Smith FS300 User manual

FS300 Gas

Heavy duty remover

User Manual

(954) 941-9744

www.SMITHMFG.com

MANUFACTURING

Cutters / Removers / Parts / Support

1-800-653-9311

www.SmithMfg.com

Phone: 954-941-9744 • Fax: 954-545-0348

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS300

VERSION 8/2013

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

INTRODUCTION

2

Congratulations on purchasing the

FS300™ heavy duty remover from

SMITH Mfg. Company.

Your machine will:

• Clean surfaces impacted by grease, oil,

plastics, tars, resins, tile adhesives, ice and

more

• Plane or mill asphalt and concrete surfaces

• Remove high spots in curbs and gutters

• Eliminate trip-hazards on concrete sidewalks

• Mill areas for rumble strips

• Clean out cracks and joints

• Create anti-slip patterns in walkways and barns

• Prepare surfaces for new coating applications

• Permanently remove all road and surface

coatings to include:

epoxy, urethane, thermoplastic, paint,

glue-backed tapes and more...

• Groove-inlay asphalt for striping

BEFORE START-UP,

READ THIS..

Please read all operating instructions, including

the provided motor manual and be completely

familiar with your equipment before operating.

When in doubt, please contact SMITH

Manufacturing Customer Service for operational

details. This Owner’s Manual will guide you

through the removal process, from start to nish,

and show you how to care for your machine.

