Smittybilt 2600i User manual

SMITTYBILT DIGITAL INVERTER GENERATOR | 1

IMPORTANT Please make certain that persons who are to use this equipment

thoroughly read and understand this user’s manual prior to operation

USER’S

MANUAL

2 | SMITTYBILT DIGITAL INVERTER GENERATOR

C O N T E N T S

1.SAFETY INFORMATION........................................................................................ 3

2.CONTROL FUNCTION........................................................................................... 4

3.PRE-OPERATION CHECK ..................................................................................... 6

4.OPERATION ......................................................................................................... 8

5.PERIODIC MAINTENANCE ................................................................................... 12

6.TROUBLE SHOOTING .......................................................................................... 15

7.STORAGE............................................................................................................. 16

8.SPECIFICATIONS ................................................................................................. 17

9.SPECIFIATION...................................................................................................... 18

10. WIRING DIAGRAM............................................................................................ 19

10.REPLACEMENT PARTS ..................................................................................... 20

10.GENERATOR WEARING PARTS LIST ................................................................ 21

10.WEARING PARTS REPLACEMENT INSTRUCTIONS........................................... 22

SMITTYBILT DIGITAL INVERTER GENERATOR | 3

1. GENERATOR LOCATION

• NEVERoperatethegeneratorinsideanybuilding,includinggarages,basements,

crawlspacesandsheds,enclosureorcompartments,includingthegenerator

compartmentofarecreationalvehicleortrailer.

• Pleaseconsultyourlocalauthority.Insomeareas,generatorsmustberegisteredwith

thelocalutility.Generatorsusedatconstructionsitesmaybesubjecttoadditional

rulesandregulations.

• Generatorsshouldbeonaat,levelsurfaceatalltimes,includingtimesofnon-

operation.Generatorsmusthaveatleastvefeetofclearancefromallcombustible

material.Inadditiontoclearancefromallcombustiblematerial,generatorsmust

alsohaveatleastthreefeetofclearanceonallsidestoallowforadequatecooling,

maintenanceandservicing.

• GeneratorsshouldneverbestartedoroperatedinthebackofaSUV,camper,

trailer,inthebedofatruck(regular,atorotherwise),understaircases/stairwells,

nexttowallsorbuildings,orinanyotherlocationthatwillnotallowforadequate

coolingofthegeneratorand/orthemufer.DONOTcontaingeneratorsduring

operation.Allowgeneratorstoproperlycoolbeforetransport,re-fueling,orstorage.

• Placethegeneratorinawell-ventilatedarea.DONOTplacethegeneratornearventsor

intakeswhereexhaustfumescouldbedrawnintooccupiedorconnedspaces.

Carefullyconsiderwinddirectionwhenpositioninggeneratorforoperation.

2. EXHAUST FUMES ARE POISONOUS

• Neveroperatetheengineinaclosedareaoritmaycauseunconsciousness

anddeathwithinashorttime.Operatetheengineinawellventilatedarea.

3. FUEL IS HIGHLY FLAMMABLE AND POISONOUS

• Alwaysturnofftheenginewhenrefueling

• Neverrefuelwhilesmokingorinthevicinityofanopename.

• Takecarenottospillanyfuelontheengineormuferwhenrefueling.

• Ifyouswallowanyfuel,inhalefuelvapor,orallowanytogetinyoureyes,

seeyourdoctorimmediately.Ifanyfuelspillsonyourskinorclothing,

immediatelywashwithsoapandwaterandchangeyourclothes.

• Whenoperatingortransportingthemachine,besureitiskeptupright.

Ifittilts,fuelmayleakfromthecarburetororfueltank.

PLEASE READ AND UNDERSTAND THIS MANUAL COMPLETELY BEFORE OPERATING THE MACHINE.

OUTDOOR USE ONLY!

