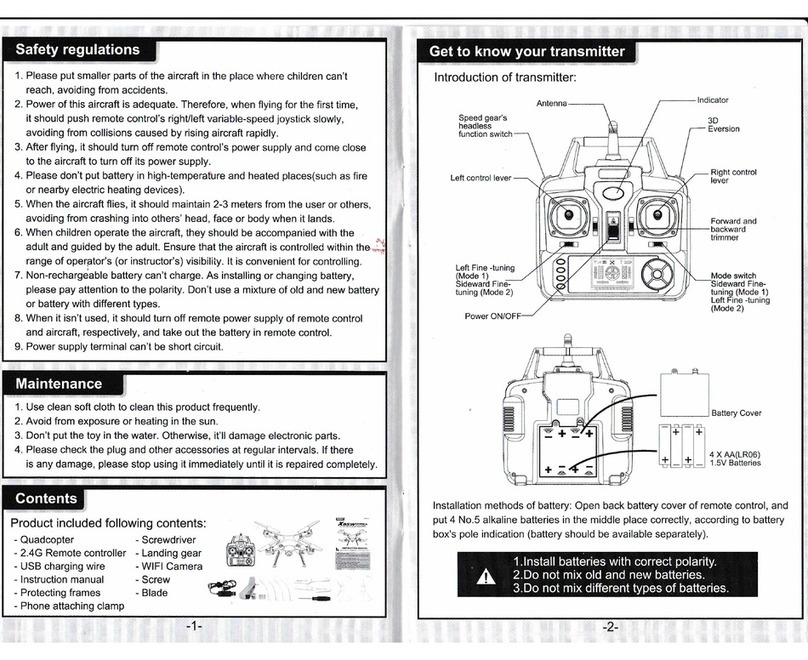

Helipal Syma X5SW user manual

M-system

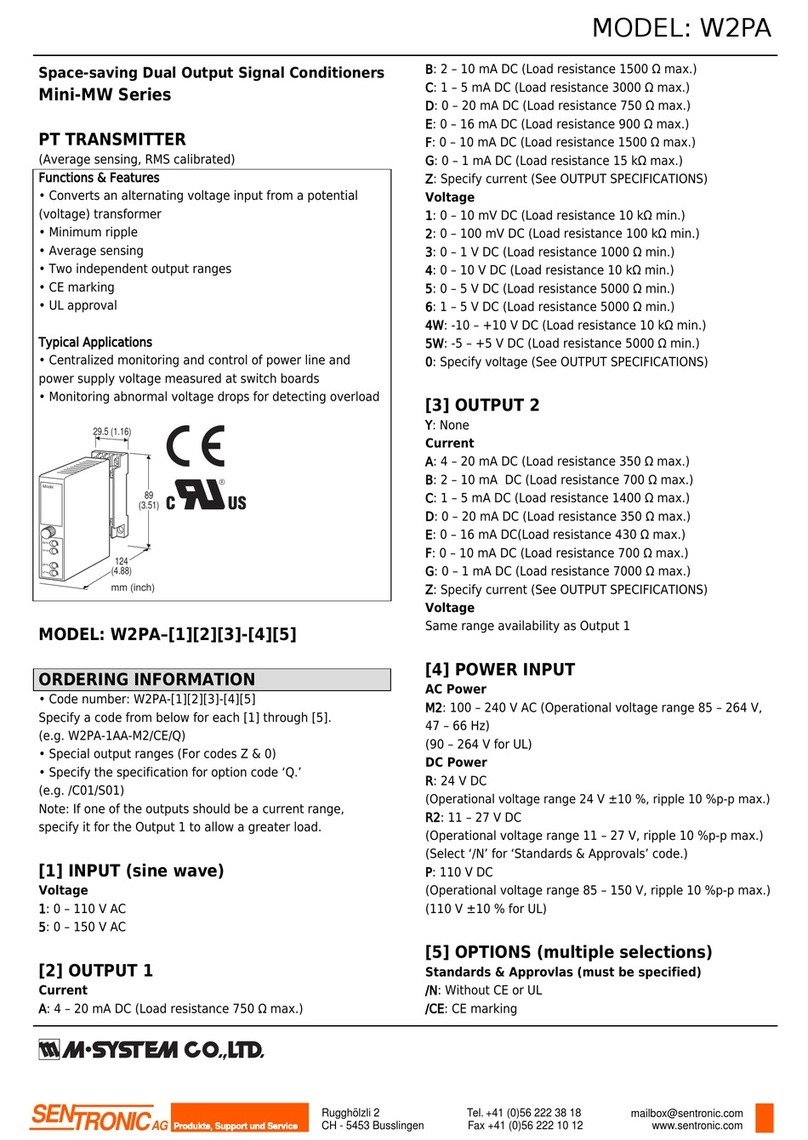

M-system Mini-MW Series operating instructions

Powelectrics

Powelectrics Metron 2 Technical Manual and Specifications

Johnson Controls

Johnson Controls HE-6800 Series installation guide

Sennheiser

Sennheiser SK 1013-6-1 manual

NBB

NBB PocketEvo operating instructions