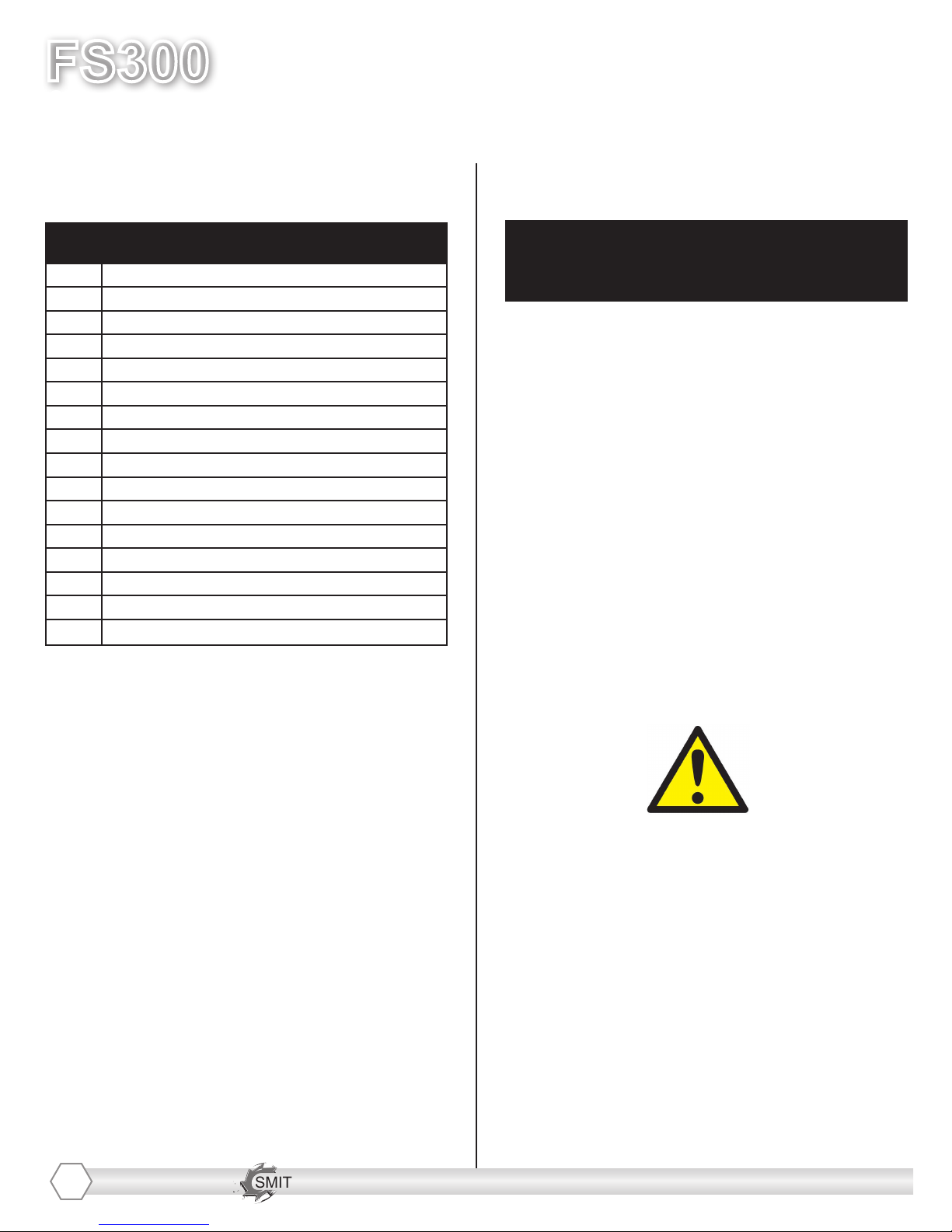

Page Contents

2Index / Introduction

3Safety Guidelines

4Your FS300 Surface Preparator

5Handle Adjustment Instructions

6Machine Start-Up

7Substrate Removal

8Storage, Ordering, and Warranty Claims

9Troubleshooting

10 Maintenance Check List

11-12 General maintenance

13-14 Bearing replacement

15-17 Optional Equipment

18-19 Maintenance Log

20 Limited Equipment Warranty

21 Warranty Activation

INDEX

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 8/2013

FS300

Gas

3

UNCRATING EQUIPMENT

When you uncrate your equipment, make certain

that the machine has not been damaged and

that all fasteners and guards are properly

tightened.

Your machine may not have been shipped

assembled with cutters and other accessories.

Assembly may be required.

REMEMBER: Only authorized, experienced and

properly trained personnel should operate this

equipment. Operating personnel should prac-

tice safety at all times and ear protective gear

(gloves, goggles, safety vests, ear plugs, steel-

toe shoes, etc.)

• Always wear protective equipment, including

ear protection and goggles.

• Never wear baggy or loose tting clothing that

can be caught on controls or moving parts.

• The surface preparator can emit ying

particles and debris during operation. Never

operate the machine near bystanders, animals

or children.

• Check uid levels and get acquainted with the

controls.

• Do not operate the machine in an explosive

atmosphere, near combustible materials, or

when gas fumes may not be properly dispersed.

• Never leave the machine unattended when

running, and you must hold onto the handle with

two hands when the cutter drum is engaged.

• Ensure that all guards are in place before the

machine is operated, since rotating and moving

parts will cause injury upon contact.

• Make sure that the machine is unplugged from

any power source before servicing.

Incorrect use of the surface planer can

result in property damage, personal injury,

or death. Be sure to read and follow all

directions and precautions as outlined in

this manual.

SAFETY GUIDELINES

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS300

VERSION 8/2013

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

YOUR FS300TM SURFACE PREPARATOR

Please take time to familiarize yourself with the FS300™’s

controls, as well as some of the features of your new machine.

Read the engine manual before preparing the engine for starting.

Adjustable Handlebar

Cutter height adjustment

Corded “engine kill” button

Removable Side Plate

4

Oil Dipstick

Engine Shut-Off

Gas Tank

Throttle

Cyclone Air Cleaner

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 8/2013

FS300

Gas

HANDLE BAR ADJUSTMENT

The handlebars are equipped with a high-density

vibration suppression material to minimize

operator fatigue and increase comfort level when

operating equipment. To adjust the handlebars

to a new position for different height operators

please follow these steps:

• Using a wrench or socket (13mm), loosen

the bolts on both sides of the handlebars

two to three turns only.

• Adjust handlebar to desired position and

re-tighten the 4 screws

Never operate with handlebars loose.

The bolts must be fastened tightly assuring

the handle is locked into position.

Loosen to

adjust

5

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS300

VERSION 8/2013

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

MACHINE START-UP

Do not start machine while drum is in

contact with the ground. Doing so can

cause the operator to lose control of the

machine, resulting in property damage

and/or personal injury.

NOTE: Do not attempt to raise or lower the cam

lever by force. If it does not move effortlessly,

raise or lower the hand wheel until the cam lever

can be adjusted. Open the fuel cock on the

carburator and then place the throttle lever at the

“Fast Idle” position. Start the engine, open choke

slightly to prevent ooding. Move throttle control

to open or run position when engine is warmed

up. Increase throttle to maximum operating posi-

tion (approx. 2800RPM) and close choke. Before

substrate removal, test run the drum with cutters

not touching the surface. If there is excessive vi-

bration, you need to re-balance the cutter set-up,

check bearing condition, and/or make sure that

the drive shaft is secured.

Corded “Engine Kill” Button (not available

on electric motor): In the event of a malfunc-

tion or an accident (such as the machine op-

erator falling or losing footing), the SPS10 is

equipped with a corded “Engine Kill” Button.