1. SAFETY INFORMATION

SMITTYBILT DIGITAL INVERTER GENERATOR | 5

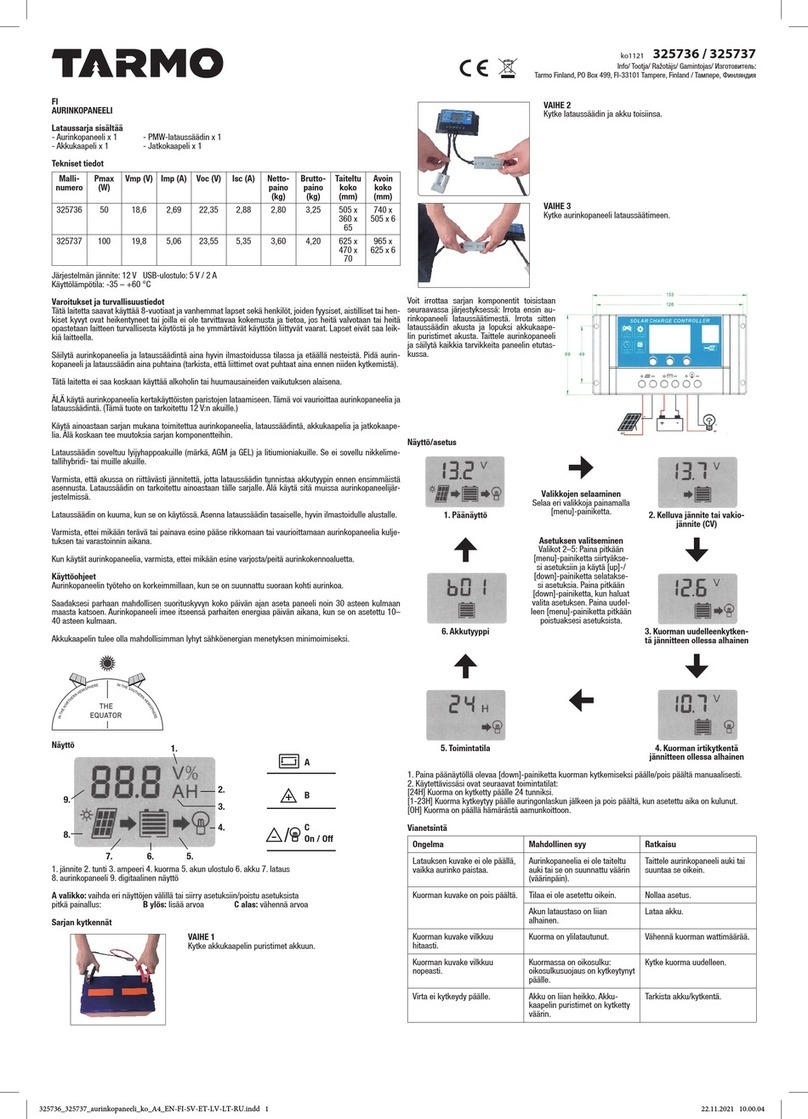

(1)Fueltank

(2)Fueltankcap

(3)Fuellter

(4)Carryinghandle

(5)Mufer

(6)Sparkplug

(7)Chokelever

(8)Recoilstarter

(9)Fuelcock

(10)Brakelever

(11)Wheel

(12)Oilllercap

(13)Airlter

(14)Fuelpump

(15)Battery

(16)OilAlert

(17)Overloadindicatorlight

(18)ACpilotlight

(19)Smartthrottle

(20)Infopanel

(21)DCcircuitbreaker

(22)Ignitionswitch

(23)DCreceptacle

(24)Ground(earth)terminal

(25)ACreceptacleL5-30R

(26)ACreceptacle5-20R

(27)Parallelconnectionsocket

(28)Parallelconnectioncontrol

socket

2. CONTROL FUNCTION

6 | SMITTYBILT DIGITAL INVERTER GENERATOR

1. OIL WARNING SYSTEM

Whentheoillevelfallsbelowthelowerlevel,theenginestops

automatically.

Unlessyourellwithoil,theenginewillnotstartagain.

2. ENGINE SWITCH

Theengineswitchcontrolstheignitionsystem.

(1) “ON”(run)

Ignitioncircuitisswitchedon.Theenginecanbestarted.

(2) “STOP”

Ignitioncircuitisswitchedoff.Theenginewillnotrun.

(3) “START”

Startingcircuitisswitchedon.Thestartermotorstarts.

3. SMART THROTTLE SWITCH

WhentheSmartthrottleswitchisturned“ON”,theeconomycontrol

unitcontrolstheenginespeedaccordingtotheconnectedload.The

resultsarebetterfuelefciencyandlessnoise.

4. DC CIRCUIT PROTECTOR

TheDCcircuitprotectorturnsoffautomaticallywhentheload

exceedsthegeneratorsratedoutput.

5. FUEL COCK

Thefuelcockisusedtosupplyfuelfromthetanktothecarburetor.

Reducetheloadtowithinspeciedgeneratorrated

outputiftheDCcircuitprotectorturnsoff.

CAUTION:

SMITTYBILT DIGITAL INVERTER GENERATOR | 7

.6 REMOTE CONTROL SWITCH

Theremotecontrolswitchcontrolstheignitionsystem

“ON”

Thestartermotorstarts.

“OFF”

Theenginewillnotrun.

7. BRAKE LEVER

Thefunctionofbrakeleveristopreventthegeneratorfrommoving.

Brakeleverisnotworking,generatorcanmove.

Brakeleverisworking,generatorcan’tmove.

3. PRE-OPERATION CHECK

1. CHECK ENGINE FUEL

Makesurethereissufcientfuelinthetank.

Iffuelislow,rellwithunleadedautomotivegasoline.

Besuretousethefuellterscreenonthefuellterneck.

Recommendedfuel:87octane+.

Donotusegasolinecontainingmorethan10%ethanol.Gasolinecontaining

higherlevelsofethanoliscorrosiveandattractsmoisture,whichcancausestart

orrunningproblems,andinsomecasesdamagethegeneratorsfuelsystem.

Damagetogeneratorfromethanolenrichedfuelsisnotcoveredbywarranty.

Fueltankcapacity:(seepage17)

Addmorethan1.32galoffuelforthersttimetouse

thismachine.Pre-operationchecksshouldbemade

eachtimethegeneratorisused.

CAUTION:

• Refuelinwell-ventilatedareabeforestartingthegenerator.If

enginehasbeenrunning,allowittocoolbeforerestarting.

• Donotrelltankwhileengineisrunningorhot.

