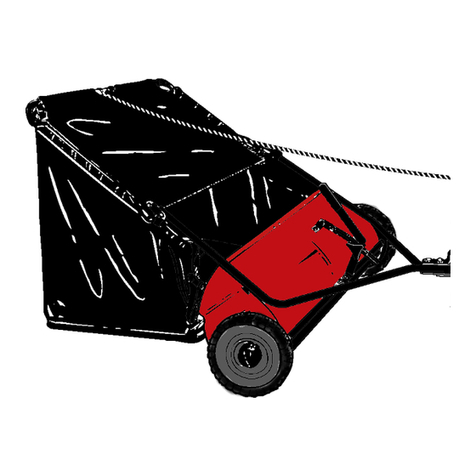

CRUSHING HAZARD

Implement is heavy. Be careful when moving or lifting as hands, finders, feet, and other body

parts can be crushed.

DO NOT exceed this implement’s maximum speed of 5 MPH. Exceeding this speed may result in

loss of control during transport or braking.

Distribute the load evenly.

Use the sweeper on flat and level surfaces. Pulling a load on a slanted or uneven surface can

result in loss of control.

Never attach the hopper tube to any part of your body or clothing. Never hold onto the rope while

towing the sweeper. Attach the rope to the towing vehicle to keep it away from wheels and

rotating parts.

Never allow riders on equipment.

Keep bystanders at least 20 feet away while operating.

Operate from tractor seat only.

Lower equipment to ground, stop engine, remove key and set brake before dismounting tractor.

DO NOT use if equipment is damaged. Repair equipment before continuing use.

Keep seat belt securely fastened while operating. Falling off can result in impalement or being

run over.

Store out of reach of children. Not for use by or around children.

If equipped, parking stands must be functional, kept in good repair, and stored on the unit. Park

and store on a hard, level surface.

FALLING OFF CAN RESULT IN BEING RUN OVER

Tractor must be equipped with Roll Over Protection Structure (or ROPS CAB) and seat belt. Keep

foldable ROPS system in “locked up” position at all times.

Keep seat belt securely fastened.

Never allow riders on equipment.

RAISED EQUIPMENT CAN DROP AND CRUSH

Before working underneath, follow all instructions and safety rules in operator’s manual and

securely block all corners of equipment with jack stands.

Securely blocking prevents equipment dropping from mechanical component failures.

FALLING OFF OR FAILING TO BLOCK SECURELY CAN RESULT IN SERIOUS INJURY OR

DEATH