1

Table of Contents

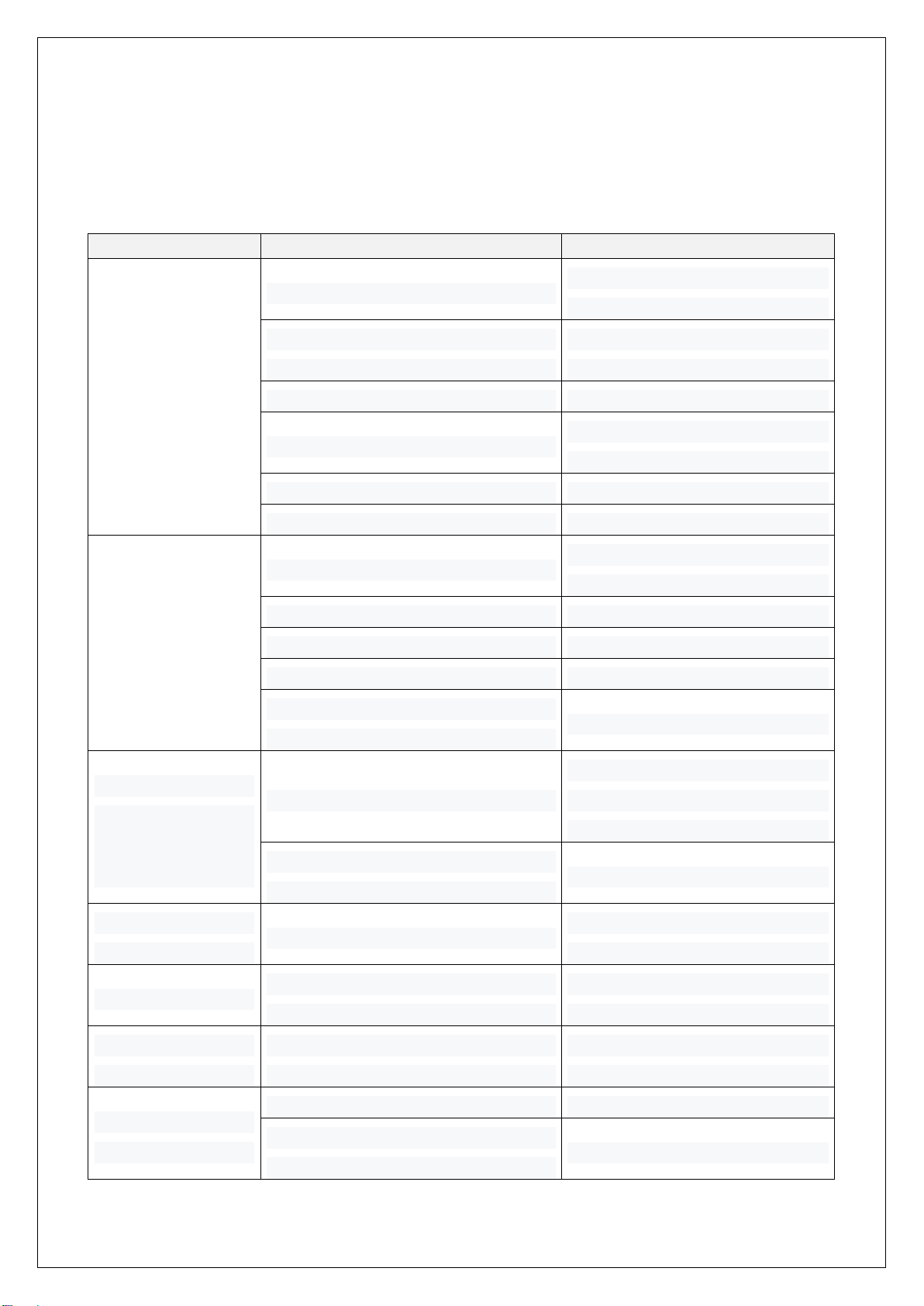

1. Maintenance List .........................................................................................................................2