• Closefuelcockbeforerefuelingwithfuel.

• Becarefulnottoadmitdust,dirt,waterorotherforeignobjects

intofuel.

• Donotllabovethetopofthefuellteroritmayoverowwhen

thefuelheatsuplaterandexpands.

• Wipeoffspiltfuelthoroughlybeforestartingengine.

• Keepawayfromopenames.

WARNING:

ON ON

OFF OFF

ON

OFF

①②

8 | SMITTYBILT DIGITAL INVERTER GENERATOR

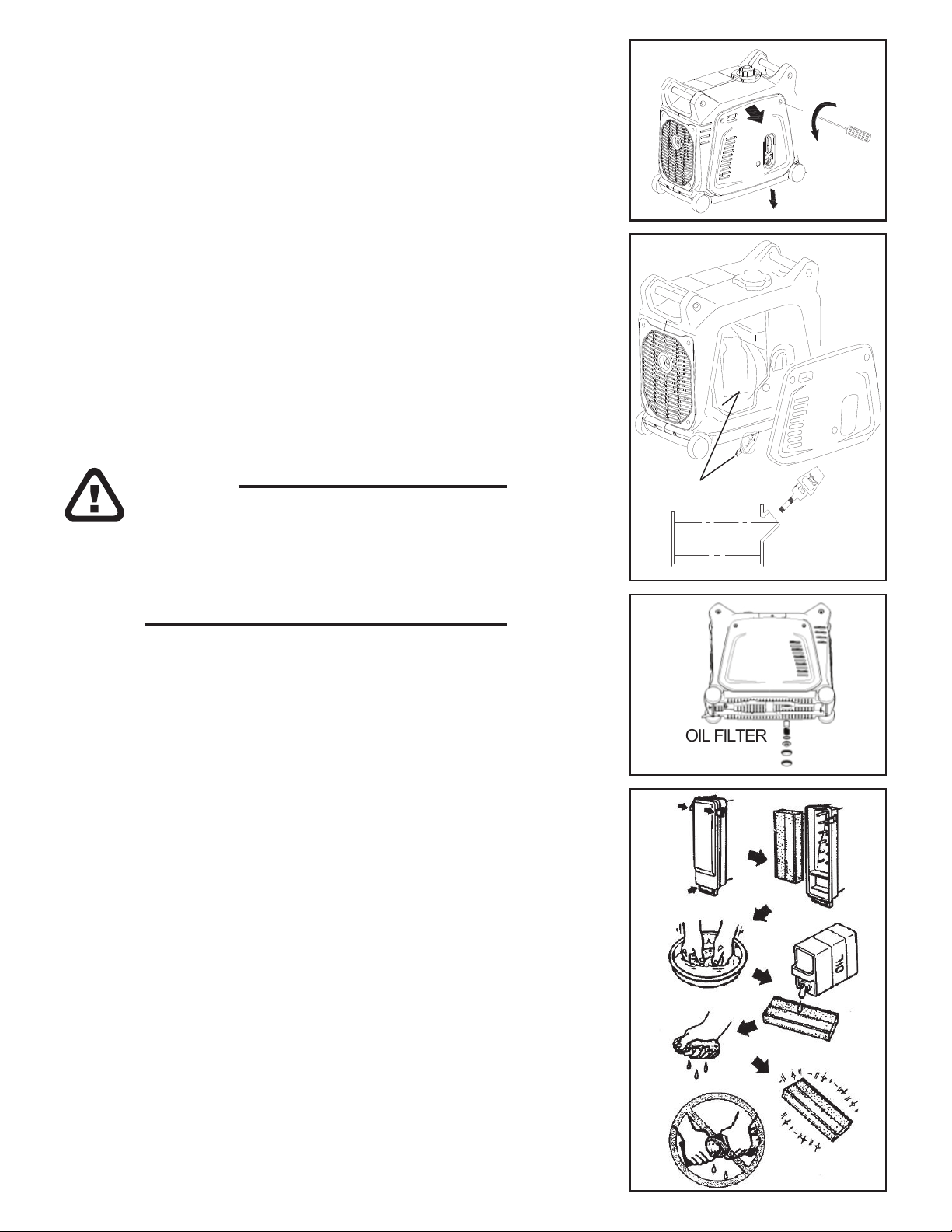

2. CHECK ENGINE OIL

Makesuretheengineoilisattheupperleveloftheoilllerhole.

Addoilasnecessary.

• Removeoilllercapandchecktheengineoillevel.

• Ifoillevelisbelowthelowerlevelline,rellwith

suitableoiltoupperlevelline.Donotscrewintheoil

llercapwhencheckingoillevel.

• Changeoilifcontaminated.

• Oilcapacity:(seepage17)

• Recommendedengineoil:APIService“SJ”

3. GROUND (Earth)

Makesuretoground(earth)thegenerator.

4.CONNECT BATTERY (for electric starting system)

• Loosenthescrewandremovethebatterycover.

• Clamptheredwiretothepositive(+)terminaland

theblackwiretothenegative(-)terminalofthebattery.

Donotreversethesepositions.

• Besurethebatteryisinstalledonthebatterymounttraysecurely.

• Installthecoverandtightenthescrew.

