WD1050 12/04/2010 Pag. 1

TABLE OF CONTENTS

1. INTRODUCTION................................................................................................3

2. SYMBOLS LEGEND ..........................................................................................4

3. GENERAL RECOMMENDATIONS.....................................................................4

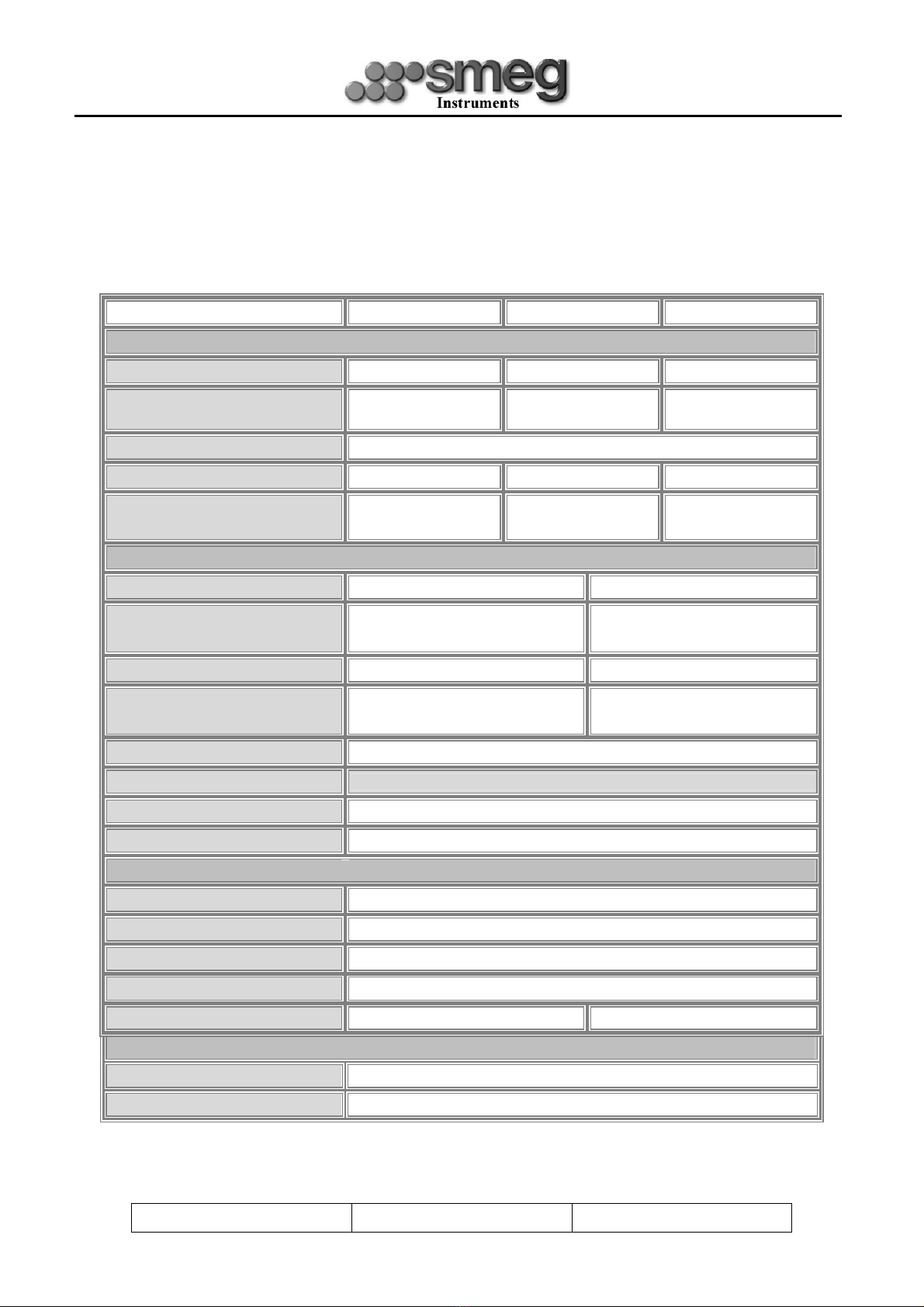

4. GENERAL SPECIFICATIONS............................................................................6

4.1. TECHNICAL FEATURES.............................................................................................6

4.2.

LIFTING

AND

HANDLING............................................................................................7

4.3.

DOOR

LOCKING

SYSTEM..........................................................................................7

4.4.

MANUAL

DOOR

UNLOCKING.....................................................................................8

5. INSTALLATION .................................................................................................9

5.1.

POSITIONING.............................................................................................................9

5.2.

LEVELLING.................................................................................................................9

5.3.

CONNECTION

TO

WATER

MAINS ..............................................................................9

5.4.

WATER

SUPPLY.......................................................................................................11

5.5.

NON

PRESSURIZED

DEMINERALIZED

WATER

CONNECTION................................12

5.6.

WATER

DRAIN

CONNECTION..................................................................................13

5.7.

ELECTRICAL

CONNECTION.....................................................................................14

6. DESCRIPTION OF CONTROLS....................................................................... 15

6.1.

WASHING

PROGRAMME

SETTINGS........................................................................16

6.2.

THERMAL

DISINFECTION

IN

ACCORDANCE

WITH

THE

PARAMETER

"A0".............16

6.3.

PROGRAMMES

DESCRIPTION ................................................................................18

6.4.

MACHINE

RUNNING.................................................................................................19

6.5.

RESIN

WASHING

PHASE .........................................................................................20

6.6.

RESIN

REGENERATION

PHASE...............................................................................20

6.7.

PROGRAMME

TERMINATION ..................................................................................20

6.8.

IN

PROGRESS

PROGRAMME

INTERRUPTION........................................................20

6.9.

RESET

PROCEDURE ...............................................................................................20

6.10.

DATE

AND

TIME

SETUP.........................................................................................21

6.11.

DEMI

WATER

SETTING..........................................................................................21

6.12.

PRINTER ................................................................................................................22

6.13.

PRINTER

LANGUAGE.............................................................................................23

7. OPERATING INSTRUCTIONS ......................................................................... 23

7.1.

USE

OF

THE

WATER

SOFTENER.............................................................................24

7.2.

USE

OF

THE

DETERGENT

AND

NEUTRALIZING

AGENT.........................................24

7.3.

DETERGENT

AND

NEUTRALIZING

AGENT

RECOMMENDED

BY

SMEG..................25

8. ALARMS..........................................................................................................27

9. CLEANING AND MAINTENANCE....................................................................31

9.1.

RECOMMENDATIONS

AND

GENERAL

ADVICE........................................................31

9.2.

IF

THE

INSTRUMENT

WASHER

IS

NOT

USED

FOR

A

LONG

PERIOD

OF

TIME........33