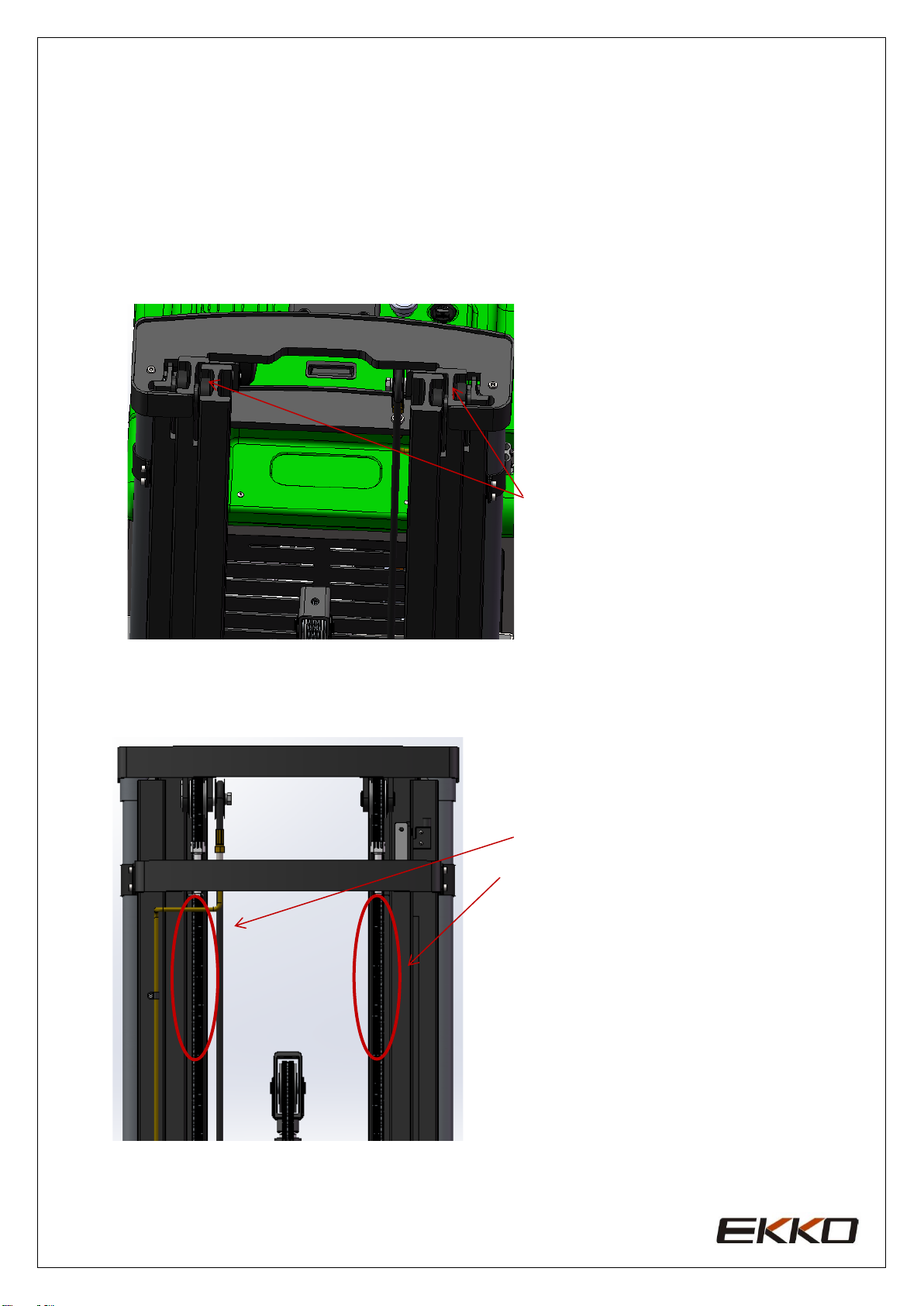

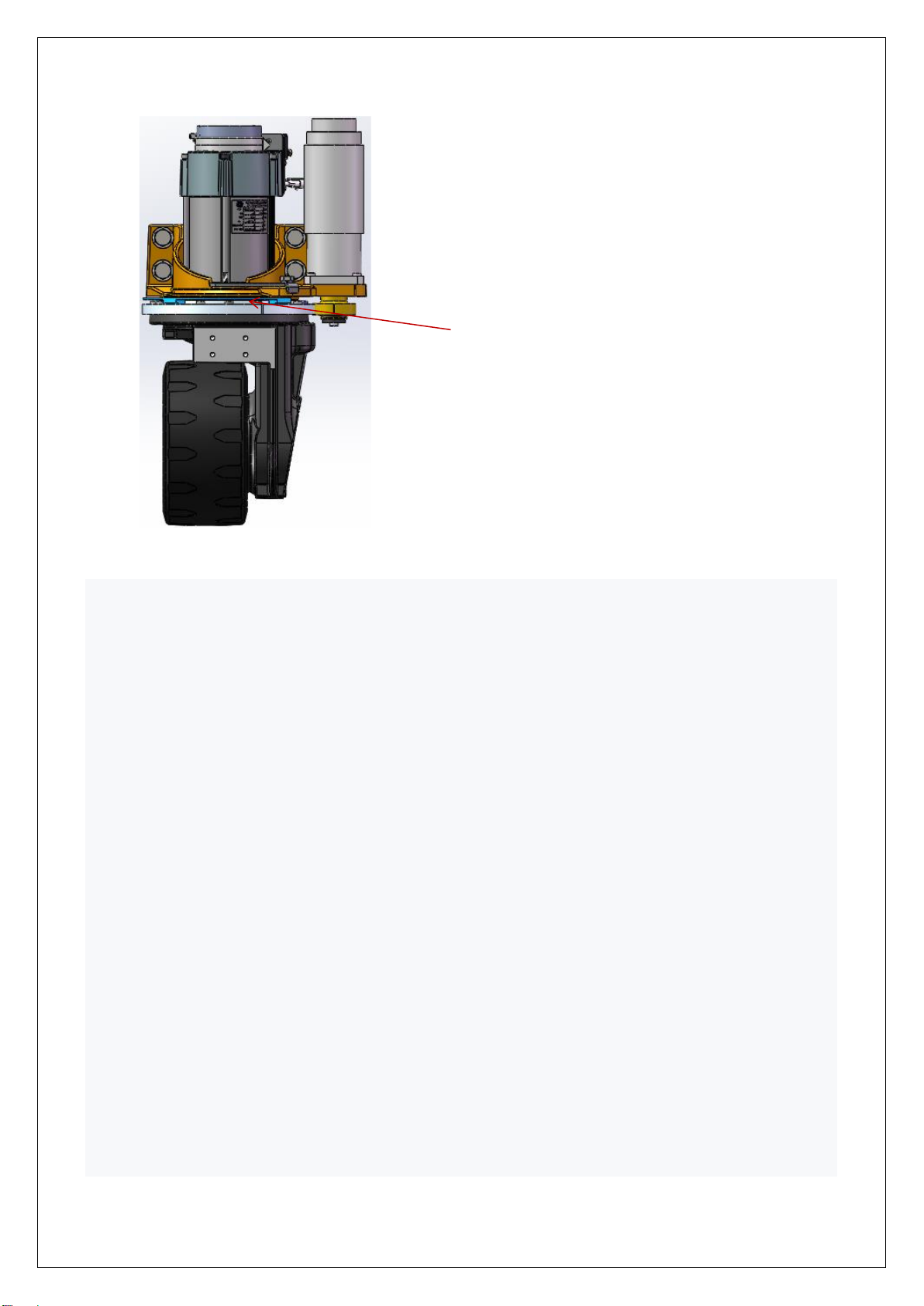

A. Overview of main components ................................................................................................2

B. Lubrication point.......................................................................................................................4

C. Check the fuse...........................................................................................................................6