Attach the end of the cord to the operator’s

belt or wrist, and snap the clip into place on

the stop switch by raising the top of the Engine

Kill Button and inserting the clip into the gap.

If the operator becomes distanced too far from

the machine, the cord will detach from the stop

switch, and the machine will stop running.

Attatch to

operator

*NOTE: the Engine will not start without the

Corded Engine Kill’s clip securely in place.

CAUTION: The machine will still move with

the engine off.

IF THE ENGINE DOES NOT

START

1) Check Engine for proper gas and oil levels

(refer to Engine manual)

2) Check spark plug. Make sure the socket

areas are clean and clear of debris, and that

the proper gap is set. (Replace if needed).

3) Check Brown Electrical clip hanging on the

front of the engine and ensure that the

electrical wires are making contact within the

clip.

4) Turn the On/Off switch, on the front of the

Engine, to “On”.

5) Check Corded Engine Kill Button’s

Connections:

a) Make sure the Corded Safety Stop “C”

Connector is dipped properly.

b) Try switching the connection to the opposite

post (From letter “C” to letter “M”, for example).

6) Engine may have tilted backwards. If so,

allow oil to drain after removing spark plug and

pulling starter cord several times

*Engine repair and engine warranty

issues are handled directly

by your local engine service center.

6

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 8/2013

FS300

Gas

7

SUBSTRATE REMOVAL

Warning: Should you desire to tilt the

machine, always tilt forward. Tilting the

machine backwards at any time will ood

the spark plug with oil and may cause

damage to your engine!

Adjust the height of the cutter drum with

the Hand Wheel and Cam Lever. (Turn the

hand wheel to raise the cutter drum off of the

substrate. Lower or raise the cam lever to

engage or disengage the drum after setting

the proper cutter depth.)

Set the deoth of cut to allow the cutters to go

through only the materials to be removed.

Make certain that the drum is positioned to

where only the cutters strike the surface,

and that the drum assembly never comes

into contact with the substrate. The cutter

tips alone should strike the surface (1/8”

to 1/4” maximum depth per removal pass on

new cutters).

The drum will not withstand substrate

contact. Contacting the removal surface

too deeply will cause premature wear to

cutters, shafts, drum and other

components!

Too much downward pressure only has

negative results. Try to remove materials in

several passes rather than one, deep pass.

Several tests will show the best, most

appropriate cutter impact. Use a forward,

backward and/or circular pattern to achieve

your desired nish.

NOTE: Only use a forward motion when the

CM2150 or CM2550 carbide milling cutters

are used.

TIP: Positioning the machine over the

surface in many direrctions, as well as

dialing the hand wheel up or down can help

create desirable surface patterns.

After several hours of practice, the operator

will become comfortable and should be able

to remove materials faster with enhanced

results.

When the job is completed, or the operator

wants to cease work, stop the engine by rst

lifting the drum above the substrate using the

hand-wheel and/or the cam lever. Stop the

machine only at the engine. Then close the

fuel cock to shut off the fuel supply.

The drum assembly must be removed daily

and inspected for drum wear, hole

elongation and possible weld separation.

Replace the cutter shafts and drum bushings

every 40 hours, or prior to any drum wear. If

the drum’s center holes are elongated, oreder

another SMITH cutter drum.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS300

VERSION 8/2013

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

STORAGE

Shut off fuel valve and remove all fuel or

add fuel stabilizer. Start engine and run until

it stalls. Remove spark plug and pour two

ounces of motor oil into cylinder and slowly

crank the engine by hand to distribute oil to

prevent rust during storage.Replace spark

plug and store machine upright in a cool, dry,

and well-ventilated area.

ORDERING

To ensure product safety and reliability,

and to maintain your warranty, always use

genuine replacement cutters and partsfrom

SMITH when making repairs to equipment.

When oredering please specify the model and

serial number of the machine. In addition, give

a part number, description, and quantity as

listed on your parts list.

If you have any questions about the operation

of your machine or would like to order

replacement parts, contact your SMITH

Manufacturing representative directly.

Contact 1-800-653-9311 (954-941-9744)

for information.

Visit our website at

www.smithmfg.com

WARRANTY CLAIMS

The manufacturer reserves the right to

change or improve the machine design with-

out assuming any obligation to update any

products previously manufactured before

this manual. It is the customer’s responibility

to complete the warranty card and mail it to

the seller within 10 days from date of pur-

chase. If a failure occurs during the warranty

period, the customer must contact the seller

to determine the appropriate action.