Recommendedbattery:12V6AH

CAUTION:

UPPER

LEVEL

SMITTYBILT DIGITAL INVERTER GENERATOR | 9

4. OPERATION

1. STARTING THE ENGINE

NOTE: Before starting the engine,

do not connect the electric apparatus.

A Recoil start

1.Turnthefuelcocklevertothe“ON”position.Pressprimerbulb.

2.Turntheengineswitchtothe“ON”or“RUN”position.

3.Turnthechokelevertotheposition.

Notnecessaryiftheengineisstartedusingtheremote.

4.Pullthestarterhandleslowlyuntilresistanceisfelt.Thisisthe

“Compression”point.Returnthehandletoitsoriginalposition

andpullswiftly.Donotfullypullouttherope.Afterstarting,

allowthestarterhandletoreturntoitsoriginalpositionwhilestill

holdingthehandle.Graspthecarryinghandlermlytopreventthe

generatorfromfallingoverwhenpullingtherecoilstarter.

5.Warmuptheengine.

6.Turnthechokeleverbacktotheoperatingposition.

Notnecessaryiftheengineiselectrictype.

7.Warmuptheenginewithoutaloadforafewminutes.

B Electric start

1.Turnthefuelcocklevertothe“ON”position.

2.Turntheengineswitchtothe“START”position.

3.Turnon“CHOKE”.

4.Turntheengineswitchtothe“RUN”position

5.Warmuptheenginewithoutaloadforafewminutes.

6.Turn“CHOKE”off.

Thegeneratorhasbeenshippedwithoutengineoil.Fillwithoil

oritwillnotstart.Donottiltthegeneratorwhenaddingengine

oil.Thiscouldresultinoverllinganddamagetotheengine

WARNING:

ON

STOP

RUN

START

ENGINE

SWITCH

10 | SMITTYBILT DIGITAL INVERTER GENERATOR

4. OPERATION (Continued)

C Remote start

1.Turnthefuelcocklevertothe“ON”position.

2.Turntheengineswitchtothe“RUN”position.

3.Slowlyclickthe“ON”buttontwice.

4.Warmuptheenginewithoutaloadforafewminutes.

2. USING ELECTRIC POWER

1. AC APPLICATION

(a)ChecktheInfopanelforpropervoltage.

(b)Turnofftheswitch(es)oftheelectricalappliance(s)

beforeconnectingtothegenerator.

(c)Inserttheplug(s)oftheelectricalappliance(s)

intothereceptacle.

2. OVERLOAD INDICATOR LIGHT

Theoverloadindicatorlightcomesonwhenanoverloadofa

connectedelectricaldeviceisdetected,theinverterunitoverheats,or

theACoutputvoltagerises.Theelectronicbreakerwillthenactivate,

stoppingpowertothegenerationinordertoprotectthegeneratorand

anyconnectedelectricdevices.Theoutputpilotlight(green)

willickerandtheoverloadindicatorlight(red)willturnon,thenthe

enginewillstoprunning.Ifsopleasefollowthefollowingsteps:

(a)Turnoffanyconnectedelectricdevicesandstoptheengine

(b)Reducethetotalwattageofconnectedelectricdeviceswithinthe

applicationrange.

(c)Checkforblockagesinthecoolingairinletandaroundthe

controlunit.Ifanyblockagesarefound,remove.

(d)Afterchecking,restarttheengine.

Besuretheelectricapparatusisturnedoffbefore

pluggingin.Besurethetotalloadiswithingenerator

ratedoutput.Besurethesocketloadcurrentiswithin

socketratedcurrent.Thesmartthrottleswitchmust

beturnedto“OFF”whenusingelectricdevicesthat

requirealargestartingcurrent,suchasacompressor

orsubmersiblepump.

CAUTION:

SMITTYBILT DIGITAL INVERTER GENERATOR | 11

3. DC APPLICATION (option)

Thisusageisapplicableto12Vbatterychargingonly.

(a)Charginginstructionforbattery

• Disconnecttheleadsforthebattery.

• Loosenbatteryllercap.

• Ifthebatteryuidislowlevel,Filldistilledwatertotheupperlimit.

• Measurethespecicgravityforthebatteryuidbyusingthe

hydrometer,andcalculatethechargingtimeinaccordingwiththe

tableshownonrightside.

• Thespecicgravityforthefullychargedbatteryshallbewithin

1.26to1.28.Itisrecommendedtoconrmeveryanhour.

(b)ConnectbetweentheDCoutputsocketandthebattery

terminalsusingthechargingleads.Theleadsshallbeconnected

makingsureofthe(+)and(-)polarity.

(c)TheDCcircuitprotectoristobesetto“ON”after

conrmingtheconnection,iftheprotectorisin“OFF”position.

ThegeneratorACoutputautomaticallyresetswhentheengine

isstoppedandthenrestarted.Theoverloadindicatorlightmay

comeonforafewsecondsatrstwhenusingelectricdevices

thatrequirealargestartingcurrent,suchasacompressorora

submersiblepump.However,thisisnotamalfunction.

Besurethesmartthrottleswitchisturnedoffwhile

chargingthebattery.

*Alwayschargeperbatterymanufacturerecommendations.

