1

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

SUMMARY

1PRODUCT IDENTIFICATION....................................................................................................................3

1.1 APPLICATION, GENERAL FUNCTIONS AND INTENDED USE ...............................................................3

1.2 NAME AND ADDRESS OF MANUFACTURER OR DISTRIBUTOR...........................................................3

SMEG S.P.A................................................................................................................................................3

1.3 DECLARATION OF CONFORMITY TO PRODUCT STANDARDS.............................................................3

1.4 DESCRIPTION OF THE APPLIANCE.....................................................................................................4

2SYMBOLS USED IN THE MANUAL...........................................................................................................4

3SAFETY PRECAUTIONS AND INSTRUCTIONS..........................................................................................5

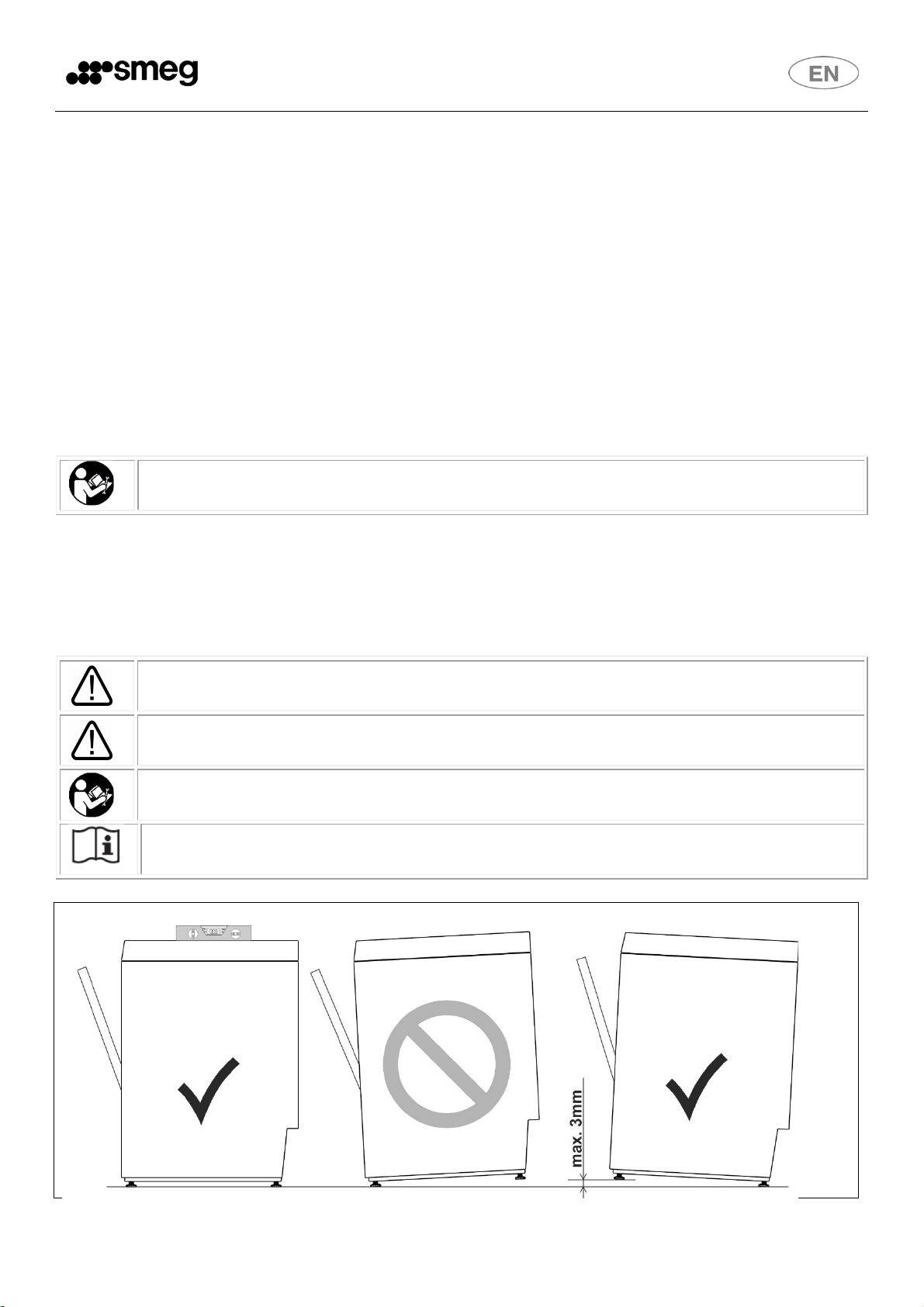

3.1 CORRECTINSTALLATION..................................................................................................................5

3.2 SAFEUSE..........................................................................................................................................6

3.3 CORRECTMAINTENANCE.................................................................................................................7