Any and all transportation charges are to

be borne by the purchaser.

8

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 8/2013

FS300

Gas

TROUBLESHOOTING

PROBLEM

Possible Reason(s)/Solution(s)

CUTTERS WEARING

UNEVENLY/PREMATURELY

Drum is too low

Icorrect set-up

Material Build-up

Cutters too tightly loaded

Wrong cutters for

application

CUTTERS SHAFT BREAKAGE

UNEVENLY/PREMATURELY

Drum is too low

End plates or bushings worn

Shafts worn

Wrong cutter set-up

Over 40 hours service-life

DRUM WEARING

PREMATURELY OR CRACKING

Drum hitting ground

Shafts and bushings not replaced

within 40 hours

EXCESS VIBRATION

Bearing worn

Hex bushing worn

Drive shaft worn

Improper cutter set-up

Drum contacting ground

Wheels worn out

MACHINE JUMPS

ERRATICALLY

Drum hitting ground

RPM is too low

Surface is severely uneven

DRIVE BELT WEARING

PREMATURELY

Pulley is misaligned

Wrong belt

Drum is contacting

the surface

MACHINE WONT MOVE IN

FORWARD OR REVERSE

Check hydraulic reservoir level

Verify v-belt to hydraulic pump

is not slipping or damaged

*Engine repair and engine warranty

issues are handled directly

by your local engine service center.

For any other problems or questions,

please contact your local representative

or

SMITH Mfg today at 800-653-9311

or

(954) 941-9744.

9

Check lifting carriage is in

upright position and drive

wheels in cocntact with ground

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS300

VERSION 8/2013

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

MAINTENANCE CHECK LIST

Note: Make sure the ignition is in the OFF

position, and the spark plug is disconnected

before servicing

• Maintain proper engine oil and crankcase

levels.

Change every 25-50 hours

(see Honda manual).

• Clean spark plugs regularly, and set the

proper gap.

• Wash the air cleaner element in a non oil-

based solvent, then squeeze out residue.

Allow lter to dry before reinstalling in cleaner.

• Keep a coating of grease on the drive shaft

and threads for easy installation or removal,

and for longer hex bushing life.

• Check all fasteners and re-tighten, since the

machine will vibrate the fasteners loose if they

are not secured. Use locktight.

• Check the Drive belt for wear, and adjust

(tension), or replace as required.

After replacing belts, check for proper tension:

• Adjust Idler to tension belt. Do not over

tighten.

• Check that the pulleys are aligned properly

to ensure the belts are running true.

10

• The inside housing must be clean, and

remove any build-up from inside the cage so

cutters and drum rotate freely.

• Inspect and change drum bushings and

shafts every 40 hours, or when worn.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 8/2013