CAUTION:

CAUTION:

3

2

1

FSpecific gravity 68°

3. 47AH 20HR

2. 35AH 20HR

1. 30AH 20HR

Battery capacity

charging time Hr

8 10

4620

1.06

1.14

1.10

1.22

1.18

1.26

1.30

Aim for specific gravity and charging time

12 | SMITTYBILT DIGITAL INVERTER GENERATOR

3. STOPPING THE ENGINE

1. Turnoffthepowerswitchoftheelectric

apparatusordisconnectanyelectricdevices.

2. Turntheengineswitchto“STOP”position.

Clickremoteswitchtothe“OFF”position.

3. Turnthefuelcockleverto“OFF”.

4.Allowenginetocoolbeforerestarting.

STOP

RUN

START

ENGINE

SWITCH

OFF

ON ON

OFF OFF

OFF

SMITTYBILT DIGITAL INVERTER GENERATOR | 13

5. PERIODIC MAINTENANCE

1) MAINTENANCE CHART

Regularmaintenanceismostimportantforthebestperformanceandsafeoperation.Themaintenanceschedule

appliestonormaloperatingconditions.Ifyouoperateyourgeneratorunderunusualorharshconditions,suchas

sustainedhigh-loadorhigh-temperatureoperation,oruseitindustyconditions,serviceintervaltimewilldecrease.

Ifusedindusty/harshenvironments,cleanoutgeneratorbyremovingsidepanelsandusingcompressedair.

Item Remarks Pre-operation

check(daily)

Initial

1month

or20Hr

Every3

months

or50Hr

Every6

months

or100Hr

Every12

months

or100Hr

SparkPlug Checkcondition

adjustgapandclean. •

Replaceifnecessary.

Engine Checkoillevel •

Oil Replace • • •

Oil Cleanoillter •

AirFilter Clean.Replaceif

necessary. •

FuelFilter Cleanfuelcocklter.

Replaceifnecessary •

Choke Checkchoke

operation •

Valve

Clearance

Checkandadjust

whenengineiscold. •

FuelLine Checkfuelhosefor

crackordamage.

Replaceifnecessary.

•

Exhaust

System

Checkforleakage.

Re-tightenorreplace

gasketifnecessary

•

Checkmufer

screen.Clean/

replaceifnecessary.

•

Carburetor Checkchoke

operation •

Cooling

system

Checkfandamage. •

Starting

system

Checkrecoilstarter

operation. •

Idlespeed Checkandadjust

engineidlespeed •

Fittings/

Fasteners

Checkallttingsand

fastenerscorrectif

necessary.

•

Crankcase

breather

Checkbreather

hoseforcracksor

damage.Replaceif

necessary

•

Generator Checkthepilotlight

comeson •

14 | SMITTYBILT DIGITAL INVERTER GENERATOR

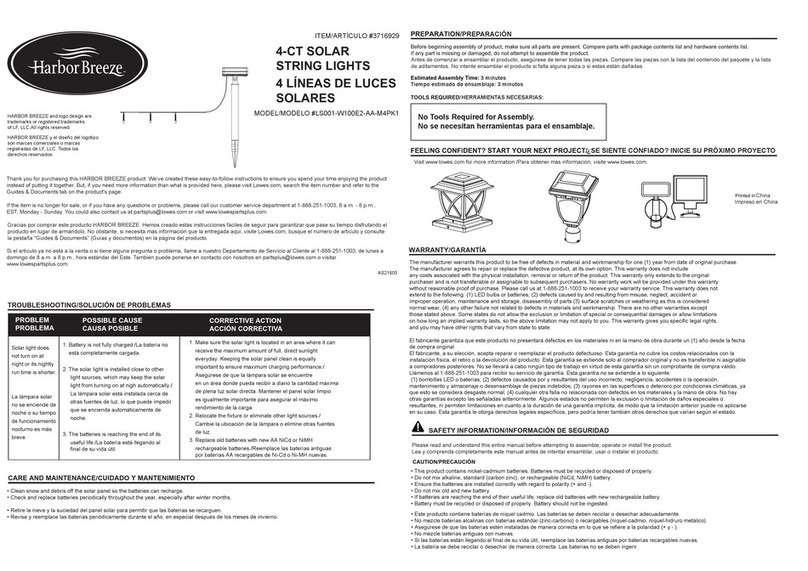

2. ENGINE OIL REPLACEMENT

1.Placethemachineonalevelsurfaceandwarmupthe

engineforseveralminutes.

Thenstoptheengineandturnthefuelcockknobto“OFF””.

2.Loosenthescrewandremovethecover.

3.Removetheoilllercap

4.Placeanoilpanundertheengine.

Tiltthegeneratortodraintheoilcompletely

5.Replacethegeneratoronalevelsurface.

6.Addengineoiltotheupperlevel.

6.5. DO NOT screwindipstickwhencheckingoillevel

7.Installtheoilllercap

8.Installthecoverandtightenthescrew

Recommendedengineoil:(seepage17)

APIService“SJ”

3. AIR FILTER

Maintaininganaircleanerinproperconditionisveryimportant.

Dirtinducedthroughimproperlyinstalled,improperlyserviced,

orinadequateelementsdamagesandwearsoutengines.

