7

Your SPYDERCRANE’s Safees and Operator Aids

Safees

System Descripon

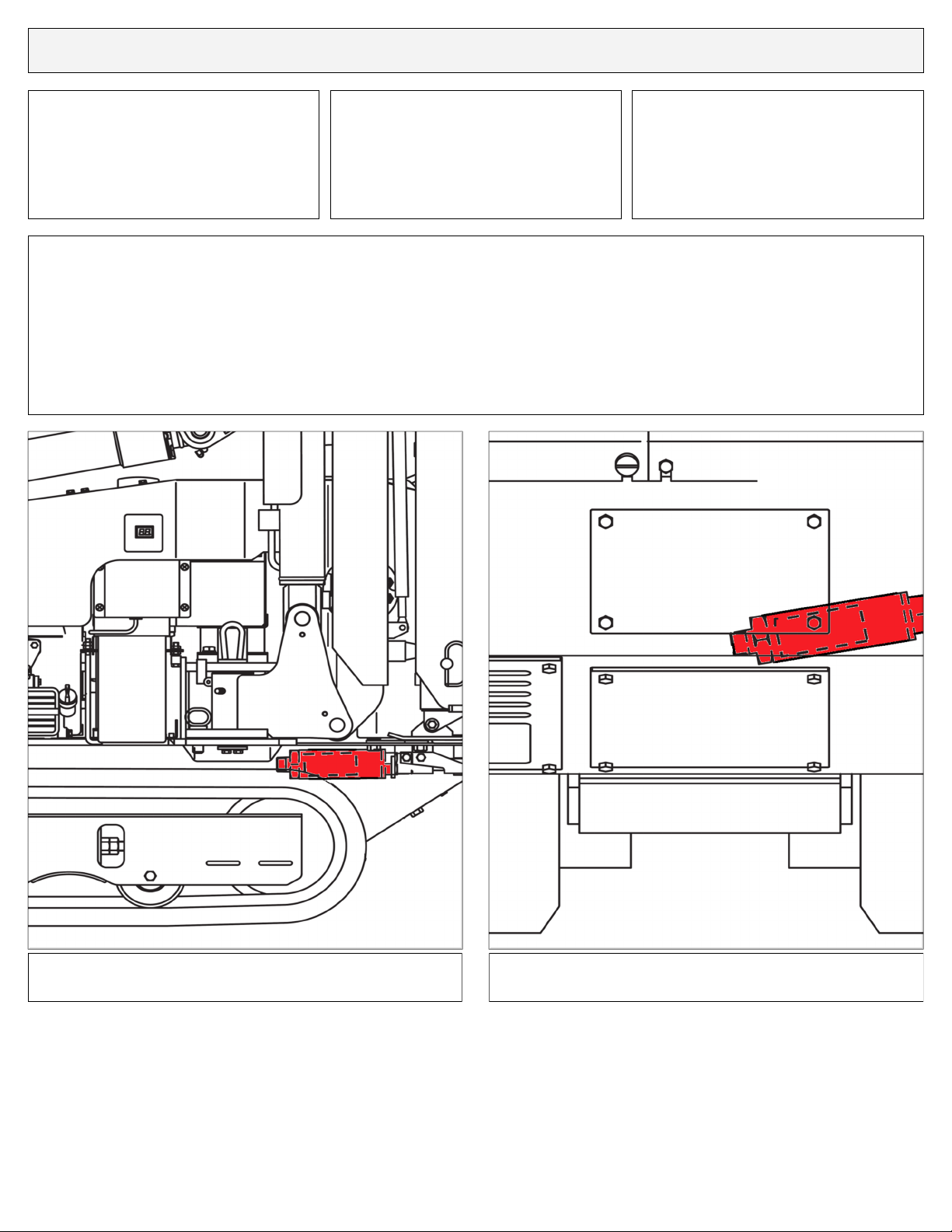

Holding Valves

Each hydraulic cylinder used by the SPYDERCRANE (Extend Cylinders for boom telescoping and outrigger deploy-

ment and the Li Cylinder used to change the angle of the boom) is equipped with a holding valve.

The holding valve prevents the cylinder from collapsing if the engine and/or hydraulic pump are shut down. Essen-

ally, if power or hydraulic pressure is lost, the SPYDERCRANE will “lock up” unl pressure is restored.

Addionally, if the hydraulic oil line to a specic cylinder is cut, or bursts, the associated holding valve will lock up

ONLY the aected cylinder; allowing the others to funcon normally.