FS300

Gas

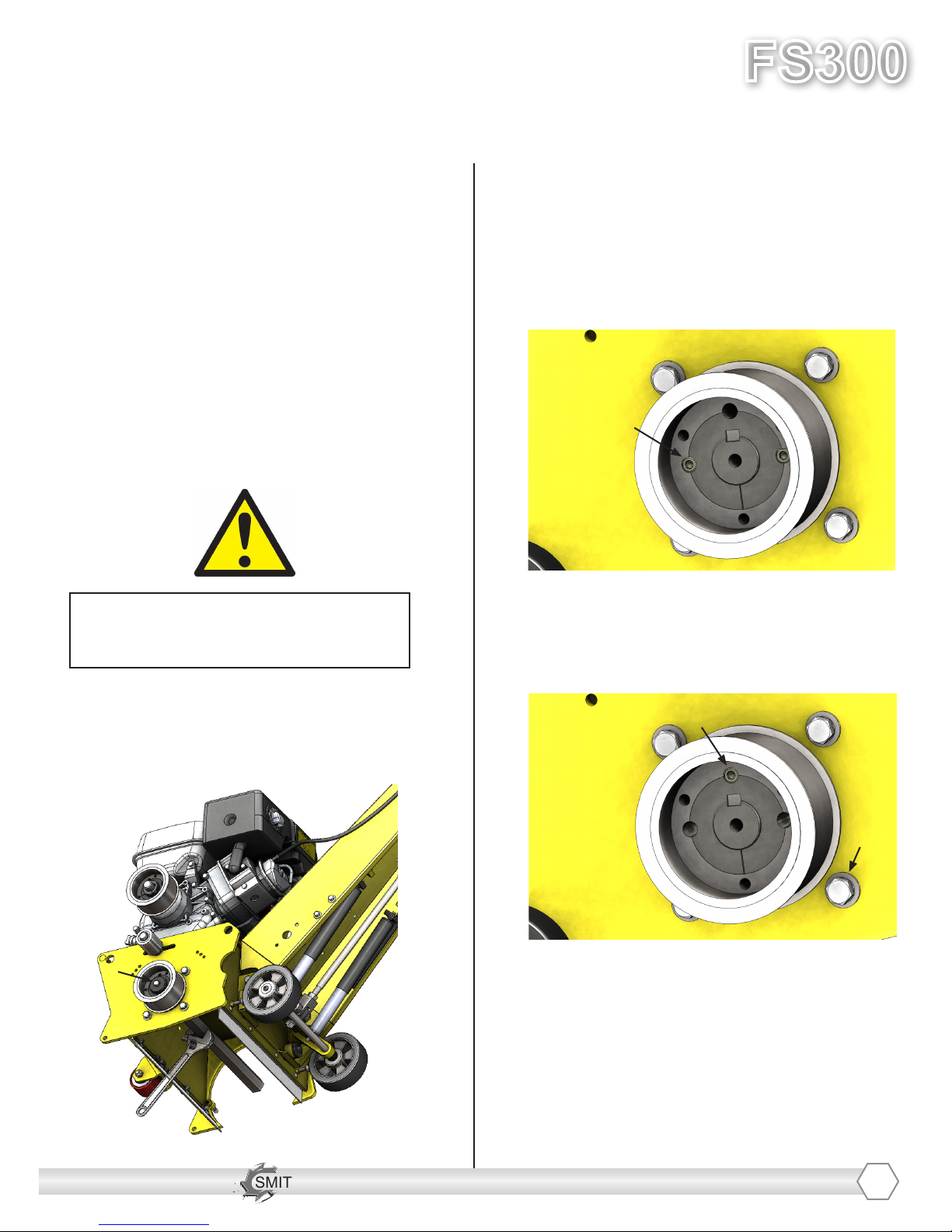

DRUM REPLACEMENT

Drum replacement is easy and requires a

few hand tools.

1. 17mm socket or wrench

2. Rubber mallet

Before beginning servicing on any

gasoline-powered unit,

DISCONNECT SPARK PLUG WIRE!

1. Lower the machine so the cutter drum is

resting on the ground. Do this either with

the cutter height adjustment handle or with

the lift carriage foot lever.

4. Slide out drum assembly. (use precaution

as it is HEAVY)

2)

4)

5. Once the cutter drum is removed take to a

workbench for assembly.

a) Inspect condition of cutters,

spacers, shafts, bushings and drum.

6) Before replacing the drum onto hex shaft:

a) Check that all bearings are in

good working order

b) Remove dirt and material build-up

from inside drive carriage and drum.

c) Lube all metal contacts

6) Align and slide drum back onto the hex

shaft.

7) Replace side plate (lift-up and lock into

place) over hex shaft and secure hardware.

NOTE: It is recomended that you use a

wooden board or something similar to place

under the drum before lowering the machine

to take the drum weight off the shaft which

makes it easier to align with side plate

2. Remove the four hex head cap screws

from the sideplate using the 17mm socket

or wrench.

3. Remove the sideplate (this may require

the rubber mallet to break it loose)

*TIP: SMITH recommends owning

an extra drum loaded with cutter for

rapid job-sight

11

3)

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS300

VERSION 8/2013

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

12

DRIVE BELT REPLACEMENT

Normal wear may necessitate belt

tensioning or replacement.

Time of replacement will vary according to

usage and belt load factors.

Replacement is easy and requires a few

hand tools.

1. 17mm socket or wrench

2. 19mm socket or wrench

Before beginning servicing on any

gasoline-powered unit,

DISCONNECT SPARK PLUG WIRE!

1. Make sure the removable side cover is

installed. This insures the drive ends are in

the proper position for servicing.

2. Clean the machine exterior so you can

locate all the appropriate parts.

3. Using a 17mm socket or wrench, remove

the two hex nuts attaching the belt cover to

the side of the machine. Remove the cover

and set it aside.

3)

4. Loosen (do not remove) the hex screw

on the idler pulley using a 19mm socket

or wrench and slide the pulley towards the

front of the machine to release belt tension,

remove/replace the belt as needed.

4)

5. To tension the belt once again, push the

idler against the belt and tighten it down

with the 19mm socket or wrench.