Keeptheelementalwaysclean.

1.Removethecover.

2.Removetheairltercoverandelement.

3.Washtheelementinsolventanddry.

4.Oiltheelementandsqueezeoutexcessoil.

Theelementshouldbewetbutnotdripping.

5.Inserttheelementintotheairlter.

6.Installthecover

Besurenoforeignmaterialentersthecrankcase.

Donottiltthegeneratorwhenaddingengineoil.This

couldresultinoverllinganddamagetotheengine

Cleantheoillterevery100hrs.

CAUTION:

OIL FILTER

UPPER

LEVEL

SMITTYBILT DIGITAL INVERTER GENERATOR | 15

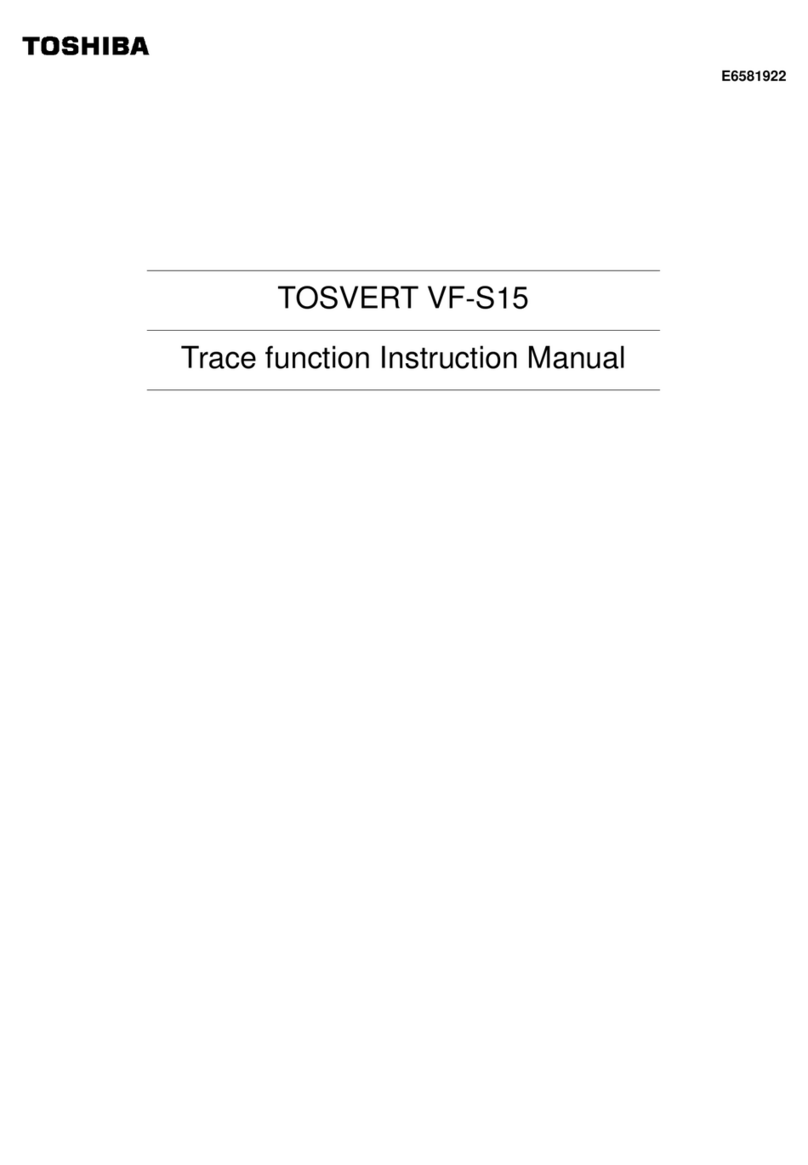

4. CLEANING AND ADJUSTING SPARK PLUG

1.Removethecover.

2.Checkfordiscolorationandremovethecarbon.

3.Checkthesparkplugtypeandgap.

4.Installthesparkplug.