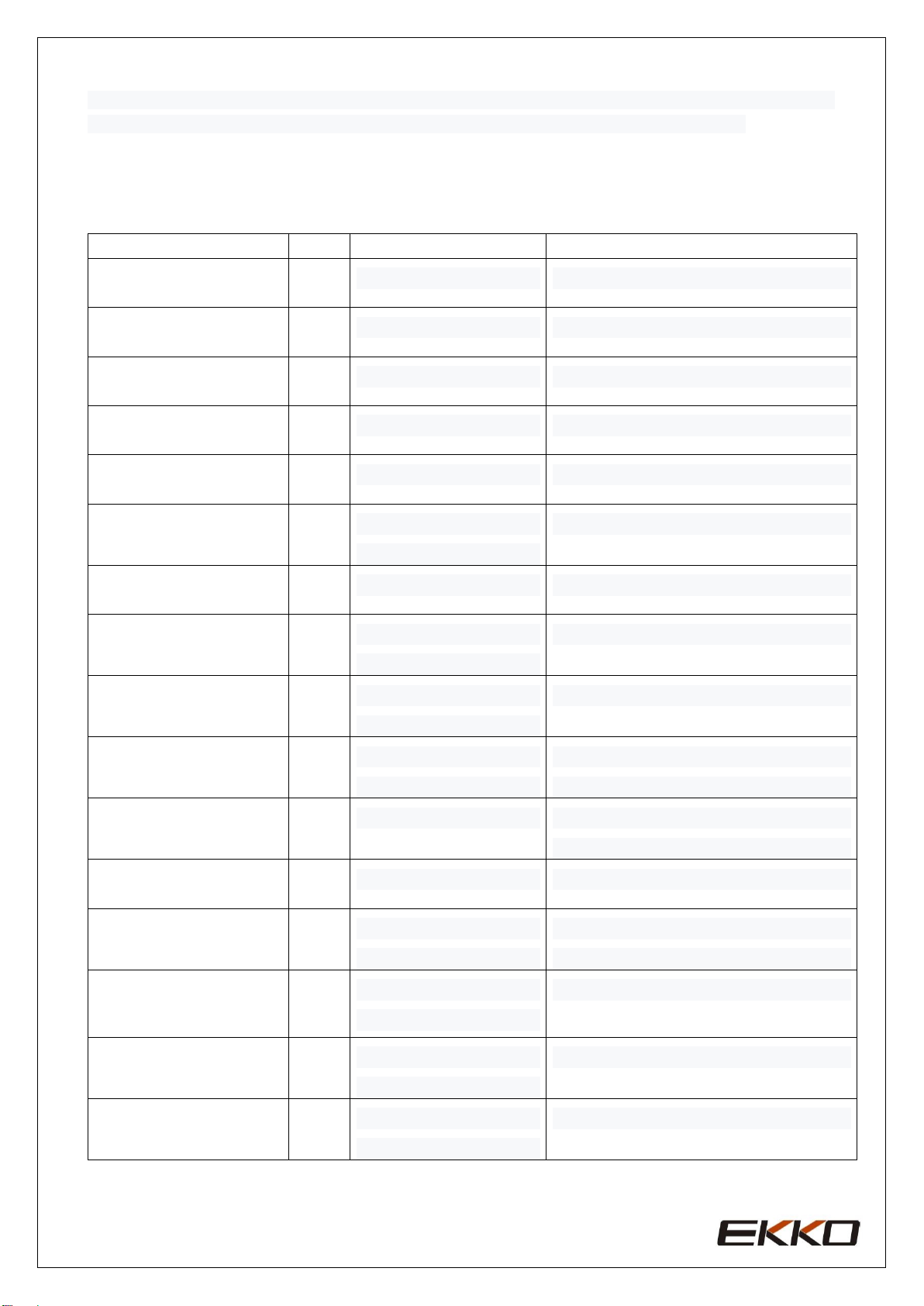

2. Fault Analysis ...............................................................................................................................7

A. Common fault analysis..............................................................................................................7

B. The fault code display ...............................................................................................................8

c. Methods for troubleshooting common faults ............................................................................9

3. Wiring/circuit Diagram...............................................................................................................14

A. Schematic diagram and wiring diagram..................................................................................14

B. Hydraulic circuit .....................................................................................................................15

4. Disassembly of main parts..........................................................................................................16

A. Removal of handle assembly ..................................................................................................16

B. Removal of electric control component ..................................................................................18

C. Hydraulic assembly removal...................................................................................................20

D. Arm guard assembly removal .................................................................................................21

E. Mast assembly.........................................................................................................................22

F. External door frame removal ..................................................................................................24

G. Middle door frame removal ....................................................................................................26

H. Inner door frame removal .......................................................................................................27

I. Electrical assembly .................................................................................................................28

5. CURTIS handhold unit ...............................................................................................................30