DO NOT overtighten the belt as it will cause

it to wear prematurely.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 8/2013

FS300

Gas

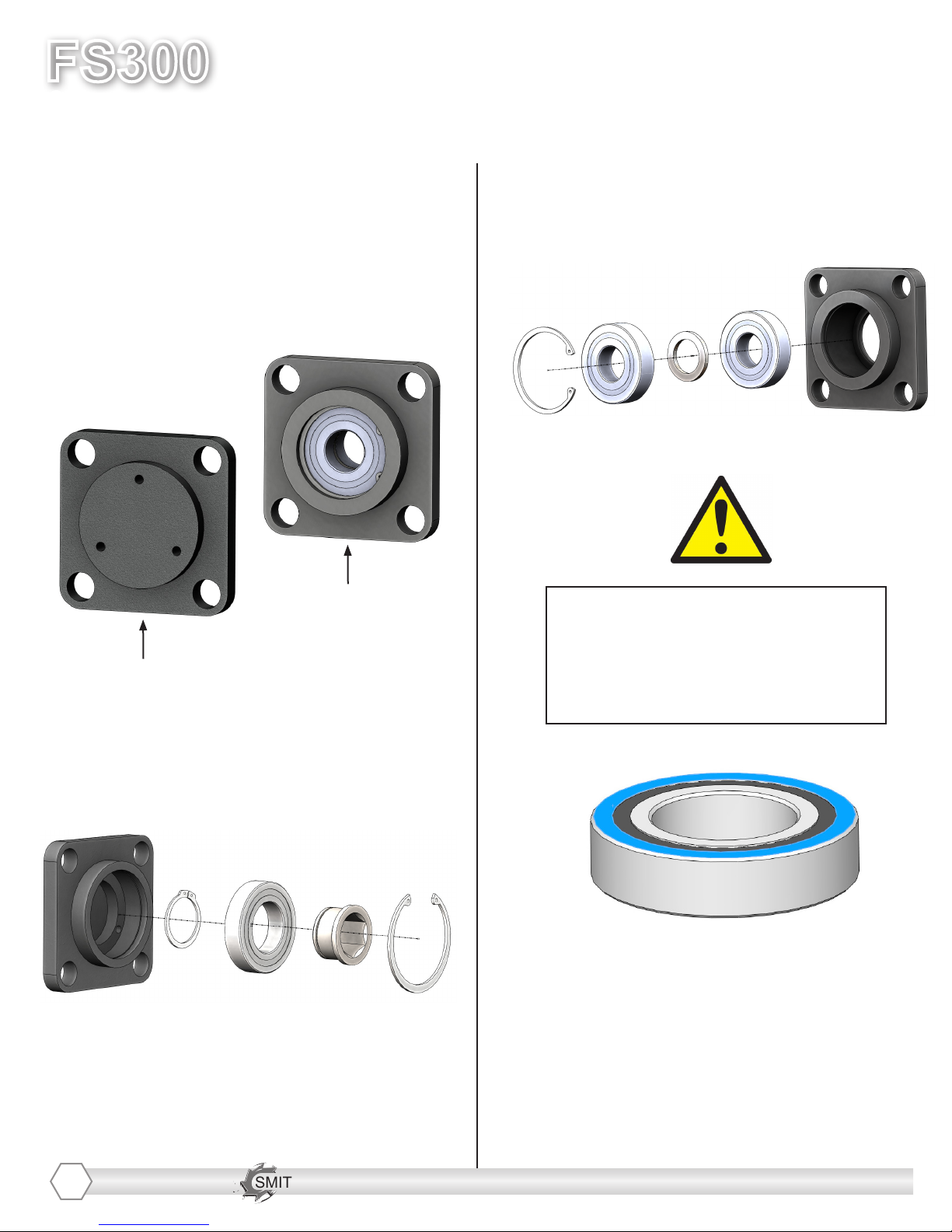

BEARING REPLACEMENT

Before reading ahead go back and follow

the instructions on how to remove the drum

and drive belt from the machine. Bearing

replacement is easy and requires a few

addtional hand tools.

1. 17mm socket or wrench

2. 9/16” socket or wrench

3. Adjustable wrench up to 1.5”

4. 7/32” Hex Key

5. Circlip pliers

Before beginning servicing on any

gasoline-powered unit,

DISCONNECT SPARK PLUG WIRE!

1. With the sideplate off the machine, use a

wrench to lock the rotation of the shaft.

Using the 9/16” socket, remove the screw

that locks down the pulley to the shaft.

2. With the shaft rotation still locked, use a

7/32” hex key to remove the 2 set screws on

the drive pulley (A). Once they are removed,

insert one of them into the hole directly on

top of the keyway to back out the bushing

as shown below (B).