5.Installthecover

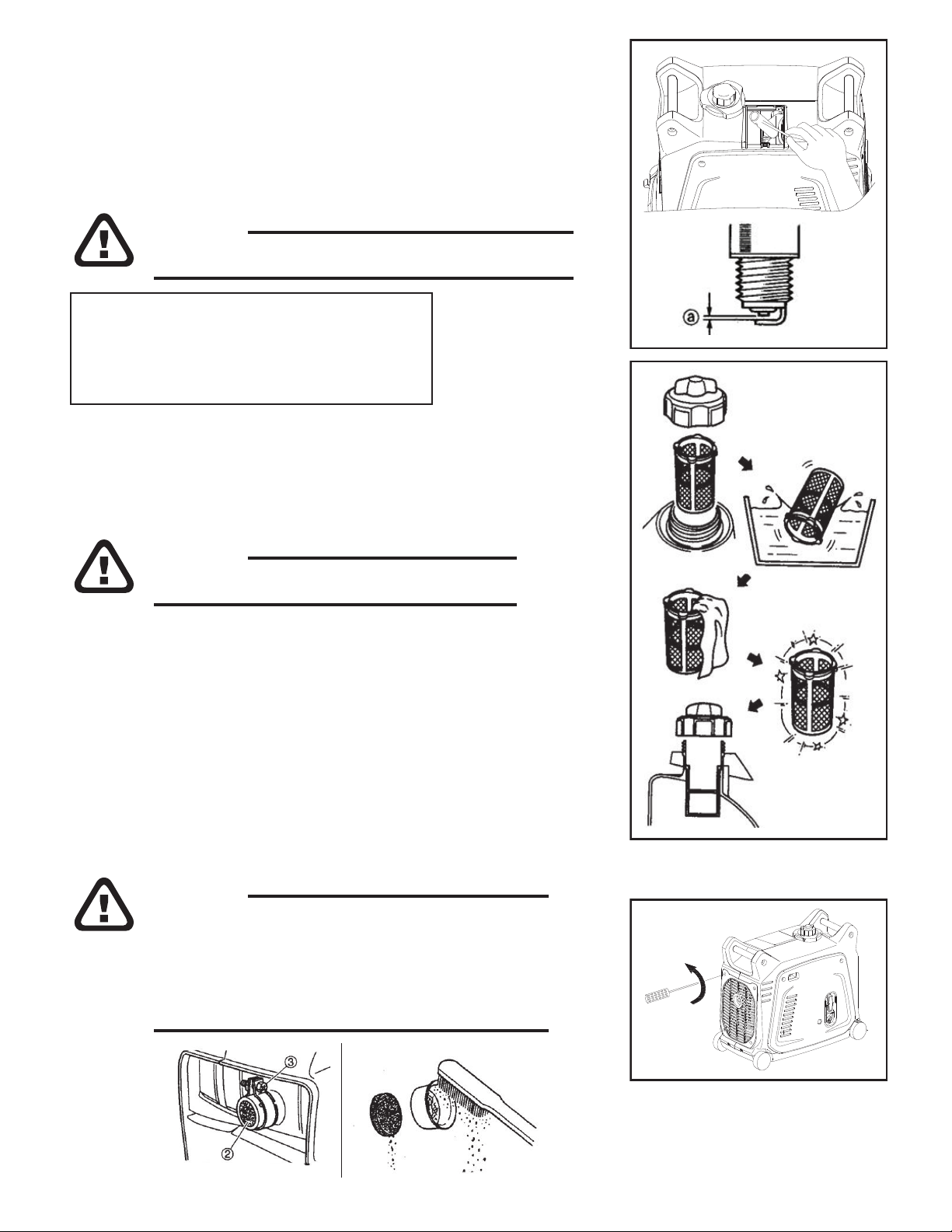

5. FUEL TANK FILTER

1.Removethefueltankcapandlter.

2.Cleanthelterwithsolvent.Ifdamaged,replace.

3.Wipethelterandinsertit.

6. MUFFLER SCREEN

1.Removethecover.

2.Removethemuferscreen.

3.Usetheatheadscrewdrivertoprythe

sparkarresteroutfromthemufer

4.Removethecarbondepositsonthemuferscreen

andsparkarresterusingawirebrush.

5.Installthemuferscreen.

6.Installthecover

Besurethetankcapistightenedsecurely.

WARNING:

Aloosesparkplugcanoverheatanddamagetheengine.

WARNING:

Theengineandmuferwillbeveryhotafterthe

enginehasbeenrun.Avoidtouchingtheengineand

muferwhiletheyarestillhotwithanypart

ofyourbodyorclothingduringinspectionorrepair.

WARNING:

Standardelectrodecolor:TanColor

StandardSparkPlug:A7RTCTorch

SparkPlugGap:1.0-1.3mm(0.039-0.051in)

16 | SMITTYBILT DIGITAL INVERTER GENERATOR

6. TROUBLE SHOOTING

(1)Enginewon’tstart

1.FuelsystemsNofuelsuppliedtocombustionchamber.

• Nofuelintank….Supplyfuel.

• Fuelintank….fuelcockknobto“ON”.

• Cloggedfuelline….Cleanfuelline.

cloggedcarburetor….Cleancarburetor.

• Allowhotenginetocoolbeforerestarting.

(2)Engineoilsystem

Insufcient

• Oillevelislow….Addengineoil.

(3)Electricalsystems

Poorspark

• Sparkplugdirtywithcarbonorwet….

Removecarbonorwipesparkplugdry.

• Faultyignitionsystem….Consultdealer.

(4)Compressioninsufcient

• Wornoutpistonandcylinder….Consultdealer.

(5)Generatorwon’tproducepower

Circuitbreaker(AC)to“OFF”…Stoptheengine,thenrestart.

Circuitbreaker(DC)to“OFF”…PresstoresettheDCprotector

(6)Generatoroutputwillbereducedinhighaltitudeconditionsand

whileusingE10fuel.Forbestperformanceusenon-ethanol

blendedfuel.

SMITTYBILT DIGITAL INVERTER GENERATOR | 17

7. STORAGE

Longtermstorage(90+days)ofyourmachinewillrequiresomepreventive

procedurestoguardagainstdeterioration.

Note:Donotuseplasticsheetasadustcover.Anonporouscoverwilltrap

moisturepromotingrustandcorrosion.