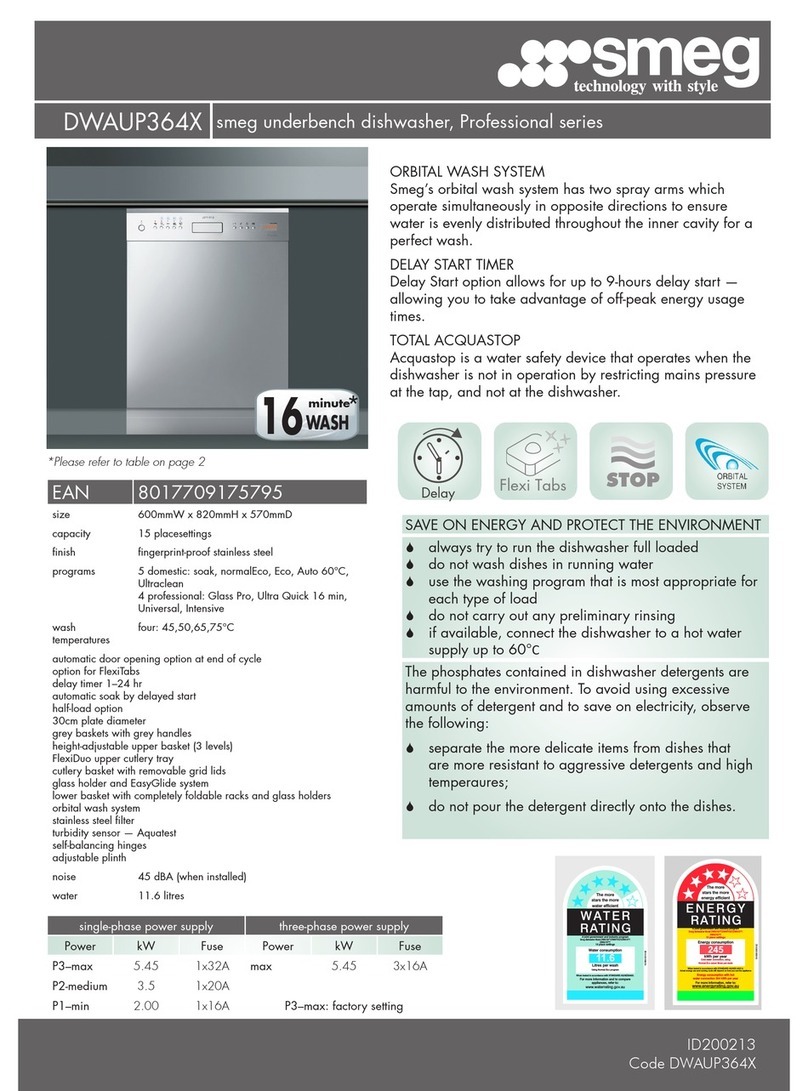

4PRODUCT CHARACTERISTICS.................................................................................................................8

4.1 OVERALL DIMENSIONS.....................................................................................................................8

4.2 TECHNICAL CHARACTERISTICS .........................................................................................................9

5PREPARING THE APPLIANCE FOR USE..................................................................................................10

5.1 POSITIONING AND INSTALLATION..................................................................................................10

5.2 CONNECTIONTO THEWATER SUPPLY............................................................................................11

5.3 DRAINCONNECTION......................................................................................................................11

5.4 CONNECTIONTO THEELECTRICITY SUPPLY....................................................................................12

6FIRST START-UP...................................................................................................................................13

6.1 FIRSTSTART-UP .............................................................................................................................13

6.2 PREPARING FOR USE (IMPORTANT ).............................................................................................13

6.3 USING THEWATER SOFTENER (ONMODELS WITH THIS FEATURE ONLY).......................................13

7CONTROL PANEL..................................................................................................................................14

7.1 SET-UP (AUTHORISED STAFF ONLY)...............................................................................................15

7.2 CONTENTS OF DISPLAY ..................................................................................................................15

7.3 PARAMETERPROGRAMMING PROCEDURE(SETUP).......................................................................16

7.4 MODIFIABLEPARAMETERS............................................................................................................16

7.5 ADJUSTING DETERGENT AND RINSE AID DISPENSING (ONLY AVAILABLE ON CERTAIN MODELS)....17

7.6 STARTING THE PERISTALTIC PUMP IN MANUAL MODE-RAPID FILLING OF DETERGENT AND RINSE

AID CIRCUIT.............................................................................................................................................17

7.7 MAINS WATER HARDNESS SETTING TABLE (MODELS WITH SOFTENER ONLY)................................18

7.8 EXTRA RINSE OPTION (LONG RINSE). - DISPLAYREADS “E.R”..........................................................18

7.9 "CLEAN WATER CYCLE" OPTION - DISPLAY READS “CL”..................................................................19

7.10 “THERMOSTOP” OPTION- DISPLAYREADS “TS”.............................................................................19

7.11 FAST/ECO STARTING OPTION- DISPLAYREADS “FI”.......................................................................19

8MALFUNCTIONS SHOWN ON THE DISPLAY (FOR THE TECHNICIAN)....................................................20

9INSTRUCTIONS FOR THE USER.............................................................................................................22