1)

2A)

2B)

3. With the Pulley and shaft removed, use

the 17mm socket or wrench to remove the

bearing housing assembly from the frame.

3)

3. With the Pulley removed, use the 17mm

socket or wrench to remove the bearing

housing assembly from the frame and from

the side plate .

13

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS300

VERSION 8/2013

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

BEARING REPLACEMENT

(CONTINUED)

4. With the bearing housing assemblies

aside, they can now be taken apart to

replace the bearings as needed using the

circlip pliers.

6. The belt side bearing assembly shown

below.

Sideplate side

bearing housing

Belt side bearing

housing

5. The sidelpate side bearing assembly

shown below.

***WARNING***

When pressing bearings in,

use a soft wooden dowel and

only apply pressure to the

outter race of the bearings

14

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 8/2013

FS300

Gas

OPTIONAL EQUIPMENT

• BALL MOUNTH HITCH

Allows attachment to other components

• POINTER/DIRECTIONAL

SIGHT GUIDE SYSTEM

Allows operator to make straight passes

easier

15

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS300

VERSION 8/2013

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

OPTIONAL EQUIPMENT

• SULKY DRIVER

with reverse mounted rear handle control

(optional upgrade-please select front or rear)

• TACH/HOUR METER

Maintenance meter for service and use

control

16

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 8/2013

FS300

Gas

OPTIONAL EQUIPMENT

17

• MAXIVAC DUST COLLECTOR

Available in both gas or electric powered applications with the

standard 5 micron bags or upgrade to the 1 micron lter with

shake down bar

Fastest way to safely remove!

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS300

VERSION 8/2013

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

MAINTENANCE LOG

18

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 8/2013

FS300

Gas

MAINTENANCE LOG

WARRANTY CLAIMS

The manufacturer reserves the right to change or improve the machine design without assuming any

obligation to update any products previously manufactured before this manual. It is the customer’s

responsibility to complete the warranty card and mail it to the seller within 10 days from the date

of purchase. If a failure occurs during the warranty period, the customer must contact the seller

to determine the appropriate action. Any and all transportation charges are to be borne by the

purchaser.

19

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS300

VERSION 8/2013

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

Limited Equipment Warranty

All statements, technical information and recommendations contained in SMITH’s literature are based on tests believed to be reliable, but the accuracy

or completeness thereof is not guaranteed and the following is made in lieu of all warranties, expressed or implied. SMITH warrants all equipment or part

referenced in this document which is manufactured by SMITH and bearing its name to be free from defects in material and workmanship on the date of

sale to the original purchaser under normal use and maintenance as herein provided. This warranty does not apply to components manufactured by others

such as, but not limited to, bearings and engines; such components that may or may not have their own warranties.

With the exception of any special, extended, or limited warranty published by SMITH, SMITH will, for a period of three months (90 days) from the

date of sale or up to ve hundred (500) hours of use by buyer, whichever shall occur rst; repair or replace any part of the equipment determined by

SMITH to be defective. This warranty applies only when the equipment or part is installed, operated and maintained in accordance with SMITH’s written

recommendations.

SMITH’s sole obligation for any breach of warranty or breach of contract for defects, deliberate or accidental omissions, shall be limited to repairing,

replacing or allowing credit for, at SMITH’s option, any part which, under normal and proper use and maintenance, proves defective in material or

workmanship within warranty period, provided, however, that notice of any such defect or omission and satisfactory proof thereof is promptly given by

buyer to SMITH, and thereafter, such defective part is returned to SMITH with transportation charges prepaid, and SMITH’s examination proves such part

to have been defective. This warranty does not obligate SMITH to bear any transportation charges or personnel time in connection with the replacement

or repair of defective parts. This warranty does not obligate SMITH to bear any expense for travel time or of personnel in connection with any service calls.

SMITH will not, in any event, be liable to the user for any consequential damages arising out of this sale for the loss of use, lost prots or revenue, interest,

lost goodwill or work stoppage. SMITH shall not be liable for any injury, loss or damage, direct or consequential, arising out of the use or the inability to use

the product or for environmental claims. It being understood that SMITH has no means of controlling the products nal use; therefore, it shall be buyer’s

responsibility to determine suitability of product for intended use and buyer assumes all risks and liabilities whatsoever, in connection therewith. In no event

shall SMITH be liable for consequential or special damages. Used products are sold on an “as is” basis, and there is no implied warranty of merchantability

or of tness for a particular purpose, unless made in writing by an ofcer at SMITH’s ofce.