1.DRAIN THE FUEL

1.Removethefueltankcap,drainthefuelfromthefueltank

2.Removethecover,drainfuelfromthecarburetorby

looseningthedrainscrew.

2. ENGINE

1.Removethesparkplug,pourinaboutonetablespoonof

SAE10W30or20W40motoroilintothesparkplughole

andreinstallthesparkplug.

2.Usetherecoilstartertoturntheengineoverseveraltimes

(withignitionoff).

3.pulltherecoilstarteruntilyoufeelcompression.

4.Stoppulling.

5.Cleanexteriorofthegeneratorandapplyarustinhibitor.

6.Storethegeneratorinadry,well-ventilatedplace,

withacoverplacedoverit.

7.Thegeneratormustremaininaverticalposition.

8.Removebatteryanduseabatterymaintainerformotorcyclebatteries.

3. SHORT TERM STORAGE

1.Addfuelstabilizerimmediatelytofreshfuelinacanister.Mixwell

beforefuelingupgenerator.

2.Allowgeneratortorunatleast10minutestoallowtreatedgasoline

toreplacetheuntreatedgasolineinthefuelsystem.

3.Turnofffuelvalveandallowgeneratortocontinuerunningtillitruns

outofgasoline.Turnoffgeneratorsignitionsystem.

4.Topofffueltankwithtreatedgasoline.Airinthefueltankwill

promotefueldeterioration.

18 | SMITTYBILT DIGITAL INVERTER GENERATOR

SPECIFICATION

37 kgs/81.6 lbs

0.95 Quarts / 0.9 Liters

24.2”x13.5”x19.9”

25.2”x14.2”x21.3”

40 kgs/88.2 lbs

5.4 HP / 5500 rpm

6.4 Liters / 1.69 gal

4.8 hours (100% load)

6.7 hours (50% load)

149.5 cc

SMITTYBILT DIGITAL INVERTER GENERATOR | 19

Ignition winding

Spring winding

Engine switch

High

pressure

wrap Spark

plug

OUTPUT

Control

winding

Oil sensor

Main

winding

Stepping motor

M

BREAKER

BREAKER

Economic

switch

RECTIFIER

ENGINE SWITCH CONTINUTY

DC

winding

BATTERY

Invert cell

OVERLOAD

LOW OIL

R

R

P

R

R

R

R

R

R

R

R

W

W

W

W

W

W

W

BL

Y/G

Y/G

BU BU

0 0

0

PI

BU

BU

BL

BUBU

Gr

BL

BL

BL

BL

BL

BL

BL BL

BL

BL

BL

BL

BL

BL

BL

BL

BL

GR

BU

Y/G

O

W

R

P

FUSE 3A

FUSE 3A

WIRING DIAGRAM

2600i

20 | SMITTYBILT DIGITAL INVERTER GENERATOR

Part # Description

2786-01 Parallel Cable

2786-02 Spring of oil-lter

2786-03 Oil Strainer

2786-04 Oil Filter

2786-05 Air Filter

2786-06 Fuel Strainer

2786-07 Fuel Filter

2786-08 Fuel Tubes set

2786-09 Spark Arrestor

2786-10 Mufer Gasket

2786-11 Carburetor

2786-12 Recoil Starter

2786-13 Ignition Controller

2786-14 Wireless remote and receiver

2786-15 Starting relay

2786-16 Fuel Pump

2786-17 Battery

2786-18 Gas Cap

2786-19 Handle*2

2786-20 Pull Start side panel

2786-21 Other side panel

2786-22 Rear Panel

2786-23 Wheel

2786-24 Top Panel/door

2786-25 Oil Cap

2786-26 Decal Set

2786-27 Battery hold down strap

2786-28 Ignition Key

2786-29 Spark Plug

2786-30 Choke assy

2786-31 Battery charging cord

2786-32 Inverter assy

2786-33 Ignition coil

2786-34 Control panel assy

2786-35 Wheel's brake

2786-36 Hardware set

REPLACEMENT PARTS

SMITTYBILT DIGITAL INVERTER GENERATOR | 21

No. Item

Qty

(pc/set) Pictures

1Spark plug A7RTC 1

2Oil ller cap Oring 1

3 Oil strainer 1

4Oil lter 1set

5Air lter Assy 1set

6 Fuel strainer 1

7Fuel lter 1

8 Fuel tubes 1

9 Spark attestor 1

10 Mufer gasket 1

11 Carburetor 1set

2786 GENERATOR WEARING PARTS LIST

No. Item

Qty

(pc/set) Pictures

12 R ecoil starter 1set

13 Lgnition controller IC-2500 1

14 Remote& Wireless receiver 1set

15 Starting reply 1set

16 Quadripuntal fuel pump 1set

Note: Customer can easy to replaced all wearing parts.

Table of contents

Popular Inverter manuals by other brands

Tarmo

Tarmo ko1121 quick start guide

Ingeteam

Ingeteam INGECON SUN 3Play 160TL Installation and operation manual

Shinefar

Shinefar SF-1k-TL user manual

Victron energy

Victron energy MultiPlus Compact 12/2000/80-30 230V manual

Xantrex

Xantrex Freedom SW Series owner's guide

Sunways

Sunways STS-1KTL-S user manual