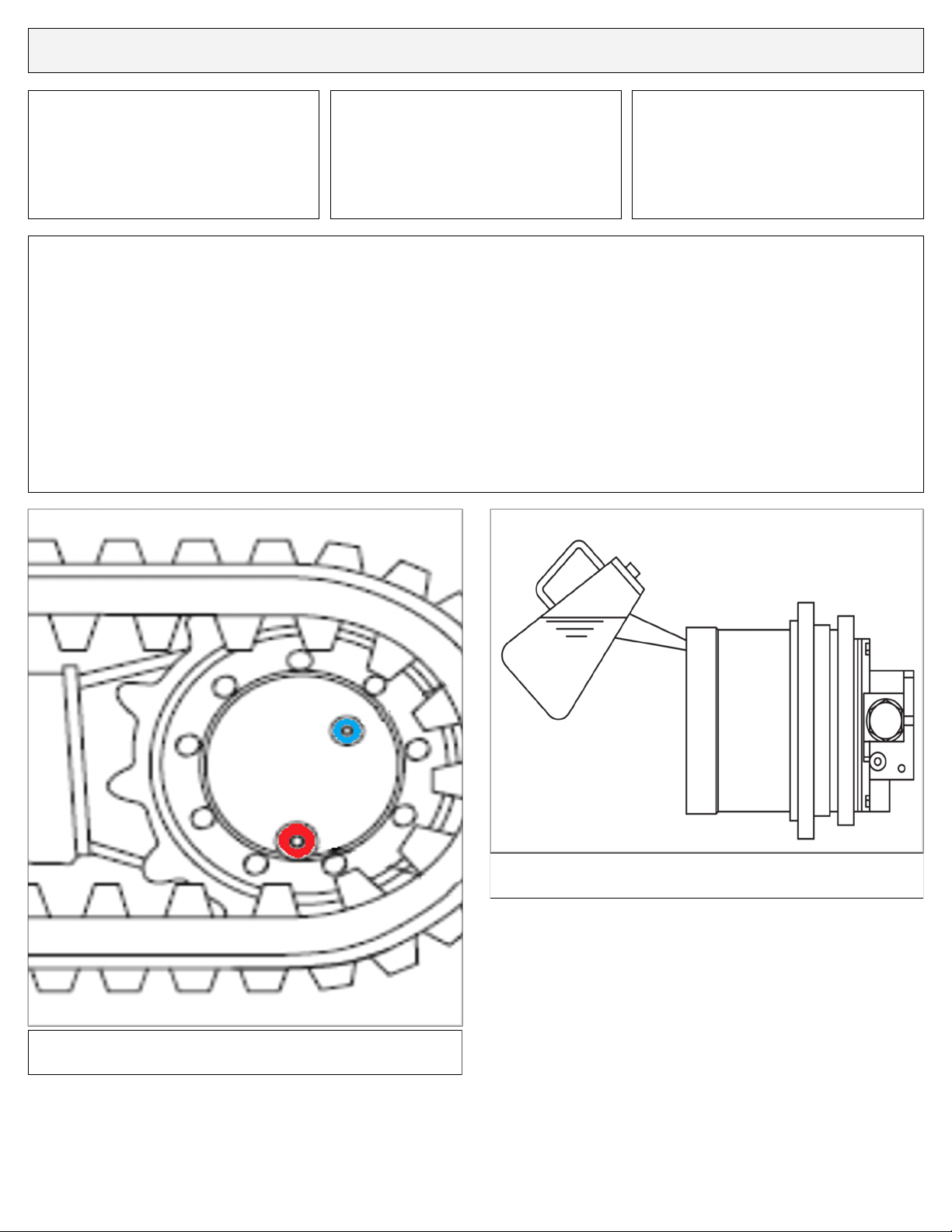

Locking Pawl The winch of the SPYDERCRANE is equipped with a locking pawl that lowers and prevents the winch from rotang if

hydraulic pressure is lost.