This warranty does not cover, and SMITH shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty installation,

misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-SMITH component parts.

Nor shall SMITH be liable for malfunction, damage or wear caused by the incompatibility of SMITH equipment with structures, accessories, equipment

or materials not supplied by SMITH, or the improper design, manufacture, installation, operation or maintenance of structures, accessories, equipment

or materials not supplied by SMITH. This warranty does not apply in respect to damages to any product or accessory or attachment thereof caused by

overloading or other misuse, neglect or accident, nor does this warranty apply to any product or accessory or attachment thereof, which has been repaired

or altered in any way which, in the sole judgment of SMITH, affects the performance, stability or general purpose for which it was manufactured. In the

manufacture of buyer’s equipment, parts may be omitted or equivalent functioning equipment and components may be substituted for the original specied

equipment upon the sole judgment and discretion of SMITH.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized SMITH Reseller for verication of the

claimed defect. If the claimed defect is veried, SMITH will repair or replace free of charge any defective parts and return of merchandise back to the

customer freight collect. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will be made at a reasonable

charge, which charges may include the costs of parts, labor and transportation.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO

WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

SMITH’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy (including,

but not limited to, incidental or consequential damages for lost prots, lost sales, injury to person or property, or any other incidental or consequential loss)

shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

SMITH MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY SMITH.

These items sold, but not manufactured by SMITH (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer.

SMITH will provide purchaser with reasonable assistance in making any claim for breach of these warranties. In no event will SMITH be liable for indirect,

incidental, special or consequential damages resulting from SMITH supplying equipment hereunder, or the furnishing, performance, or use of any products

or other goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of SMITH, or otherwise.

ADDITIONAL WARRANTY COVERAGE - SMITH does provide extended warranty and wear warranty for products.

Corrections - typographical or clerical errors contained herein are subject to correction by SMITH.

Assignment - buyer shall not assign or transfer this warranty without SMITH’s written consent.

Entire agreement and applicable law - the rights and obligations of SMITH and buyer shall be governed by the laws of the state of Florida, U.S.A. In force

on date hereof. The provisions hereof are intended by buyer and SMITH as a nal expression of their agreement, and are intended also, as a complete

and exclusive statement of all terms apply cable to buyer’s order. No waiver, modication, or addition to any of the terms hereof shall be binding on SMITH,

unless made in writing by an ofcer at SMITH’s ofce as stated herein. In the event of conict between buyer’s purchase order and the terms hereof, the

latter shall control. If any provisions herein are to any extent invalid or unenforceable, the remainder of the warranty shall not be effected thereby and shall

be valid and enforceable to the fullest extent permitted by law.

Legal action - buyer shall be responsible for all costs of collection of outstanding indebtedness, including but not limited to attorney’s fees and court costs

to seller. Buyer shall reimburse seller for any and all litigation expenses seller incurs as a result of an unsuccessful buyer claim. The jurisdiction and venue

of the court for any litigation, state or federal, brought by the buyer and/or seller shall be located in venue determined by seller.

Fair labor standards - seller’s products are produced in the United States and in conformity with all applicable provisions of the fair labor standards act of

1938 as amended and any regulations and orders of the United States Department of Labor issued thereunder.

All written and visual data contained in this document reects the most current product information available at the time of this publication. SMITH reserves

the right to make changes at any time without notice.

TO ORDER, contact your SMITH distributor or call 1-800-653-9311 to identify the nearest distributor.

SMITH Manufacturing Co, Inc.

1610 South Dixie Highway

Pompano Beach, FL 33060

www.smithmfg.com

20

This manual suits for next models

1

Table of contents

Other Smith Floor Machine manuals

Popular Floor Machine manuals by other brands

KENT

KENT Razor Blade 26D parts list

MK Diamond Products

MK Diamond Products MK-SDG-7 OWNERS MANUAL, PARTS LIST & EXPLODED VIEW

NSS

NSS STALLION 818 SC Operation manual

Tennant

Tennant T3 Operator's manual

Advance acoustic

Advance acoustic SC400 Instructions for use

Kärcher

Kärcher BD 50/70 R Bp Classic manual

MK Diamond Products

MK Diamond Products MK-VTS/50 Owner's manual operating instruction & parts list

SCANMASKIN

SCANMASKIN Scan Combiflex 330 manual

WOLFF

WOLFF TURBO-STRIPPER Translation of the original instruction

Windsor

Windsor D250(115V) 10070100 operating instructions

ADIATEK

ADIATEK Opal 66 Use and maintenance

Minuteman

Minuteman C-BOX 100 instruction manual