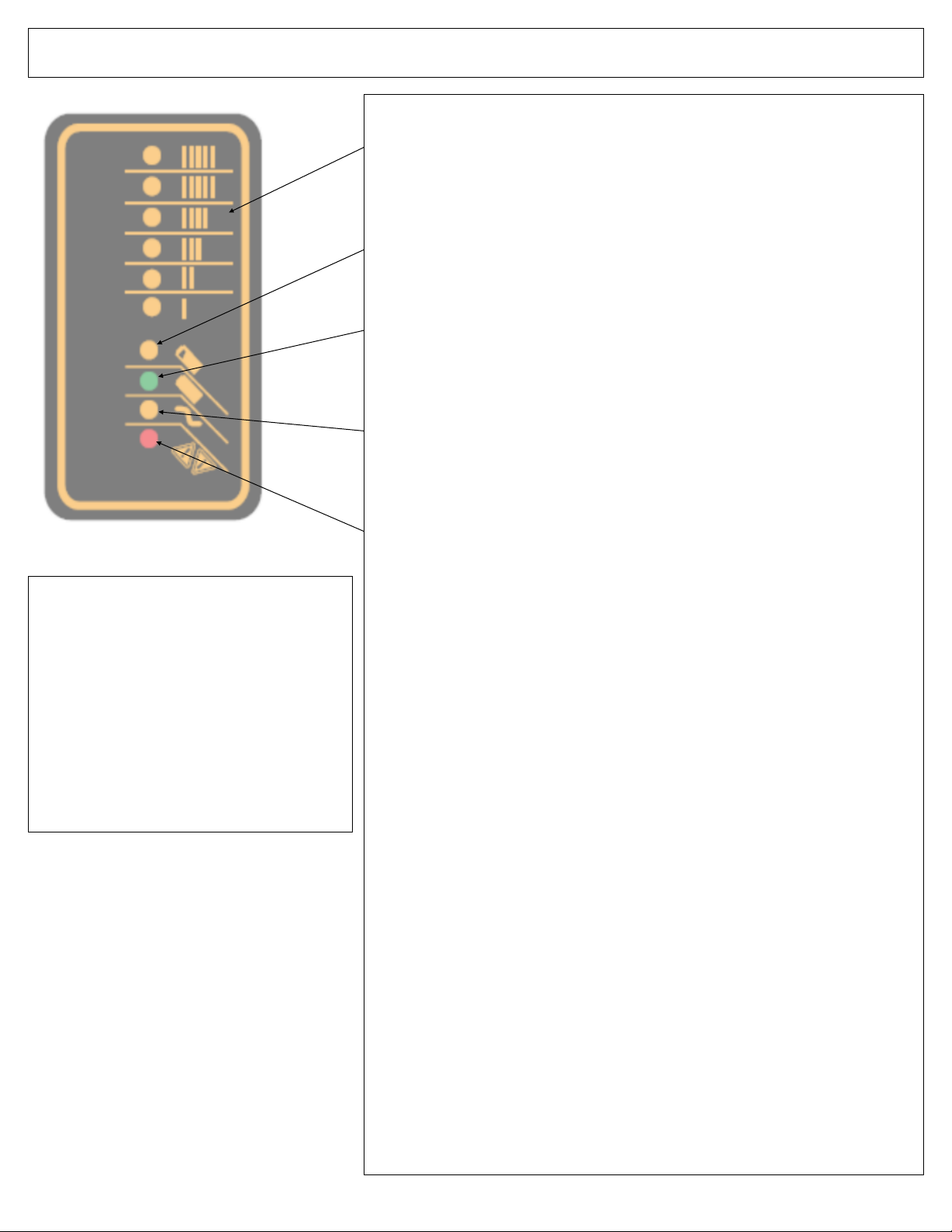

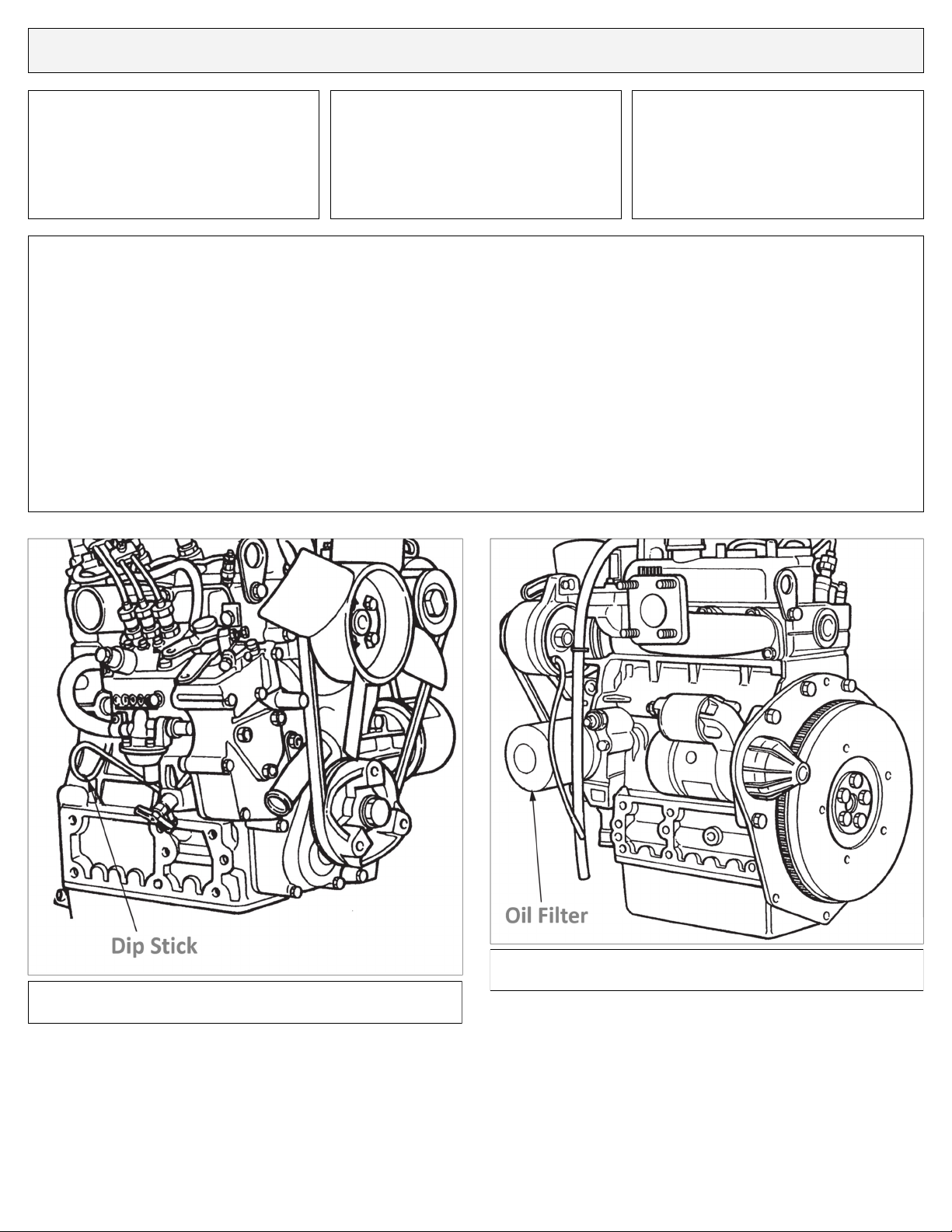

An-Two Block

Safety

The An-Two Block (A2B) Safety is designed to prevent the hook block from being WINCHED UP (or otherwise

raised) into the boom p. Allowing the hook block to smash into the boom p (“two-blocking”) can result in crical

damage to the wire rope, SPYDERCRANE, or the aached load. The A2B Safety prevents this by commanding a CMU

CODE 15 Funcon Kick-Out (FKO) when it is ACTIVATED.

The A2B Safety is acvated when:

The A2B Switch is OPENED by the hook block being WINCHED UP to the point where it impacts and lis the

A2B Weight, which causes the A2B Switch to spring into the OPEN posion. This can also be caused if the

boom is extended WITHOUT WINCHING DOWN the hook (to prevent the hook from rising).

The A2B Switch, or the electrical connecon to it, is broken.

Minimum Wire

Rope Safety

The Minimum Wire Rope Safety is designed to lockout the WINCH DOWN command when acvated (CMU CODE

96). Its purpose is to prevent the operator from WINCHING DOWN unl all of the wire rope is unspooled o the

Wire Rope Drum.

Boom Stored

Safety

The Boom Stored Safety is a limit switch that locks out the SLEW command when acvated. The Boom Stored Safe-

ty is used when storing the hook and boom. The URW094 IS NOT equipped with the Boom Stored Safety.

Safety Latch Every hook block on the SPYDERCRANE is equipped with a spring-loaded safety latch that acts as a one-way gate.

When a load is properly rigged and aached, the Safety Latch keeps the rigging from slipping o the hook.

Operator Aids

System Descripon

Turnover Prevenon Device

The Turnover Prevenon Device (TPD) is a system of load cells and a centralized computer (the TPD

Amplier) that monitors the stability of the SPYDERCRANE and can acvate a CMU CODE 15 FKO

when it detects that the SPYDERCRANE is nearing its stability limits (do to overloading, or boom

movement). The URW094 IS NOT equipped with the TPD.

Boom Angle Indicator

A mechanical operator aid, the Boom Angle Indicator indicates the boom angle of the SPYDER-

CRANE’s boom and can be used in conjuncon with visually determining the Boom Stage to calculate

the SPYDERCRANE’s Working Radius.

Load Chart The Load Chart displays the various Rated Load Capacies for the SPYDERCRANE, based on its Boom

Stage, Working Radius, and Deployment State.

Working Range Chart The Working Range Chart indicates the approximate posion and length of the boom based on its

Working Radius, Boom Angle, and Boom Stage.